Alexey Vashkevich: “Our Task is to Find a Zone of Monetization of Fundamental Science”

Aleksey Vashkevich, Director of Technology Development at Gazprom Neft, who also heads the company’s Science and Technology Center, told TASS in an interview why the oil and gas industry today has become the epicenter of the development of Russian science, how hydrocarbons can be generated in a matter of hours instead of millions of years, and why oilmen need colliders and startups.

– What is the most curious thing you have learned about oil in your career?

– We constantly learn a lot of interesting things about oil. And there are still a lot of questions that have not yet been answered. After all, one cannot physically go down to the place where oil is directly extracted and look at the process, “feel” it. You are at a distance of several kilometers and with very indirect measurement tools you are trying to predict where it lies, how best to approach it and how to make mining even more efficient.

There is a common misconception that oil is the seas or lakes underground. Actually it is not. Today we extract it from rocks that are ten times denser than concrete slabs. This is a very difficult challenge in many ways, and its solution is associated not only with the oil industry, but also with humanity as a whole. What we do in the field of materials science, dynamic processes or in the field of specialized chemistry is moving the scientific development bar for the entire world community.

– For example?

– Any process proceeds faster at elevated temperatures. If it is increased where the oil flows from, then it will do it faster. Let’s imagine that we hit a reservoir, and in it, for example, 15% of the oil is already in a liquid state, and 75% is still in kerogen, that is, it is still “ripening” from organic matter there. Heating this reservoir to a certain temperature will help to get oil not in hundreds of millions of years, as it happens naturally, but in just hours.

But how to heat the rock deep underground to 400 degrees? The task is clear, but unrealizable – there are no technical solutions and materials that allow this to be done. And here we turn to fundamental science and begin to develop a whole range of innovations almost from scratch. That is, one task – to heat the rock – immediately causes a cascade of challenges in other areas of science, in which it is necessary to create solutions that do not yet exist in the world.

Thus, if we talk about development on a global scale, the oil industry, indirectly or directly, is one of the largest customers for new technologies, which are then applied in completely different industries.

– Is it possible to say that scientists and specialists come to work with you just because they are interested in solving such problems?

At least one of the incentives is the diversity of areas of application of knowledge. In almost any area of oil and gas engineering, there is no ceiling for creativity and development: physics, chemistry, materials science, areas related to automation and digitalization of processes. Choose what reveals you, and the tasks will definitely outpace your ability to solve them.

On the other hand, we still have to turn all creative energy and incredible ideas into practical value. Simply put, everything that happens within the walls of the Scientific and Technical Center, after some time, should physically produce more oil. We have the so-called technology management system – a whole set of tools, methodologies, processes, expertise that allow any thought, after passing all the checkpoints, to reach the final decisions expressed in a new production, software product or business process.

The symbiosis of these two entities creates that qualitative effect in the form of scientific and technological progress, which is expressed in the constant replenishment with new technologies.

– I know that you once moved from a Western company to the Russian Gazprom Neft. Why?

– I never had a question where I would like to end up working. I knew it would be Russia. The foreign period has become a way to gain life and work experience. I managed to work in Africa, and in the jungle, and in the ocean to live on platforms. Such opportunities professionally expand and give an understanding that the world is very different. In Siberia, when conducting seismic surveys, we create clearings in the forest, and on an oil platform near Equatorial Guinea, we drive away curious baby whales so that they do not get under the boat. It seems that the process is the same – seismic, but the conditions are completely different. In the States, I also had a very interesting project – we were developing the Bakken field in North Dakota. This is one of the first projects of the so-called shale revolution.

– Why did they leave?

– I always understood that mentally and from a linguistic point of view I would not be completely my own. There are unwritten rules for career growth that are directly related to age. Having become a project manager in my early 30s, I realized that the next director role might not be available until ten years later. There was simply no director under 40 in that system. Considering many factors, the potential for development and the dynamics of technological progress, it turned out that the Russian oil and gas industry is exactly where I wanted to be. When I received an offer from Gazprom Neft, I thought for a maximum of two days.

– Is it difficult to manage creative scientists?

– You know, it is both difficult and interesting. On the one hand, in production departments they work differently – people there still think more in terms of tasks. There is a specific task that needs to be completed, and this is the defining focus and goal setting.

Our Scientific and Technical Center has recently turned 15 years old, and we strive to maintain such an atmosphere that employees go beyond the perimeter of their current tasks and responsibilities written in the job description. To constantly look for ways to improve a process or technology. This is how we develop the competence of search and curiosity, which sometimes begins to “bite” us ourselves. You can’t just say to our employee, “Go and do it.” We taught him differently. If he personally did not believe in the task, he will say: “Why should I do this if I do not believe in it?” Managing such people is declaratively impossible. Either you will kill that unique atmosphere that you yourself created, or the solutions will not take root.

Such a management model deviates in a more trusting direction. Dialogue and persuasion are more important to us than command management. On the one hand, this requires much more managerial resources, and on the other hand, it drives me very strongly and gives me a completely different experience. As soon as the team begins to believe in the task, as soon as the guys say: “Yes, this is really a cool thing, let’s do it,” their eyes light up, and my function is no longer to push them, but to restrain them, because some employees forget to eat, and can work until night.

– Let’s name some of the most interesting technologies that can be created in the oil and gas industry with this approach.

– The most interesting technologies are those that make you do the usual things in a different way. There are evolutionary technologies, and there are revolutionary technologies that destroy established processes and perceptions. Conventionally, people have been heating food on fire all their lives, and then a microwave oven appeared – a revolutionary solution.

For example, we have the Green Seismic project. When we come to new potential fields, where hydrocarbon reserves may be located by a combination of indirect signs, we conduct a seismic survey. This is, in fact, tapping the earth. Like a watermelon is tapped, we are tapping the earth to a depth of several kilometers. By the speed of the return of the sound wave, we can imagine what kind of structure is underground.

For a seismic survey, you need to place equipment with a certain spacing frequency. This means that we need to cut down a lot of trees in one season. This is a serious environmental challenge and a big risk for industrial safety. When you have 500-600 people cut down every day from morning to evening, it’s only a matter of time before someone gets injured.

“Green seismic” helps to minimize the impact on nature and reduce production risks. This approach required many changes even at the legislative level. A number of technical solutions were selected, and some of them were developed from scratch. Nevertheless, having implemented everything, we have learned how to carry out seismic surveys practically without logging. First they reduced it by 40%, and now by 80%. This is serious progress.

The whole industry has already transformed under this. Previously, the party that carried out seismic surveys was a platoon of heavy machines. Then we told our contractors that we are now working with mobile equipment. It is small, you do not need to cut anything to install it, and to deliver it to the point you need a maximum of a snowmobile. It took a huge effort to convince our partners that now their business can work in a completely different way. For the first two years, they still stubbornly dragged their heavy cars, and we said that they were not needed. As a result, the whole industry has now completely transformed.

The same example can be given from the world of digital solutions. There are different types of studies that help to understand the prospects of oil production: electromagnetic, sound study of earth rocks, geochemical study using biomarkers. For this, separate software solutions were previously built that issued recommendations, and the person in his head tried to combine everything. That is, the geologist had information from geochemistry, electromagnetic, space, gravitational-magnetic surveys, and it all came down to the fact that he himself combined them and made a decision. We wondered if this could be done at the software product level. The first answer was – it is impossible, because these are different foundations of physics. How to combine electromagnetic and sound signals, how to get a clear additional effect? Each method gave its own probability of finding hydrocarbons. One said: the probability of finding a deposit here is 20%, the other said that it is 30%, the third – 25%, the fourth – 37%. What does this mean in aggregate? 37% at the maximum mark, or somehow bring the average? This was the geologist’s subjective opinion, based on his own experience.

We tried to unite everything, create a methodology, digitize and bring complex search engines to a single foundation. We started with the first two methods – electromagnetic and sound, gradually expanded. Now the whole complex is combined into a single digital product, which, by analyzing all the readings from different types of sources for studying a particular area, produces a multiplier effect.

What else is important to understand in such projects: we, in fact, are translators for business and fundamental science. This is a very important role. Business and science have a different language in terms of problems and solutions. In my own experience, I have seen many times how great ideas die due to the inability of all participants to hear each other and agree on roles and tasks. Fundamental science, as a rule, likes to get carried away with a scientific idea or hypothesis for the sake of the scientific idea itself. Their task is to create a new molecular lattice, and what happens to it next is no longer their concern. Historically, we have not nurtured the competence to think about the applied purpose of work in such specialists. Maybe they shouldn’t have it. But our task is precisely to find applied areas for monetization of fundamental science.

As an example, our work with Skoltech, where we have really fundamental research at the level of crystal lattices of future materials. We use them in application areas with our partners, forming new types of spraying, alloys, and so on.

We also have a complex project called “Digital Core”. Globally, there is a problem in the limited material – the core, which we raise from the well. From the reservoir, you can get just a few meters of a cylinder of rock with a diameter of just over ten centimeters.

– Do you need to drill a new well for a new cylinder?

– Yes, and it is again hundreds of millions of costs to get a small cylinder. At the same time, there are research methods, after which there will be nothing left of the core. As a result, what we are doing now: taking out the original rock, we drive it through special equipment that shines through it like an x-ray.

– Digital twin?

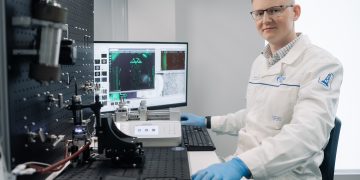

– Yes, in fact, a digital twin is being created. We are currently cooperating with Novosibirsk State University. They are building the Siberian ring emitter of photons – SKIF. This is, by and large, a collider that accelerates particles and, thanks to the release of photon energy, makes it possible to conduct research using unique methods.

SKIF makes it possible to focus a photon beam at the level of thousandths of microns. He shines through any type of rock, seeing in it not only statics, but also observing the dynamics of any process due to the enormous frequency of repetition of these beams. We are now forming a whole database of research that will be unique for domestic, and perhaps even for international research practice.

So, we have created a core with a figure – a double, as close as possible to the original in terms of all its characteristics. Then there are programs that use it for modeling. But any research needs to be tested in practice. For example, different types of chemistry effects – they are very difficult to create at the level of a mathematical code, they need to be tested. So, to solve this problem, we have a project that helps to create a physical core from a digital core. That is, we can copy one core indefinitely. This is an example of just a combination of fundamental research and applied science.

Everything related to the field of chemistry at the level of creating molecules is very important for us, as well as everything related to materials science and process mechanics. Here we interact with fundamental scientific schools. Of course, our partner universities play a big role.

In general, we have built a separate partner ecosystem with universities, where we develop all aspects of interaction, from fundamental research to applied education programs with the subsequent use of universities to solve production problems. We not only teach students and undergraduates (more than 100 teachers are our employees), but we also involve students in our work. Today, about 350 guys in our university ecosystem are, in fact, our part-time employees. For them, this is a great opportunity to prove themselves and begin to really work on the tasks of a potential employer, for universities – a chance to touch the actual tasks of the industry, and for us – an opportunity to attract a motivated, not the most expensive, but already quite competent engineering workforce.

– If you imagine that a genie appears on the terrace over there, and he tells you that you can ask him for any technology that is currently lacking for the oil industry, what would you ask?

– We know well in almost all areas, or at least we have a good idea of what we would like to receive. We even know how we would like to do it, but the limitations are of a technical and applied nature.

A huge challenge for us is getting a signal from wells during the construction process. When a well is being drilled, we lower a large amount of high-precision equipment into it, which registers a huge number of parameters. The current technology for transmitting this information is quite primitive in terms of design. It is impossible to use a cable, the wireless data transmission system has not yet reached the required resolution either. In fact, the principle of Morse code is applied, transmitted by pulsation through the fluid in the wellbore. And instead of possible gigabytes of information per second, we get only bytes.

– Such an environment?

Yes, pressure, temperature, etc. Finding a more efficient technical solution would be a breakthrough. Can you imagine what a huge amount of information we could register in the process of drilling? After all, we need information at the level of seconds, maximum minutes.

– If you miss a little, and you need to drill a new one?

– Yes. The drilling process cannot be stopped. I didn’t make the right decision in time, and in a minute the well will go to the wrong place where the productive layer is located.

To solve such problems, we have a very well-tuned system for expanding the call funnel. There is a whole competence: how can we get out of the blinkered zone. One of the main problems was the lack of ideas. At first, the experts immediately said: “It’s impossible.”

– Dead end…

– Exactly. What’s the point of discussing something if it’s impossible? We said: “Let’s imagine that everything is possible.” And even then everything went with a creak, and it took a lot of effort to get people to look at the situation from a different angle. Nevertheless, as soon as we learned how to enter the creative zone, thousands of hypotheses were immediately formed about what to do next.

I always give an example that I saw at one foreign automobile plant. There was a circle on the wall and it was written that the radius of the circle is the cost of the car. Back then, the base model cost $27,000. Inside this large circle, another black filled circle is drawn in the center – this is the real cost of the machine. Two and a half thousand dollars. Everything else is a loss. They explained to us that if everything was done without losses in logistics, in costs, then the car would cost ten times less. And the difference between the circles is an area for improvement. For me, it was a huge change in awareness. Today we have learned to understand that our potential is actually very far from what we have already achieved. Although a lot has already been done. But the potential is such that technological progress, scientists and engineers will be enough for the next few generations. This captures and motivates me: we have an inexhaustible volume of challenges to solve and solve.

– Is it possible to be completely independent of imports in your field?

– Now the key task is to prevent a decrease in the level of manufacturability of production. This is the focus of our direction on import independence. We have chosen a model of integration with major industrial partners. That is, we do not create solutions on our own, but team up with companies for which this is the basis of their business. And then together, sharing the costs and risks of financing, we quickly create solutions, replicate them and implement them in production. For example, rotary-controlled systems are equipment that allows you to direct the bit in different directions during the drilling process. Almost all the wells that we are currently creating have a horizontal wellbore: first, a vertical section goes, then the well is introduced into the horizontal azimuth. These types of wells require controlled drilling. Previously, all rotary-steered systems were 100% imported.

– And some Western companies are now reducing their business in Russia.

– Yes. As a result, we chose a partner who provides drilling services. We didn’t go directly to the hardware developers, we said: “Guys, there is a service that is a key service for us. Are you interested?” Having chosen such a partner, having pooled our financial and technological resources, we released the first three crews to the field and started drilling wells with Russian rotary steerable systems.

The speed of technology development and implementation very much depends on what model you use to involve all participants. The same solution can be created over the course of several years, or it can be done in six months if everyone is motivated for the final result.

We call the search for the right interaction structures business engineering. If the business model is put together incorrectly and all partners are not motivated to achieve the final result, then scientific engineering will not work. Finding the optimal structure is not easy: there is a lot of variation in the commercial model, ownership model, future division of intellectual rights, financing and contracting. In general, a huge number of questions, each of which creates variability in more than 100 unique combinations of all elements. But if everything goes right, all internal barriers are removed, all the necessary levers work, and the speed of the project development is amazing.

In parallel, we are now thinking about the next wave of import independence, more fundamental, related to everything related to special software and complex components of the chemical industry. This will require us to create new manufacturing facilities, new test components, and so on. The instrumentation base also requires a serious development of competencies.

– By the way, let’s talk about software. What kind of IT specialists are needed in such an industry? You, in fact, extract oil from stones.

– Such IT people who help to extract oil from stones. This is also the difficulty that oil itself does not flow anywhere. To get it, you need to understand a lot of processes.

Given that you cannot, as I said, go down into the well, touch the oil production site and look at it, a lot needs to be predicted or modeled. The creation of complex models that combine all fundamental scientific knowledge and all elements of the technologies achieved, the search for optimal solutions in terms of economic effect – all this requires tens of thousands of options for sorting out how to develop this or that field as efficiently as possible. For this, unique digital solutions are needed.

The supercomputers we use sometimes take days to run just one run of such a complex model. Of course, without our own competencies, without our own resource for managing this process, we will not be able to work. So we have a large layer of specialists who understand very well how predictive analytics is used, and those who are constantly improving IT solutions.

– IT people come to you, obviously, not only for the idea, they go to work.

– Undoubtedly, IT specialists have quite flexible options. Today they can work in medicine, tomorrow – with us, the day after tomorrow – in construction. In this regard, their world is more barrier-free than that of the oilmen. But in our case, word of mouth works well. The guys who have already come like us, and they tell others about it. I have seen many times how at first one person comes to us, and after three months – his whole team. They are interested. Everyone says that in terms of the scope of the tasks, we have very complex challenges at the level of the technical limits of today’s digital tools, especially in the field of subsurface, geomechanical modeling, hydraulic fracturing modeling or complex chemical processes.

– If you imagine that I have a startup with technology that can be useful in solving your challenges, then how can I propose it to you?

– If you really had such a startup, we would definitely know about it. We are looking for such startups. There is an annual accelerator, within the framework of which we invite everyone who, in one way or another, develops solutions applicable to our industry, to talk about their developments and projects. About 650 teams signed up last year.

Another platform for dialogue could be the New Industry venture fund. Through a certain model of technical reviews and pitch sessions, we evaluate projects and invest in some of them together with other interested partners.

There are many initiatives that come from within the company. The guys come and talk.

We will activate the leverage to find teams that have already developed technologies in certain directions and need additional partners to replicate and bring to production scale. Because many develop some kind of solution almost in garages, because there is nowhere to test it. For such startups, partnership with us is an opportunity to test their technologies in practice in real conditions, at the field. Because a prototype can perform well in the lab, but we, as a company, need industrial solutions. And they must pass industrial tests. This is such a vicious circle that we help break within our ecosystem in order to eventually transform raw prototypes into technology products that are in demand on the market.

This fall, recruitment for the second stage of our accelerator was completed. Hundreds of startups come to us again to participate in our annual acceleration programs and develop their products with us.