Automated Control of Drilling Process to Improve Efficiency of Oil Well Construction

Bit efficiency is determined by several factors; penetration per bit, rate of penetration, drilling speed per run, and operating costs per meter of penetration. Optimal drilling conditions usually meet the criterion of a minimum cost per 1 m drilled, which is defined as the minimum amount of energy required for rock destruction, high mechanical penetration rates and effective service life of the drilling tool.

With that, the range of parameters that impact mechanical drilling performance is complex and depends on different drilling parameters (geological features, mechanical properties of the rocks, design features of the rock cutting tools, etc.).

In the above conditions, expressing the drilling performance indicators through specific variables determines the drilling parameters influence on drilling performance.

The main advantages of the information technologies application to technical processes control is to improve the process quality, its productivity, reduce time, cost, and increase the accuracy and stability of the operations performed.

Well drilling – a rock destruction process – is accompanied with numerous and various physical phenomena, which effectiveness shall be assessed by a number of quantitative indicators specifying the performance speed of individual operations, for example:

• rate of penetration (mechanical speed; drilling speed per run; m/hour; commercial, m/rig-month;

• bits consumption per 1000 m of penetration, pcs;

• drilling time schedule per well or 1 m drilled, hour;

• cost of 1 m drilled, RUB, etc. and qualitative indicators describing the achievement of well drilling performance targets (core recovery, %; well deviation intensity, degree/m, etc.) [1].

These values depend on several non-controlled (geological settings of drilling, rock mechanical properties, conditions of rock occurrence, random events,etc.) and controlled factors, which include the drilling parameters.

However, these criteria do not always enable a reliable assessment of drilling efficiency.

According to V. S. Fedorov [2, 3, 4] the effect of the operating parameters on drilling performances is complex, and it is not an easy task to assess the different parameters effects on drilling based on the quantitative indicators.

To optimize the drilling process a modeling was built based on the theoretical calculations and empirical regularities. The following works are known among domestic researches: V. S. Voнtenko [1], V. S. Fedorov [4], B. A. Zhlobinsky [5], B. V. Baydyuk, V. Yu. Bliznyukov, V. S. Zaretsky [6], V. D. Evseev [7], V. V. Neskoromnykh [8] etc. considering the effect of different factors (geological settings, drilling parameters, bottomhole conditions, etc.) on rock destruction.

Hence, according to V. S. Fedorov, the following parameters have a significant impact on the rate of well deepening: the mechanical properties of rocks, conditions of occurrence; origin of the substance filling pore space; method of rock destruction; drilling bit design and service life; methods of cuttings removal from hole; perfection and power of drilling equipment, etc.

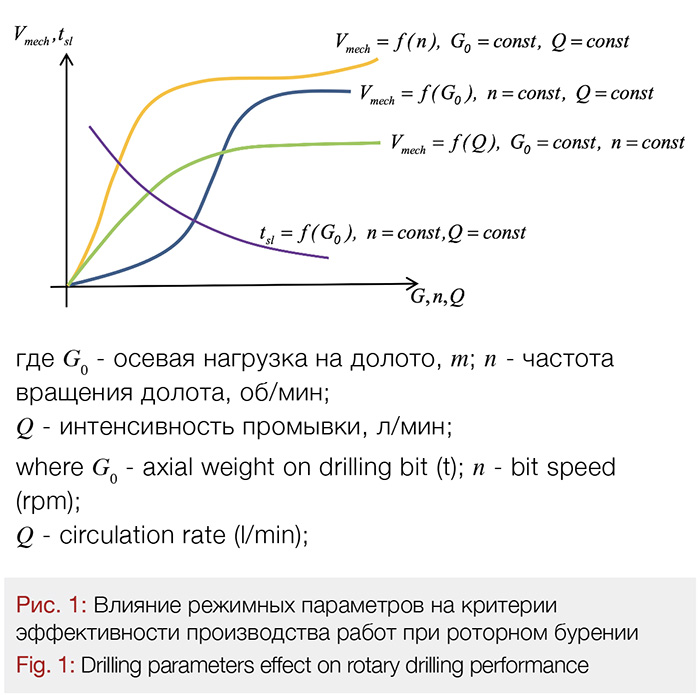

The effect of rock destruction tools operating parameters on rotary and turbine drilling performances as described in the above publications depicts the general trends of the drilling rate VMEX and bit operating time td (service life) which changes over the course of rock destruction is shown in Fig. 1.

The effect of each parameter G0,n,Q on rock destruction during drilling is a function of the preset values of the other parameters. An increase in of one of the controlled parameters, such as, axial weight, contributes to a drilling performances improvement only in combination with other controlled parameters: circulation fluid flow rate, bit speed, etc [7].

In turbine drilling, a change in drilling mud flow rate Q results in a change in the bit speed n and axial weight G0. Here, the main drilling parameter is the volume of circulation fluid pumped Q. In this case, the axial weight on bit G0 is a function of the circulation rate Q.

G0 = f(Q), (1)

In turbine drilling, bit speed n is a variable value that is a function of the amount of fluid pumped and of the axial weight on the bit, that is

n = f,(Q,G0) (2)

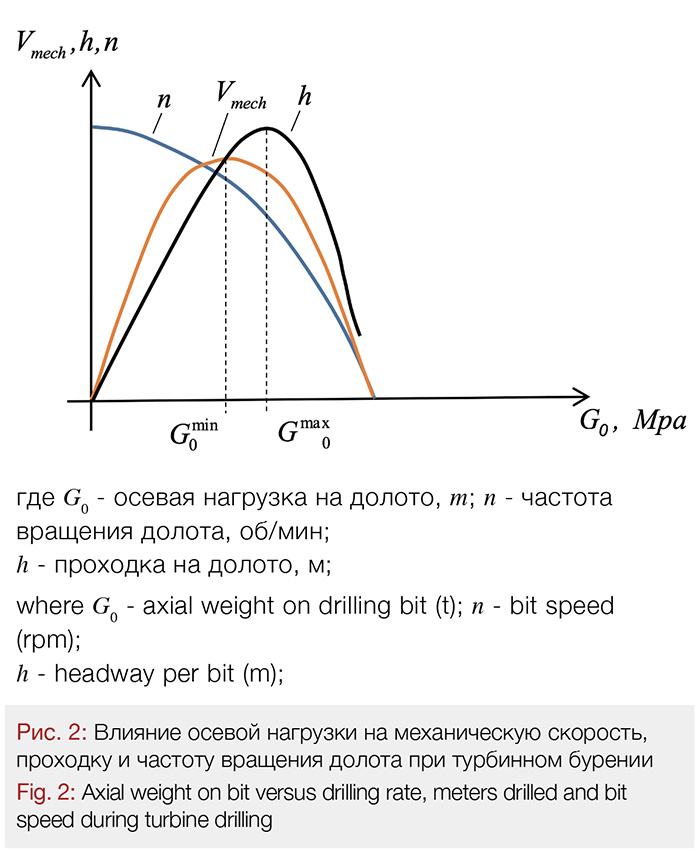

In turbine drilling, any change in the axial weight on bit leads to a change in bit performance, Fig. 2.

The optimal mode at maximum bit run speed will be achieved at an average axial weight value Gmin0 corresponding to maximum rate of penetration Vmaxmech, and an axial weight Gmin0 corresponding to maximum headway per bit, Fig. 2, [1].

The combination of the controlled parameters effecting drilling performance allowing their highest quantitative and qualitative values determines the optimal drilling mode.

V. V. Neskoromnykh [8] indicates the optimal drilling parameters as those corresponding to minimum drilling cost and are characterized with minimal energy consumption for rock destruction, the highest drilling rates and effective bit service life.

Different research and design institutes, and universities have been involved in studies of the optimal combination of drilling parameters: VNIIBT, VNIIKR, VNIIKAneftegaz, Azizbekov Azneftekhim, Gubkin Oil and Gas University, etc. As a result, bit bottomhole performances were modeled based on the following optimum criteria: rate of penetration, bit run and cost of 1m drilled.

Empirical equations derived from the sufficiently wide experience of well drilling in Russia (USSR), USA, Canada and other countries describes the complex relationship between the numerous parameters, Table 1.

Galle-Woods-Lubinsky, Bingham and other models are world-wide known [13].

Mathematical models based on world-wide drilling data establish the relationship of the control parameters subject to this or that drilling process requirement (minimum well drilling cost, maximum drilling rate and maximum bit run).

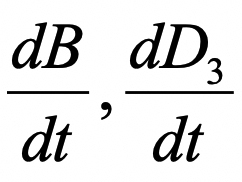

In the above models, the optimal combination of drilling parameters is determined by the extreme values of the efficiency indicators as: well penetration rate ![]() , bit wear

, bit wear  , cost per 1m drilled q, which are described with high values of drilling rate, minimum energy consumption for rock destruction, and maximum bit service life.

, cost per 1m drilled q, which are described with high values of drilling rate, minimum energy consumption for rock destruction, and maximum bit service life.

With that, quantitative values of the optimal indicators cannot play a decisive role in the assessment of well drilling effectiveness since the improvement of one parameter may be accompanied with degradation of another. Besides, the dimensionality of the right and left parts of the equation does not coincide, when physical values are introduced, hence the coefficients are required to smooth the dimensionality of the units of measurement.

It is not an easy task to build a mathematical model clearly imaging all physical drilling aspects, which is impractical due to:

• lack of a present-day unified efficient strength theory explaining physical phenomena of rock destruction;

• numerous random factors, which parent population is unknown;

• uncertainty of geological settings of exploration well drilling.

Hence, when the theoretical trends of the process (like drilling process) are affected with a great number of critical factors which are unknown, it is extremely difficult to find an analytical solution (by means of differential equations) of the problem.

Because the effect of different factors (geological settings, drilling parameters) the bit design (features, etc.) impact on drilling performance cannot be observed individually, but as a combination of factors, and this also depends on the preset values of other parameters, the following solution of the problem of drilling effectiveness improvement is determined by the relationship between individual groups of values.

The transition from common physical values to those of a complex type has the following advantages for a research task solution:

• potential determination of the parameters that have a complex effect on selected performance criteria

• reduction of interdependent variables.

• when a problem with complex variables needs solving, a wide range of events need to be considered rather than a single case of any one parameter’s contribution to drilling performance [11].

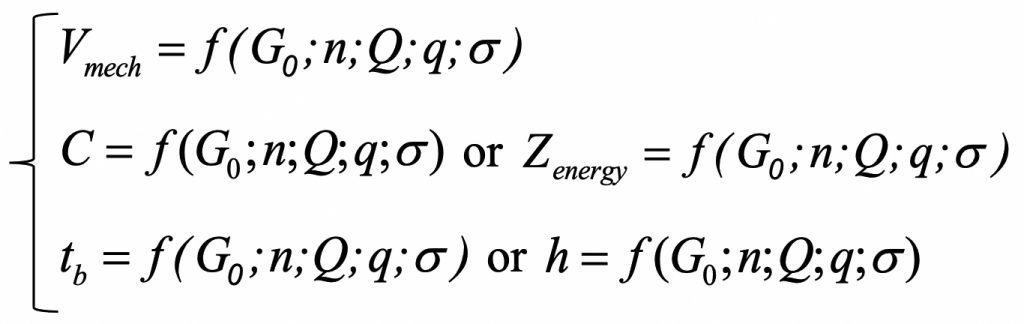

In light of the selected criteria for drilling effectiveness (Vmech – rate of penetration; C – cost of 1m drilled; tb – bit run), the mechanical process of well deepening can be presented mathematically through a system of equations:

(3)

(3)

Where: q – drilling mud weight; ? – rock ultimate strength; G0;n;Q – interdependent parameters, which optimum combination enables extreme values of selected criteria Vmech;C;tb or Zenergy;h.

To determine a functional relation between the drilling parameters G0; n; Q, which may be affected in accordance with this or that process requirement (Vmech; C; tb) ⊥ MIN;MAX or (Vmech; Zenergy;h) ⊥ MIN;MAX the provisions of similarity theory have been assumed [11].

Equation (3) formulation and solutions with the help from the included values dimensional method, enabled a determination of the functional relationship between the drilling parameters [12].

(4)

(4)

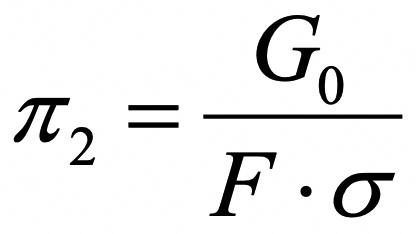

where F – bit-to-rock contact area, mm2; vls bit cutter linear speed, m /s, ?,?,? – exponents to be determined empirically.

Select complex variables from equation (4) as follows:

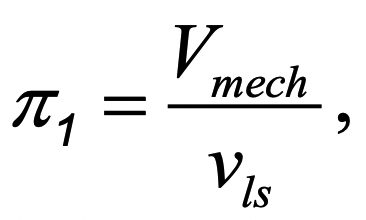

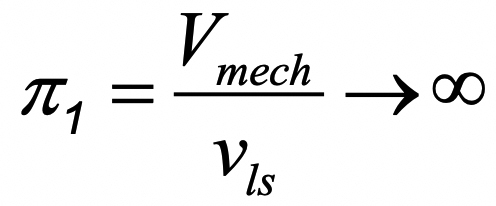

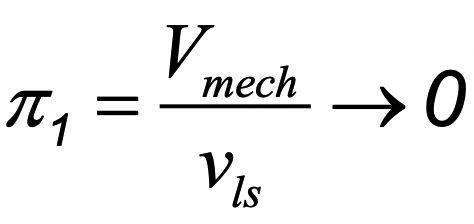

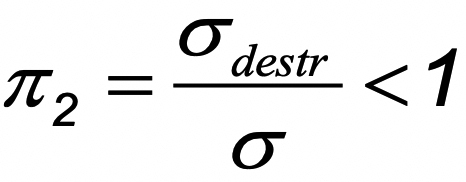

1) ,  describes rock destruction mode: from bit impact penetration, when

describes rock destruction mode: from bit impact penetration, when  to friction without rock destruction, when

to friction without rock destruction, when

.

.

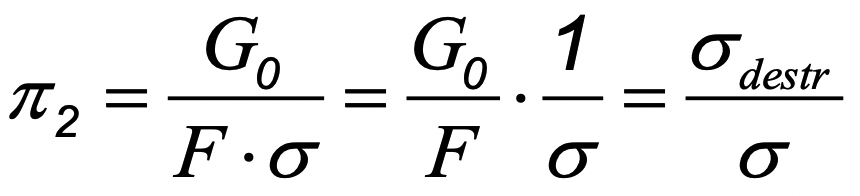

2)

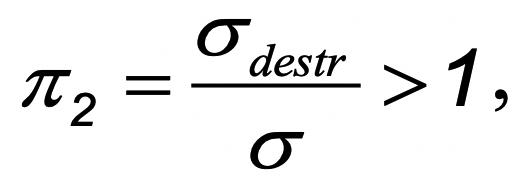

describes the condition of solid body (rock) mechanical destruction with external forces applied to a drilling bit, which strength is higher than the rock strength.

If  , stresses created in rock do not exceed its strength limit, and rock does not fail.

, stresses created in rock do not exceed its strength limit, and rock does not fail.

If  stresses created in rock exceed its strength limit, and rock fails, respectively.

stresses created in rock exceed its strength limit, and rock fails, respectively.

The values of complex variables are shown below based on the oil well drilling practice (the well was drilled in Volgograd Region, its drilling parameters were defined from positions Vmech – MAX and h –MAX), Table 2.

The table includes: full depth well column; rock description and drillability data (as per scale of the unified classification of rocks by drillability, according to a handbook of estimate standards for geological exploration); [14]; drilling parameters (median values of MWD station data; design values of drilling complex parameters).

Conclusion on Complex Calculations

1) Within well drilling intervals under consideration (50–340 m; 1240-1290 m; 3760-4395 m) the values of complex  vary by an exponent part

vary by an exponent part

that is indicative of the process instability with abrupt changes from bit impact penetration to rotation without rock destruction.

Impact dynamic loads may cause failure and premature wear of polycrystalline diamond cutters with drastic reduction of their service life.

2) The values of complex  vary within even larger range. Stresses, which a bit creates in rock (ratio

vary within even larger range. Stresses, which a bit creates in rock (ratio ![]() ) exceed the rock ultimate strength ? from 3 to 87 times that is indicative of excessive (inefficient) energy consumption during rotary drilling.

) exceed the rock ultimate strength ? from 3 to 87 times that is indicative of excessive (inefficient) energy consumption during rotary drilling.

3) Functional relationship between drilling parameters described with complexes ?1 and ?2, determining the process of rock mechanical destruction during rotary drilling, can be used to develop a system for automated control of the drilling process.

Based on the preset drilling rate in well intervals, and subject to a bit design, the system controls drilling parameters (bit speed and axial weight on bit) in order to maintain the complex values ?1 and ?2 within the min and max range, which characterizes the process as optimal.

References

1) Drilling technologies and methods: 2 parts / V. S. Voytenko, A. D. Smychnik, A. A. Tukhto, S. F. Shemet. – M. : Infra-M, 2013. – P. 2 : Well drilling technologies. – 613 p.

2) V. S. Fedorov. Determination of drilling parameters based on the study of key factors affecting rate of penetration: Author’s abstract, Dissertation of Doctor of Engineering Sciences / V. S. Fedorov – Grozny, 1949. – 32 p.

3) Practical calculations in well drilling: tutorial / V. S. Fedorov, V. G. Belikov, F. D. Zenkov, et al., – M. : Nedra, 1966. – 600 p.

4) V. S. Fedorov. Design of drilling modes: tutorial / V. S. Fedorov – M. : Gostoptekhizdat, 1958. – 215 p.

5) B. A. Zhlobinsky. Rock dynamic destruction with indentation / B.A. Zhlobinsky. – M. : Nedra, 1970. – 151 p.

6) V. B. Baydyuk, V. Yu. Bliznyukov, V. S. Zaretsky. Methodical approach to selection of a drill bit, its driver and operating mode with consideration of rock properties. International Conference: Rock Mechanics When Drilling. Abstracts of Reports. Grozny, 1991. p. 58. Grozny Oil Institute. Printed by GNI OVPP.

7) V. D. Evseev. Physics of rock destruction when drilling oil and gas wells: tutorial / V. D. Evseev – Tomsk : TPU, 2004 – 151 p.

8) V. V. Neskoromnykh. Destruction of rocks while drilling wells: tutorial / V. V. Neskoromnykh – Krasnoyarsk : Siberian Federal University, 2014 – 335 p.

9) P. A. Rebinder. Surface phenomena in dispersed systems. Physical and chemical mechanics: Selected publications / P. A. Rebinder. – M. : Nauka, 1979. – 384 p.

10) Handbook of estimate standards for geological exploration. – M. : VIEMS, 1992. – Iss. 4 : Exploration, App. 2 : Uniform rock drillability classification. – 42 p.

11) A. A. Gukhman. Introduction to similarity theory: tutorial / A. A. Gukhman. – 2nd edition, amended and edited – M. : Higher School, 1973. – 296 p., Ill.

12) V. A. Shmelev. Improving efficiency of well drilling. Part II. Drilling process study based on similarity theory / V. A. Shmelev, Yu. P. Serdobintsev // Construction of oil and gas wells onshore and offshore. 2020. No. 9. – pp. 5-10.

13) A. A. Tsuprikov. Intellectual system of adaptive control of oil and gas well drilling: Dissertation of Doctor of Engineering Sciences : 05.13.06 / A. A. Tsuprikov. – Krasnodar, 2017. – 193 p.

14) Handbook of estimate standards for geological exploration. – M. : VIEMS, 1992. – Iss. 4 : Exploration, App. 2 : Uniform rock drillability classification. – 42 p.

15) Methodological guidelines for the determination and use of indicators of rock properties in drilling / RD 39-3-679-82, VNIIBT, M., 1983. – 93p.

16) Handbook on the mechanical and abrasive properties of rocks in oil and gas fields / Abramson M.G., Baydyuk B.V., Zaretsky V.S., Kirsanova A.T., Matveeva A.M., Pyankov N.Ya. , Urmantsev M.M., Shevaldin I.E. – M., Nedra, 1984, 207s.

17) Instructions on the composition, development procedure, coordination and approval of design and estimate documentation for the construction of oil and gas wells. (VSN 39-86), approved by order of the Ministry of Oil Industry on 09.08.86, N 443. – M., VNIIOENG, 1987.

18) RD 39-0148052-537-87 «Model of the working design for the construction of oil and gas wells». – M., VNIIBT, 1987.

19) Bliznyukov V.Yu., Bliznyukov Vit.Yu. Assessment and classification of mining and geological and technical and technological conditions for drilling wells and lowering casing strings [Text] / Bliznyukov Vit.Yu. // Construction of oil and gas wells on land and at sea. – 2008. – No. 7. – p. 26-31.

Authors

Valery Shmelev, Senior Research Associate, Ph.D., PermNIPIneft, LUKOIL-Engineering LLC Branch in Perm

Yury Serdobintsev, Professor, Department of Industrial Process Automation, Volgograd State Technical University, Ph.D.

Aleksey Makarov, Candidate of Engineering Sciences, Associated Professor, Head of Department of Industrial Process Automation, Head of Prototyping Center, Volgograd State Technical University