Gazprom Neft Increases ROP by 46%, Saves 27 Drilling Days with StingBlade and AxeBlade Bits, Russia

Conical and ridged diamond element bits save trips, improve footage, and increase ROP while drilling 12 horizontal wells in challenging, interbedded formations

Reduce drilling time in formations with high UCS

The production section of the Tsarichansko-Filatovskoe field, located in the Orenburg region of Russia, is composed of interbedded terrigenous-carbonate formations. With high UCS in the range

of 10,000 to 25,000 psi [69 to 172 MPa], these formations typically cause heavy impact damage to the PDC cutting structure during drilling- requiring multiple PDC bits and unplanned trips. In addition, wellbore instability, thief zones, and formation abrasion challenges contributed to slow ROP and decreased build rates.

Use engineered bits toimprove drilling efficiency

Smith Bits, a Schlumberger company, used the IDEAS* integrated dynamic design and analysis platform to analyze bit durability and drilling efficiency before recommending the StingBlade bit for the top part of the section and the AxeBlade bit for the remainder of the 811/16-in section. The unique 3D geometries of the Stinger* conical diamond element and Axe* ridged diamond element provide an ultrahighly concentrated force that resists wear and fractures high-UCS rock more efficiently-significantly improving footage and ROP in challenging formations.

The Axe and Stinger elements, in addition to a thicker, more durable diamond layer, enabled the engineered bits to drill farther and faster without sustaining the impact damage seen with conventional PDC bits.

Saved 27 days across 12 wells

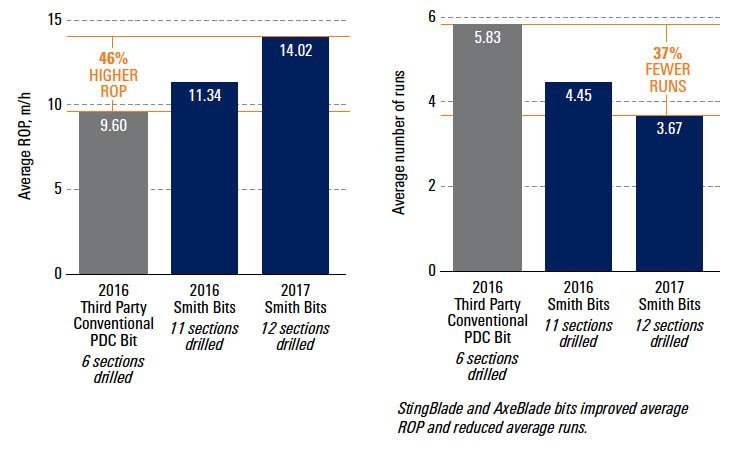

Using the application-specific diamond element bits, the operator increased the average ROP to 46 ft/h [14.02 m/h] in 2017—a 46% increase compared with offset wells drilled with third party conventional PDC bits in 2016. The technologies used increased drilling efficiency to reduce average interval time by 2.2 and 4.6 days — saving a total of 27 drilling days across 12 wells in 2017, compared with that achieved with previous bits in 2016.

CHALLENGE

■ Reduce trips and improve ROP while drilling the 811/16-in sections through interbedded formations with high unconfined compressive strength (UCS), wellbore instability, and severe lost circulation zones.

SOLUTION

■ Optimize drilling performance by customizing the StingBlade* conical diamond element bit and AxeBlade* ridged diamond element bit for the field.

RESULTS

■ Saved 27 drilling days during a 12-well drilling campaign.

■ Increased average ROP by 46% in 2017, as compared with third-party bits run in 2016.

■ Reduced average interval time by 4.6 days