Brownfield: Development Drilling With ECO System

CASE OVERVIEW

A drilling company operating in mature brownfields, with a well-defined subsurface play model and extensive knowledge of the Volga-Ural region geology, adopted the digital ECO System to optimize production wells construction time. ECO implementation included the deployment of the cloud component, setting up ECO gateway at the rig, and Client personnel software training.

CONTINUOUS ANALYSIS

An automated system incorporating real-time live dynamic modeling and data analytics tools made it possible to continuously analyze abnormalities and key parameters deviations. Experience proves that even the most meticulously pre-engineered drilling plan requires continuous updates, re-evaluation to achieve defined objectives facing specific conditions. For example, the slightest changes in the BHA composition or in the rheology of the drilling fluid, the achieved trajectory and the tortuosity of the well trajectory requires to re-estimate the feasibility of further safe and efficient drilling.

Thanks to dynamic automated calculations, Client was able to estimate well construction projects associated risks in real time. ECO enabled tracking of actual loads at bit both for rotary and slide drilling, capture the slightest overpulls and string hanging while tripping and wellbore treatment operations, notify the over torques and abnormal SPP deviations in real time. The prescriptive analytics allowed to minimize downhole hazards of getting pipe stuck, washed out or twisted off, permitted to preserve wellbore integrity and open hole quality, mitigate risks associated with cuttings bed, transport, hole bridging, and fractures while drilling.

Predictive analytics tools detect deviations of all key indicators and warns personnel in advance about emerging hazards, automatically notifying drilling crew and the remote operational center. ECO targeted recommended mitigation actions allow to prevent downhole complications. The knowledge gained about geology, downhole hazards and emerging operational complications are automatically captured and taken into consideration in the prospect wells drilling plans, allowing to continuously improve operational practices and avoiding near misses associated with human error.

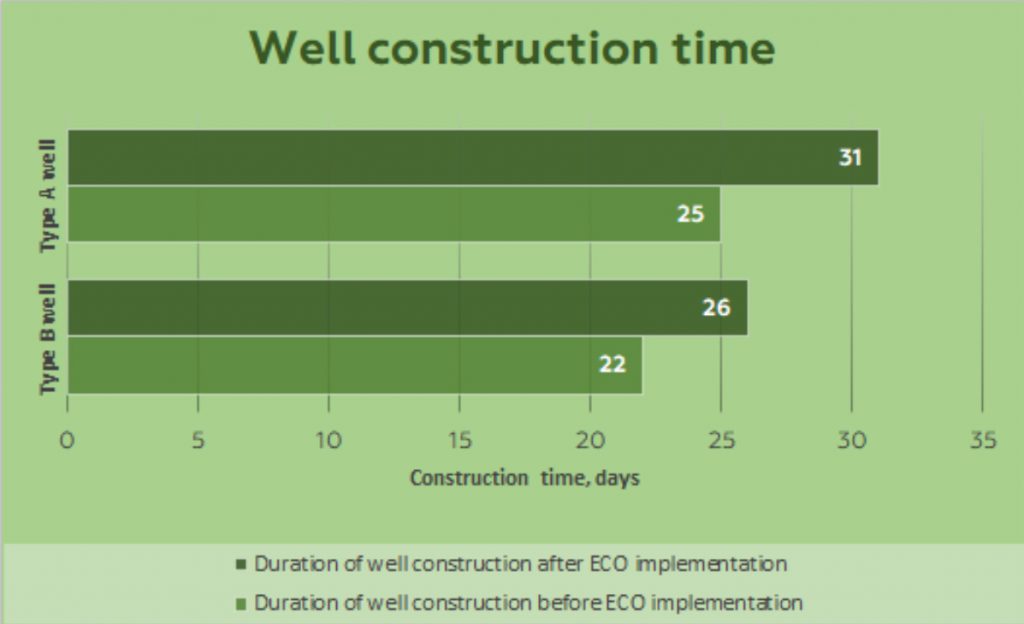

Tracking the current drilling parameters in real time without the possibility of meddling the data allowed the Client to reduce the average construction time of typical wells by 15%, reduce accidents, defects, NPT time to eliminate geological complications by 25%, and also detect previously hidden and invisible lost time.

Achieved improvements in feet drilled per day, and in overall per, well construction time vary depending on the types of wells and drilling scales. In the case of sidetracking (well type A), the acceleration, in general, was 20%, and during the construction of directional wells (well type B), on average – 16%.

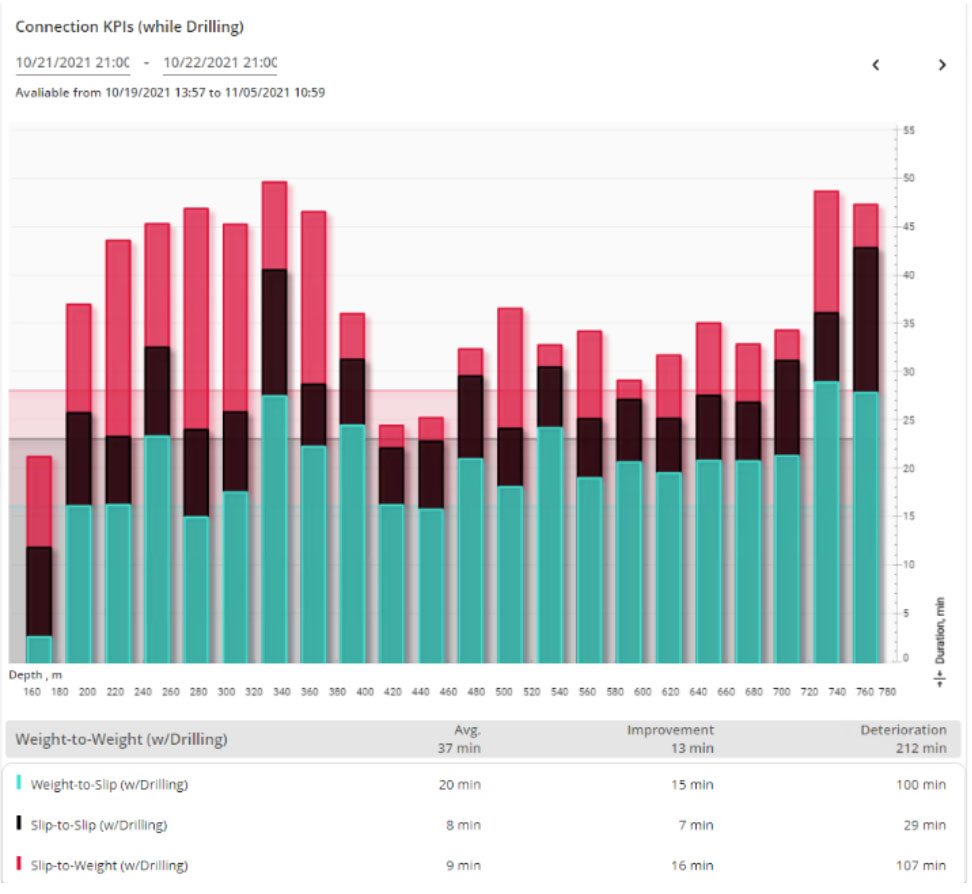

Analytical tools allowed the Client to identify a significant amount of hidden downtime. For example, automated analysis of the off-bottom activity in drilling revealed that up to 30% of this time were NPT.

The main tool for preventing accidents in case of violation of drilling technology in ECO is the system of early warnings and alerts. When the limit values of technological parameters are reached, the system notifies on the potential hazard, or drilling dysfunction taking place, recommends, and notifies personnel, sending emails or messages, as well as highlighting the issue on the drillers HMI screen. Driller sees all sensor readings on his display along with dynamically identified associated threshold values and optimal safe working intervals on gauges and logs in real-time.

Challenge

- To reduce well construction time and consistently hold reduced times.

- Identify ILT and eliminate NPT at turnkey well construction projects.

- Mitigate Drilling Hazards.

Solution

- Single digital drilling knowledge repository for all drilling data.

- Predictive trends analysis.

- Continues dynamic drilling parameters analytics in real-time.

- collaborative single entry digital platform for all well construction parties.

- Automated reporting to prevent human factors negatively affecting the decision-making process.

Results

- Improve drilling performance benchmarks, reducing well construction time and associated costs by 15%.

- Reduction of accidents and downhole downtime by 50% due to timely hazard warnings and mitigation actions recommendation

- Improving decision time and quality archived by working in one information and analytics digital environment.

15%

Reduction of well construction time

50%

Reduction of accidents

30%

Uncovered ILT and standard procedures excessive timing masked as a productive time

ECO System

Houston

17002 Cypress Knee Dr. Cypress Texas, USA

+1 (713) 502-65-13

Moscow

37/3 Leningradskiy Pr-t.

125167, Moscow, RF

+7 (985) 222-41-75

Al Khobar

Al Noor Building 2, Aljawarah Area, Al Khobar, KSA

mohanad@powerteamco.com

All rights reserved

WellsX LLC

ECO System Interview – Kamil Zakirov

What Is Well Construction Digitalization? Hear The Experts

Greenfields: Exploratory Drilling With ECO System