Casing While Drilling: One of the Ways to Reduce a Carbon Footprint

Global problems such as climate change require immediate technological solutions and tactical measures to minimize that impact on the environment.

The concept of «carbon footprint» is used to objectively characterize the environmental efficiency of the life cycle of any product, including the oil industry.

The carbon footprint is directly influenced by the efficiency of industrial equipment and energy technology equipment, the efficiency of consumption of fuel and energy resources, measures to reduce greenhouse gas emissions, etc. The carbon footprint is an indicator to characterize the level of environmental pollution.

As we know, drilling of wells is a challenging technological process that involves a lot of machinery, equipment, and transport. Obviously, drilling of wells, like any high-technical production, entails a negative impact on the environment.

During drilling of wells on land rigs, the main sources of emissions of pollutants into the atmosphere are:

• Machinery on rig site

• Additional mechanisms and equipment

• Vehicles

• Equipment for earthworks (bulldozers, tractors)

• Power generators

The construction of the entire well consists of the several sections drilling. Therefore, for the entire construction cycle, a certain number of pollutants emitted.

What if the time spend for this process significantly shorten? It is logical to assume that the carbon footprint and negative impact on the environment per well unit is going to decrease.

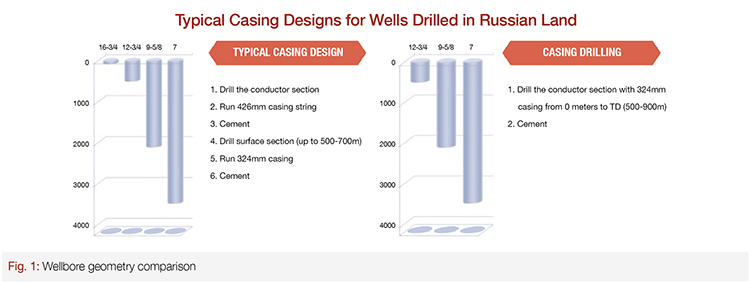

Figure 1 is showing typical well design in Russia Land, where 16-3/4” (426mm) casing pipe is being run to 50 meters and protects the well from the soft rock on the well head. Then surface section is being drilled with the rotary or motor BHA to the Target Depth of 500-700 meter. Once drilling completed 12-3/4” (324mm) casing is being run and cemented. In normal (trouble free) conditions, this takes from 4 to 7 days.

We have proposed a new way to deliver top hole for such wells, where 16-3/4” (426mm) pipe is completely eliminated and 12-3/4” (324mm) casing is used to drill the section to TD. With such approach on some projects target depth has been extended to 900 meters. Once casing reach target depth, its being cemented. This way drilling of the top-hole section takes 1-2 days, as a result, 2-4 days are being saved from the well construction time due to elimination of number of operation steps. Also advantages of this technology is well construction cost reduction, overall time reduction, stuck pipe prevention, casing being set to target depth in difficult hole conditions (carvings, pack-off risk, etc.) Casing while drilling has many technological advantages that affect the well quality and the well construction process as a whole – reducing accidents & potential NPT, strengthening the borehole, etc.

Casing-while-drilling – one of the most advanced techniques for the well construction at the moment – reducing exposure from the common drilling problems, where the drilling and casing off the section performed simultaneously.

Advantages of this technology includes reduction of the drilling cost, minimization of the sticking risk, solution for casing running in complicated geological conditions such as wellbore instability, tight holes, etc.

A casing pipe has a larger diameter compared to a drilling pipe and therefore it continuously contacts the borehole wall, resulting in an action termed the “plastering effect” – the casing smears the drill cuttings into the borehole wall sealing pores and fractures to reduce or eliminate fluid losses. As casing pipes are constantly run into the well, the casing off the problem zones performed while drilling.

The plastering effect reduces NPT resulting from borehole-related problems, such as

• Sloughing shales

• Tight holes

• Borehole bridges

• Lost circulation

• Large-diameter surface hole resulting in hard-to-remove cuttings from the annulus

• Damaged producing zones

• Stuck pipe

Operations for the casing-while-drilling are further optimized to mitigate risks that may appear during the well construction. A pre-job analysis and Drilling Bit / BHA customization ensures reaching a Target Depth in much safer and efficiently manner in any drilling applications.

When the target depth reached, a cycle of circulation performed after which the cased hole is ready for the cementing. After the cementing and the casing drilling bit drilled out using the conventional BHA with the standard PDC or 3-cone milled tooth bit during 40 minutes. The same BHA used to drill the next hole section. Dedicated run to drill off casing accessories, cement and casing drilling bit is not required.

The Allegro XCD casing-while-drilling service includes a casing while drilling tool (CRT), multi-lobe torque rings (for non-premium connections BTC/OTTM), accessories and casing drilling bit made of drillable alloy. Specialized double valved float collar is normally utilized for these applications. This engineering solution allows the combination of drilling and casing operations (Fig. 4).

As for the improvement of performance indicators, the advantages are obvious, if we compare a set of operations required for drilling a section using conventional drilling and the casing while drilling technique. During conventional drilling the following operations are performed: drilling with a standard BHA, a wiper trip and casing running. The casing while drilling technique allows to eliminate the conductor casing and avoid additional operations.

Implementation of the technology in the surface section at the one of the projects has already reduced the well construction period by 3 times (Fig.5). Consequently, less time spent on the operation is decreasing emission of pollutants into the atmosphere.

After the first implementation, the surface section casing drilling service was adopted for each subsequent well. We bring to your attention a summary of 8 wells drilled over the past year for Novatek-Yamal LNG in Chart No. 1.

CwD has become the standard technology to drill top-hole sections at the Yamal LNG project. As the wells were drilled, productivity (ROP curve) improved from well to well due to automation of the drilling contractor’s operations and optimization of the bit, drilling regimes. At well 5252 of the Yuzhno-Tambeyskoye field, we set a field ROP record of 54.53 m/h when drilling with 12-3/4” (324mm) casing string. This record was achieved due to extensive planning and experience gained on the project.

Casing Drilling has been also performed with 13-3/8” (340mm) and 16-3/4” (426 mm). Thus, the successful experience of drilling with 12-3/4” (324 mm) surface conductor was replicated to Evo-Yakhinskoye, Ust-Yamsoveyskoye, Verkhnetiuteyskoye fields at Novatek projects.

As can be seen from the graph, at each subsequent job, thanks to the implemented solutions and analysis of the experience of previous wells, as well as based on the well-coordinated cooperation between Schlumberger engineers and the Eriell Neftegazservice drilling crew, it was possible to improve the performance and shorten the construction of sections. Several records were set in terms of ROP and construction time, including the well of the Evo-Yakhinskoye field 8304, where, due to elimination of thermal casing (permafrost isolation), it was possible to drill a section of 450m in 0.77 days, with a record ROP of 73.51 m/h.

The expert casing while drilling technology Allegro XCD™ requires a thorough applicability analysis to reduce drilling risks. This technology involves the use of a modeling with the software package, which includes a drillable bit design platform and allows assessment of such conditions as formation strength and interaction between a bit and rocks to develop a perfect cutting structure with unique diamond inserts.

When developing a customized drill bit this technology improves reliability and efficiency of casing while drilling operations.

The optimization of the BHA and drill bit design is based on calculations made with the modeling software.

All these allow us to select a design of drill bits for a specific geological cross section of fields and achieve the high drilling performance.

There are continuous efforts taken for the casing drilling bit optimization; since the beginning of the project, an updated roadmap is being developed, casing drilling bits hydraulics optimization, premium cutters selection, ceramic inserts, and depth-of-cut limiters for drilling in active clay intervals is being implemented.

The gained experience and the implemented solutions lead to a significant reduction in the well construction time and, therefore in a reduction of the carbon footprint of the project.

Novatek pays great attention to reducing carbon emissions, which was reflected in the company’s annual performance report. The use of casing drilling technology reduces the well construction time and carbon emissions.

Together with the customer, we estimated the carbon reduction for 10 drilled wells on the project. 2.5 days of the average reduction of the well construction time on each well due to the technology implementation resulted in a decrease of the generated energy (3500 Giga Joules per well), which corresponds to a reduction in emissions of 12600 light vetches per year.

Preliminary calculations for 10 operations made it possible to achieve the following indicators.

Finding a safe and effective approach in drilling is a challenging task for the construction of oil and gas wells as every field and every well is unique. The range of problems we face is broad and keeps growing with every new field.

We believe that the implementation of this technology throughout other projects of the Customer will have an impressive effect in terms of carbon footprint reduction and cost optimization.

Authors

Jalal Karimov, Askhat Usmanov, Valeriy Pogurets, Vsevolod Klyusov