CHEMIX CASEGUARD: A New, Field-Proven Solution for Sustained Casing Pressure (SCP)

Sustained Casing Pressure (SCP) is a global problem with significant safety and environmental risks to Well Integrity. In a cemented annulus, CHEMIX CASEGUARDTM is the solution.

Introduction:

In this article we introduce CASEGUARD™ as THE rig-less solution to SCP. We describe a case history and explore the unique properties of the fluid. We discuss the importance of proper diagnostics and managed injection.

CASEGUARD™ is applied whist allowing production to continue and the treatment represents a step change in SCP mitigation.

Sustained Casing Pressure – CHEMIX CASEGUARDTM is THE rig-less solution

The oil and gas industry is in yet another downturn with oil prices at their lowest, major cutbacks in staffing levels, projects getting cancelled, and drilling at an all-time low.

Well Integrity and the safety of existing producing assets in an oil price slump becomes even more critical. Operators have been told to reduce costs now, but tough questions remain for wells exhibiting worryingly high levels of SCP which is compounded with the threat of lost production or worse.

SCP can be categorised in three different ways (API 90-2)

- Thermally induced casing pressure.

- Operator imposed pressure.

- “Real” intercasing casing pressure, or SCP.

In this context, we will address the third occurrence; this imposes the greatest risk to the Operator.

SCP is a global problem confirmed in countless industry papers, with a high proportion of all producing wells exhibiting this phenomenon during their lifetime. A study conducted by the US Minerals Management Service identified that SCP in the Gulf of Mexico is a significant issue, with 70% of the 11,498 casing strings exhibiting this problem. When not managed correctly, SCP has the potential to cause catastrophic problems as seen with the Aliso Canyon (California 2015) and Elgin (UKNS 2012) gas leaks.

Sustained casing pressure is evidence of failure in one of the well barrier elements. Once the sustained pressure is confirmed, the well does not comply with most companies’ barrier policies.

However, the goal of well integrity is to prevent well control situations (uncontrolled release of hydrocarbons to surface).

SCP wells clearly have the potential to develop further barrier failures that can lead to a well control situation.

Do your wells have SCP and are levels reaching the point where something needs to be done but funding is disappearing in this downturn?

Are any of your wells shut-in or pending shut-in because of SCP?

How will your P&A plans cope with SCP?

CHEMIX CASEGUARD™

Successful management of SCP in a cemented annulus is notoriously difficult to achieve. Proper diagnosis of the root cause routinely confirms how inaccessible the source is.

Simply bleeding off pressure provides temporary relief, but pressures rebuild, often quickly and sometimes to higher levels than before. Regular bleed-offs can make matters worse, routinely result in environmental releases and themselves can be costly. Well interventions through Workovers are a costly alternative with no guarantees of success.

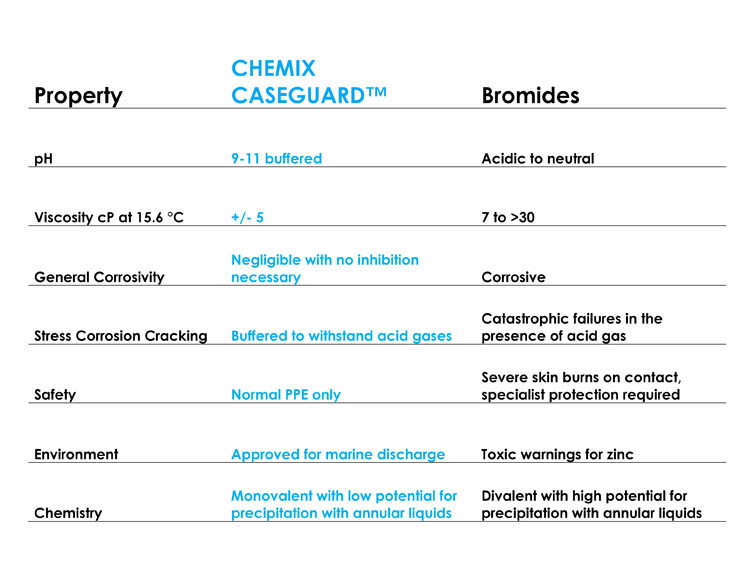

Rig-less Bleed and Lube using a heavy brine to overcome the annulus pressure is a more economical solution compared to a Workover, but success depends on correct diagnostics, management and brine choice. Bromide brines pose significant HSE risks and can cause catastrophic damage when used incorrectly, CASEGUARD™ is different.

The rig-less application of CASEGUARD™ allows production to continue, is safe to use, and has a high rate of success.

Case History and the unique properties of CHEMIX CASEGUARD™

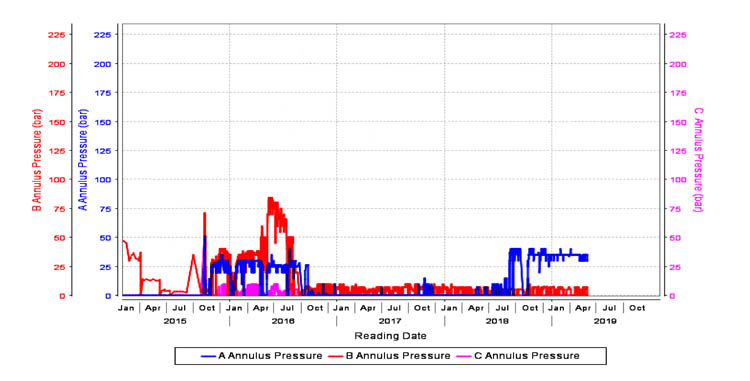

Example case history: B annulus pressure showing the elimination of SCP after CASEGUARD™ injection.

This gas condensate well was exhibiting concerning levels of SCP in the B annulus and previous attempts to mitigate it had failed. Injection of CASEGUARD™ penetrated the micro annuli in the cement column building sufficient hydrostatic head to balance the SCP source pressure. The A and B annulus conditions are monitored by a small positive back pressure to confirm continued SCP mitigation.

The Operator had tried other products (including other heavy brines such as bromides) without success and when comparing properties with the bromide brine products it is easy to see why.

CASEGUARD™ can be supplied from S.G. 1.60 to 2.20 depending on specific well requirements.

Not only does CASEGUARD™ possess the chemical and physical properties to best penetrate the annulus but it protects people, the environment, and the well itself.

Diagnostics and managed injection

When faced with problematic SCP the importance of rigorous diagnostics cannot be overstated. We see well data without current critical parameters, as well as missing information from historic reports, which complicates the understanding of the problem. Cement job reports from the drilling phase often tell more of a story than the results of a CBL interpretation. The drillers have left behind a lot of poor cement jobs as every Well Integrity Engineer knows all too well…

Chemix would encourage and assist the Well Integrity Engineer to investigate the well history from the drilling phase to the present day. A knowledge of fluid levels and the chemistry of the residual annular fluids are fundamental to designing the bleed and lube fluid composition and density. Casing strings without premium connections are capable of allowing gas transmission between annuli. End of well reports may uncover non-commercial hydrocarbon zones previously unrecognised as possible sources of SCP. Can the gas composition identify the source (or indeed eliminate other possible sources) and is H2S present?

When in doubt, Chemix strongly advise collaboration with industry recognised Well Integrity experts.

Wells with SCP in multiple annuli can be treated via just one annulus when the pressure source is a common factor and has been accurately diagnosed.

Once the Operator is satisfied that the SCP source and leak paths are properly identified, it is equally important to involve the service provider who will perform the injection. Once the job design has been agreed, the execution of the bleed and lube application requires a rigorous risk assessment and input from all the stakeholders concerned. Equipment specification is dependent on the fluids to be bled off, pressures involved, access to the wellhead and the anticipated treatment duration. This is normally performed in two different sequences while the well continues to produce:

Fill-up and Displace – When fluid in the annulus is low, a simple Fill-up and Displace is the initial treatment. Fill-up and displace will increase the effective hydrostatic pressure and this may be enough to reduce the SCP to an acceptable level.

Bleed and Lube – Injecting the fluid into the micro-annuli by Bleed and Lube is best performed with a high differential density between the injected and residual fluids and will take time.

Interpreting the response from the annulus as the application is initiated and progresses is critical. The experience of the service provider is vital at this stage.

In summary:

- The Bleed and Lube method requires the frequent extraction of small volumes of annular fluids and gases via the wellhead casing valves, and their replacement by an equivalent volume of CASEGUARD™ injected through the same valve(s).

- During treatment, the gradually increasing hydrostatic pressure exerted by CASEGUARD™ will slow or stop the rate of ingress into the annulus through channels in failed cement.

- Multiple wells in the same field can be campaigned for maximum cost efficiency.

We have presented a safe, cost-effective and rig-less method for managing SCP using the unique chemistry of CASEGUARD™.

We would like to thank all readers and always welcome input so we can expand the discussion further.

I would like to extend special thanks and acknowledgement to Simon Sparke, Morten Iversen and Steven Key for their input.

Please visit www.chemixsolutions.com to learn more about CASEGUARD™. If your wells exhibit SCP, please contact us directly.