Copper Catalysts Will Facilitate In-Situ Combustion

The technology of Kazan scientists can be used to develop difficult oil.

Kazan Federal University has developed a new catalyst for heavy oil production based on organic copper salts. Specialists from the world-class Scientific Center (NCMU KFU) have proven that this substance increases oil recovery and stabilizes the combustion front of hydrocarbons in a porous medium.

The development can be applied to many heavy oil fields, including in Tatarstan. The Devon News Agency learned about this from a message from the press service of the NCMU.

Many of the existing catalysts for the oxidation of heavy oils are synthesized based on transition metals. Most often, these are oxides of vanadium, iron, cobalt, and nickel. But almost all of them do not dissolve in oil, which means they are poorly distributed in it. This reduces the catalytic effect.

A promising compound was found by specialists from the NCMU Laboratory of Enhanced Oil Recovery Methods. It has a high degree of solubility in petroleum media and is the main effective oxidation catalyst.

“An effective catalytic composition based on a copper compound using an organic compound as a ligand has been obtained,” said Mehrabi Kalajjahi Seyedside, a junior researcher in Mehrabi’s laboratory. These types of catalysts accelerate the oxidation of heavy oil in porous media. This makes it possible to reduce the viscosity of oil and the content of heavy compounds in it.

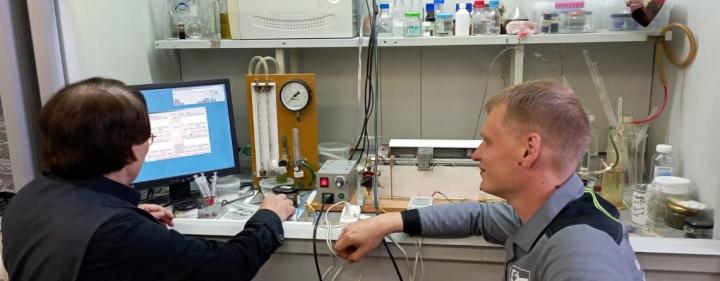

The effectiveness of the new catalyst was studied using a porous media thermal effect control (PMTEC) device and a quartz combustion tube (VCT) invented by Kazan scientists.

“The new approach is based on measuring and recording a thermogram in front of and behind the combustion source with a differential thermocouple when combustion of the core material is initiated by external heating,” explained Kamil Sadikov, senior researcher at KFU. “This allows us to study the dynamics in the initial stage of in-situ combustion.”

A patent was received in China for the PMTEC installation in 2018. The second VCT installation makes it possible to visualize the movement of the combustion front and analyze its stability. Analysis of oil and flue gas samples obtained during combustion and interpretation of temperature profiles of combustion fronts make it possible to study reaction mechanisms during in-situ combustion.

“The development is already ready for use in the oil industry,” noted Mikhail Varfolomeev, head of the laboratory of methods for increasing oil recovery at the NCMU, head of the department of REMTU. “The reagent allows you to initiate ignition at lower temperatures.”