Digital Supervision Transformation Strategy for Drilling and Well Service Operations

Digital transformation of oil and gas services at drilling and field facilities improves the economics of hydrocarbon field development.

Technological progress is accelerating so much now that it will soon be difficult to track the diversity between different technologies and even more difficult to choose the most effective technology. In digital oil and gas services, there are trends of transferring services from the online service sector: on-demand service, mobile service, sharing service, collaboration, wikinservice, hi-tech gift service, and others. For example, on-demand service means that a customer requests a specific service from a provider if there is the need for such service. On-demand economy is a business model that provides not only the sale of goods and services, but also access at the right time. Tasks are assigned online and completed offline: the Supervisor application will provide advice in case of an accident or wellbore complication, and the Engineer application will provide specialists to handle well complications or accidents. The grant service for high-tech drilling and downhole operations is an online service for high-tech services and opportunities to the customer free of charge.

In the digital economy of online services (online shops, pharmacy chains, etc.) trends of digitalization leaders are rapidly changing (Apple, Google, Microsoft, Amazon, Facebook, Yandex Taxi, Ozone…). The oil and gas industry has yet to experience a digital transformation boom, which is due to the multi-disciplinary and capital-intensive nature of oil and gas equipment, machinery, and technology. Digitalization should cover all the links of the oil/gas product chain: research and educational institutions, design institutes, design departments and engineering plants, oil and gas companies and production subsidiaries, providers of equipment and services for the development of fields that are remote from companies head office’s and staff working on a rotating basis in difficult climatic conditions of the Far North and the Arctic shelf.

The emergence of new competitive drivers depends primarily on unique assets and resources. However, innovative digital service technologies form new consumer experiences. In 1980-1990’s, corporate culture covered the entire civilized world, but was missed by Russia. In the 21st century, digital business models and the interrelation of business models and strategies became the driver of competitiveness [1].

Digital ecosystems, platforms and communities of developers, producers, potential and current consumers are becoming particularly important for the oil and gas industry. The digital ecosystem is an environment that provides the conditions for the innovative development and distribution of digital services, products, applications, and devices. The goal of the ecosystem is to provide a digital service that is «on demand», in real time, in compliance with rules and regulations and with the utmost trust.

The growth rate of digital transformation of the oil and gas industry is significantly lower than in the service and consumption sector, from 2017 the driver of business competitiveness was the relationship «business model – digital transformation strategy – key performance indicators (KPI) – corporate strategy». The digital transformation of the oil and gas business radically changes the management of oil companies and service contractors. The turbulence of the digital environment reduces the time for management decisions and requires system thinking in developing a digital transformation strategy and organizational and economic conditions for its successful implementation. Strategic formation, in turbulent environments, cannot be based on the comparative analysis of different business processes of service companies and competitors, benchmarking becomes less useful than during the transformation of the socio-economic system of our country in the 1990’s.

The digital economy and the transition to the fourth industrial revolution bring serious changes in the oil and gas industry (mass application of automated drilling rigs, intelligent wellbore systems and smart wells, robots and robotic technologies), and innovative drivers in the context of new management solutions determine the directions of digital transformation [2-5].

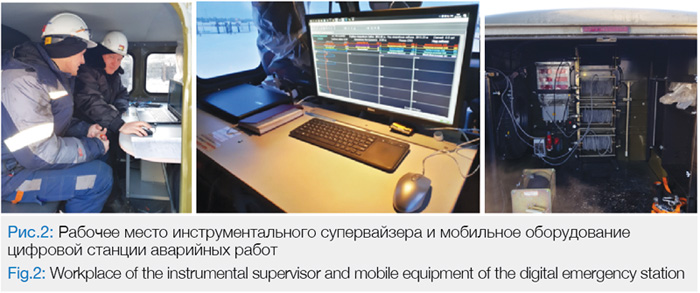

In the turbulence conditions service companies, drilling and workover crews develop the adaptive abilities, aimed at reducing the risks of accidents and complications, when the process of obtaining information about the state of the well, the tool becomes continuous. JSC «Scientific Research And Design Center Of Oil And Gas Technologies» (JSC SRDC GOT) forms digital oil and gas services related with each over: digital well drilling geosupervising and instrumental supervising of well interventions (workover operations) with the intention to dominate (Figures 1 and 2). It becomes evident that there is a close interconnection between integrated information-intensive services in drilling and downhole operations (DDO), digital stations for the control of parameters during drilling and well services, software and mobile applications. The integrated information-intensive geosupervising services of downhole operations will replace the geological and technological research. The number of examples is growing. The systematization of knowledge about the digital environment and the evolution of digital technologies predict the transformation of businesses and make it easier to find solutions and new key performance indicators.

The strategy of geosupervising has most clearly demonstrated effectiveness in managing well drilling, integration of service contractors into the team – drilling crew in a single workspace of the wagon (Fig. 1) [5, 7].

The digital supervising of workover operations, especially emergency operations, provides the drilling crew with a specialist with knowledge in the information-measuring systems (fig. 2). Transition to digitalization of supervising services in 2015 – 2016 was caused by crossing the boundaries of online and offline, due to both the fact that offline lost to online technologies, and backward methodological support of stations for geological and technological studies of drilling processes [6]. The leadership of online enterprises was predetermined for the nearest years due to the accumulated experience of personnel and production process management via the Internet. This situation allows upscaling of artificial intelligence solutions, which stimulates the demand of oil and gas companies.

Research into drilling and downhole operations have shown the correlation of the decisions from JSC «SRDC GOT» with the trends of development in digital technologies. Also, this research has allowed the company to further plan actions, to influence the services market. This is confirmed by results of tenders conducted by the oil and gas companies: many participants lost to more innovative participants because of digital backwardness or a lack of awareness.

Customers of services – oil companies are burdened by the inconvenient system of contracting and maintaining (control, supervision, and management) tens of hundreds of contracts with contractors for oilfield services. In the short term, customers are likely to prefer an integrated service, and in the near future a management service that is responsible for the entire cycle of product creation, such as turnkey wells. The main determinant of the quality and efficiency of new services is the creation of software products that primarily forecast and localize complications and emergencies, which requires new engineering solutions and logistics products.

The digital economy is generating new monopolies very quickly. Field control, integrated operations, intelligent production – many terms describe the same approaches used and actively developed by oil companies. Approaches are more comprehensive than just introducing technologies that make oil production easier and more efficient. These approaches also involve significant organizational changes and cover all aspects from drilling and workover to working with personnel. In the oil and gas industry, PJSC «Gazprom Neft» has the highest potential for digital leadership, and in other sectors of the country – Sberbank, Aeroflot, Telecom, and Russian Railways.

JSC «SRDC GOT» is the leader in the market of geospervising on management of drilling and workover that presents its digital solutions, technologies and software products of DDO on the basis of artificial intelligence, digital twins (drilling tools, digital setback), Internet of things (Master of acts for workover and drilling) and BIM-technologies (digital modeling of drilling tools and equipment) as a new direction of strategic development of the company.

Labour market structural changes are an important challenge to the digital oil and gas economy. While digital engineers researched and designed field developments, and geonavigators optimized horizontal wellbore trajectories remotely, engineers of the digital professions of geosupervision and instrumental supervisors manage hazardous production facilities (HPF) directly at the drill site and fields. They are personally responsible for the results of the decisions [7, 8].

Building business models based on new opportunities for the digital age is complicated by insufficient level of perfection of traditional techniques and technologies, automation and digitalization. The benefits of digital technologies is not evident. Thus, there can be doubts on investments in developments of such technologies. The lack of competition in the digital market slows down cooperation, and a mature market for oil and gas services, without clear boundaries, does not facilitate preventive regulation. The high costs of software development and acquisition of digital equipment hinder the development of small/medium-sized businesses in downhole operations and do not allow competition with oil companies in this area.

In order to respond quickly and adequately to all the new challenges of digital transformation within the framework of corporate strategies of oil and gas companies well intervention contractors need to build the necessary competencies, accumulate experience in managing customer needs and build user-friendly interfaces, and eventually create ecosystems for the development of competencies in digital technologies by combining research, design, testing, implementation and educational centers [8].

Meanwhile, in companies one can meet managers who are wary of the rapid digitalization of the oil industry and the need for digital transformation, due to high depreciation charges for more expensive digital equipment, which complicates the launch of innovative processes. If there is a negative or passive attitude to the digital transformation process of DDO, at the most difficult initial stages, there will be a slow down in its implementation which will cause significant damage to oil and gas companies for years and years. Digitalization forces the company to reconsider decades of entrenched principles in well construction and oil production management. Besides the digitalization of DDO technological processes, it is also vital to carry out digital education and training of young specialists – junior supervisors of drilling and workover, additional professional training and re-training of engineers and personnel [9]. It is necessary to organize mentoring institutions, schools of excellence, and digital training sites that are united into a system of continuous online education.

Digital leadership is more dependent on new business models defined by the nature of digital technologies and built on capabilities of these models. When defining a digital transformation strategy, it is necessary to clearly correlate all the processes of a digital enterprise with the quantitative indicators of digitalization: how these processes will affect the cost of the digital life cycle, how much less will the cost of maintaining digital equipment be, how these processes will affect the reduction of occupational accidents and improve the health of employees working at hazardous production facilities.

Digital services based on geosupervising, equipped with intelligent software, will improve and have greater demand. These services will convince the customer to reconsider the priorities among the services of directional drilling, drilling fluids, geological and technological research, etc. in exchange for a significant reduction in the well construction cost per meter and the production of tons of oil. This is facilitated by the trend of unmanned technologies, especially at hazardous drilling and workover facilities, when monitoring of the parameters is carried out by a remotely autonomous digital geosupervising station, which includes a software and hardware complex for identifying the risks of complications and emergencies.

Service customers – oil companies determine the ecosystem of small/medium enterprises, up to stagnation and disappearance. Rosneft’s strategy,

as an example, is to develop its own drilling supervision, drilling companies and oil service teams. However, the digital economy allows small oil service businesses not only to survive, but also to accelerate their growth. Oil companies are also starting a systematic digital transformation: creating centers for the development of digital competencies and new technologies, in the future – powerful digital ecosystems will have better starting conditions (finance, resources, economic and political preferences). In the coming years, the leadership future will be won by small/medium businesses entering the market only with a unique digital product. Justified digital transformation leads to the attraction of startups to oil companies. Digital oil service enterprises, serving the main business processes of oil companies, cooperating to solve individual problems, especially at peak loads, must respond quickly to changing business conditions, accumulate competencies for the development and implementation of digital technologies, create multilateral platforms, go beyond the «title» business to strengthen the stability of the enterprise in the digital turbulent environment, contributing to the achievement of positive synergies for the customer.

In the digital economy, the main driver is the digital technology, artificial intelligence technology, «digital twins», achieving network effects through the Internet and unmanned technology. Digitalization leads to the reduction of horizontal product chains, reduces the number of engineering staff, which is proved by pilot tests of geo-supervising, which integrates the drilling crews with multidisciplinary and cross-functional interaction in a single workspace in the wagon and reduces non-productive time, i.e. the well construction cost per metre [5].

Digital technologies are altering the opportunities with oil and gas industry, which provides new opportunities for fast reacting small enterprises. Oil companies understand that with the help of digital technologies it is possible to abandon intermediaries and directly interact with service and equipment providers, benefiting from the accumulation of history activities, opportunities and development.

Building a business model with a new communication channel for digital stations and online diagnostics software for predicting complications and accidents in wells, the reliability of drilling tools and equipment will convince the customer to accelerate the introduction and investment of digital technologies. The strategy of further digitalization requires reaching higher levels of artificial intelligence, robotic systems, virtual and augmented reality technologies, distributed registers, etc.

For the system digital transformation of the engineering enterprise JSC «SRDC GOT» created a center of innovative competencies – Academy of drilling and oil and gas production supervision, developed a substation «ARM Supervisor» to optimize internal business processes (accounting, management of thousands of employees of 12 separate subdivisions, containment of the volume of management staff, etc.) This academy forms the scientific basis for the digitalization of downhole operations, which ensures the integration of supervising and the transition to a higher level – management supervising with elements of unmanned technology, conducts pilot testing and introduction of new digital technologies and software.

As a result, the development of one thousand employees has increased by 25%, which is the key to digital leadership.

In conditions of limited resources (profitability less than 10%) of the company with a sound tax policy it is necessary to allocate priority and perspective digital technologies with the lowest costs and the greatest effect, taking into account the demand by oil and gas companies. The leading positions in high-tech markets will be achieved by enterprises that create competence centers faster than other centers, whose managers will be able to see promising transformations long before its mass implementation. Oilfield services will have to conduct business activities on the principle of «Transform or give way to fast-growing competitors and innovative enterprises». At the same time, the turbulent digital environment helps accelerate the emergence of innovations that will provide a competitive advantage for oilfield service enterprises. The main task will be to find ways to replicate digital solutions in order to reduce costs and minimize risks.

As part of the implementation of the national program «Digital Economy of the Russian Federation», approved by the Presidium of the Presidential Council for Strategic Development and National Projects (Protocol of 24.12.2018 № 16), the Interregional Public Organization «Scientific and Technical Society of Oil and Gas Workers named after academician I.M. Gubkin» has established the Committee for digitalization of the oil and gas industry. The objectives of the Committee are:

• uniting scientists, engineering and technical workers working in the oil and gas industry, as well as teachers, students of higher education institutions, preparing specialists of digital professions to enhance intellectual potential in the field of scientific and engineering activities;

• implementation of scientific and technical progress in digitalization of oil and gas industry;

• full assistance in development and improvement of scientific and engineering activities aimed at increasing the role of digitalization in scientific research and production activities;

• assistance to international cooperation in oil and gas digitalization, development of relations with scientific and engineering community of foreign countries, integration of Russian specialists in the world scientific community.

Growth of capital investments per ton of produced oil requires radical improvement of field development techniques and technology on a digital basis, which will allow Russia to maintain its global oil leadership.

Literature

1. Hamel G., Prahalad K., Thomas G., O’Neill D. Strategic flexibility. Publishing: St. Petersburg. St. Petersburg. Peter. 2005. 384 с.

2. Kulchitsky V.V. Well as an element of the intellectual control system for hydrocarbon fields development. Oil economy. №2-2002. С.95-97.

3. Kulchitsky V.V. Geonavigation of a cyber-well. Oil&Gas Journal. Russia. No. 1-2 (46), January-February 2011. С. 64-67.

4. Kulchitsky V.V. Cybernetization of Underground Space. To 10th Anniversary of the First Russian Laboratory of Geonavigation and Intelligent Well Systems. Drilling & Oil. №10-2011. С.74-76.

5. I.F. Rustamov, K.V. Kulakov, S.A. Ilyichev, V.V. Kulchitsky. Digitalization of Well Drilling. ROGTEC. Issue 54, 2020. С.24-33.

6. Lukyanov E.E., K.N. Kayurov, A.A. Shibaev, I.L. Shrago 50 years of geological and technological research. History. New View on Development of EOR operations in Russia. Drilling and Oil. №№7-8. 2018. С. 2-9.

7. Kulchitsky V.V. Supervising of Oil and Gas Wells Construction. Industrial-Practical Edition. Moscow: Veche. 2019. 367 с.

8. Kulchitsky V.V. Drilling supervision. Moscow: I.M. Gubkin Russian State University (NIU). 2018. 307 с.

9. Kulchitsky, V.V.; Martynov, V.G.; Oganov, A.S.; Ilyichev, S.A.; Shchebetov, A.V. Cluster initiative for creation of a digital platform for distance interactive industrial training in oil and gas business. Science and Technology in Industry. 2019, №3-4. С. 87-96.

V.V. Kulchitsky,

Chairman of the Interregional Scientific and Technical Society of Oil and Gas Workers named after Acad. I.M. Gubkin, President of JSC «Scientific Research And Design Center Of Gas and Oil Technologies», Director of Scientific Research Institute Of Drilling Technologies at the Gubkin University of Oil and Gas, Doctor of Science, Professor.