Technology Roundtable: Drill Bits

1. The crash in the oil price has had a major impact on global oil and gas projects. Russia has also had to deal with sanctions and the exchange rate drop. What impact has this had on Russian demand for drill bits? How are you dealing with the situation?

Halliburton: Together with the whole industry, we are focused on the optimization and maximum localization of our market segment under the conditions of prices drop and customers striving to minimize their costs during well construction. When oil prices drop the first thing oil and gas producers tend to save on are drilling costs. We are an oilfield services company and a manufacturer of drill bits and coring tools. Our business is directly related to the demand for drilling equipment ordered by our customers.

NOV Wellbore Technologies: In spite of the oil crisis, the drilling scopes planned for 2015 have not been changed considerably. Indeed, some of our customers are increasing their drilling programs. So even with the current political and market conditions, the demand for our drill bits and technologies remains high. We are fully compliant with all sanctions and while there have been some delays and an added administrative burden, our business has not been materially affected. The ruble exchange rate fall, on the other hand, can be considered a majorly significant negative factor. The Russian bit market has always been sensitive to prices however, and long before the current crisis our strategy was to reduce the dollar content in the final bit cost and decrease the total price of our bits by optimizing processes and improving the materials that we use. This allows us to feel quite confident in the current market condition.

Schlumberger: Last year was a record year for the oilfield services industry in general and for Schlumberger. It was a year in which the price for Brent averaged $99 per barrel. In 2015, the EIA forecasts a lower $58 for the same barrel, and it’s clear that the coming year or so will be very different. Indeed, views on the supply-demand balance and competition between various marketed sources of supply are likely to lead to a significantly different environment for the industry once the market recovers. Russia is not an exception. We are therefore forecast on what we can control to manage our business and deliver better decrementals than in previous downturns.

We are actively engaged with customers to tailor resources to activity, and to manage pricing through the most cost-effective solutions. But we also see this year as one offering multiple opportunities that we intend to leverage as we strengthen our technologies and service offering. With our geographical footprint in Russia and Central Asia, unique technologies and extensive business portfolio, we remain confident in our ability to outperform.

NewTech Services: So far we have seen no reduction in demand, in fact demand has increased. This is probably because we manufacture drill bits using western technology in Russia.

However we have noticed that some major customers are in a very strong cost cutting mode and under instruction from purchasing departments, our drilling department customers are being forced to take lower quality products because of their lower price.

2. Has there been a compromise on bit quality recently, during the down turn? How can you ensure maximum bit quality at the best price for your customer?

Halliburton: We absolutely cannot compromise on the quality of our bits. The entire range of drill bits manufactured at our facilities (mostly in the USA and partly in Belgium) and supplied to Russia are subject to continuous quality control, from materials and components to the end products. The quality of the equipment supplied to the Russian market meets our worldwide Company standards. As to the quality of type selection or recommendations for the best bit runs, it depends on the competence of our experts who are in charge of the drilling programs. The customer’s decision on bit selection should not be based on bit price but on a confidence to complete the target section with the highest efficiency i.e. with the lowest costs using this particular bit. The maximum rate of penetration, the minimum number of trips, and top borehole quality for smooth casing running are the main criteria for bit selection. Selecting the right drill bit by our customers translates into savings on more expensive drilling services such as drilling fluids, directional drilling, etc.

NOV Wellbore Technologies: Our company has over 100 years of drill bit manufacturing experience, and our main priority has always been to improve our quality. During this time, the oil and gas market has faced a number of ups and downs, including specific problems in the Russian economy. Throughout all of this, our company has never compromised our principles of maintaining and improving quality. Looking at this from a pragmatic viewpoint, client confidence is earnt over many years but can be lost very quickly if quality is compromised. With the current market conditions, it is true that savings can be made by using other, cheaper bits. These will of course not perform as efficiently due to their cheap component materials. Nevertheless, we can guarantee absolutely the same level of product quality as has always been the case, because the quality control standards of our company do not depend on the final bit cost. We are also actively moving drill bit production to Russia, which has has several cost advantages. We can however continue to guarantee our world-class product quality.

Schlumberger: The market conditions change has not affected the quality of our services that can be proved by the constantly improving drilling results at our projects. Despite all the challenges, we keep looking for cost-effective solutions without compromising the drilling construction schedules, borehole quality, and work safety.

At the same time, we prefer performance based model the business model that provides a system of bonuses for overachievement of the key performance indicators. This allows the client, significantly reduce the drilling time and overall costs despite of some increase in spend for drill bits. Such a system better incentivizes the bit manufacturers and allows them toincrease investments in development and introduction of new technologies. From the other side if the only considered factor is the cost of one particular service and performance results are not taking into account, it’s difficult to achieve progress. Unfortunately, that’s the situation we often see today.

NewTech Services: NewTech Services is not prepared to reduce quality in the hope of a short term completive advantage. In the end we know what our customer’s requirements are and we strive to deliver them. Of course we have had to reduce prices, but not at the expense of product quality.

3. What level of regional customization do your bit solutions offer? And what design process do you use to ensure maximum bit performance?

Halliburton: Different drilling environments across the Russian regions do not allow our customers to use the same drilling solutions: e.g. drill bits which are effective in West Siberia for drilling soft rocks most likely cannot be used as effectively for drilling hard igneous rocks, in Yakutia. That is why the range of selected bit types varies considerably from region to region, be it Volga-Urals, Timan-Pechora or East Siberia. In addition, there are also regional preferences in Russia as to the specific bit sizes. For example, the most common size for production casing drilling in the Volga-Urals region is 215.9 mm; in Timan-Pechora (since recently), 219.1 mm; in West Siberia, 220.7 mm is now used almost everywhere. A 2 mm difference per wall may seem of no importance for the well, but it is important for the customer to gain additional benefits for casing running and cementing. We take into account all these regional aspects when designing and optimizing bit solutions. Through our unique Design at the Customer Interface (DatCI™) process, our highly trained Application Design Evaluation (ADE™) service specialists provide new, application-specific drill bit designs within the shortest time possible and in line with the customer’s conditions and requirements. This is a continuous improvement loop employed by our on-location ADE™ specialists using the industry’s most powerful proprietary software tools, including SPARTA™ for geological modeling and reservoir analysis, Direction by Design® for drill bit optimization and improved directional performance, CFD for computer-aided modeling and hydrodynamics analysis, and iBitS™, the software employed by ADE™ specialists to design a new bit for specific applications and optimize bit selection. It enables Halliburton engineers to design the highest performing bits by simulating the forces that the bit will be exposed to under specific drilling parameters. IBitS™ software calculates the torsional, axial, and lateral forces of each cutting element depending on the geometry and space position on the bit face. The sum of these forces (total bit force balance) is displayed as an output to indicate how the bit will perform in the application. IBitS™ software can be used to rapidly design a drill bit in 3D. The ADE™ service specialists can collaborate in a customer’s office or at the rig site. This process enables Halliburton DBS to achieve industry-best cycle times and manufacturing precision, which leads to best-in-class performance.

NOV Wellbore Technologies: Drill bit customization and optimization is a continuous process. Similar to other hi-tech industries, breakthrough designs have a short life until the next improvement comes along. We design unique drill bits for every application and every major market in Russia. Drill bit design and optimization is often an iterative process, involving state of the art modeling tools and plenty of trial and error in the field. Drill bit selection is influenced by geology, equipment, rig cost, trajectory, drilling objectives and many other factors. That is why regional adaptation has been a normal component of the optimization process for a long time. Russia is no exception. Our company’s design centers around the world have engineers focused exclusively on Russia. These designers work very closely with our local technical experts and our customers to ensure each drill bit is designed for its intended application. In addition, by the end of 2015, each of the three Russian regional subdivisions will have local design engineers who will be in direct contact with the customers’ representatives. We will also have another three design engineers who will work at a new, state of the art factory to be opened in the Kostroma area of Russia. This will allow us to not only have closer contact with our clients but it will considerably increase the speed of new drill bit designs being delivered to the field.

Schlumberger: In Smith Bits, A Schlumberger Company, every bit is 100% customized for specific application to address unique challenges. We consider formation type, strength and abrasion using our proprietary software DBOS (Drill Bit Optimization System), local offset data not only for our runs but also results from competitors utilizing our Drilling Record System (DRS) and our Integrated System IDEAS (Integrated Dynamic Engineering Analysis System), unique platform allowing us to model entire BHA from drill bit to the surface providing best in class modeling and prediction to insure that our bit has the most stable cutting structure for specific application. But, of course, our key strength and differentiation is our local Engineering teams. Product Engineers are located in every key location of our activity. Local team always in a contact with Research & Development (R&D) and Design Centers making sure we implement our latest technologies and standards and, on the other hand, providing local expertise and knowledge ensuring that we set right objectives for design as well as proper preparation and evaluation of new products’ tests.

NewTech Services: For bit selection we use the below process.

Step 1. Analysis of input data in GeoScience.

Step 2. Modelling of a Cutter using SPOT Software.

Step 2а. Suggested existing design.

Step 3. Selection and development of required drill bit design using Pro-Engineer CAD.

Step 4. Hydrodynamic modelling (CFD – Computational Fluid Dynamics).

Step 5. Producing design and CNC documentation using Pro-Engineer CAM. Manufacturing the drill bit at the plant.

Step 6. Drilling bit run and subsequent analysis in GeoScience.

In this process, our starting point for new business is a fundamental geological analysis and analysis of offset drilling records using Varel software (Geoscience).

Our CAD design tool allows us to model the potential forces acting on the bit and optimize the cutting structure and type of cutter to use.

We also evaluate the hydraulic efficiency of the bit geometry using a CFD analysis.

4. What level of integration do your bits experts have with your customers drilling teams to ensure the maximum possible bit performance and drilling optimization for each job?

Halliburton: Over the last few years, Russia has seen an increase in the demand for bit services. In addition to the supply of the required amount and range of bits and auxiliary tools to the drill site, this service also includes the presence of our field engineer on site. The field engineer is in charge of continuous bit running control during drilling parameters, performs calculates hydraulic parameters to ensure the best circulation, monitors drilling parameters, performs dull grading and investigates the possible reasons for bit wear immediately after pulling out, and offers quick recommendations to achieve maximum bit performance. This service facilitates decision-making by the customer and eventually minimizes drilling costs.

NOV Wellbore Technologies: It certainly largely depends on a specific Customer and their desire to participate in the process. Our sales engineers and technical support engineers always show maximum interest in customer representatives participation, as they are often most familiar with the challenges of their projects and this is the main starting point for any optimization. Besides, client representatives often know and can offer solutions to these problems which we, in our turn, can implement.

Schlumberger: As the drilling conditions, section lengths, lithology become more challenging, and the cost of the rig and the associated service rise, the demand for closer integration with the client’s drilling department increases.

In general, while the drilling program is at the stage of developing, the engineers of Schlumberger’s bit department draw up the programs based on the already gained local experience either in the target field or in the nearby fields similar to the target one in terms of geology and lithology. They elaborate the required drilling parameters for each trip, approve key performance indicators with the client and start the drilling operations, during which the field bit engineer of Schlumberger makes sure that the parameters and recommendations provided in the program are strictly followed by and modifies them in time if required. Once the work is completed, they submit a drilling report to the client’s drilling team that contains conclusions and recommendations.

However, there are projects where the price of an error is very high – a day rate of an offshore drilling rig may be as high as the drilling cost of an onshore well. At projects like these, the level of integration of our engineering team with the client is even higher, and it requires preliminary modeling of all the BHA’s and drilling parameters using our IDEAS system

NewTech Services: The success of our business depends on our pro-active support of our customers in their drilling offices around Russia. We have our representatives on 24 hrs call in all our operational areas. We strive to be the “drillbit solution guys” for our customer drilling departments.

5. How can you ensure your bit experts are up to date with the latest technology and market knowledge?

Halliburton: Halliburton provides training for our specialists on a regular basis. Every time a new series of bits is created using the state-of-the-art technology in metallurgy, hard alloys, PDC cutters or materials, we hold workshops and give presentations to ensure our experts stay up to date with the latest knowledge in rock cutting tools. Moreover, we analyze and keep track of region-specific bit applications. The lessons learned from bit runs are used for further planning and continuous improvement.

As an example of our successful knowledge sharing initiatives we recently utilized the TurboForceTM drill bit. Whilst drilling intervals of hard and highly abrasive formations in the Timano-Pechora region, you would expect to used 5 to 7 expensive PDC bits. We recommended to the customer that they should use our latest TurboForceTM diamond impregnated line of drill bits with high speed turbines. This solution has resulted not only in higher ROP but also considerable run savings. This solution saved more than 5M Rub per well for the client.

NOV Wellbore Technologies: We continuously work internally as well as with external experts to ensure we are constantly improving and innovating in this critically important part of our industry. Our company has always paid great attention to the development of the technical knowledge of our employees. And I mean both fundamental knowledge and familiarization of our employees with the latest technologies applied in the industry as a whole, and within our company in particular. While 8-10 years ago it was limited to 3-4 conferences per year which could not be attended by all the employees, today, thanks to the common availability of high-speed Internet, in addition to these conferences we hold online conferences practically every week, and now every company employee can participate. In addition to training, our R&D teams are constantly working on improving all aspects of our drill bits. From cutter design, to material selection and the layout of the PDC cutter in respect to the way they cut rock, every aspect of drill bit design is being continually improved upon by our many product experts. Designing the components that go into making a drill bit that can efficiently cut long intervals of formation, and that are easy to steer while generating low vibrations (at the lowest cost possible) takes a tremendous amount of resources.

Schlumberger: Our Product Engineers are always in contact with R&D and Design Centers. Engineering meetings hold locally every year, providing platform for face to face interaction between R&D experts, designers and product champions. Multiple product launches internationally and locally are introduced every year. Intensive training programs are developed to make sure our engineers have latest technology updates as well as fundamental knowledge about drill bits and drilling in general.

NewTech Services: Our partner in Russia, Varel is an international organization who has considerable resources dedicated to oilfield technology, and we have 70 drill bit crews working in different regions of Russia, which allow us to know the customer needs and provide best quality services.

6. What are your latest product launches? What advantages do these feature bring?

Halliburton: One of our latest and far going innovations is a new series of PDC drill bits – MegaForce™ — a new series of the industry’s most robust matrix body PDC drill bits, as well as SteelForce™ — the most advanced steel body PDC drill bits, and TurboForce™ — high-performance scraping drill bits used with downhole mud motors. The new Geotech™ PDC drill bit product line is expected to be launched shortly. It will incorporate the state-of-the-art technology in drill bit design. Geotech™ drill bits will be aimed to achieve the complex goals and solve the most complicated drilling problems of our Customers.

NOV Wellbore Technologies: Fusetek™ bits are a unique hybrid technology applied in PDC bits designed to drill abrasive and hard rocks. This technology involves coating of the bit blades with a special impregnated layer. The main row of cutters uses our Helios® line premium cutters, and the secondary cutting structure consists of an impregnated layer made in the form of cutters. The bits demonstrate unrivaled durability and increased stability, and may be applied with regular mud motors. We started using them in Russia last year. The results are excellent. At present, on some projects in Eastern Siberia, such bits are used on a permanent basis. Helios Inferno® is the latest line of premium cutters. This is a completely new approach not only to manufacturing but also to understanding the root causes of cutter wear. Properties of each cutter type in this product line are evaluated by 3 parameters (abrasive wear resistance, thermal stability, shock resistance) and are assigned an individual index of 0 to 10. Depending on drilling conditions, the cutter with optimum properties for maximum performance is selected. This is achieved by means of pressing technology and various depth of PDC layer leaching. Laboratory tests as well as field tests have proved the efficiency of this technology — the results considerably exceed the parameters of our Helios® top of the line cutters.

This year we are going to present other new bits developed for specific applications, but all in good time.

Schlumberger: Over the last few years, Schlumberger has introduced a number of revolutionary technologies to the global market. Specially we would like to highlight the launch of StingBlade technology in Russia.

The StingBlade Bit technology is the one we are really proud of! StingBlade Bit technology – conical diamond elements bit. According to our data, StingBlade bits has set records in footage and rate of penetration in every second run while drilling through hard and extremely hard chert contaminated formations.

NewTech Services: Drillbit technology is continually improving, bit designs make incremental improvements with new cutters, improved CAD modelling and improved manufacturing processes.

7. Can you describe any recent success from the field, where your bits have clearly improved drilling rates/performance?

Halliburton: The high-speed downhole motor and the customized MegaForceTM 8-5/8” drill bit MMD65C enabled the client to drill a section for intermediate casing a nothern group of fields in Timan-Pechora and achieve double the ROP. It shortened the well construction period because there was no need to make a trip for bit changing. As a result the customer saved at least 7 mln RUB.

NOV Wellbore Technologies: NOV specialists are continuously researching and developing new technologies applied in bits, perfecting designs, hydraulics and, of course, cutting structure for drilling both soft and very hard formations. I would like to focus on PDC bits, which have become much more popular, compared to other bit types in the recent years.

I can name a lot of records which have been set recently thanks to using our company’s bits; take FusetekTM bits I mentioned earlier, for example. In Western Siberia, in the I.M. Baibakov field, a Paleozoic interval, which had been drilled in a minimum of three runs with different bit types before, was drilled with a FusetekTM hybrid bit in one run with a higher ROP. After the bit was pulled out of the hole it was still in a suitable condition for further use. In general, increased ROP and reduction in the number of trips in halving this interval’s drilling time – over 30 hours were saved.

But where we see the most success is when we combine our new drill bit designs with our leading edge drilling tools. This “total package” approach often provides a step-change in drilling efficiency. One particular tool is our Fluid Hammer. While this article is primarily about drill bits, it should be noted that improving drilling performance is often a combination of different aspects. Briefly, the Fluid Hammer, when combined with one of our custom designed drill bits can improve ROP in hard formations by a factor of 2-3 times when compared to just changing to a better drill bit. All of these parameters are part of our comprehensive approach to lowering the costs of well delivery for our customers.

Schlumberger: We want in particular highlight, a multiple records set by Stinger and StingBlade technologies in Russian and CIS countries. Volga-Ural, Timan-Pechora, Eastern Siberia, and Kazakhstan are the regions where we set records in meters drilled, fewer trips per well, and rate of penetration.

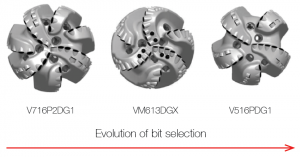

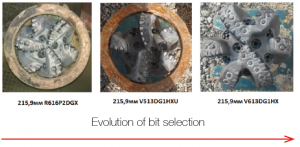

NewTech Services: Application evaluation, design, running the bit and re-evaluation are the key improving bit selection. Here are two cases to illustrate how we combine design evaluation with field experience to improve overall performance

Case History 1.

In Serbia, working together with our directional drilling services we optimized the ROP with a few iterations of bit selection.

Drilling the 8 ½” section with matrix PDC from competitors they were averaging 9 m/hr, with the current 6 bladed, 13mm design bit V613DG1HX the customer now averages around 40 m/hr.

Case history 2.

Drilling 8 ½” section in Orenburg area, in soft to medium hard limestones we have progressively improved or performance in terms of durability and ROP. At the start of the project we were running a heavy set 7 bladed 16mm cutter bit, averaging 10m/hr and making 880m with one bit.

We realised that bit cleaning in clastic formations was the slowing factor to this application. We are now running a five bladed double row, 16mm cutter bit and achieving 13 m/hr over 4900m.

8. What is your forecast for the regional drill bit sector for this year?

Halliburton: In 2014 Russia drilled over 20 mln meters for production wells. Many Russian companies are now rushing to re-evaluate the economics of their domestic hydrocarbon production projects due to the oil prices drop, currency devaluation and financing issues. The most challenging and expensive drilling projects are expected to be brought to a halt or delayed. This, in its turn, may slacken the demand for bit services. Some estimates suggest that the market for these services may shrink by 10–15 % in 2015. Despite all these obstacles we stick to Paul’s Getty formula for success: ‘rise early, work hard, strike oil.’

NOV Wellbore Technologies: Today, it is very difficult to make any forecasts taking into account the political and economic situation in the country and the trends of the global oil and gas market. There are certain problems; some companies are staying to work, trying to save resources. Other companies cannot withstand the pressure and retire. The market is adapting. In spite of the considerable drop in the oil price, the demand for oil will only grow, so its production will build up sooner or later. For this, more and more meters have to be drilled.

Most tenders for the bits supply or bit services have already been held. And we can see a high demand for drilling tools this year. We can also see high competition and decline of prices. Therefore, unless some force-majeure circumstances occur, nothing critical will happen. The key is to adapt to the current situation in time. And I think we are heading in the right direction.

Schlumberger: We look into the future optimistically: our unique technologies that have already proved their efficiency in most of the oil and gas regions of Russia and CIS allow us and our clients to achieve the record results. Our investments in R&D aimed to engineer new technologies are proving successful results every day, and this can be easily see it!

NewTech Services: We expect to have an increase in development drilling in West Siberia and reduction of more expensive exploration drilling in remote locations.

Dmitry Zulpikarov – Halliburton

Dmitry Zulpikarov is working as Halliburton Drill Bits and Services Country Manager, Russia. Dmitry finished technical school having diploma in Operation of oil and gas wells. His career started in engineering sphere of Oil and Gas industry in 2002, right after graduating from Tomsk state university of control systems and radioelectronics, where he obtained two diplomas both in engineering and economics specialties. Working in Halliburton since early 2005 Dmitry held various positions in technical and business advice. Deep technological knowledge and wide range of skills and expertise helped Dmitry to develop his career in Halliburton from Drilling Engineer to Country Manager.

Sergey Plyutta – NOV Wellbore Technologies

Sergey Plyutta is a graduate of the Drilling Department of Gubkin Russian State University of Oil and Gas. Since 2005 he has worked as a Technical Support Engineer for ReedHycalog (later NOV). Sergey is currently the Head of Technical Support and Quality Control Department for Russia and CIS, NOV Wellbore Technologies.

Maxim Petrenko – Schlumberger

Maxim Petrenko – Sales manager, Smith Bits & Advanced Technologies A Schlumberger Company.

Work experience: 10 years in Oil & Gas industry and 9 years in the Drill bit business.

Previous positions in Drill bit business: Field Engineer, Technical Support Engineer, Application Engineer, Business Development Manager.

Alexander Dunaev – NewTech Services

Date of birth 16 January 1970

Education:

Gubkin Russian Government Oil & Gaz University 1987 – 1992.

Specialty: Drilling

Experience:

1992-1999г «Far-East Marine Co.»

1999-2009 «Smith Siberian Services»

2009-now «NewTech Services»