Drill Pipe Hardbanding Technology in the Russian Drilling Industry

Introduction

Russian drilling practices are changing, with the percentage of directional and horizontal drilling increasing significantly during this decade. Between 2010 and 2017, the share of horizontal well profiles in explorational drilling grew from 11 percent to 41 percent. Russian companies are achieving better production performance by adopting advanced technologies. However, these modern drilling methods put more strain on the drill string, and so tool joint wear has become more of a problem for the end users.

As a result, the majority of Drilling Contractors are protecting the drill string with hardbanding; a tough, wear-resistant metallic alloy which is welded in bands around the outside diameter of tool joints. Hardbanding can be applied by the manufacturer as an option on new drill pipe, or it can be applied and reapplied to used drill pipe by licensed service companies. As the use of the technology increases, it’s important for end-users to understand how hardbanding works, the differences between various materials on the market, and how hardbanding should be managed to ensure the greatest cost savings are realised.

Hardbanding Basics

Hardbanding is applied using a welding process to Drill Pipe Tool Joints, HWDP Tool Joints and Centre Wear Pads, and to Drill Collars. On drill pipe, three 25mm wide bands are normally applied on the box tool joint, close to the 18-degree taper, leaving the tong space clear. (Pic 1) The result is a raised area 75mm wide, and between 2.4mm and 3.2mm in height, which takes the contact with the casing and open-hole during drilling operations, protecting the tool joint from wear. Hardbanding can also be applied to the pin connection, for added wear protection.

Modern hardbanding wires are formulated to have a low friction coefficient when rotated with a side-force against the casing, and so they are described as being ‘casing friendly’. In fact, laboratory testing by Mohr Engineering (USA) has proven that casing friendly hardbanding wires can reduce wear on the casing by around 50% compared to a tool joint without hardbanding. A 2017 study conducted in Moscow showed similar results.

Finally, the reduced friction in the well, between the drill sting and casing, and the reduced contact area between the drill string and the open hole deeper in the well, reduces drag and can lead to more efficient drilling and a higher ROP.

The cost of hardbanding, as an option on new drill pipes varies depending on the drill pipe manufacturer. If we take an average, it’s around 13,000 rubles per ton of drill pipe, or approximately between 4-9% of the order cost. The resultant savings emerge through a longer service life of the assets, and so less frequent capital spend on replacement. This saving can be extended and multiplied by having the hardbanding reapplied multiple times by a local licensed service company when it eventually becomes worn. Therefore, the potential medium to longer term savings on a drill string could be counted in the millions of rubles. The cost of the hardbanding material itself varies by product, however the overall difference to the end user upon purchase is minimal, as the amount allocated to hardbanding as described includes the service of application and its associated costs.

Reapplication of Hardbanding

Premium hardbanding materials are made from a combination of a tough steel matrix with added carbides, to give maximum abrasion resistance and casing protection. The material will eventually wear during drilling operations, with the rate of wear determined by the wells profile, formation characteristics, drilling methods and other factors. When inspections reveal the height of the hardband has fallen to 0.8mm or less, it should be sent for reapplication. Different Hardbanding materials will wear at different rates under the same conditions.

Depending on the worn hardbanding material previously applied, reapplication can be straight forward and simple, or it can be more complicated. During welding, the material being applied penetrates and mixes with the base material it is being applied to. On the first application to a new tool joint, the final hardbanding layer will have some dilution from the base tool joint material and contain a percentage of both the softer and harder chemistries. With reapplication, the weld material is being applied over the previous partially diluted hardband, and so the result is a higher percentage of hard material.

Dilution is an important consideration because the chemistry of different hardbanding products varies greatly. The base matrix and carbides used for wear resistance are unique to each product. Carbides used include Niobium, Titanium, Boron and Chromium and they are found in varying percentages in the overall chemical footprint of the product. Each product can be categorised depending on which carbide is present. Although some hardband materials are compatible, care should be taken when applying one product over another, as conflicting chemistries may cause the hardband to crack and fail. Similarly, some products have a chemistry which is stable after the first application but can fail after reapplication when the effects of dilution from the softer tool joint material are reduced. Laboratory testing has shown that some elements, for example boron, are unstable in higher percentages and result in cracking.

When the correct product is used, hardbanding can be reapplied an infinite number of times to the same tool joint without defects. With continued inspection and reapplication, tool joint wear will never be the reason for the drill pipe to be downgraded or scrapped. In a recent survey of Russian Drilling Contractors conducted by Hardbanding Solutions, it was found that wear on the unbanded and unprotected tool joint was responsible for drill pipe to be downgraded or taken out of service 67 percent of the time. The cost saving and convenience earned by reapplying drill pipe hardbanding before it wears off to keep it in premium class condition, as opposed to allowing tool joints to wear down, can be substantial.

Modern drilling methods mean the service life of the unprotected drill string has been greatly reduced. Approving capital spend on a new drill string so often is unnecessary and for most pipe owners no longer an option. Some pipe owners are beginning to see the benefit of inspecting and reapplying hardbanding as needed, so that their assets are not taken out of service prematurely. One West-Siberian service company reported that of all the used drill pipe they inspected with a premium hardband between 2011 and 2016, 96.7 percent of the tool joints remained in premium class.

Reapplication can be carried out at the workshop of a licensed service company who offer a hardbanding service, or it can be done at the rig site by companies who offer mobile hardbanding. (Pic 2).

The Evolution of Hardbanding in Russia

10 years ago, it was unusual to see casing friendly hardbanding used for Russian land drilling operations. The technology was mainly used in offshore projects in the Sakhalin and Caspian regions. Since then, the major drill pipe manufacturers in Russia such as TMK and Technomash Hilong, have installed their own hardbanding equipment and orders of new drill pipe with hardbanding applied have increased significantly. It’s estimated that in 2018 more than 60% of new box tool joints manufactured will have hardbanding applied before they are shipped to the end-user.

A recent study commissioned by Russian Drilling Contractor SSK, tested various products in a laboratory environment and attracted a lot of interest from across the industry. The number of licensed facilities in Russia with hardbanding equipment offering reapplication has risen from 3 in 2010 to more than 20 today.

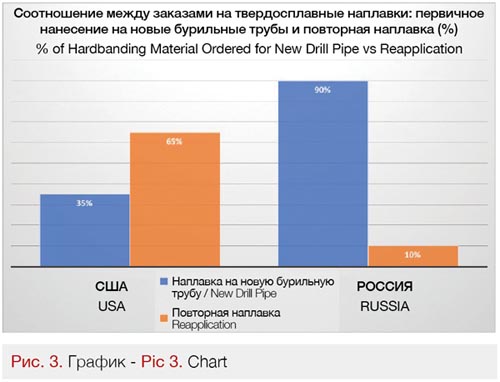

Despite this sharp rise, the uptake and management of hardbanding in Russia does not match that in other drilling regions such as North America, Europe and The Middle East. In these areas, hardbanding is applied to over 95 percent of drill pipe, and it is reapplied as standard practice. If we compare the total spend on hardbanding material in Russia and the USA, according to whether it’s purchased for new drill pipe at the manufacturing plant or for field reapplication by service companies, there is a significant difference. In the USA around 65% of all hardbanding material sold is for field reapplication, and in Russia that figure is around 10%. (Pic 3) This shows that in most cases, hardbanding is only being applied once per drill pipe in Russia, when the tool joint is manufactured. In other regions hardbanding is applied to the same drill pipe several times during its useful life.

Drill Pipe Endurance

The reason for this difference is that drill pipe in Russia is being taken out of service because of other failures before the initial hardbanding wears, so the opportunity for reapplication never happens. Washouts on the pipe body and threads requiring recuts are the most common reasons, according to respondents to the Russian Drilling Contractors Survey. Threads can be repaired, and regularly are with machine shops around the country offering this service (often the same companies who offer hardbanding reapplication). However, a washout on the drill pipe is fatal.

So, the issue that is slowing the progress of hardbanding technology in Russia appears to be the higher rate of washouts experienced during drilling. Maximum value is gained from hardbanding when drill pipe is regularly inspected and repaired, and when it survives for an extended period. Russian Drill Pipe Manufacturers report that orders of Internal Plastic Coating (IPC) for new drill pipe are increasing. IPC increases the efficiency of hydraulics during drilling and, crucially, prevents or reduces corrosion to the internal diameter of the pipe body, which is one reason why washouts occur. An increase in the share of drill pipe with IPC should therefore lead to longer life and a greater requirement for hardbanding reapplication.

Also, a recent study on ‘Predicting and Preventing Drill String Fatigue Failure’ published by SSK specialist Oleg Fomin in ROGTEC magazine, found that fatigue failure washouts were often caused by an accumulation of micro-cracking in the pipe body. Micro-cracking occurs during drill string rotation within the curved section of the well, when the drill pipe flexes, and with cumulative fatigue wear the micro-cracks grow and pipe wall failure (washout) is the result. (Pic. 4).

This type of drill pipe failure is more frequent in Russia compared to other regions of the world. One reason is that 12m long drill pipe (API Range 3) is more widely used in Russia, while in other regions 9m long drill pipe (API Range 2) is more prevalent by a considerable margin. Regarding endurance of drill pipe, if all other parameters like quality of steel are equal, the shorter 9m pipe has greater fatigue strength than 12m pipe. This is because 9m long pipe rotated in curved sections has more contact points with the wall of the well (at each tool joint) which reduces the bending stress on each individual pipe.

Much of the hardbanding sold in Russia for reapplication is applied for the few contractors who use 9m drill pipe and IPC. With less IPC used and a higher percentage of 12m drill pipe, it’s clear to see why the useful life of drill pipe is reduced and reapplication of tool joint hardbanding is yet to become mandatory in Russia. The use of 9m drill pipe in Russia is on the rise, again as a result of an increase in directional drilling. Other factors also affect the longevity of drill pipe such as quality of the steel, operational conditions, and the frequency of inspection and repair.

Conclusion

The rapid rise in the use of hardbanding in Russia over the past decade can be explained as a direct result of the increase in modern drilling methods by Russian Drilling Contractors over the same period. As with any new technology, end-users must be supported by manufacturers to enable them to gain an understanding of the products, and how to get the most value out of using hardbanding.

Most companies already understand the value of protecting tool joints with hardbanding and order new drill pipe with their preferred material applied at the factory. However, uptake of reapplication of hardbanding has been lower than in other drilling regions, so the full potential benefit of the technology is not yet being realised. The main reason is most likely that the majority of drill pipe is not surviving as long as the first application of hardbanding. However, with an increase in the use of other technologies such as internal plastic coating, and an increase in the amount of shorter, 9m drill pipe being used in Russia (also demanded by harsher modern drilling methods) this is likely to change.

With reapplication on the rise, choosing a hardband material with the chemistry to provide the perfect balance of abrasion resistance, casing friendliness, and reliability is going to become even more important to the drill pipe owner. Some chemistries of hardbanding alloys are more applicator friendly with regard to reapplication. These products often have certifications that have a third-party validation of reapplying their hardbanding products over their own material as well as other hardbanding alloys on the market.

The Russian drilling industry is striving towards higher performance goals with modern drilling methods. The drill string specification, inspection, repair, and protection technologies such as hardbanding will help in allowing those goals to be met economically.

Author: Colin Duff, Director, Hardbanding Solutions (Europe) Ltd.

Reference

Oleg Fomin: Siberian Service Company (SSC).

SSC: Predicting and Preventing Drill String Fatigue Failure. ROGTEC Magazine, Issue 52