Enhanced Oil Recovery Methods and ASP Technology

Yakov Volokitin, Mikhail Shuster, Volodimir Karpan,

Salym Petroleum Development N.V.

A steady growth in global energy demand requires more efficient production of traditional reserves. One way to address this challenge is to employ improved oil recovery (IOR) methods, which improve the existing recovery techniques (e.g. waterflooding) and apply new oil recovery methods. The latter are referred to as enhanced oil recovery (EOR) methods and are the focus of this article.

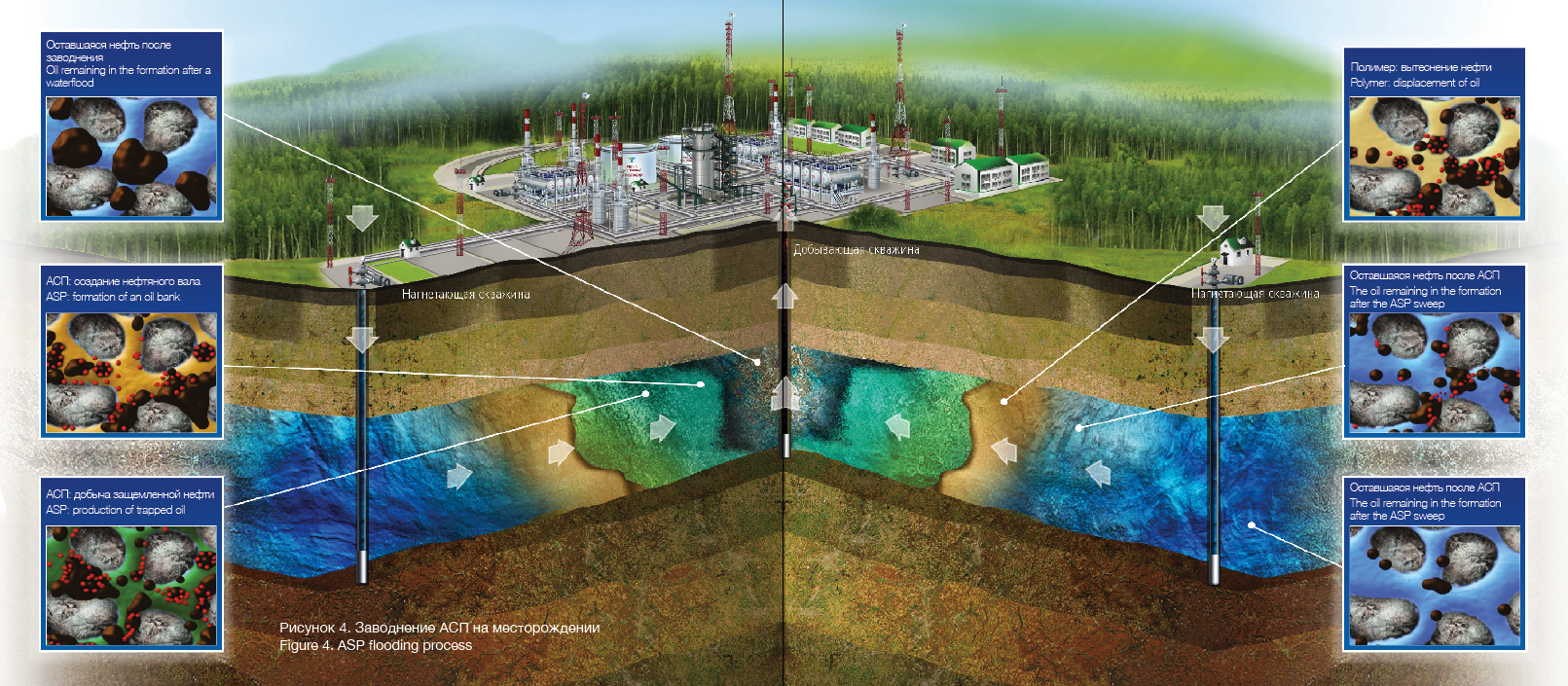

The importance of IOR/EOR can hardly be overestimated considering that a large proportion of major fields are in the mature stage of development, showing an annual average production decline of 5% per year [1]. Besides, the task of finding new reserves becomes more challenging, pushing exploration activities into hard-to-access and/or deepwater areas. Recent increase of recoverable reserves has been driven by technological breakthroughs in well drilling and completion enabling commercial production of unconventional oil, including shale oil and heavy oil (bitumen). However, the development of hard-to-recover and unconventional reserves entails additional risks, which considerably increase unit production costs (See Figure 1).

Currently, most of the oil is produced from the fields discovered around a quarter of a century ago. The estimated averaged ultimate recovery from these fields is about 35% which means that almost 2/3 of oil will be left behind. Studies indicate that that just a 1% increase in global recovery would raise recoverable reserves by 88 billion barrels, which is equivalent to three years of annual production at today’s level [2]. Another important consideration is that these mature fields are well studied from the geological perspective and have well-developed infrastructure, which reduces the risks associated with the production of additional reserves through the implementation of the IOR/EOR technologies.

Currently, most of the oil is produced from the fields discovered around a quarter of a century ago. The estimated averaged ultimate recovery from these fields is about 35% which means that almost 2/3 of oil will be left behind. Studies indicate that that just a 1% increase in global recovery would raise recoverable reserves by 88 billion barrels, which is equivalent to three years of annual production at today’s level [2]. Another important consideration is that these mature fields are well studied from the geological perspective and have well-developed infrastructure, which reduces the risks associated with the production of additional reserves through the implementation of the IOR/EOR technologies.

Enhanced Oil Recovery

In this article we qualify the EOR method as an oil recovery process that involves the injection into the formation of a considerable amount of fluid (in proportion to the porous volume of a reservoir) that was not present in the reservoir originally [3]. This implies changing the whole development process. Such activities as near wellbore treatment (i.e. gel injection to isolate the high permeability interval) would not qualify as EOR, because of the small quantities of the fluid involved in the operation. The EOR methods are often referred to as tertiary recovery methods, although, by definition, they may actually be used at any point in the life of a field development. EOR methods are much more likely to be applied at later stages of field development, when traditional recovery methods no longer perform and most geological risks have been removed, which explains association of EOR with tertiary recovery.

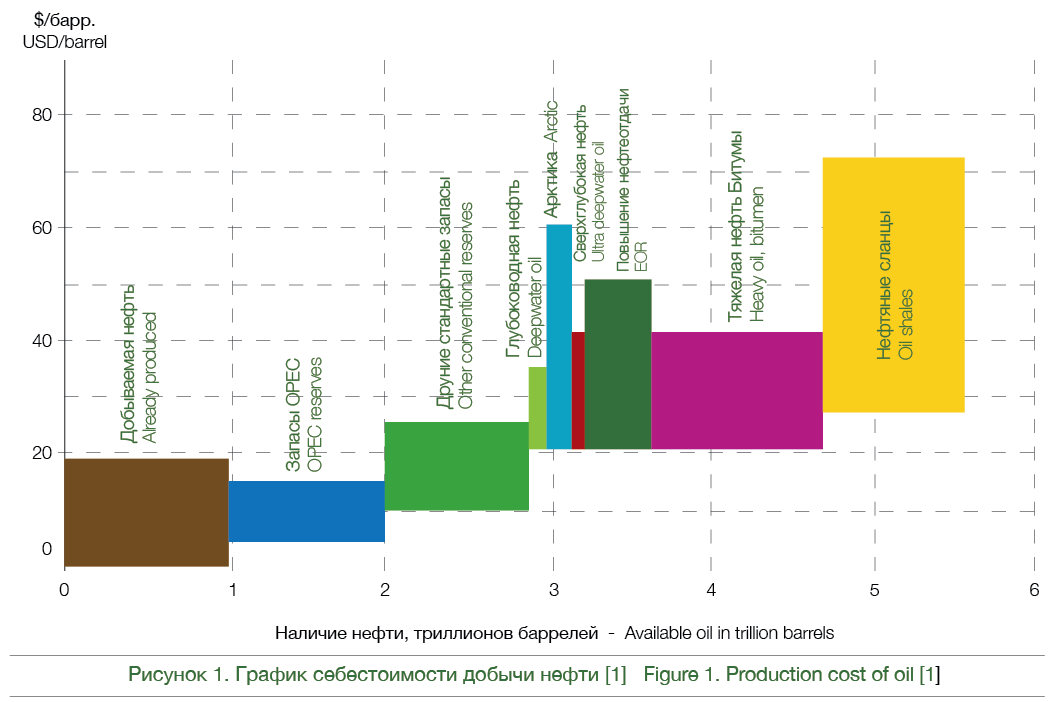

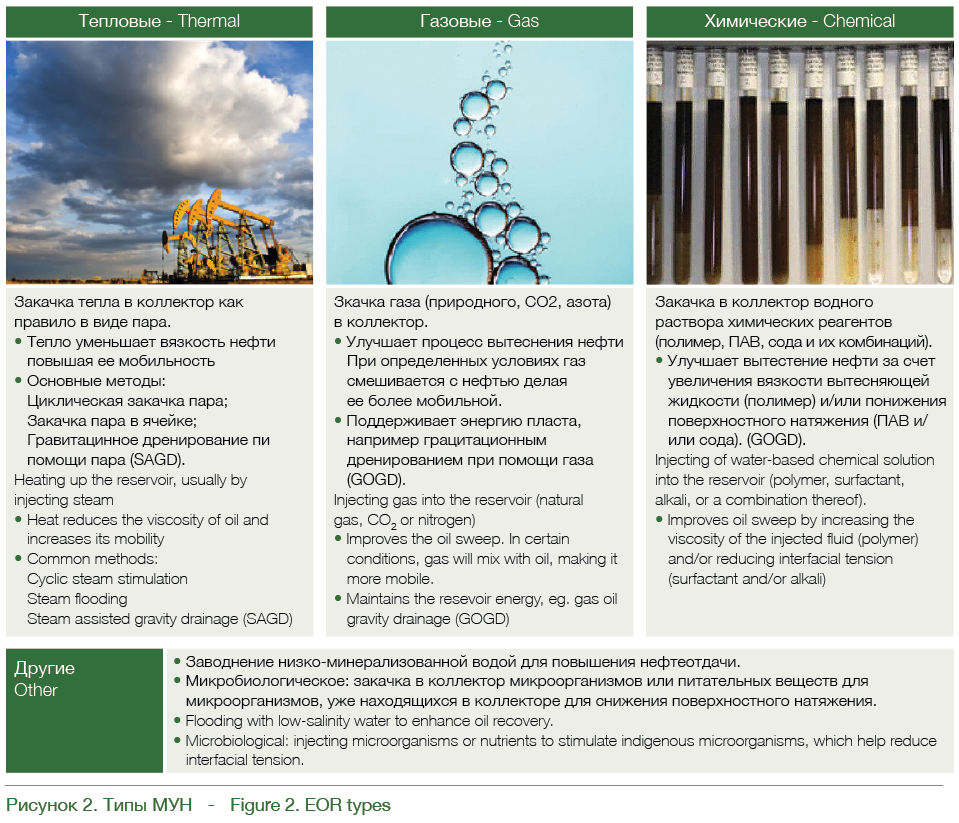

Most of the EOR methods may be classified into three types: thermal, chemical and gas (See Fig. 2). Some methods, such as the High Pressure Air Injection and foam injection, may fall within several categories at the same time. Thermal methods involve the introduction of energy into the formation (most commonly, in the form of steam) to reduce oil viscosity and facilitating its production. Gas methods involve the injection of gas (natural gas, nitrogen or CO2) to improve the oil sweep. Depending on the interaction between injected gas and oil, the process may result in an oil/gas mix (miscible condition) or coexistence of two distinct phases (oil and gas) in the formation (immiscible condition). The efficiency of the sweep process in case of miscible gas injection is higher than that of immiscible gas injection. Miscibility of gas with oil is identical to that of liquid solvents. Liquid solvent injection qualifies as a separate EOR type and can be applied in a broad range of conditions (See Fig. 3). Chemical EOR methods (cEOR) involve the injection of a water-based solution of chemicals into the formation: a surfactant, polymer, alkali or their combination. Currently the most commonly implemented EOR technology is polymer flooding [4]. At the same time it is recognized that ASP flooding – injection of all three components: alkali, surfactant, and polymer (ASP) is the most promising cEOR technology. Injection of the ASP mixture improves the sweep efficiency, and mobilizes the oil trapped after the initial flood by reducing the interfacial tension between oil and water. The synergetic effect of these chemical and physical processes helps achieving a doubling of the oil recovery in comparison with that of polymer flooding. However, the technological complexity and the high surfactant costs have held back the implementation of the ASP technology.

Most of the EOR methods may be classified into three types: thermal, chemical and gas (See Fig. 2). Some methods, such as the High Pressure Air Injection and foam injection, may fall within several categories at the same time. Thermal methods involve the introduction of energy into the formation (most commonly, in the form of steam) to reduce oil viscosity and facilitating its production. Gas methods involve the injection of gas (natural gas, nitrogen or CO2) to improve the oil sweep. Depending on the interaction between injected gas and oil, the process may result in an oil/gas mix (miscible condition) or coexistence of two distinct phases (oil and gas) in the formation (immiscible condition). The efficiency of the sweep process in case of miscible gas injection is higher than that of immiscible gas injection. Miscibility of gas with oil is identical to that of liquid solvents. Liquid solvent injection qualifies as a separate EOR type and can be applied in a broad range of conditions (See Fig. 3). Chemical EOR methods (cEOR) involve the injection of a water-based solution of chemicals into the formation: a surfactant, polymer, alkali or their combination. Currently the most commonly implemented EOR technology is polymer flooding [4]. At the same time it is recognized that ASP flooding – injection of all three components: alkali, surfactant, and polymer (ASP) is the most promising cEOR technology. Injection of the ASP mixture improves the sweep efficiency, and mobilizes the oil trapped after the initial flood by reducing the interfacial tension between oil and water. The synergetic effect of these chemical and physical processes helps achieving a doubling of the oil recovery in comparison with that of polymer flooding. However, the technological complexity and the high surfactant costs have held back the implementation of the ASP technology.

EOR Screening

Screening is the starting stage in the selection of the right EOR technology for a field. In this article we will focus on high-level screening, whereby average formation properties are compared against the limits, within which a particular EOR technology works. There is broad coverage of various screening approaches available in literature, and there are commercial products to perform this kind of work [5]. Final decision on EOR technology selection depends on the properties of the field that company operates, and the operator’s experience with a particular technology. Figure 3 illustrates the approach used by Shell to screen EOR technologies [2]. In this particular case the screening focuses on the depth of the reservoir and oil viscosity. In addition to these basic properties, many other parameters have to be analyzed in the selection process. In particular, in the case of gas EOR, the design formation pressure is an important factor, and for chemical methods, the properties of formation water and type reservoir rock (carbonate or sandstone) play a major role.

Screening is the starting stage in the selection of the right EOR technology for a field. In this article we will focus on high-level screening, whereby average formation properties are compared against the limits, within which a particular EOR technology works. There is broad coverage of various screening approaches available in literature, and there are commercial products to perform this kind of work [5]. Final decision on EOR technology selection depends on the properties of the field that company operates, and the operator’s experience with a particular technology. Figure 3 illustrates the approach used by Shell to screen EOR technologies [2]. In this particular case the screening focuses on the depth of the reservoir and oil viscosity. In addition to these basic properties, many other parameters have to be analyzed in the selection process. In particular, in the case of gas EOR, the design formation pressure is an important factor, and for chemical methods, the properties of formation water and type reservoir rock (carbonate or sandstone) play a major role.

Salym Petroleum Development N.V. (SPD) is a 50:50 Joint Venture of Shell and Gazprom Neft. Since 2003 SPD has been developing the Salym group of oilfields (West Salym, Upper Salym and Vadelyp), which are located in the Khanty-Mansi Autonomous Okrug in Western Siberia. The Salym project is one of the largest investment projects with foreign participation in the Russian oil industry. Since its start SPD has drilled over 1000 wells and produced more than 60 million tons of oil.

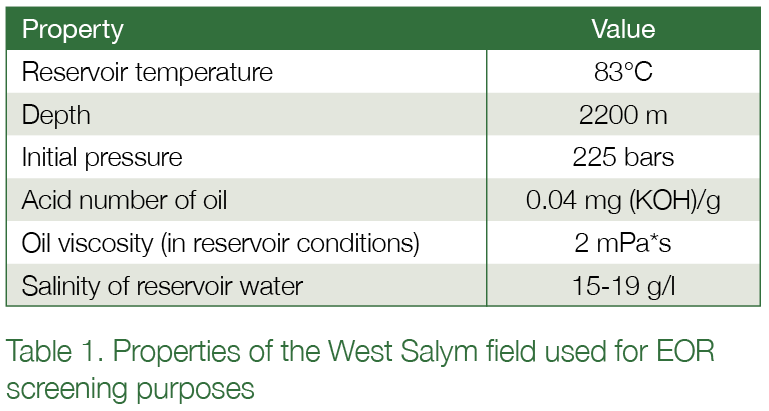

The main properties of the West Salym field used in EOR screening are shown in Table 1. The viscosity of the oil in the field is low, which makes application of thermal EOR methods inefficient. The injection of gas, be it nitrogen, CO2 or flue gas, should not results in large incremental oil production due to the immiscible gas-oil conditions. The injection of hydrocarbon gas, which is miscible with the oil at reservoir conditions is not possible due to the insufficient amount of associated gas. Moreover SPD monetizes almost 100% of it’s associated gas.

The injection of low salinity water can potentially be applied in the West Salym field (see Figure 2). However, analysis has showed that the use of this technology in a mature field has marginal effect, with insignificant incremental oil production over a long period of time with high watercut [6]. SPD continues to consider this technology as an option for the reserves at early stages of development. Chemical EOR methods remain the only other possibility that complies with the reservoir properties (in particular, temperature and water composition). However, pure polymer flooding at West Salym would be less efficient, considering the maturity of the field and the relatively low oil viscosity. The screening process has resulted in the conclusion that ASP flooding would be the optimal EOR technology for West Salym.

The injection of low salinity water can potentially be applied in the West Salym field (see Figure 2). However, analysis has showed that the use of this technology in a mature field has marginal effect, with insignificant incremental oil production over a long period of time with high watercut [6]. SPD continues to consider this technology as an option for the reserves at early stages of development. Chemical EOR methods remain the only other possibility that complies with the reservoir properties (in particular, temperature and water composition). However, pure polymer flooding at West Salym would be less efficient, considering the maturity of the field and the relatively low oil viscosity. The screening process has resulted in the conclusion that ASP flooding would be the optimal EOR technology for West Salym.

ASP Flooding Technology

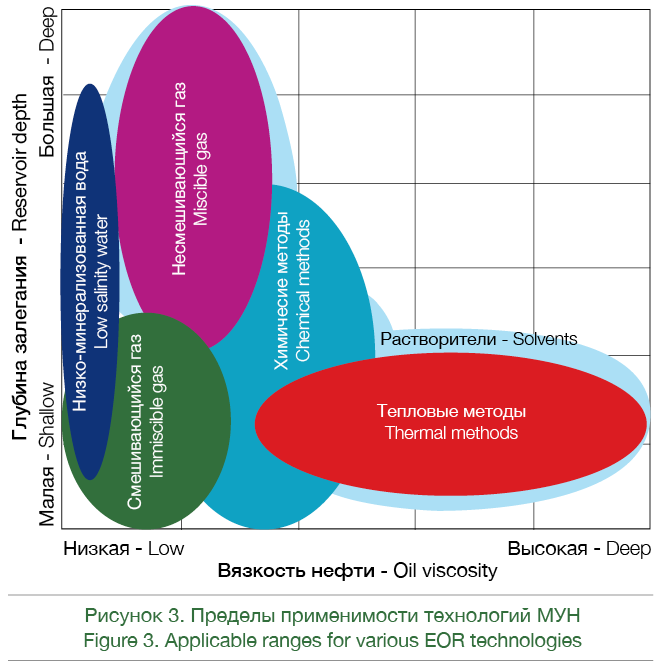

The ASP technique was developed in the early 1980’s at Shell’s Bellaire Research Center in Houston [7]. As stated earlier, it involves the injection of a water-based solution of three components: Alkali, Surfactant, and Polymer. The surfactant reduces the interfacial tension between oil and water, which helps mobilizing oil that would normally remain trapped in the formation rock. Alkali serves two purposes. The first one is to reduce the adsorption (or loss) of the expensive surfactant in the formation. After injection into the formation, alkali reacts with the reservoir rock and increases its negative charge that leads to reduction of surfactant adsorption. The second function of alkali is the hydrolysis of naturally-occurring acids in the crude oil to form additional volumes of surfactant in the reservoir. However, West Salym crude has insignificant amount of acids (See Table 1), which means that alkaline is used to prevent the adsorption of the surfactant. Polymer is added to the injected chemical mixture to increase its viscosity, which improves the sweep of crude mobilized by the surfactant. The traditional ASP flooding process consists of the following stages (See Figure 4):

» Pre-flush. Water of specified salinity is injected into the reservoir to influence the salinity of reservoir water, which would minimize the loss of surfactant during the ASP flooding and/or reduce the risk of salt precipitation when the formation water reacts with the ASP solution;

» Injection of the ASP slug. The maximum size of the slug used in commercial projects amounts to approximately 30% of the reservoir’s pore volume. Once injected into the formation, the ASP solution starts to mobilize trapped oil, forming an oil bank;

» Injection of the polymer slug. This solution is injected to displace the ASP slug and push oil in the direction of production wells.

» Postflush – water injection for pressure support to propagate injected ASP and polymer solutions in the direction of production wells.

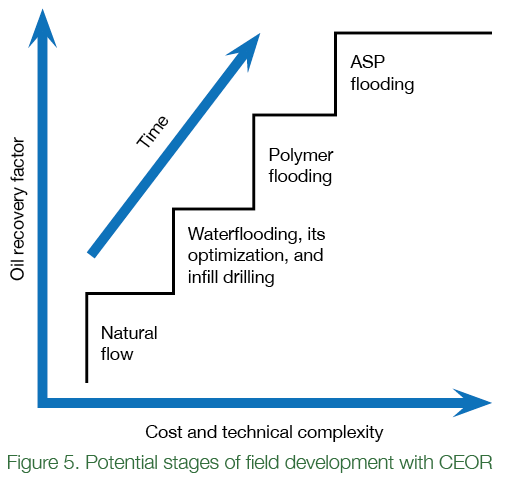

The current leaders in cEOR are China, Canada, and Oman [7, 8]. In most cases, the ASP projects were preceded by other activities, including the traditional waterflood and the injection of a polymer solution (See Figure 5). Fields with high oil viscosity like Marmul in Oman and Pelican Lake in Canada benefited from polymer flooding, because the efficiency of a traditional waterflood in such fields is low, and the injection of a polymer solution generated an additional 5% to 10% of incremental oil recovery. ASP flooding may result in higher values of incremental production, ranging between 10% and 20%, because it enables the production of both mobile and trapped oil. A polymer flood as a preliminary stage before an ASP flood removes a considerable proportion of technical and operational risks and helps prepare for the more complicated ASP process.

The current leaders in cEOR are China, Canada, and Oman [7, 8]. In most cases, the ASP projects were preceded by other activities, including the traditional waterflood and the injection of a polymer solution (See Figure 5). Fields with high oil viscosity like Marmul in Oman and Pelican Lake in Canada benefited from polymer flooding, because the efficiency of a traditional waterflood in such fields is low, and the injection of a polymer solution generated an additional 5% to 10% of incremental oil recovery. ASP flooding may result in higher values of incremental production, ranging between 10% and 20%, because it enables the production of both mobile and trapped oil. A polymer flood as a preliminary stage before an ASP flood removes a considerable proportion of technical and operational risks and helps prepare for the more complicated ASP process.

Due to low viscosity of West Salym crude injection of polymer after a prolonged period of waterflooding is not economic. Therefore it makes sense to start ASP flooding immediately after the traditional waterflood.

The following are the main challenges and constraints in implementing the ASP technology:

» Relatively high OPEX associated with the cost of chemicals

- Surfactant (100% active) – 3-5 $/kg

- Solvent (e.g. isobutanol) –1-1.5 $/kg

- Polymer – 4-6 $/kg

- Sodium carbonate – 0.15-0.25 $/kg

- All chemicals in an ASP solution – 50-80 $/m3

» Loss of chemicals that reduce efficiency of ASP flooding:

- Retention in the reservoir (adsorption in clays, loss of surfactant in oil)

- Loss of chemicals in non-productive areas

- Chromatographic separation of ASP components

- Reduced activity of the solution caused by a reaction with the reservoir fluids

» Reduced injectivity of injection wells, which may be caused by the following:

- High viscosity of the solution due to polymer

- Scale precipitation due to reaction between chemicals and reservoir water/rock

- Formation of viscous water-oil emulsions in the reservoir

- Polymer plugging in the near wellbore area

» The operation of the ASP process equipment is more challenging than during the traditional waterflood process

- The production of stable emulsions requires a more complex treatment process

- The make-up of the ASP solution should be carefully managed, including water treatment and dosing of chemicals

- The produced process liquid containing chemicals creates a disposal challenge

» There may also be logistical challenges, if large quantities of chemicals have to be delivered to fields with unsuitable infrastructure.

Literature

[1] International Energy Agency statistics [2] Shell’s “Enhanced Oil Recovery” brochure [3] Lake, L.W., “Enhanced Oil Recovery”, Prentice-Hall, 1989 [4] Sheng, J. J., Leonhardt, B., & Azri, N. “Status of Polymer-Flooding Technology.” SPE-174541 (2015) [5] Alvarado, V., Manrique, Э., “Enhanced Oil Recovery. Field Planning and Development Strategies,” Technopress Ltd, 2011 [6] Suijkerbuijk, B. M. J. M., Sorop, T. G., Parker, A. R., Masalmeh, S. K., Chmuzh, I. V., Karpan, V. M., Volokitin Y.E., Skripkin, A. G. “Low Salinity Waterflooding at West-Salym: Laboratory Experiments and Field Forecasts.” SPE-169102, (2014) [7] Nelson, R. C., Lawson, J. B., Thigpen, D. R., & Stegemeier, G. L. “Cosurfactant-Enhanced Alkaline Flooding” SPE 12672 (1984) [8] Sheng, J. J., Leonhardt, B., & Azri, N. “Status of Polymer-Flooding Technology.” SPE-174541 (2015) [9] Delamaide, E., Bazin, B., Rousseau, D., & Degre, G. “Chemical EOR for Heavy Oil: The Canadian Experience. SPE-169715 (2015)