ERIELL Group: Direction Drilling at the Urengoy Field – Drilling Smarter

The ERIELL Group has worked at the Urengoy Oil and Gas Condensate Field since the beginning of 2013. The first wells drilled were not successful, however, after reviews and a radical replacement of drilling technologies the wells were delivered within half of the contracted times.

The construction complexity of subhorizontal wells within the Achimov deposits is connected with the large producing depth of Ач3-4; Ач52-3 (3715 TVDSS) and abnormally high formation pressures (61.5 MPa).

Problem Identification and Solutions

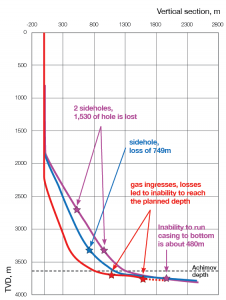

In 2013, the drilling of 3 sub-horizontal wells was conducted without the engagement of geomechanics services. The wells suffered from gas ingresses, mud loss, borehole loss, an inability to run casing to the bottom were detected.

The well was contracted to be delivered within 120 days. One of the main problems regarding the drilling program was the uncertainty regarding a safe drilling slot. The difference between the formation pressure gradient and the fracturing gradient did not enable the drillling mud to be of the required density. The density of the drilling mud was insufficient to prevent gas ingress and to keep the borehole stable. As a result circulation pressure limits were adopted, because the increase the equivalent circulation density led to immediate drilling mud loss.

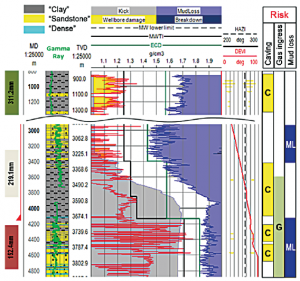

In May 2013, for the first time during well construction within the Achimov deposits, the geotechnical model was integrated into the well construction program.

This resulted in:

» the monitoring and control of the static and circulation density during drilling;

» the optimisation of the mud’s density and rheologic properties for each specific section

» the valves’ maximum pressure ratings were determined;

» the main risks were discovered and actions for their prevention were formulated;

» the drilling procedures were significantly improved (TFF, connection making, pumping).

These processes provided the opportunity to drill and successfully complete the first ultra complicated well with a subhorizontal section of around 1,000 m within 86 days.

Subsequent subhorizontal wells were successfully drilled based on the geotechnical model of the deposit and a result of the additional calculations which were made.

Risk Mapping For Subhorizontal Wells

Cutrently 18 subhorizontal wells have been drilled with horizontal section lengths from 1,000 to 1,230 m.

The effective cooperation between JSC “ARKTIKGAZ” and ERIELL Group, with engagement of subcontractors, gave the opportunity to achieve some outstanding results:

» the much faster delivery times for well construction — 46 days versus 100, according to the drilling schedule;

» completion layouts for multistage hydraulic fracturing were used for the first time;

» 3-stage hydraulic fracturing was performed for the first time within the Achimov deposits.