FlexConnect HP Frac Hose: Efficiently Handle High-Pressure Frac Operations without Traditional Iron

We understand the current industry’s challenges with numerous leak points and long rig-up and rig-down time with traditional iron set ups. The FlexConnect™ high-pressure frac hose is a composite hose that can be readily manufactured to multiple lengths, from 2- to 7-in. ID, and pressures up to 15,000 psi to meet your individual requirements. This hose provides improved frac media resistance and enhanced flow rates which enables you to enhance your frac operation.

FlexConnect hoses reduce the connections down to two instead of the multiple connections needed with traditional iron products, and offer improved performance and an easy solution to rig up and rig down.

These hoses are provided with visual wear indication inherent in the hose construction that allows inspection to determine approximate percentage level of wear and resultant life remaining in the hose body. Manufactured for extended life, the FlexConnect saves you on replacement costs, recertification, and tracking.

Features and benefits

• Actively dissipates fluid energy inherently reducing vibration and system stress

• Protective outer coating provides long-lasting life of high-pressure hosing

• Eliminate costly iron replacements and recertification with specifically designed ID to withstand harsh frac environments

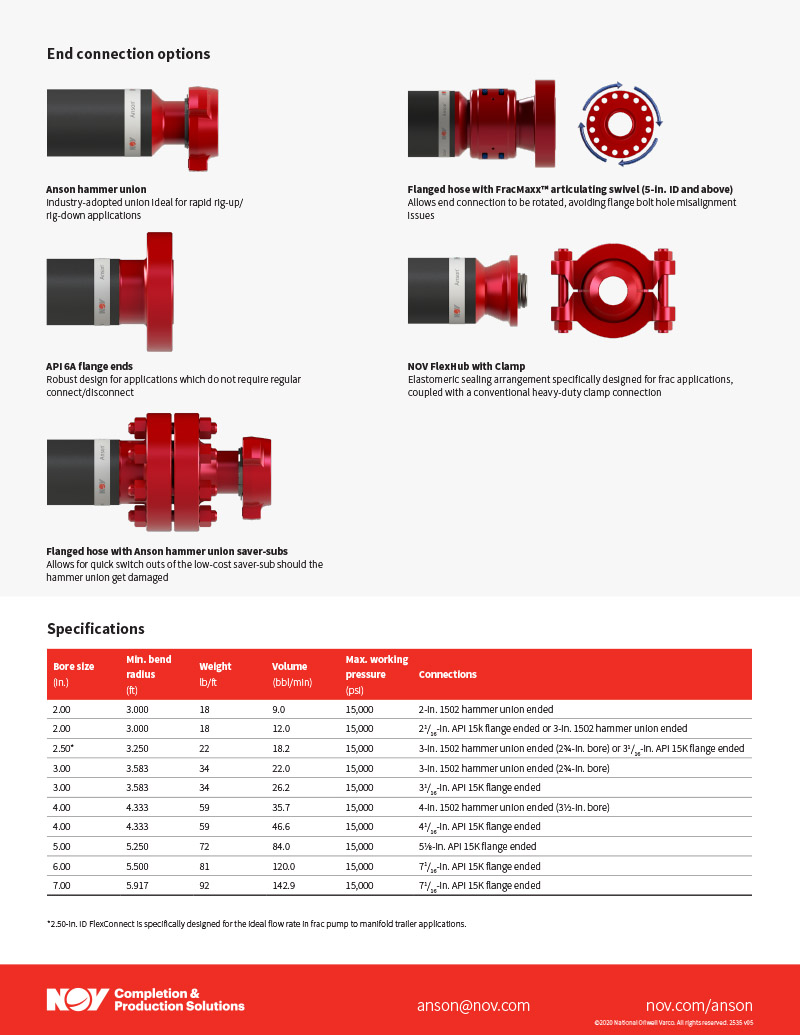

• Reduce rig-up and rig-down time with quick and safe AnsonTM hammer unions, hubbed, or flanged connections

• Reduced number of connection points eliminating the need for multiple iron configurations

• Higher flow rates versus conventional iron

• Available with integral end fittings captive within the hose body construction and end-of-life wear indication

• In-line swivel available for end connections to prevent torque transfer on makeup

• Compact and easily transportable design

Inspection and recertification

We have standardized the use of three wear indicator threads on every FlexConnect hose which provide a visual wear indication—green at 25%, orange at 50%, and red at 75% liner thickness. Inspection of the hose condition is completed using a borescope and can be facilitated by NOV’s team, or we also provide training to allow end user self-certification.