Gazprom Neft: Drilling Management Centre Case Study – Integrated Operating Management Systems

Introduction

Plummeting hydrocarbon market prices have presented oil producing and service companies with the challenge of fundamentally reconsidering their operation and approaches efficiency. This challenge requires focusing on major concepts shaping the company’s operations. One such concept is the degree of integration and quality of multi-discipline and cross-functional interaction between employees from different company units and subcontractors involved in the company’s projects.

The global trend, over the last several decades, has been toward an expanded use of IT technologies within the oil and gas sector. The aim is to improve inter-discipline interactions between professionals of all the units participating in the company’s projects at all the different stages. The term enterprise resource planning (ERP) system was introduced at the beginning of the last decade [1]. It initially referred to the information technology (IT) tools opening new levels of acquiring, categorizing, and quickly sharing real-time information of any data size and format within the company’s corporate network. It should be mentioned that since then the IT industry has made a huge leap forward in tackling this challenge: it has developed and introduced new standard, routine operational IT tools which supporting the acquisition, processing, classification, and even analysis of enormous real-time data volumes [2–3]. The EPR systems have gradually encompassed a broader meaning and come to be known as the integrated operating management system (IOMS). The term IOMS currently means expanding the scope of the system beyond a single company and also comprises the integration of all tasks that impact the efficiency of operations (production activities, information technology, HSE, cost control and finance, etc.).

The key to a successful IOMS launch is a common understanding of the purpose of the system being created, its use in an easy and convenient manner, and clear requirements to further support operations and provide on-going updates. It is therefore necessary that participants from all areas who will create, use, and support different tools within this system get involved in the IOMS development , beginning from the concepts initiation. At the planning and requirement definition stage, it is necessary that the IOMS accurately mirrors the expectations of the future system’s users and factors in the particular nature of the current and target approaches to the company’s operations and operational decision making. Furthermore, it is important to develop a strategy for moving the IT infrastructure and architecture from its current situation into the target at an early stage. These challenges require all the participants in the IOMS project to actively involve themselves in developing mutual solutions and utilizing state-of-the-art approaches to cross-functional interaction to ensure the projects success[4].

Developing a Philosophy for an Integrated Operating Management System within the Drilling Management Center

Gazprom Neft’s Drilling Management Center, was established in 2016 within the company’s Research and Development Center. This project is an illustration of an IOMS implementation success during well construction. All the Drilling Management Center project stages, starting from an initial assessment and ending with project launch, included the active involvement of a project team with participants from many fields; drilling, reservoir and production engineering, information technology, capital construction, human resource management, procurement, project management, and organizational change teams. This approach resulted in a phased development and implementation of the solutions that eventually improved the company’s drilling efficiency and took the well drilling management process to a whole new technology and managerial level, which is, of course, the major goal behind IOMS.

A basic and core IOMS elements include a repository, a single data storage containing all information accumulated during operations: data related to production, HSE, etc. During the IOMS development, it is necessary to ensure that all current online information from the offices and field is sent to the repository in live real time and engineering tools, supporting early analysis of this information and technical process management, are available. For such large data quantities, a crucial and sensitive issue is the automated quality and control of the information fed into the repository [5]. The main features of the IOMS repositories are their capacity, data processing speed, stable operation, high information security, preliminary data quality control tools, remote access, etc.

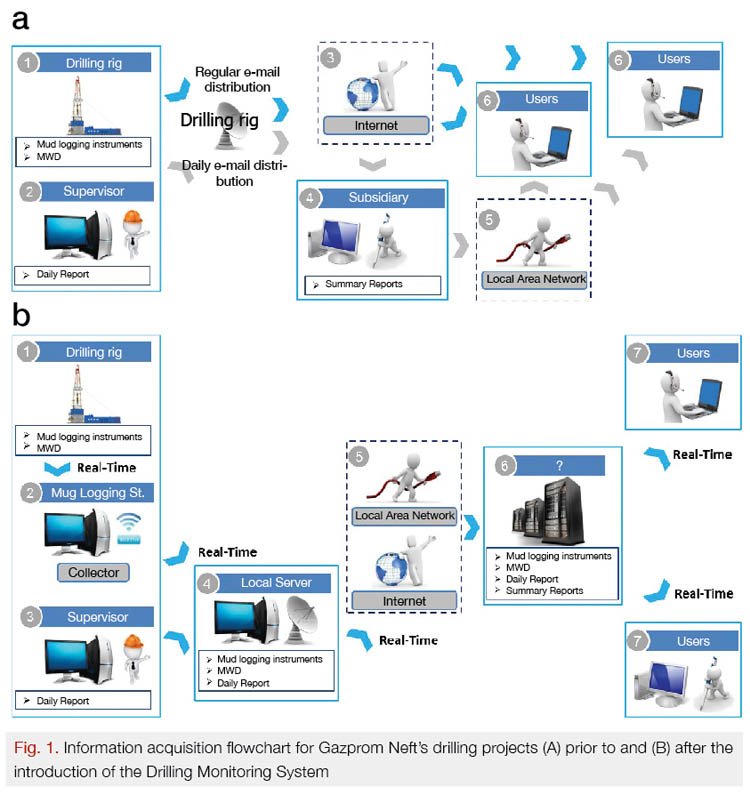

The corporate network of Gazprom Neft has a repository, the Drilling Monitoring System, where all information from all the drilling projects, owned or operated by Gazprom Neft, is gathered. The total repository capacity exceeds 13 TB with about 17 GB of real-time information sent to it daily from the drilling projects. In order to acquire and forward real-time information to the repository a local server is launched on each on-line drilling project. The bandwidth between a drilling site and the central repository is up to 1 Mbps. Developing and introducing the Drilling Monitoring System for operations has underpinned a change in fundamental approaches to acquiring, categorizing, and storing of information which is supplied by the drilling projects (Fig. 1).

The Drilling Monitoring System supports real-time acquisition of data and eliminates the need for the one-to-one data submission (e. g., via e-mail) since any information is simultaneously accessible to any Gazprom Neft employee, with proper authorizations.

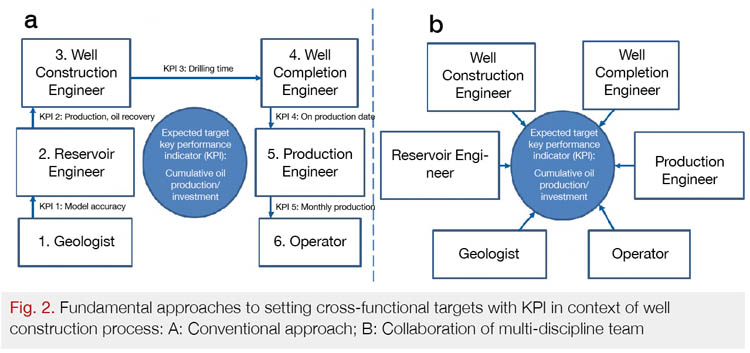

Another essential IOMS feature is the use of integrated cross-functional approaches to setting, monitoring, and measuring performance for multi-discipline targets through a key performance indicator (KPI) mechanism. Generally, prior to IOMS’ introduction, companies use a sequential approach to meeting multi-discipline targets: a complex process is broken down into stages with action owners, with their own KPI’s, assigned to each of them. In this case, the problem is that KPI for action owner, at each stage, and an expected target outcome, are not always fully aligned. It is quite likely that the target KPI for each stage are met but the expected outcome for the overall project is not achieved. Another system for setting cross-functional targets is to abandon individual KPI’s for action owners at various stages and to instead introducing the common KPI’s which fully correspond to the expected project outcome (Fig. 2). In this case, each employee has a personal stake in meeting the target outcome for the entire project, not only KPI for her/his task area.

The starting point for introducing the integrated KPI’s, for the Drilling Management Center employees, was a memorandum for the function leaders for Drilling and Well Intervention and Reservoir and Production Engineering about mutual responsibilities for performance of the wells drilled and meeting the targeted performance including the responsibility for costs and targets oil production. This agreement led to a shift in the traditional approaches to setting KPI’s for the employees of the two functions – cost and production. Previously, for the Reservoir and Production engineers, their major KPI’s in the drilling projects, was the initial production rate and for the Drilling and Well Intervention team’s, their focus was on the production date and productive time. Following the transition to the new system of setting multi-discipline targets, the main KPI’s for the team’s, of both functions, had been a ratio of the cumulative investments in well construction to cumulative production for a well, on an annual rolling basis. Such KPI’s as non-productive time with well construction, efficient horizontal well construction, meters drilled minus non-productive time, etc. are further applied to the Drilling Management Center employees. The primary difference from a conventional approach to setting multi-discipline targets is that these narrowly focused KPI’s are fully applied to all the Drilling Management Center employees. The next necessary component for starting and developing an IOMS is effective communication between all employees involved within the business processes [6]. It applies to both communication between employees inside the company and external communication with employees of any third-party companies hired for operations. Any barriers preventing prompt and productive discussion of the issues arising during operations are required to be removed.

These barriers include:

• Spatial barriers /Distance: employees stationed in different offices, buildings, cities, etc.

• Administrative barriers: employees belonging to different company units, communication via management, etc.

• Motivational barriers: conflicting KPI’s, inefficient bonus systems for collaboration, etc..

• Instrumental barriers: use of unsuitable communication tools, overlooking IT

• Organizational barriers: poor office space allocation, lack of efficient meeting culture in the company, etc.

Each company approaches this challenge in its own way. However, removing barriers is a necessary component of an IOMS development, thus, the companies who strive to improve their operational efficiency have had to change the deeply rooted principles of an organization’s culture and operations if they hinder effective communication.

Shortly before establishing the Drilling Management Center, Gazprom Neft had to reconsidered their communication strategies. One of the outcomes was to develop a target model of the Drilling Management Center as a separate structural unit residing in the same location and comprising participants from the drilling and reservoir units. In addition, overcoming any barriers arising from outdated communication tools and poor office space planning (Fig. 3A) .

This required establishing a new office for the Drilling Management Center, which was opened in 2016. Its design and development addressed the unique needs of the Drilling Management Center including effective multi-discipline communication both inside and outside of the company (Fig. 3B).

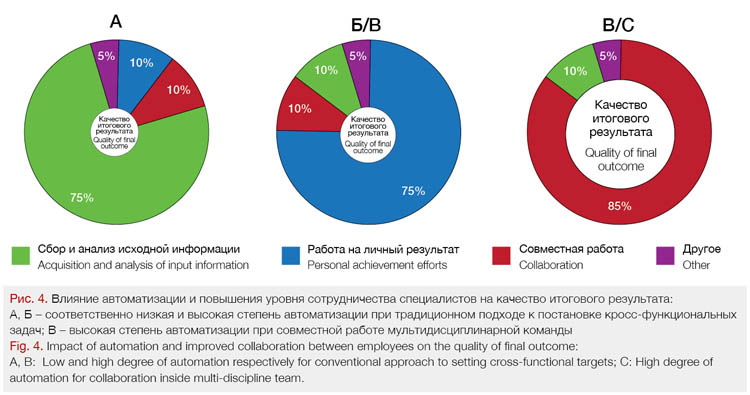

Continuously increasing the overall degree of automation for engineering and developing tools, for proactive analysis, and the remote monitoring of process operations are also key elements to an efficient IOMS operation. This is crucial for such a dynamically evolving and operational information rich process, as well drilling. For drilling, data acquisition, engineering information processing, and analysis of the data may consume up to 75% (or more) of the employees’ time resources. A much better outcome can be achieved by joining efforts, for routine task automation, with a shift to a more efficient system of cross-functional interaction, which is then the backbone for employee collaboration and their focus on the expected outcomes for the entire project (Fig. 4). Routine task automation is an everlasting process brought about through the interaction synergies between various disciplines resulting in the reshaping of routine tasks and the expansion of new areas for further development and a robust evolution of the automation tools themselves. The most efficient paradigm for the interaction between a business and the IT industry is when the company not only purchases the IT solutions, currently available in the marketplace, but also prepare specifications for developing new IT tools which best fit their specific operational requirements.

The Drilling Management Center takes an active part in creating new IT systems and developes the existing ones to ensure well drilling management operations reach the next level. Such projects include the development of the preparation module for real-time petrophysical interpretation as a part of geosteering software solutions, IT systems for proactive well drilling management, state-of-the-art interactive environments for remote engineering communication in real time, etc.

It should be mentioned that the above described design and development philosophy for an integrated operating management system entails changes in the traditional routines and requires the company to be ready for these changes. For this reason, introducing and maintaining a culture of continuous improvement, grounded in lean production, is a fundamental component of developing an efficient IOMS [7].

Conclusion

1. The GeoNavigator Drilling Management Center case study showcases a successful implementation of an IOMS related to well construction.

2. The case study of the Drilling Management Center highlights the following basic IOMS design philosophy: setting up a repository, a single data storage, supporting acquisition, classification, and the analysis of all operational data in real time; employing integrated, cross-function KPIs; nurturing an environment for effective communication of all employees involved in the production (both inside and outside the company); increasing an overall degree of the routine task automation, developing the existing IT systems and creating new ones for a proactive remote control of operations.

3. Introducing and maintaining a culture of continuous improvement (LEAN management) is a fundamental component of developing an efficient IOMS.

Reference

1. Broussard F.W., Edwards M., Quantifying the ROI benefits of integrated systems management, IDC White paper, October 2004.

2. Zachariah J., Ahsan A., Reid I., Optimized decision making through real time access to drilling and geological data from remote wellsites, SPE 77855-MS, 2002.

3. Seemann D., Williamson M., Hasan S., Improving reservoir management through big data technologies, SPE 167482-MS, 2013.

4. Kamal S.Z., Al Mubarak S.M., Scodova B.D., Naik P., Flichy P., Coffin G., IT and OT convergence Opportunities and challenges, SPE 181087-MS, 2016.

5. Svensson I., Wooley M., Halland Th., Improving data quality in WITSML data, SPE 181038-MS, 2016.

6. Bilinchuk A.V., Govzich A.N., Sitnikov A.N., Sadetskiy G.D., Koryabkin V.V., An integrated approach to the well drilling support in Gazprom Neft group (In Russ.), Neftyanoye khozyaystvo = Oil Industry, 2014, no. 12, pp. 48–51.

7. Roos D., Womack J.P., Jones D.T., The machine that changed the world: The story of lean production, Harper Perennial, 1991.

Author

A. Bilinchuk, Ph.D. in Engineering, I. Rustamov, E. Bulgakov

Gazprom Neft, PJSC

M. Khasanov, Grand Ph.D. of Engineering, V. Koryabkin

Gazprom Neft Science & Technology Centre (Gazpromneft STC LLC)