Gazprom Neft: Hidden Resources

Gazprom Neft adopted technological program for the development of gas cap deposits

The gas cap deposits make up a significant part of the reserves to be processed by Gazprom Neft in the very near future. It is sufficient to say that there are gas cap deposits in the large fields such as the East Messoyakha and Novoportovskoye fields. The successful implementation of the technological program adopted in 2016 in regard to development of such deposits, will have a direct influence on the company performance.

The gas cap deposits, or oil rims, are a special type of deposits with the oil column overlain by a gas cap that is usually large. The oil and gas sections are interconnected in such fields causing a range of difficulties for the development thereof. For example, gas production without regard for the influence it has on the oil section often results in significant loss of reserves, while gas breakthrough to the oil well may make further oil production impossible.

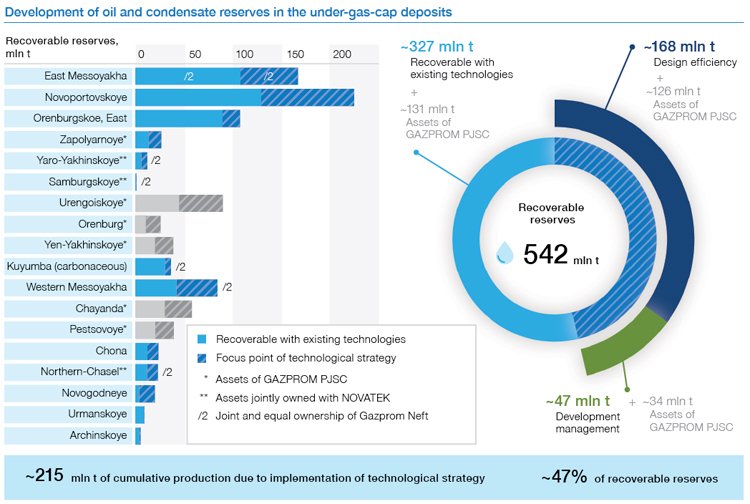

Besides Novy Port and Messoyakha, gas cap deposits are available in the Urmanskoye, Archinskoye and Novogodneye fields of Gazprom Neft, in the Eastern section of the Orenburgskoe oil and gas condensate field, Kuyumba and Chona, as well as in some reservoirs developed in cooperation with Novatek (the Yaro-Yakhinskoye and Samburgskoye fields). The oil rims are also present in many Gazprom’s fields (the Zapolyarnoye, Urengoiskoye, Orenburg, Yen-Yakhinskoye, Chayanda and Pestsovoye fields) and the parent company attracts Gazprom Neft to process the oil section.

Such reserves as the gas cap deposits can enrich the base of resources for oil and gas companies. While developing the wet gas fields with a high content of gas condensate the liquid phase may start segregation during production process forming an oil rim. Again, in the light oil fields with a high content of saluted gas, pressure change during production process may be followed by generation of self-inflicted gas cap like occurred in the Novogodneye field.

The total recoverable oil and condensate reserves in Gazprom Neft’s gas cap deposits exceed 500 mln t,

where only about 300 mln t can be produced with application of conventional technologies. The company expects to recover over 200 mln t of oil implementing a new technological program developed by Gazprom Neft Research and Development Center.

Profitability Concerns

Up to the present time the Russian oil companies have not expressed strong interest in regard to the gas cap deposits since the peculiarities thereof complicate development and define their status as hard-to-recover reserves. Suffice to say that compared to traditional oil fields, in the gas cap deposits the oil is usually influenced by two displacement agents at the same time: water from below and gas from above. So, there are more parameters to be considered complicating the oil recovery estimates and well designing.

However, the main issue that is related to development of the gas cap deposits and affects their profitability is gas breakthrough to the well. The rather low level of drawdown* in the wells needs to be maintained in order to avoid, or at least, to delay, gas breakthrough as far as possible. Thus, the oil recovery factor can be increased affecting the flow rate that directly depends on the reservoir drawdown. In this case production may appear to be unprofitable.

Maxim Fedorov, Head of Research and Methodological Support of Geology and Development of New Reservoirs for Gazprom Neft Research and Development Center noted that “it’s not possible to apply conventional methods of development in regard to most Gazprom Neft’s oil rims, preventing gas breakthrough and ensuring a favorable economic performance; so the issue may be settled by increasing the coverage ratio”. The wells in such fields become longer and have more and more branches. As such, the inflow area can be enlarged with simultaneous decrease of reservoir drawdown and maintenance of acceptable production rates.

Alexander Zhagrin, Head of Director of the Production Directorate, Gazprom Neft

Since there is almost no light oil left in Russia, Gazprom Neft has to start new ambitious projects to ensure further development and achieve the strategic objectives. The Novoportovskoye field became such a project in its time. The next step in this direction is development of oil rims that, in particular, belong to the parent company, Gazprom. The potential of projects that are related to the under-gas-cap deposits is very high in Russia. With today’s processing of oil rims in the oil, gas and condensate fields, we gain unique experience in application and enhancement of modern technologies that will be much-in-demand during development of such deposits in future.

Another advanced option that contributes to overcoming the undesirable gas/oil ratio is the application of inflow control equipment consisting of remotely controlled valves and bottom-hole measuring systems. It helps to restrict oil inflow into the well and prevent gas breakthrough. Should the gas breakthrough occur, such equipment can isolate the affected sections

of wellbore.

The optimization of drilling and infrastructure costs can also contribute to the profitability of project related to development of the gas cap deposits. This makes it possible to expedite a return on investment and profit more quickly before gas and water reach the wells.

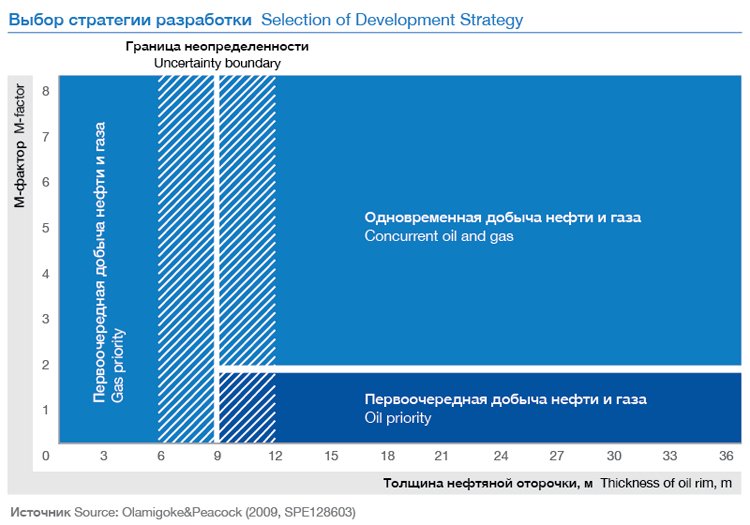

While developing the fields that have both the oil and gas sections it becomes important to define the priorities correctly: either preference for oil or gas or a concurrent production. The key factors here are a so-called M-factor (gas to oil ratio) and the thickness of oil rim. If the M-factor is high, that is the volume of gas significantly exceeds the volume of oil in the field and the oil column is not very thick (less than 9 m), gas production is usually preferred. Should the oil rim be larger, gas and oil are recovered concurrently. Should there be a rather small gas cap, the oil production is preferred.

According to the world practice, oil production usually becomes preferable (63 %) when oil rims are developed. The oil and gas have been concurrently produced on 24 % of fields while gas only has been produced in 13 % of fields.

Valuable Experience

Unlike the Russian oil companies, the world leaders of industry have been processing the gas cap deposits to produce the oil for over a dozen years. Considerable experience has been gained in regard to protection against gas breakthrough: the application of horizontal and multilateral wells, active and passive wellbore inflow control systems, injection of various chemicals.

For example, in the Oseberg field in the North Sea the horizontal wells that are up to 2.5 km long have been constructed by Statoil with application of “smart” completion systems with inflow control. In the Shaybah field in Saudi Arabia the fishbone** wells have been drilled with up to 10 bores. The total length comes to 12km. The inflow control systems have been used on the Troll field in the North Sea. The different reservoir pressure systems with water and gas injection have been tried by Petronas on the Samarang field in Malaysia. For the range of fields including Russian ones barrier waterflooding*** has been used. In the US fields (Northeast Hallsville and Byron) injection of polymers for oil rims has ensured higher oil recovery factor (13% increase). With application of foaming agents in the Snorre fields the gas to oil ratio has become 50 % lower for up to 6 months.

As for Gazprom Neft, currently, the company has mostly succeeded in application of drilling technologies that contribute to profitable flow rate of oil. They involve construction of long horizontal and multilateral wells. For example, in the Novoportovskoye field a well with 2km long horizontal bore and bilateral wells have been drilled. In the East-Messoyakha field the company is exploring construction of fishbone wells with multiple branches. Four multilateral wells of this type have been already drilled. The average overall length of their horizontal bores with branches is about 2500m.

Efficient development of the under-gas-cap deposits requires application of innovative technologies

Roadmap

One of main challenges related to development of Gazprom Neft’s gas cap deposits, and defined by the technological development program, is a necessity to gain more experience in creating the integrated models of fields, as well as in applying different reservoir pressure systems, enhancing the existing models of gas/oil ratio estimation, modernizing the equipment for geophysical study under the conditions of gas inflow into the well. An important task under the program will be the selection of suitable well completion design solutions that correspond to the specific mining and geological conditions as well as the testing of oil recovery enhancement methods that can ensure protection against gas breakthrough (injection of various gels, polymeric compositions, foams, etc)

Should there be a high content of gas in the oil it is inefficient to lift the oil with electrical centrifugal pumps with gas separators. So, either these aggregates must be enhanced or the use of them stopped and changed to the gas lift method. For the fields where gas production from the gas cap has been already started, it becomes important to search for the most efficient methods to localize the remaining recoverable reserves.

Another very important issue, considering the low production of most fields, is the possible application of hydraulic fracturing for the oil rims. This method of production intensification is very popular today, however the hydraulic fracturing in the gas cap zone increases the risk of gas breakthrough and requires to be really careful during application.

The technological development program in regard to the gas cap deposits includes 13 projects dedicated to search for solutions to the challenges and issues above. As Maxim Fedorov says, the primary task under the program for the next year is to become more qualified in creating integrated models of fields. Such a project is currently in progress in Novy Port. The distinctive feature of the integrated model is close cooperation while designing the underground and aboveground sections to ensure the best solution and avoid the infrastructure gaps and consequent expenses to settle the related issues.

In general, the Novoportovskoye field is currently the main site for execution of projects under the program related to development of gas cap deposits. So, in summer of 2017, gas injection into the gas cap will be started here to increase oil production – for Gazprom Neft, or any other company in Russia, it will be the first time when such a large reservoir pressure system with gas re-injection is used. This project helps to gain important experience in creation of reservoir pressure systems for the fields with the gas cap deposits and ensures maximum efficiency while applying similar solutions in future.

A range of high priority projects is to be executed on the Messoyakha field as well. One of them is dedicated to development of technologies for the execution of field research, geophysical and hydrodynamical study of wells and interpretation of the results. They ensure required input to design and select the well operation mode. However, as for the gas cap deposits, the conventional methods often result in incorrect results. So, they require enhancement.

One more project shall commence in the Messoyakha field. It’s dedicated to the search for the most efficient technologies of well completion under different geological conditions. The outputs can be used to select the option of well completion (multi-hole wells, long horizontal wells, hydraulic fracturing) that ensures the best results for each particular area.

* The reservoir drawdown stands for the difference between the reservoir pressure and the flowing bottom-hole pressure. The more reservoir pressure exceeds the bottom-hole pressure the more fluid inflow to the well is.

** A fishbone well stands for the multi-hole well that involves multiple horizontal branches of different directions. The well looks like a fish bone.

*** Barrier waterflooding stands for water injection on the gas-oil contact for generation of a barrier between the oil rim and gas cap to prevent gas breakthrough to the oil wells and penetration of oil into the gas cap.

* Пластовая депрессия (депрессия на пласт) — разность между пластовым и забойным давлением в работающей скважине. Чем давление в пласте выше давления на забое, тем больше приток жидкости к скважине.

** «Фишбон» — многозабойная скважина, у которой от одного горизонтального ствола в разные стороны отходят многочисленные ответвления. По форме она напоминает рыбий скелет (англ. fishbone).

*** Барьерное заводнение — закачка воды на газонефтяном контакте для создания барьера между нефтяной оторочкой и газовой шапкой для предотвращения прорыва газа в нефтяные скважины и вторжения нефти в газовую шапку.

Text by: Alexander Alekseyev

Photos: Eugene Uvarov, Roman Chernov

Infographics: Tatiana Udalova

Материал любезно предоставлен компанией ОАО «Газпром нефть» и журналом «Сибирская нефть»

Published with thanks to Gazprom Neft & Sibirskaya Neft MAGAZINE