Gazprom Neft Implements Technology Strategy for Development of Non-conventional Reserves

Sofiya Zorina

Development of the Bazhenov formation is one of the key strategic objectives of Gazprom Neft in the medium term. Success in achieving this objective directly depends on the company’s technological development.

In 2014 plans to develop non-conventional reserves which had been announced in Gazprom Neft some time ago were quantified: by 2025 the company intends to produce some 2.5 million tonnes of hydrocarbons a year from the Bazhenov formation while accumulated production by that time should exceed 15 million tonnes. It is expected that the resource base of oil reserves prepared for development, and recoverable from the Bazhenov formation, will exceed 400 million tonnes. However, the calculations indicate that one would have to strive to achieve such high indicators: based on the current level of the company’s technological development the Bazhenov would not produce more that 70 million tonnes.

As far as the in-place reserves are concerned, the resource base could be increased either by organic growth, i.e. by development of the Bazhenov formation in the fields available to the company or by inorganic growth, i.e. by acquisition of new prospects. In 2014 specialists from the Exploration and Production Block together with their colleagues from the Research and Development Centre and the Gazprom Neft Department of Strategy and Innovations evaluated the economic feasibility of development based on all possible options. As the result, price ranges of well construction costs were identified, as well as their future production rates and key technological challenges. Solving such challenges will considerably improve the project economics.

“The Bazhenov is a technology project”, believes Kirill Strizhnev, General Director of the Khanty-Mansi Oil and Gas Union and Manager of the Bazhen Design Office. “The Bazhenov covers the whole of Western Siberia and traces of hydrocarbons could be discovered everywhere. However, commercial production could only start provided certain technological challenges are resolved. We identified five main challenges and divided them into single projects. At least four of those challenges will need to be resolved to achieve economic benefit”.

Innovations Instead of Wild Cats

Before implementing any production project it is necessary to obtain answers to two questions: “Where should we produce from?” and “How much will we manage to produce?”. In the case with the Bazhenov the accuracy of these answers is particularly important as it is directly associated with the costs of further development. The programme for technological development envisages implementation of two projects aimed to make an assessment of production potential in specific license areas.

The first technology already created in the Beta version is the technology to forecast potential oil and gas presence in the Bazhenov deposits. It will prove essential when the Gazprom Neft resource base is extended by inorganic growth, i.e by search for and selection of new fields, and will allow us to make savings due to the reduction in the geological exploration required. Creation of respective software – a calculation module for qualitative and quantitative ranking of territories – was started some years ago. A basic version of the programme has been developed and is being appraised by the Research and Development Centre specialists. Last year it was used to rank practically the whole territory of the Yamal-Nenets Autonomous District and the Khanty-Mansi Autonomous District based on attractiveness of the areas. “All that is left for us to do is to “train” this programme and test its efficiency in respect of the key points”, stated Vladislav Zhoukov, Head of the Non-Conventional Reserves Projects Directorate of the Gazprom Neft Research and Development Centre. To enable us to do that we should gather statistics and obtain as many practical results as possible. This is going to be done in the next two years as part of the extended programme of geological exploration in a number of fields”.

The next stage is locating production areas in promising deposits and determining operational parameters for the development (number of wells, well effective length, start-up production rate, potential accumulated production, etc.). This task will be completed by using a geological/hydrodynamic simulator. Gazprom Neft specialists are working on developing this simulator in collaboration with the country’s leading science institutes. There are no analogues of this development in the world – western companies producing shale oil prefer to search for hydrocarbon-saturated areas by the “wild cat” methods, i.e. drilling random wells. “In the Western Siberian environment, i.e. complex logistics, harsh climate and the absence of infrastructure, we cannot afford to drill unnecessary wells. It is too expensive”, explained Kirill Strizhnev. According to the project manager, it is far more profitable for the company to invest in a unique intellectual product.

The hydrodynamic simulator is based on the Bazhenov geological models, identified evidence of oil and gas presence in beds, relationships between oil saturation and other characteristics of a pool. The programme will be verified using well logging and core study results obtained on several Gazprom Neft shale projects such as the ones implemented in the Palianovskoye and Verkhne-Salymskoye fields.

Selection of Parameters

Another way to improve the economics of the Bazhenov development is to reduce the capital costs associated with well construction and increase well operation efficiency. First of all this refers to selection of an optimum technology for the construction of horizontal wells – the only productive wells in the Bazhenov formation due to its special structure. This technology could then be applied on all the shale fields of the company.

❝The search and commitment to develop non-conventional reserves to a large extent will determine how Gazprom Neft will progress in the medium term. Undoubtedly, the work to extract hard-to-recover oil will require the company specialists to meet new complex technological challenges. We are ready for this and already today we are making confident steps towards a better understanding of the Bazhenov pools’ geological structure. Our plans include increasing the resource base by organic and inorganic growth, developing our own technologies for forecasting oil and gas presence in the pools and geological and hydrodynamic modelling of non-conventional reserves. These technologies will enable us to take a leading position in the area of hard-to-recover reserves development and create a national school of shale oil production.❞

ALEKSEY VASHKEVICH, Head of Gazprom Neft Geological Exploration and Resource Base Development Directorate

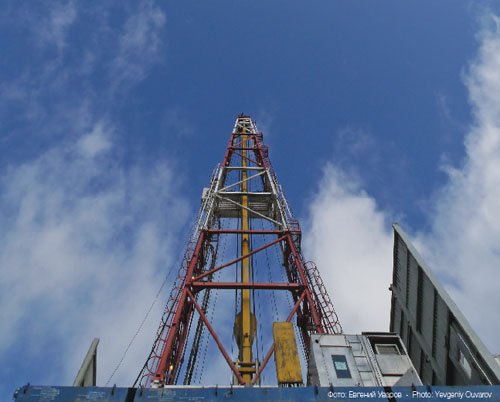

One of the specific aspects of developing the Bazhenov is the so called “narrow drilling window”, i.e. the ratio between formation and downhole pressure. Due to the narrow window, maintaining well wall stability becomes a problem, even with a small deviation in drilling mud weight, penetration rate and well diameter, the likelihood of caving remains high. Selecting the best technological parameters for drilling becomes the primary objective which has to be achieved if we hope to be successful in subsequent development. In this case the necessary results could be only obtained by trial. “We have already drilled two low-angle wells in the Bazhenov with inclination angles of 75 and 85 degrees and horizontal length of 200 and 300m”, said Aleksander Bilinchouk, Head of Gazprom Neft Reservoir and Petroleum Engineering Department. “The next stage is to drill two 1 km holes at a 90 degree angle. Our target is the “horizon” at 1500m. This is the optimum length of a well horizontal section for the Bazhenov in respect of return on investment and maximum reduction of capital costs. As soon as we collect a sufficient amount of empirical data we could build respective theoretical correlations and apply the technology in any field.”

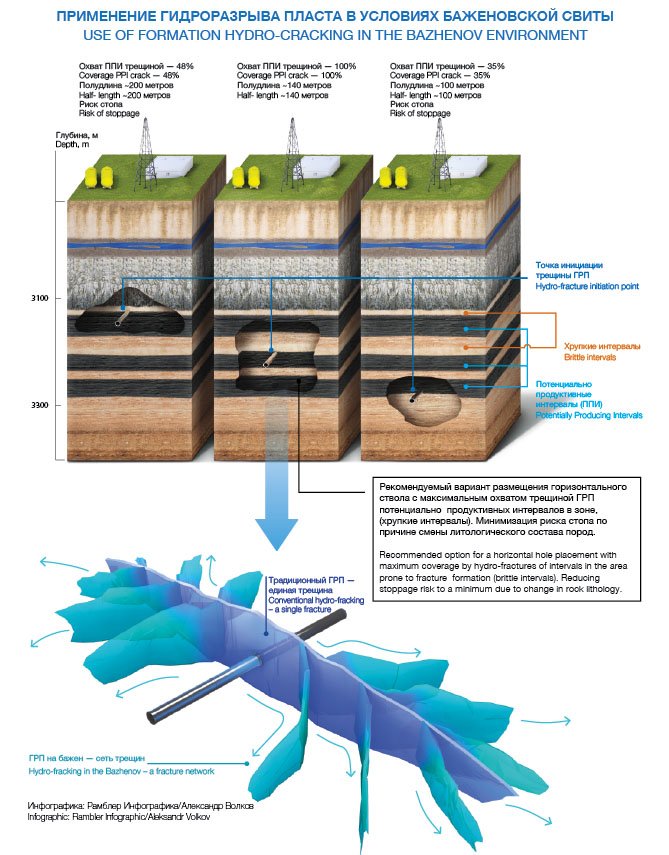

The other, equally important objective is increasing well production rates. Generally, high production rate could be achieved by performing a multistage hydro-fracking, but in the Bazhenov it is not that simple. Based on the adopted geological model potentially productive intervals in the Bazhenov occur as separate streaks in the formation. To create optimum conditions for multi-stage fracking and ensure that the resulting fractures cover the formation to the maximum, it is important not to miss while drilling a hole (see the diagram). Errors in this case will render hydro-fracking useless. The solution to this problem is development of technology for real-time monitoring of formation geo-mechanical properties and controlling drilling modes, depending on the change in these properties. Such well monitoring system (LWD – logging while drilling) is available and is successfully used by the industry’s leaders. Gazprom Neft specialists together with service companies are currently working to adapt this system to the Bazhenov conditions.

One more project is directly dedicated to actual multi-stage hydro-fracking – a technology without which shale oil production would be impossible. In this case it also necessary to adapt the best international practices to the” stubborn” Bazhenov which is characterized by extra-low permeability. In the usual sense the Bazhenov does not have porosity or flow properties which are understood. Therefore, applying a standard multi-stage hydro-fracking which creates large main fractures would not be effective in this case. Here, additional flow will only come from the areas around fractures, covering only several tens of centimetres. “Squeezing” the oil from the Bazhenov would only be possible by creating a fracture network which is a technological challenge on its own. There are a number of hydro-fracking parameters – fracking rate, rheological properties of fracking fluid, size and shape of a proppant and pulsating or continuous formation stimulation – which determine a fracture design. Correct selection of all these parameters is a formula for success in the Bazhenov.

As described by Mikhail Cherevko, the head geologist of Gazprom Neft-Khantos, “Currently engineering design of fracking in the Bazhenov is a prerogative of service companies. External specialists determine main fracking parameters and costs and they are responsible for the result. However, we want to create our own fracking simulator for the Bazhenov environment. This product will become the base for an integrated system to control technological processes and will enable us to control and reduce fracking cost”. Essentially, the objective here is to transform hydrocracking in Russian shale deposits from a unique and costly operation to a standard one. It could be only achieved by accumulating sufficient experience in performing fracking in the Bazhenov with simultaneous monitoring of the fractures. This extensive challenge could be only met in a technological partnership with service companies together with the scientific and financial support of the state.

To Source Rock Reserves

Based on the current concept of the Bazhenov geological structure, two main rock blocks are identified in the formation – oil source rocks containing kerogen* and streaks containing light oil. The latter make up approximately 30% of the whole Bazhenov formation. It is such a method of formation stimulation as multi-stage hydro-fracking that is aimed at recovering hydrocarbons from the streaks. However, oil source rocks remain inaccessible to the standard production methods. “Without using additional technologies aimed at producing hydrocarbons from the Bazhenov formation, we could only produce from a small part of the Bazhenov even though this production could be commercially feasible”, believes Aleksandr Bilinchouk. “This said, such technologies are in existence and are already being successfully used in shale deposits by a number of companies. Primarily, I am talking about in-situ catalytic retorting (see extract) which enables formation pressure and temperature to be raised significantly and expel oil from tight rocks. Notably, this technology could be used both in oil source rock and in streaks after performing hydro-fracking to create additional micro-fractures and increase inflow”.

The main disadvantage of this technology is the high cost. Implementation requires the whole complex of surface and subsurface equipment and thermal insulation of wells. However, based on preliminary calculations, this technology could be economically feasible when developing the Bazhenov horizon. Gazprom Neft will verify the calculations in collaboration with the Moscow Institute of Physics and Technology and the Skolkovskiy Institute of Science and Technologies which have laboratory equipment to conduct respective tests on the Bazhenov core. “Until recently, such equipment was not available in Russia. Now we are able to conduct our own studies and perform technical and economical calculations specifically for one of our shale projects”, informed Kirill Strizhnev. “Subsequently, everything will depend on return on investment”.

Although achieving non-conventional oil production volumes is possible by 2025 due to resolving the geological challenge of increasing well construction and operation efficienc, the search for new technologies for the Bazhenov is just a matter of time and the wish to make the next step in uncovering its huge potential.

* Kerogens are polymer organic materials occurring in such rocks as oil shale and are one of the non-conventional types of oil. Based on the organic material oil generation theory, remains of plants and marine organisms, affected by high temperatures and pressure, turn initially into kerogen, then into bitumen and, finally, into oil and gas.

Published with thanks to Gazprom Neft & Sibirskaya Neft MAGAZINE