Gazprom Neft: Innovations on the Horizon

Today’s oil wells are highly sophisticated and costly facilities. The company’s successful introduction of innovative construction technology is directly linked to the oil production costs, achievements in developing non-conventional and hard-to-recover reserves and extended operation of brownfields with their falling production.

Drilling 2.0

Gazprom Neft has approved its Well Drilling and Completion Technology Development Program. The Program is actually not that new: it is an update on and further elaboration of the document approved in 2015. The previous long-term program comprised of 27 projects. Some of them were implemented while other were canceled since new, better alternatives arose, with 10 projects being moved to the updated Program and a total project number reaching 79.

However, the major difference is not the quantity of projects, but a paradigm shift. «The first revision of the Program discussed investigating and testing individual technology,» Ksenia Antipova, Project Manager for Gazpromneft NTC, said. «While implementing the first revision of the Program, we generated a sizable bank of innovative solutions and got mobilized toward a more focused response to the reservoir challenges by selecting an optimal package of technology.»

In fact, some solutions that are not economically practical when tested separately may prove to be a whole different story in a synergy with another technology. This is the true meaning behind the term «optimal well design» that underpins the main focus of the Technology Program. «Optimal well design is a range of process solutions aimed at cutting down on well construction time and costs without any compromise on quality while maintaining or increasing the production level,» Yuri Kolesnikov, Head of New Technology for Gazpromneft NTC, explained.

«Development of such optimal designs for varying fields and mining & geological conditions is the major goal of the Program. The Program further covers two more areas: well completion under challenging conditions and technology cooperation. Their goal is to expand the array of technology: Develop and trial balloon the technology that will be further integrated in the targeted comprehensive solutions for various reservoirs.»

Optimize It

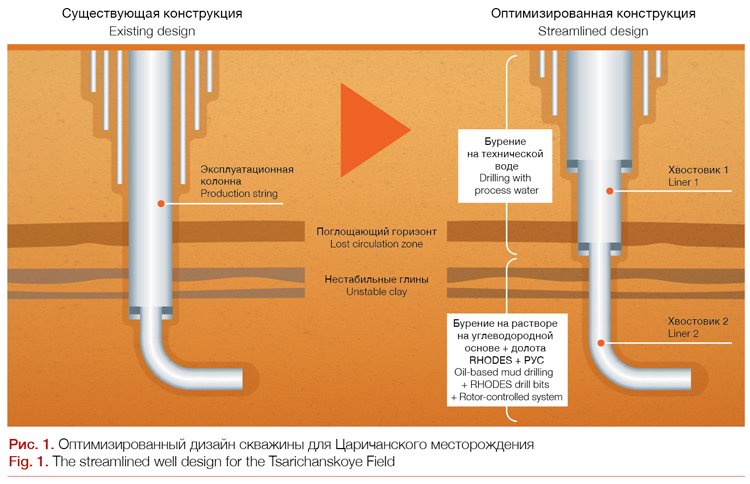

The Tsarichanskoye Field was the sandbox for the optimal design concept. The major issue with this reservoir is a massive loss of mud during drilling.

And there is an unstable clay area beneath the lost circulation zone that cannot be tapped without overcoming the mud loss in the above lying formation.

A conventional approach would take up considerable time and funding thus turning the wells unprofitable. Individual tests of several new technologies didn’t produce the intended outcome.

However, the new way made a tremendous difference. The solution did not lie in an individual technology but in the synergy that provided a footing for the optimal well design for the Tsarichanskoye Field. The new design envisaged penetration of the lost circulation zone with a cheaper mud then running a casing string down the hole and drilling the lower interval embracing unstable clay and the producing reservoir with oil-based mud. Use of the rotor-controlled system and high performance drill bits supported a notable increase in penetration rate for this interval that would otherwise make such design impossible. The production string in the lower part of the well was replaced with a liner while the later version embodied a hitherto unused design with two liners hung one after the other that enabled an even further decrease in steel intensity.

This well design significantly cut down on the final construction cost. The cost advantage realized through the technology package is 34 million rubles.

Each field has its own challenges that may be dealt with using a similar but a case-tailored, unique bunch of technology solutions. For instance, using the Fishbones multilateral wells, which reach the individual areas of a highly compartmentalized reservoir, is spot on when developing the B cyclothem in the Messoyakha Field (see the Glossary). However, the common Fishbones are open hole with no casing, but it would cause a borehole wall caving or collapse leading to a rapidly diminishing well productivity given the Messoyakha geological conditions. To prevent this from happening, it is necessary to construct the cased Fishbones, the multilateral wells with the lined walls, here. No one has ever constructed such wells in Russia. This is the design that provided a footing for the optimal well design in the East Messoyakha Field.

The optimal design for the Priobskoe Field sees a switch over from the quadruple casing well construction to the dual casing one. It is also envisaged to use the oil-based mud and the rotor-controlled system to readily penetrate the unstable area here. Beyond that, a combined liner of varying diameter pipes never before used by Gazprom Neft will be run down the well.

A similar project but in the somewhat different mining & geological circumstances will be also implemented in Megion, in Western Siberia. It envisages a shift from the triple casing well construction to the dual casing one. Geomechanical modeling to select the drilling mud with the required density will be instrumental in project implementation to successfully penetrate the challenging intervals.

Such projects place an increased emphasis on substantial engineering efforts and close connections between the disciplines. Apart from the examples mentioned above, the top priority for 2017 is to implement the optimal design projects in such reservoirs as the Eastern Section of the Orenburgskoe Oil & Gas Condensate Field and Novoportovskoye.

Bottomhole Innovation

Another portion of the Program is the well completion under challenging conditions. This part extensively relies on import making development and appraisal of domestic technology as well as reducing its costs, especially pressing. A vital facet of business is to develop the relevant competencies, especially, within

the subsidiaries.

The emphasized projects of 2017 include the construction of the TAML1 through TAML4 multilateral wells (see the figure) in Messoyakha, the Novoportovskoye, Gazpromneft Khantos, and Gazpromneft Vostok fields. «Multilateral completion is a complicated, high technology area that requires considerable resources and a wide range of competencies to grow and evolve,» Philipp Brednev, Well Completion Head for Gazpromneft NTC, remarked. «Developing and making it profitable is an ambitious task that, when implemented, will have a huge positive impact on the business.»

The TAML1 well construction project in the Novoportovskoye field is one of the projects already implemented within the Program. «It is a Russian technology. And it increased the drainage area at a minimum cost that led to a significant improvement in the well’s economic performance,» Philipp Brednev clarified.

One more essential project is underbalanced drilling. Technology is vital for developing the naturally fractured carbonate reservoirs whose fractures open up during well construction triggering a massive loss of mud. During underbalanced drilling, the wellhead is sealed and the bottomhole pressure is set up below the reservoir pressure thus causing oil to flow to the well and preventing mud from flowing into the formation. «In this way, we aim to increase the number of the open fractures,» Ksenia Antipova explained. «And if now we have to stop when the first fracture has opened up because it sets off loss of mud, this technology will aid in opening as many fractures as the design bore length permits.»

The lateral construction project that keeps the existing bore in operation will be implemented in the Gazpromneft Khantos reservoirs. It will breathe new life into the old wells whose profitability plunged along with their rates. The technology allows keeping oil inflow from the old bore when there is no guarantee of the new bore hitting an economically viable production level.

Inflow control equipment is scheduled for testing in 2017. This technology is vital to develop the under-gas-cap deposits since it prevents gas breakthrough to the oil wells, which is highly common in such fields.

Simultaneously, wells with an ever deepening horizontal bore are under construction. The 2016 all-high record is a two kilometer horizontal well. The 2017 plans provide for construction of a Novoportovskoye field well with a 2.5-km horizontal section.

Cooperation for Oil

Technology cooperation should provide Gazprom Neft with access to the competencies and technology they are otherwise lacking. Besides that, the industry’s existing cutting edge well construction technology gets tweaked to meet the company’s crucial needs.

One example of the project implemented based on technology cooperation is to develop a base oil for oil-based muds that are now growing in demand. For the moment, the oil comprising 65% of the mud is procured from abroad while its production at the Gazprom Neft plants will slash down the OBM cost by 40–50% and thus bring an upsurge in the drilling efficiency under challenging conditions.

Another project is to test the chemical diverters for a multistage re-fracturing on the wells with falling productivity. A special composition is injected in the wells that previously underwent fracturing to plug the old fractures and form the new ones. The agent decompose with time, and the well returns to operation. In the rest of the world, this technology is used for the low permeability shale reservoirs. The issue facing the cooperation members is to fine-tune the chemical diverter composition to use it for the conventional terrigenous fields.

One more project contemplated to be implemented within the cooperation is to develop a hybrid drilling rig. It is a high technology rig, easy to haul and install. An automated trip system enables a notable increase in penetration rate. The rig will be further equipped with its own coiled tubing that will radically simplify

most operations.

The casing drilling project is also scheduled to be implemented in 2017. The technology envisages the use for drilling of the same pipes that will later form the production string of the well. The end of this string has a special turbo shoe on it that both protects / guides its bottom end while running in the hole (as a typical casing shoe) and starts rotating to drill when mud is supplied. The dedicated remotely controlled deflecting rods placed on the bottom of the string are used to deviate the well

if necessary.

Among the rest of the close future projects, mention can be made of discovering the best possible surfactants for the formulations for initial penetration. There is some positive experience of their use in the world but so far no universal guidelines as to how surfactants should be selected considering the rock type they are to be used on. The project is aimed at developing such guidelines.

«One of the most essential areas to develop the cutting edge technology is technology scouting,» Alexei Cherepanov, In-House Oil Service Efficiency Program Manager for Gazprom Neft, clarified. «It embraces identification of both new technology and engineering solutions or knowledge of their particular features. It is anything that gives a company an edge over its competitors through a more efficient allocation of resources.»

As estimated by the developers of the Well Drilling and Completion Technology Development Program it will reduce the well construction cost by 20%. As a result, capital costs will go down by 46 billion rubles by 2025, and the company will additionally produce 21 million tons of oil. The previously unprofitable reserves re-entering production will amount to 134 mln. TOE.

Glossary

Cyclothem: a natural sequence of alternating sedimentary rocks due to cyclical changes in their deposition conditions

Fishbones: a multilateral well that has multiple laterals branching off the horizontal bore in different directions

Liner: a casing string that does not extend to the top of the wellbore, but instead only slightly overlaps the previous casing string.

Well completion: a cluster of procedures and techniques that enables penetration of the producing reservoir, support for the bottomhole area, inflow stimulation, and hydrocarbon deposit development.

Coiled tubing: a continuous length of pipe wound on a large spool and meant for pumping fluids into the well to the required depth, well cleanout, and other applications. Such pipe can be provided with various tools for drilling, hydraulic fracturing, and geophysical survey. Compared to the jointed tubing, the coiled tubing provides the ability to work safely under live well conditions. Operations using coiled tubing are completed in a much shorter time than those using the jointed tubing.

Text: Alexander Alekseyev

Photos: Alexander Taran

Infographics: Tatiana Udalova