Gazprom Neft: Integrated Well Completion Systems for Gas Cap Drive Reservoirs

Introduction

One of the main tasks of the modern oil production industry is to efficiently manage the production of the remaining recoverable reserves, the major part of which are confined to gas cap drive reservoirs and oil rims. Such reserves are challenging to develop, and in many cases, they are not developed because of the high risks, a lack of technology or economic unprofitability. One of the key challenges for developing gas cap drive reservoirs and oil rims, is the early breakthrough of gas, which leads to loss of reservoir pressure, the production of no-purpose phases and the low efficiency of recovery. The solution to the given problem is considered in this article in the context of new technologies which can be applied in well completions. Such approaches will make it possible to increase the efficiency and development of complicated gas cap drive reservoirs.

Novy Port Field Geological Structure

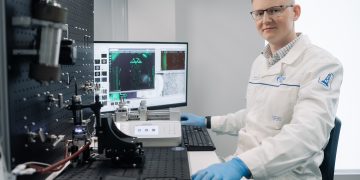

The Novy Port field is in the Yamalo-Nenets Autonomous District, in the north of the Western Siberia. It’s basic reserves are accumulated in the Jurassic deposits, which are specified by high vertical heterogeneity, which enables the development of only part of them. As an illustration of the reservoir Ю2-6 (J2-6) was selected, it has a complex geological structure: an extensive gas cap, underlying water and high anisotropy. Permeability anisotropy creates an uneven fluid movement profile, and as a result of this, it enables gas breakthrough (fig. 1).

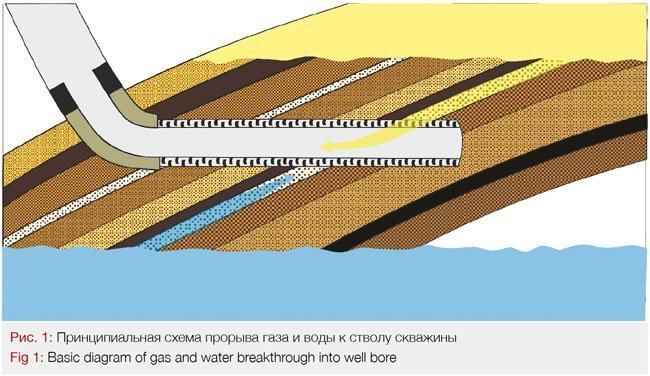

When developing reservoirs with high vertical heterogeneity, to increase connectivity in the reservoirs, multistage hydraulic fracturing is usually applied, but it is usually conducted at the bottom interlayers, to avoid the fracture growth towards the gas cap. This leads to the situation when the under-gas-cap-zone of oil reservoir remains untouched by development (fig. 2).

Integrated Well Completion System

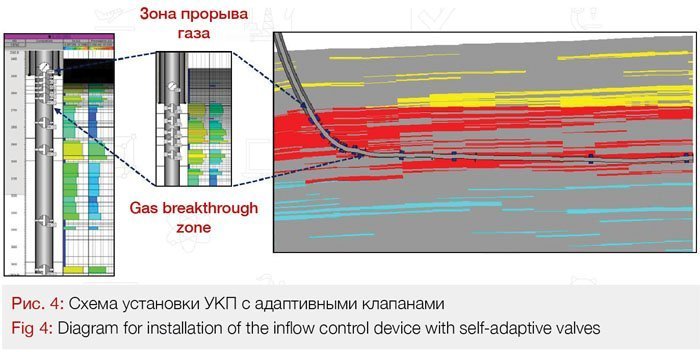

To resolve the problem of early breakthrough of no-purpose fluids and to improve the efficient recovery of the under-gas-cap-zone of the reservoir, it was suggested to apply an integrated well completion system which would enable the development of the whole oil-saturated reservoir. Such systems are composed of two fundamental techniques: inflow survey with employment of inflow control device with self-adaptive valves and multi-stage hydraulic fracturing (fig. 3).

The inflow control device creates hydraulic resistance to the flowing fluid with the use of special «labyrinths», the number and length of which are setup depending on the permeability profile. The longer the section of the inflow control device, the higher hydraulic resistance is created in the segment. Self-adaptive valves in the inflow control device are limited in case of gas breakthrough. The valves are installed in the under-gas-cap-zone of a well and in the event of gas breakthrough they get closed, letting the resting part of the borehole work in the previous mode. The multi-stage hydraulic fracturing is conducted in a way which had been accepted as the most efficient for any specific reservoir. To avoid the risk of gas breakthrough into the gas cap, the multi-stage hydraulic fracturing is conducted in the bottom interlayers. It should be noted that the inflow control device with self-adaptive valves is composed of several segments, separated with packers, depending on the reservoir permeability profile, obtained from horizontal well drilling. (fig.4).

The operation mode of the inflow control device with the self-adaptive system lies in the fact that the fluid from the reservoir passes through the first section, where the mechanical impurities strain out, and then it gets into special chamber. Within the chamber, due to the configuration of its channels, the flow of fluid is repeatedly separated and then merged, thus decreasing depression. In practice, a longer chamber is installed at the section where fluid breakthrough is expected across a high permeability zone, therefore, that zone is developed with lower depression values. Chambers of shorter length are installed at other sections, or not installed at all. In case of gas breakthrough the section is capable of closing itself with the use of self-adaptive valves, adjusted for a certain rate of flowing fluid. The valves can close or unclose depending on the deviation from the preset rate. Thus, the system makes it possible to level up the inflow profile avoiding risks of gas breakthrough.

Gauging the Efficiency of the Approach

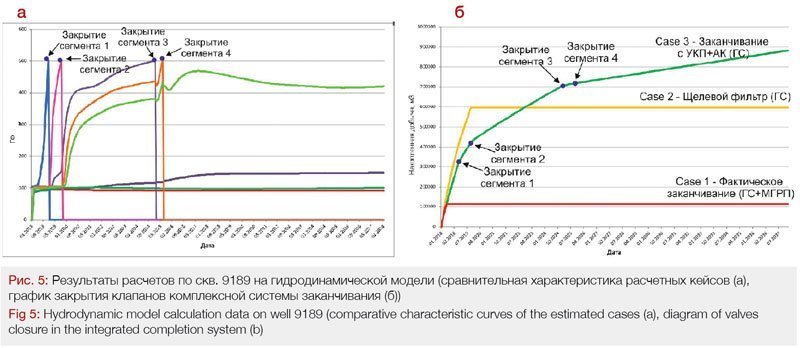

Simulations of the well completion systems have been modelled in the Multisectional well plug-in in the Petrel Software. Three basic options were selected for one well of the Ю2-6 (J2-6) reservoir (fig. 5):

1) actual completion – horizontal well+multi-stage hydraulic fracturing, conducted at the bottom part of reservoir only (case 1);

2) horizontal well with regular strainer across the whole reservoir, including the under-gas-cap-zone (case 2);

3) completion with self-adaptive system across the whole reservoir (case 3).

The fig. 5 illustrates that the option with the actual completion demonstrates the worst results, because the reservoir at the bottom part is relatively worse than the reservoir in the under-gas-cap-zone. Horizontal well with regular strainer at the first year of operation is the best result, but the well gets also shut in because of gas breakthrough. The proposed self-adaptive system enables recovering of smaller amounts of gas, with development of the under-gas-cap-zone at that.

Conclusion

The integrated well completion system is an integration of new Russian equipment into the existing approach to well completion. Regarding the Ю2-6 (J2-6) formation of the Novoportovskoye field (The Novy Port field) it is the use of the inflow control device with self-adaptive valves as auxiliary equipment for well completion in the under-gas-cap-zone of reservoir, with the use of the multi-stage hydraulic fracturing technique. This approach makes it possible to test the new technique without considerable capital investments and with minimum of risks.

Hydrodynamic calculation demonstrates the perspective of this approach which will make it possible to increase the efficiency of development of the gas cap drive reservoirs and oil rims.

Reference

1. Semenov A.A., Islamov R.A., Nukhaev M.T., Design of inflow control devices in the Vankor field (In Russ.), Neftyanoe khozyaystvo = Oil Industry, 2009, no. 11, pp. 20 – 23.

2. Antonenko D.A., Amiryan S.L., Murdygin R.V., Khatmullina E.I., The impact of changes in the parameters of equipment for flow control on the effectiveness of its use in horizontal wells (In Russ.), Vestnik OAO «NK «Rosneft», 2007, no. 5, pp. 34-38.

3. Nukhaev M., Zhuravlev O., Shchelushkin R., Andrianov O., Features of equipment for the construction of horizontal wells (In Russ.), Neftagaz, 2014, no. 4, pp. 20-24.

4. Semenov A.A., Kiselev V.M., Horizontal well performance modeling in the case of reservoir properties heterogeneity (In Russ.), Zhurnal Sibirskogo federal’nogo universiteta = Journal of Siberian Federal University. Engineering & Technologies, 2011, no. 4, pp. 429-437.

Author:

M.S. Kuvakina

Gazpromneft NTC LLC, RF, Saint-Petersburg

Published with thanks to Gazprom Neft & PROneft Magazine