Gazprom Neft is Expanding the Use of Domestic RSS and Telemetry for Drilling High-Tech Wells

Based on the test results at the Gazprom Neft fields, a decision will be made on full-scale production.

Gazprom Neft and Novaya Servisnaya Kompaniya have agreed to use Russian-made rotary-steered systems (RSS) at the company’s assets in the Khanty-Mansiysk and Yamalo-Nenets Autonomous Okrugs (KhMAO and YNAO). The document was signed at the Industrial and Energy Forum in Tyumen, the press service of Gazprom Neft reported on September 22, 2022.

The cooperation of the companies is aimed at the development of mass production of Russian RSS and telemetry. Based on the test results at the Gazprom Neft fields, a decision will be made on full-scale production.

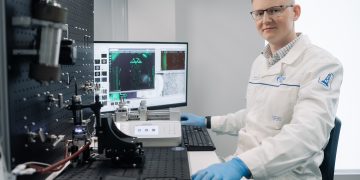

RSS are needed for drilling high-tech wells in thin oil reservoirs at depths of more than 2-3 km. This requires increased accuracy in well drilling and communication with telemetry, which makes it possible to observe the operation of the equipment. When using the RSS, not only the bit, but the entire drill string rotates, and due to the opening of special blades in the desired sector, drilling control is achieved with the maximum accuracy of well drilling. Telemetry provides remote collection and measurement of geological information in wells using special instruments.

V. Yakovlev, Deputy Chairman of the Management Board of Gazprom Neft, noted the importance of Russian technological solutions for maintaining stable production and developing hard-to-recover oil reserves (TRIZ). Therefore, Gazprom Neft, together with partners, continues to develop and test various domestic systems at our fields, incl. for drilling and telemetry. The goal of the project with the New Service Company is to further launch the mass production of equipment that can be used by the entire oil and gas industry.

RSS became one of the first areas of import substitution in high-tech drilling. In 2015, 2 Russian manufacturers Elektropribor and NPP Burintekh completed the stages of conceptual development and design and entered the borehole testing of prototypes of domestic RSS. Gazprom Neft tested the RSS of both manufacturers.

In 2015, the rotary-controlled assembly RUK-8.75BS manufactured by the Elektropribor enterprise passed pilot tests at the Vyngapurovskoye field in the YaNAO. Test results reported that the equipment performed well in response to signals and commands from the surface, and the assembly was able to control the trajectory in the hole with continuous rotation of the bottom of the drill string. The total penetration was 216 meters, the average speed was 29 m/h.

RUS-GM-195 NPP Buritntekh Gazprom Neft was tested at the Yuzhno-Priobskoye field in Khanty-Mansi Autonomous Okrug. The first prototype was tested at the Yuzhno-Priobskoye field in February 2017, and in October 2020 the final tests were carried out, confirming the reliability of the domestic system. With the help of the RSS, a section of the well was drilled with a length of 1920 m (from 1560 to 3480 m).

The construction of the well section was carried out without deviations from the design profile, the final zenith angle of the drilling interval was 85.75