Gazprom Neft Launches 3D Printing for Oil Field Equipment

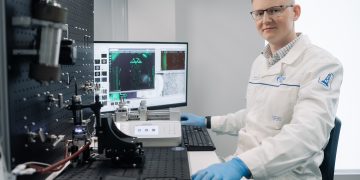

Gazprom Neft has started using a 3D printer at an oil field in the Arctic. Using the device, engineers create new parts and spare parts for upgrading equipment and repairing equipment – previously, important components had to be ordered from other regions.

The project is part of Gazprom Neft’s program for developing 3D printing services: more than 3.5 thousand different parts made of metal, plastic, and other materials have already been manufactured under it. In addition to oil fields, they are used at the company’s factories, bunker ships, and icebreakers.

The installation of a 3D printer at the Gazpromneft-Zapolyarye field has increased the technological reliability of oil production processes in the Far North. In the event of equipment breakdown or wear, several hours or days pass from the start of printing a replacement part to its installation. Previously, the delivery of components took months due to the autonomy of the oil field, located 160 km from the nearest city and logistics infrastructure.

Vladimir Krupenikov, CEO of Gazpromneft-Zapolyarye:

“Our company is constantly introducing modern technologies that are necessary for working in the Far North. Now, with the help of 3D printing and a 3D printer, we will be able to speed up the delivery times for components and equipment maintenance – as a result, we will optimize logistics costs and increase the productivity of our equipment without downtime for repairs and upgrades. This is one example of how new engineering solutions can improve the efficiency of implementing hard-to-reach Arctic projects.”

Danar Podkopaev, Head of Additive Technologies at Gazprom Neft:

“Placing a 3D printer at the production facility itself solves several problems at once: it ensures continuous operation due to the prompt creation of spare parts and eliminates logistics costs for enterprises in the Far North. In addition, with the help of 3D printing, we can create parts that previously could not be purchased separately from the entire device.”