Gazprom Neft: Successfully Tests BURINTECH’s Rotary Steerable System

The Russian rotary steerable system (RSS) was successfully tested at the Yuzhno-Priobskoye field of Gazprom Neft. The equipment is designed for drilling complex wells with a large length of horizontal and directional sections. Duplication of the technology will significantly reduce the cost of equipment and improve the economics of the well construction process.

In rotary drilling, in contrast to traditional drilling, not only the bit rotates, but the entire drill string as well. Rotary steerable systems allow in the process of string rotation to quickly change the drilling trajectory, achieving maximum accuracy of well placement and oil production efficiency.

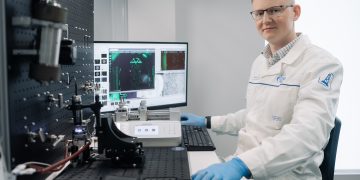

The rotary steerable system RUS-GM-195 for well drilling was developed by the Russian research and production enterprise BURINTECH and tested at the assets of Gazprom Neft. The first prototype passed tests at the Yuzhno-Priobskoye field in February 2017. Final tests in October 2020 confirmed the reliability of the domestic system. Using RSS, a section of the well over 1900 m long was drilled.

Like the existing imported rotary steerable systems, the new development can be used for drilling all types of wells. The start of serial production of RUS-GM-195 is scheduled for 2021.

“I am pleased with the successful completion of tests of the Russian rotary steerable system – one of the most common standard sizes, the share of which is used in the domestic drilling market is more than 10%. In the future, this will make it possible to switch to the development of more compact and high-tech standard sizes, which will almost completely satisfy the market demand for Russian technologies, ”said Mikhail Ivanov, Deputy Minister of Industry and Trade of the Russian Federation.

“We work with complex reserves, the share of which in our portfolio is growing from year to year. High-tech equipment is required for their successful development. The use of domestic development will allow us to reduce the cost of drilling complex wells and improve the economics of projects, and hence our competitiveness, which is extremely important in today’s economic conditions. Independently and together with partners, we create and apply many new technologies, tools and equipment at our fields. In addition, for the first time in the industry, we have introduced the format of technological polygons, where Russian companies can test their advanced developments. This allows not only to increase the stability of the entire industry, reducing dependence on imported equipment, but also to obtain tools, Vadim Yakovlev, Deputy General Director for Exploration and Production of Gazprom Neft.

“BURINTECH has been producing high-quality tools for drilling and well workover for over 20 years. Successful tests of the RUS-GM-195 system, despite severe restrictions in a pandemic, are successful tests of the entire company, whose team managed to mobilize, adapt and work out for results. We have created a unique product that can be applied to all types of wells, is reliable and easy to operate. The Industrial Development Fund of the Russian Federation rendered great financial support to us, having allocated a loan for the development of the RUS-GM-195 system, thanks to which the project gained life and prospects, – said General Director General Director of NPP “BURINTECH” Gniyatulla Ishbaev.