Gazprom Neft: The Competency Leader in Multi-stage Hydraulic Refracturing Operations

Since 2011, most of the newly-commissioned wells delivered by Gazprom Neft’s drilling units have been horizontal wells (HW) with multi-stage hydraulic fracturing (MSHF). To date, about 2,700 horizontal wells with MSHF, equipped with ball-drop-activated “packer-and-port” liner assemblies (uncemented), have been drilled in the Company’s fields, out of which about 800 are equipped with reusable frac sleeves.

Over time, the productivity of such wells tends to decrease gradually under the influence of various geological and technological factors (withdrawal of solids, perforations filling with loose rock fragments, fracture clogging with proppant pack material (due to its embedment into plastic rocks and crushing under stresses), asphaltene deposits, salts, etc.). It is, thus, apparent that one of the most pressing challenges facing Gazprom Neft’s specialists today is how to develop more reserves and increase oil recovery through repeated stimulation of horizontal wells with MSHF.

The main reasons for carrying out repeated HF operations (refracs) are:

• A decrease in well productivity during the production phase (as indicated earlier);

• Instances of premature injection termination (screen-out alerts) and other premature work completion scenarios (with deviations from the program);

• Stimulation of ports skipped during the initial treatment.

The following criteria are recommended for refrac candidate selection:

1. Reservoir pressure PR – not lower than 0.6 x PR (initial);

2. Water cut percentage – not more than 80 %;

3. Residual reserves – more than 5,000 tonnes;

4. Current skin factor – higher than -3;

5. Shale barriers at least 15 m thick separating gas- and water-saturated sublayers;

6. Remoteness from the water-injection front;

7. Existence of an interval which has not been stimulated during the first-time frac treatment.

The technological challenge lies in the fact that the typical well designs that have become common (“ball-type” liner assemblies with non-reusable MSHF sleeves) do not provide for repeated stimulations, which creates the following difficulties in the selection of re-stimulation technologies:

• Port control functions are not available;

• Selective interval treatment is not possible without the use of additional technologies;

• No predictions are made for the secondary fracture initiation point and propagation direction;

• Existence of intervals at which the liner assembly diameter narrows.

This status quo dictates the following two paths for further development:

1. Selection of refrac technologies that will work on currently-used assemblies;

2. Selection of alternative well completion methods.

Today’s market for oilfield services related to hydraulic fracturing offers a fairly large number of technologies and approaches for carrying out repeated MSHF operations. All of them, without ex-ception, deserve due attention, but are they all workable and versatile?

Work aimed at answering this question and selecting a refrac technology optimized for the condi-tions specific to Gazprom Neft’s fields began as early as in 2014 (see P. I. Kryukov, R. A. Gimaletdi-nov, S. A. Doktor, I. G. Fayzullin, R. G. Shaykamalov. Optimizing the repeated multi-stage hydraulic fracturing technology // Neftyanoye Khozyaystvo. – UDC 622.276.66.02. – 2015. – No. 12. – pp. 64–67).

This line of work is ongoing to this day and is continuously enhanced with new experience, tech-nologies, and solutions for carrying out re-stimulation operations on HWs with MSHF. Pilot tests are being carried out to identify the optimal technology for refrac projects.

This work has made it possible to select several solutions that can be used on the producing well stock as well as in new well projects to be commissioned.

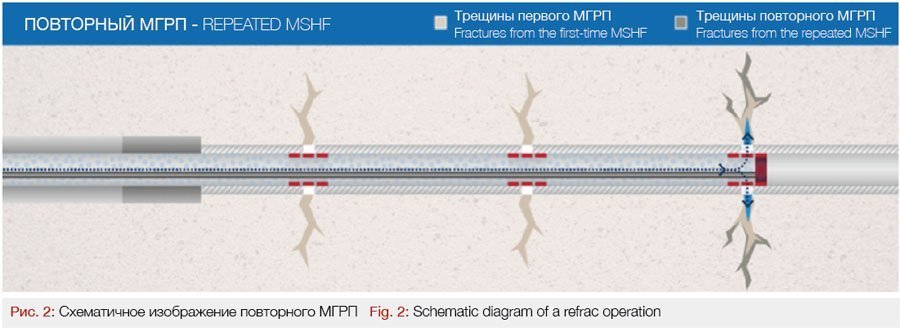

Repeated MSHF Technologies Using Run-in-Hole (“Ball-Type”) Assemblies

One of the most important stages in refrac implementation is the preparation of the well, which includes:

• Milling the seats and balls (if this work had not been performed before the well was put into production);

• Reaming the wellbore;

• Cleaning the wellbore using a junk basket;

• Flushing the well until the fluid reaching the surface is of the required quality;

• Optionally, the wellbore can be cleaned using the jet-flushing technique: it removes the sand and solids present in the tubing (paraffins, asphaltenes, soluble solid impurities, and cement);

• Frac projects that involve additional run-in-hole operations require that the liner section of the well be drift-tested using a simulator of the assembly (to verify the diameter and length conformity with a view to avoiding accidents during the run-in-hole/pull-out-of-hole (RIH/POOH) operations performed on the dual-packer assembly).

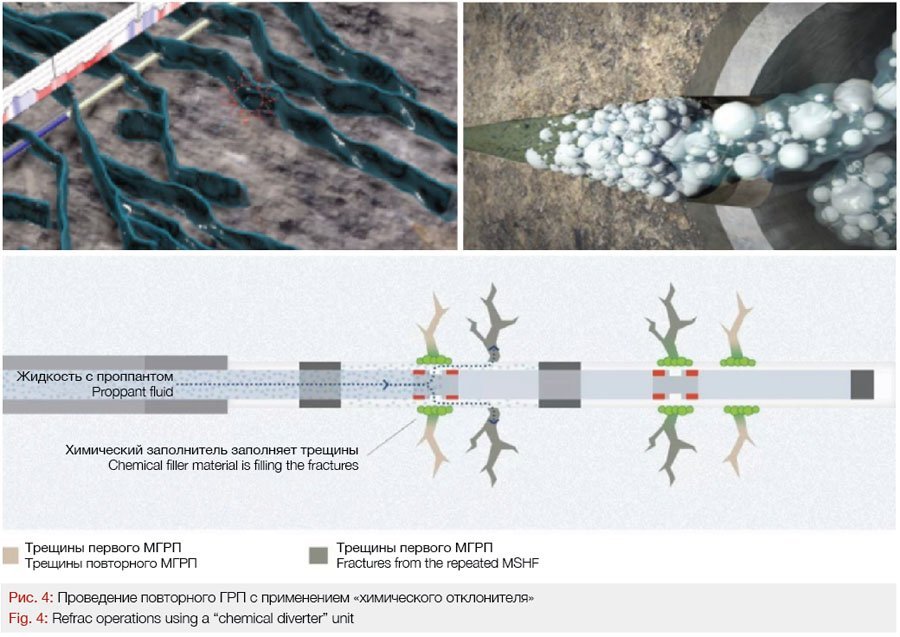

1. Dynamic-Diversion Technology

One of the refrac technologies that have been tested uses the so-called “dynamic diversion” method. This technology makes it possible to carry out re-stimulation projects on the existing HW stock with MSHF (uncemented liners). Its key idea is to block the existing, previously stimulated fractures with degradable material and then to start selectively injecting frac fluid into the existing intervals, one by one. If a decision is made to stimulate new zones along the horizontal wellbore, this is achieved using the hydro-sandblasting perforation (HSP) method.

The fluid used in the dynamic diversion process works as follows: large particles are blocked at the mouth of the fracture, small particles reduce the permeability of the pill material for temporary isolation of the fracture, the fibers consolidate the pill; the time it takes for the blocking pill to decompose depends on its size and on the reservoir temperature.

The typical work procedure is as follows:

• Carrying out thermometry testing to identify the depleted zones, i. e. recipient intervals (studying the temperature profile of the horizontal wellbore);

• Injecting the diverter fluid and blocking the existing fractures (recipient intervals);

• HSP (optional);

• HF;

• Carrying out thermometry testing to identify the location of a new fracture obtained via HF by identifying temperature abnormalities (studying the temperature profile of the horizontal wellbore);

• Completing the cycle again as many times as required;

• Bringing the well on-line;

• Dismantling and demobilizing the frac fleets and coiled tubing (CT).

The Company has implemented this technology:

• At 3 wells drilled in the Vyngapurovskoye field operated by Gazpromneft-NNG (5, 4, and 4 stages, respectively) – Phase 1;

• At 2 wells drilled in the Yuzhno-Priobskoye field operated by Gazpromneft-Khantos (4 stages each) – Phase 2;

• The greatest success was achieved at 3 wells operated by Slavneft-Megionneftegaz (3, 2, and 3 stages, respectively).

This technology has proven to be a workable solution, but at the same time has demonstrated the following limitations:

• Risk of fracture propagation in the interval where the blocking pill is located;

• Risk of fracture propagation into the depleted zones of the reservoir;

• High cost of work due to the need to use a CT system for thermometry;

• Inconsistent production results call for a revision to the candidate well selection criteria.

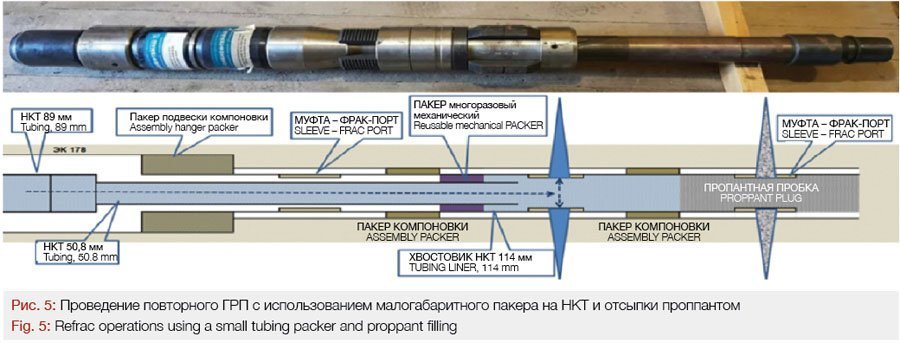

2. Technology Using a Small Tubing Packer and Proppant Filling

Re-stimulation operations using a small tubing packer and proppant filling.

The typical work procedure is as follows:

• High-quality well preparation, drift testing to avoid accidents during the RIH/POOH operations per-formed on the small packer;

• Setting the small packer to cut off the upstream frac ports that are open;

• Carrying out the “substitution” operation, determining the injection capacity;

• Injecting the minifrac fluid;

• Carrying out the main frac treatment with proppant under-flushing (at the final stages, the concentration should be quite high – 2000 kg/m3);

• Waiting for the fracture to close and compacting the proppant pack;

• Resetting the packer (by the well workover crew, WWO) to the next interval,

• Repeating the cycle as many times as required;

Despite the apparent simplicity and the use of “standard” equipment, this technology has a number of significant limitations.

• High requirements for the wellbore preparation quality (milling of seats and balls);

• Risk that the small packer will get stuck and damaged; wear and tear of the elastomer material used in the RIH/POOH operations;

• Additional costs associated with the use of coiled tubing and RIH/POOH operations by the WWO crew.

At the same time, there is no guarantee that any stage will be properly isolated (leaks into the previously-stimulated intervals are possible, screen-out risk is a concern).

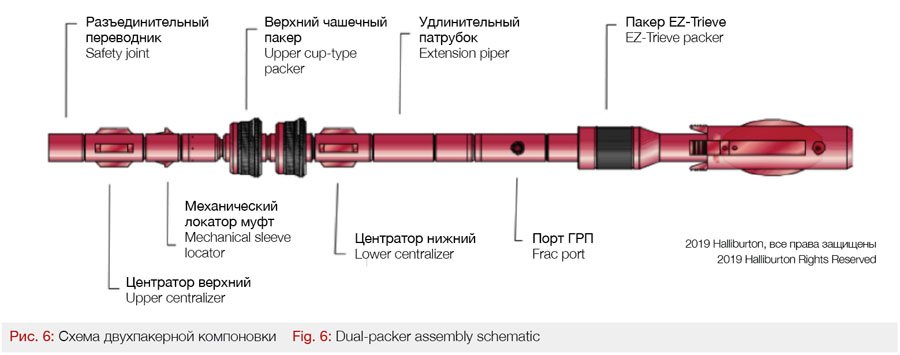

3. Frac Technology Using a Dual-Packer Assembly

Using a dual-packer assembly. The tool is a reusable assembly, the upper packer is a cup-type device equipped with nozzles for HSP operations (optional), suitable for handling an unlimited number of stages.

The typical work procedure is as follows:

• Preparing the wellbore;

• Running the tool into the required interval, positioning;

• Sealing the tool;

• Carrying out HSP;

• Activating the cup-type packer;

• Testing for injection capacity;

• Conducting the main frac treatment;

• Unsealing the tool and switching it to the transport position;

• Going up to the next interval.

• Setting the packer;

• Repeating the cycle as many times as required.

Thanks to to the availability of a dual-packer system making it possible to isolate the desired in-terval, this tool can be used to carry out refrac operations on existing “ball-type” assemblies. Such work was successfully implemented at three wells drilled in the fields operated by Slavneft-Megionneftegas:

• 1 well – 3 frac stages preceded by HSP operations, 25 tonnes of proppant each (114 mm cemented liner of constant cross-section).

• 1 well – 3 frac stages using existing ports, 25 tonnes of proppant each (114 mm, uncemented liner, drilling through “ball couplings” was required);

• 1 well – 3 frac stages using existing ports, 15 tonnes of proppant each. A sidetracked well (102 mm, uncemented liner, drilling through “ball couplings” was required).

Slavneft-Megionneftegas successfully used a similar assembly during the initial frac treatment in constant-cross-section liners equipped with “burst” frac sleeves (the sleeve is activated and the perforation holes open when a certain pressure is created) at three wells, 8 stages each (5–7 tonnes of proppant per stage).

Dual-packer assemblies have also been used for re-stimulation projects at wells operated by Gaz-promneft-Yamal, whose liner designs comprised sections of annular casing packers and filters.

The tool run-in-hole and pull-out-of-hole (RIH/POOH) operations were carried out by the WWO crew: the wellbore was prepared in advance (reaming and conditioning of the intervals where it was planned to position the cups and to set the assembly itself, drift-testing of the horizontal por-tion of the wellbore, flushing the sand screen using a jet-flushing nozzle, and removing the wall packing layer in the bottom-hole zone of the formation). Next, before the commencement of the work, the assembly is located above all the filters in the “dead string” section (to prevent any cross-flow through annular casing packers), and its cups are pressure tested. If the pressure test is successful, the assembly is then lowered to the required interval, its cups are positioned between the filter sections, and the frac operation is carried out. This experimental project was unique in how the assembly was put together in such a way that the distance between the cups was equal to the length of the filter section (which, in this case, matched the length of the perforation interval for hydraulic fracturing) – i. e. 140 and 170 m.

RIH/POOH operations for the dual-packer assembly can be performed on both conventional and coiled tubing. The use of this technology is associated with a high risk of the assembly getting stuck and damaged; also, the elastomer material used in the RIH/POOH operations is exposed to high wear and tear. Where a screen-out alert has been received, there are high risks associated with possible unsealing of the dual-packer system and the proppant being washed out.

4. Re-stimulation Technology Involving “Ball-Type” Assemblies with Reusable MSHF Sleeves

With the full-scale rollout of the MSHF technology using “ball-type assemblies,” as we voiced our concerns about the upcoming work involving the re-stimulation of wells with non-reusable “ball-type” frac ports, some of the manufacturers promptly responded and went proactive. About 30 % of the assemblies delivered and distributed down the Company’s supply chain after 2015 turned out to be equipped with reclosing/reopening functionality.

After three years of work at Gazpromneft-Khantos, the time has come to refrac these HWs with MSHF, and such work began in 2018.

A well previously subjected to a 7-stage MSHF treatment (1 hydraulic port and 6 frac ports) was prepared, the seat pockets (for the balls) were milled, the borehole was cleaned and drift-tested.

The initial plan was to close all the sleeves, test them for leak-tightness, then to open them one by one, carry out the refrac operation, and then close the sleeves in the following order: 1, 3, 5, and 7.

The first attempt to close the sleeves was carried out using a special CT-deployed single-packer assembly. Despite the high-quality preparation of the wellbore, work progress was hindered mul-tiple times due to dragging and sticking problems; also, the assembly demonstrated numerous operational abnormalities associated with inadequate leak-tightness of the reusable packer. Out of the 6 frac ports, it was found possible to close only 2: 7 and 6.

Next, an attempt was made to replace the assembly with a special impact-action hydraulic wrench capable of delivering large loads to the port and producing shock action. However, these attempts also proved unsuccessful.

According to the manufacturer, the reason why the wrenches have failed to produce the desired action on the frack ports was most likely that this equipment is quite sensitive to the presence of proppant and foreign objects (various fragments that emerged during the milling of the assembly and exploitation of the well) in the wellbore. Yet another factor that may have contributed to the failure is a design defect in the reusable sleeves themselves (jamming of the sleeve cylinder).

The decision made regarding this well was to continue the re-stimulation work using bridge plugs to cut off the lower intervals that were open. Work on this project is currently still in progress, and these are just the first steps in doing this kind of work, so it is too early now to call it a day and draw any conclusions about the functional capability of reusable ball-type frac ports.

MSHF Technologies Applicable for Alternative Completion Configurations

In view of the foregoing, it can be concluded that the lessons learned from the refrac operations carried out on the producing well stock have made it clear that we need to change our very ap-proach to well construction, namely, to switch to cemented liners of constant cross-section with reusable frac sleeves.

As early as in 2014, at almost the same time that the first attempts were made to carry out refrac operations on “ball-type” assemblies, Gazprom Neft pioneered the construction of next-generation horizontal wells which can eliminate the main restrictions that are currently in the way of refrac projects.

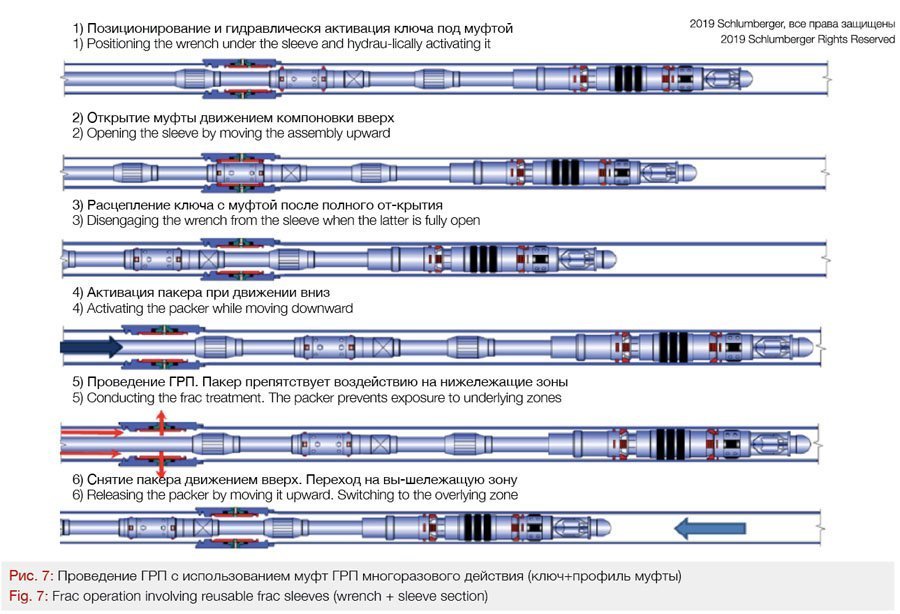

Ball-Free MSHF Technology with Reusable Sleeves of Constant Cross-Section

One example of the new approach is the construction of horizontal wells equipped with cemented liners of constant cross-section with reusable MSHF sleeves. The sleeves are controlled via a special CT-deployed wrench.

The typical work procedure is as follows:

• Closing all the ports in the course of one RIH/POOH operation;

• Opening the required frac sleeve;

• Raising the CT or lowering it below the stimulated interval;

• Conducting the frac treatment;

• Closing the sleeve;

• Switching to the next sleeve and repeating the work cycle.

The main advantages of this approach are as follows:

• The number of stages is conditionally “unlimited” (if there is a risk that the fracture will break into closely located gas- or water-bearing zones, the developer can reduce the tonnage and increase the number of stages to achieve the planned production parameters);

• A wellbore of constant cross-section (reducing the risk of accidents and sticking problems, the abil-ity to analyze the functioning of the frac ports);

• Because the liner is cemented, the fracture will be initiated opposite the frac sleeve within a predetermined interval (no cross-flow behind casing);

• Selective stimulation of the required interval is possible;

• Well control (closing the reusable sleeves) is possible if there is a water or gas breakthrough;

• No restrictions on the frac design (concentration, flow rate, tonnage, etc.).

The following risks exist:

• Possible sticking problems during CT operations;

• High costs associated with the use of CT.

The technology was implemented at four wells operated by Gazpromneft-Yamal:

• 2 wells, 27 and 30 MSHF stages, respectively;

• 2 wells, 8 MSHF stages each;

8 wells (8, 12, and 21 stages) are awaiting frac treatment. A number of refrac projects using this technology have been planned for the near future.

Despite the fact that the Company has no history of successful refrac implementations with reusable ports, this technique is currently one of the most promising approaches to well construction and hydraulic fracturing, which is confirmed by its technological as well as economic efficiency.

Conclusions

The search for a refrac tool that can work on assemblies currently used in HSs with MSHF is in progress to this day.

The question of whether reusable MSHF sleeves can reliably be used in refrac operations, 3–5 years later, is still open. Pilot testing of a refrac technology involving reusable ports is expected in the near future.

A comparative analysis of economic efficiencies derived from the implementation of repeated MSHF operations has also demonstrated the superiority of ball-free technologies inasmuch as they obviate the need for accident-prone work required to drill through the liner accessories and to normalize the bottom-hole environment using a CT system.

For the existing HW stock with MSHF, the technology we can highlight as one of the sensible solutions on the market is: the MSHF technology using a CT-deployed dual-packer assembly.

An analysis of technologies that can be used on newly-commissioned HWs with MSHF has shown that the most promising avenues for the implementation of repeated MSHF operations on HWs are the construction of cemented liners of constant cross-section equipped with reusable slider-type sleeves as well as the transition to ball-free technologies and assemblies based on soluble elements, which suggests a revision to the current well completion approaches.

Bibliography:

1. Методический документ ПАО «Газпром нефть»: Методические указания на проведение работ по многостадийному(многозонному) ГРП на месторождениях Компании. М-01.05.07-03 [Guidance document of Gazprom Neft: Guidelines for carrying out multi-stage (multi-zone) hydraulic fracturing at the Company’s fields. М-01.05.07-03]

2. Крюков sП. И., Гималетдинов Р. А., Доктор С. А., Файзуллин И. Г., Шайкамалов Р. Г. «Оптимизация технологии повторных многостадийных гидроразрывов пласта» // Нефтяное хозяйство. – УДК 622.276.66.0. – 2015. – № 12. – С. 64–67 [P. I. Kryukov, R. A. Gima-letdinov, S. A. Doktor, I. G. Fayzullin, R. G. Shaykamalov. Optimizing the repeated multi-stage hy-draulic fracturing technology // Neftyanoye Khozyaystvo. – UDC 622.276.66.02. – 2015. – No. 12. – pp. 64–67].

3. Images owned by:

1 & 2 – Gazprom Neft;

3 – Schlumberger + Gazpromneft-STC;

4 – Sibneftemash + Gazpromneft-STC;

5 – Halliburton;

6 – Schlumberger.

Article Authored By:

Konstantin Vladimirovich Kulakov

Chief Development Officer, Drilling and Downhole Operations Function, Gazpromneft STC.

Sergey Viktorovich Tishkevich

Head of Downhole Operations Department,

Gazpromneft STC.

Anatoly Dmitrievich Ostashuk

Area Manager, Downhole Operations Department, Gazpromneft STC.

Stanislav Yuryevich Barkalov

Chief Specialist, Downhole Operations Department, Gazpromneft STC.

Published with thanks to Gazprom Neft & PROneft Magazine