Gazprom Neft: The Development and Implementation of Remote Intelligent Subsurface Hydrodynamic and Geophysical Monitoring Systems

Introduction

The project was performed between 2012-2018 as a part of dedicated science and technological program of Gazprom Neft by two of its subsidiaries: The Science and Technology Center of Gazprom Neft (theoretical and procedural framework, data processing and analysis, development of software and algorithms) in conjunction with Gazpromneft – Khantos LLC (development and implementation of technology, field well tests).

Technologies for hydrodynamic and geophysical monitoring of tight reservoirs in Russia and abroad

A prompt, robust, cheap, and flexible digital technology for the efficient control over the development and monitoring of oil production wells has not existed in Russia until recent times. This problem became particularly challenging in recent years due to the increased development by oil producers of horizontal wells multi-stage fracturing and development of tight reservoirs with unconventional reserves.

In fact, neither has similar universal technologies that have been developed abroad – the cost of existing hi-tech systems for permanent remote geo-monitoring is so high that they are only implemented at selected offshore wells that are being developed from platforms.

In Russia each oil producing company strives to increase the monitoring efficiency of development and production of their hydrodynamical and geophysical wells using various means of technology. As a rule, they employ generally known approaches to data interpretation and analysis that are not suitable for subsurface remote information and measurement systems (IMS) as neither have been customized for this application. Besides the corresponding state regulatory documents haven’t been issued.

Subsidiaries of Gazprom Neft that face an increasing share of unconventional reserves in their portfolios could benefit from an intelligent completion system in hi-tech wells and permanent remote digital monitoring of the bottom-hole area. In order to realize this potential, it’s

required to:

• Find a way to reduce the costs of equipping wells with permanent subsurface information and measurement systems.

• Define approaches to extract robust quantitative data sets which are required to perform historical matching of the hydrodynamic models for the well-formation system out of seemingly redundant datasets of permanent remote geo-monitoring.

Compliance with conditions specified above is essential to maximize the economic benefits of digitalization and optimization development, through the operational management of the well life cycle. However, the goal of equipping production wells with systems for permanent hydrodynamic and geophysical monitoring is not limited to digitalization efficiency and well diagnostics.

A crucial technological target is to reduce production losses associated with the need for long downtimes in productions that are required for carrying out geophysical logging and hydrodynamical testing – studies that are required in Russia in the licensing arrangements and state regulatory documents in order to achieve the goals for the fields development. Let’s revise one of the typical sides of the issue. In order to satisfy the requirements for conventional well testing (pressure recovery curve logging with quantitative estimations of instant effective permeability and skin-factor of near-wellbore formation zone, refinement of formation’s geometry, adjacent wells’ influence etc) as per valid industry-specific regulatory documents, a well which produces from low-permeable formations with absolute permeability of 0.1-2.10-3 um2 – which corresponds to unconventional reservoirs – must be shut down for dozens of days or even for several months (if a radial flow regime is under consideration).

Systems for permanent geophysical and hydrodynamical monitoring that have been sporadically implemented within various oil producing companies prompted the development of an innovative technological trend amongst oil and gas engineering disciplines namely permanent remote hydrodynamic and geophysical monitoring of production wells.

As a rule, oil producers intentionally don’t perform full-scale well tests at unconventional reservoirs. This practice basically either reduces the required volume of well testing logging or compromises its results.

Consequently, the development targets state of exploration, the efficiency of geological and technical operations based on the results of the well test (including drilling of new wells) and solutions for the optimization of the fields development are affected.

A similar situation has arisen in the domain of production logging especially in hi-tech wells, due to increased volume, by most Russian oil producers, in the drilling of horizontal wells (including multilateral wells and horizontal wells with multi-stage fracturing) which has resulted in increased cost for conventional well logging. This is because the hi-tech delivery of geophysical tools into an elongated (1-2 km) horizontal wellbore together with a stimulation treatment during drawdown which has been induced by the electrical submersible pump is required. These technologies are quite costly which highlights the need for real-time wellbore measurements via geophysical and hydrodynamical sensors which have been permanently embedded into the completion and lifting systems. Technologies for the permanent geophysical and hydrodynamical monitoring that have been sporadically implemented within various oil producing companies and have pushed the creation and development of a new technological direction in the oil and gas field – permanent remote hydrodynamic-geophysical monitoring of production wells.

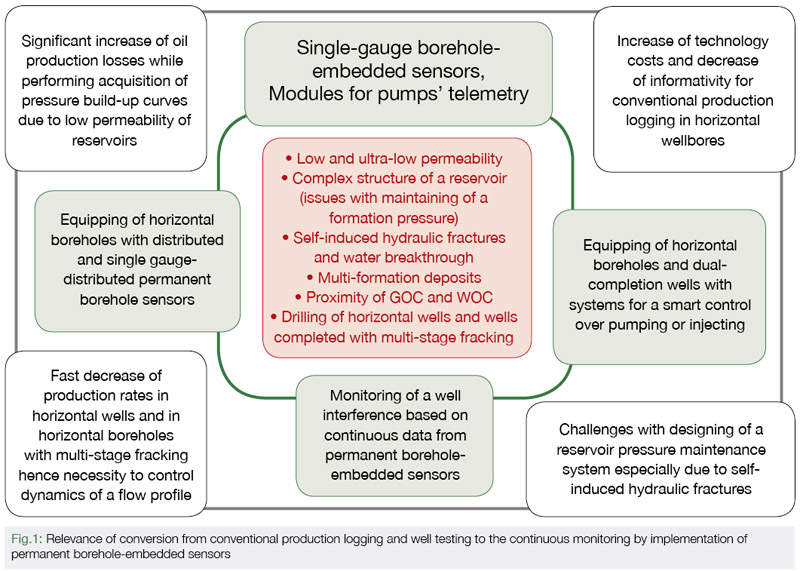

This trend has also become of a consideration for Gazprom Neft due to company’s transition to the development of low-permeable unconventional reservoirs where conventional well logging and well testing suites are not efficient enough. The need to change over from conventional well logging and well testing to remote hydrodynamic and geophysical monitoring based on permanently installed wellbore sensors (logging-while-production, LWP) is illustrated at Fig. 1.

Stage I (before 2014) of the development of the technology involved the upgrading of the embedded pressure and temperature sensors for the pumping systems telemetry that had been initially designed to control the operating parameters only. A comprehensive set of measures taken by Gazprom Neft in order to replace the indicator sensors with certified high-sensitivity pressure and temperature gauges and to expand the memory of logging devices has allowed the direct access of remote wellbore pressure logging data and wireless transmission of this data to the processing centers.

Therefore, completion of Stage 1, the technology development, which required installation of single-gauge permanent wellbore sensors, allowed for the realization of so-called ‘passive experiment during reservoir development’ concept. The latter stipulates for maximizing the use of digital measurement and telemetry systems which have been integrated into downhole equipment for remote diagnostics and control over wellbore conditions. As a result, within core assets of Gazprom Neft the following targets have been achieved:

• Abandonment of ultrasonic scanning measurements for estimation of bottom hole pressures out of drawdown levels that were not always showing adequate results.

• Realtime monitoring of wellbore conditions with high precision: sensitivity range of certified pressure gauges is currently 0.0001-0.001 MPa;

• Over 95% of scheduled well testing activities in operating well stock are currently performed using permanent single-gauge measurement systems without engaging of wireline services;

• Approaches and software algorithms have been developed that allow elimination of using costly technologies based upon logging of lengthy pressure build-up curves with logging of long-term pressure-level curves – which starts immediately after a well becomes an active stream and can last for many years; these measurements are accompanied by logging the build-up curves during the well’s operational shutdowns.

The results at the Gazpron Neft sites, even after the completion of just the initial stage of implementing single-gauge permanent sensors, has resulted in multiple cuts in oil losses that had previously occurred due to forced shutdowns of the productions wells, without loss of information and the quality of the well records themselves. As a result of being able to remotely control the ESP pump rate in conjunction with continuous wellbore data, including wellbore pressure measurements and nonstationary well testing loops transmitted by surface wireless telemetry systems – it has become possible to perform prompt operational control over production processes and to quantitatively ground optimum operation performance for a whole lift system comprised of a well and formation(s). This technological principle concept of a Smart Well or the “smart (digital) well” is widely publicized and discussed in the world today.

Major implementation of the ‘Smart Well’ concept at Gazprom Neft assets, was completed and most production wells were equipped with pumping systems in 2014. This allowed a significant reduction in the planned losses in oil production associated with well testing and logging of the wells production, to obtain the economic benefits in the framework of the integrated technology and controlled development of the oil fields (both for vertical and directional wells. The specified effect is achieved due to:

• Targeted boosting of the water injection system;

• Conformance control with prevention of water breakthrough via so-called unstable self-induced hydraulic fractures;

• Optimization of the pumps performance;

• Selection of candidate wells for re-fracking and other factors.

A comprehensive set of measures taken by Gazprom Neft in order to replace the indicator sensors with certified high-sensitivity pressure and temperature gauges and to expand memory of logging devices has allowed for direct method for remote monitoring of wellbore pressure and wireless transmission of this data to processing centers.

Single-gauge permanent sensors for wellbore hydrodynamic and geophysical monitoring have been developed at Gazprom Neft assets between 2014-2018. They allowed the addressing of the above listed challenges and for basing the well intervention strategies upon the well monitoring data. Cumulatively these measures resulted in significant economic benefit in the form of incremental oil production. For instance, at the Yuzhno-Priobskoe oilfield the annual oil production increase is currently estimated at 880 thousand tons, not counting the effect of lower operating costs.

Sensors, distributed over horizontal wellbores also increased the information and the cost efficiency of permanent geo-monitoring systems. These sensors can be designed in the following ways:

• Fiber optic sensing cables (mainly leveraged on DTS technology for thermal field measurements based on Raman scattering) [1];

• Single-gauge-distributed indicator systems embedded into inflow mandrels (ports and filters) of BHAs for horizontal wells completions.

Currently permanent sensors of the above-listed types are subject to active testing by Gazprom Neft and other major oil producers both in Russia and worldwide. Apart of their individual customization it’s very important to work out a strategy for their implementation at oilfields which should account for conducting specific studies, describe data acquisition technologies and suggest methods for data interpretation and analysis that take advantage of dedicated digital simulators which take into account and correctly evaluate the physical chemical processes.

In the authors opinion, an increase in the efficiency of an oil and gas fields development is possible by sophisticated implementation of monitoring systems that have already been effective customized and approved and validated by experts. To that effect, experts at Gazprom Neft in 2012-2018 were performing systematic selection, testing, customization, estimation of informativity and the installation of application-specific technological equipment and hardware components of single-gauge and distributed wellbore-embedded sensors.

The results of this long-term study and theoretical justification for the remote permanent geo monitoring of production wells have been summarized among others within a monography issued by a team of experts from Gazprom Neft Science and Technology Center’ [2]. This monography incorporated essential process solutions and mandatory requirements for equipping production wells with systems of single-gauge and distributed remote-operated sensors; it also contained algorithms for interpretation and analysis of corresponding digital information.

Results of the practical implementation of an integrated system for hydrodynamic and geophysical monitoring within Gazprom Neft

Work on implementing the integrated system for hydrodynamic and geophysical monitoring included:

a) Conceptual design of studies to be performed at the various stages of the system’s deployment including theoretical justifications and execution processes; same regarding implementation of the system in order to optimize field development;

b) Statement of problems that require solutions in order to create the efficient system for permanent monitoring of producing oil wells;

c) Development of regulatory and guidance documents, algorithms and software to perform acquisition, processing, quantitative interpretation and documenting of continuous digital monitoring data and to evaluate the obtained results (including big data processing algorithms);

d) Development of technology for implementation of permanent wellbore sensors sets; statement of requirements to deployment and coverage of backbone survey networks;

e) Upgrade of equipment and measuring systems related to wellbore permanent sensors;

f) Field tests of equipment, technologies and hardware at various types of production wells (vertical, horizontal, with multi-stage fracking etc.);

g) Development of technology for estimation of obtained logs informativity; development of algorithms for log interpretation as applied to basic types of permanent wellbore sensors;

h) Composing of patents portfolio based upon solutions developed for designated tasks.

At the initial stage of implementation on Gazprom Neft assets a system of single-gauge permanent wellbore sensors embedded into standard pumping equipment was universally deployed. This allowed for remote continuous monitoring of bottomhole pressure and the prompt transfer of information back to the data processing centers. Scheduled well testing programmes have been completely revised due to the introduction of certified pressure gauges with increased sensitivity (up to 0.0001-0.001 MPa). As a result, scheduled well testing procedures in production wells are performed without engaging of geophysical services and prevent long-term well shutdowns. Moreover, switching to real-time monitoring of pressure has allowed for additional realtime control of the following parameters:

• Changes in reservoir pressure;

• Dynamics of a skin-factor (indicator of a near-wellbore zone contamination);

• Effect of adjacent production and injection wells – controlling of this parameter allows for preventing of water breakthrough from injection wells thus achieving leveling of oil displacement front by water.

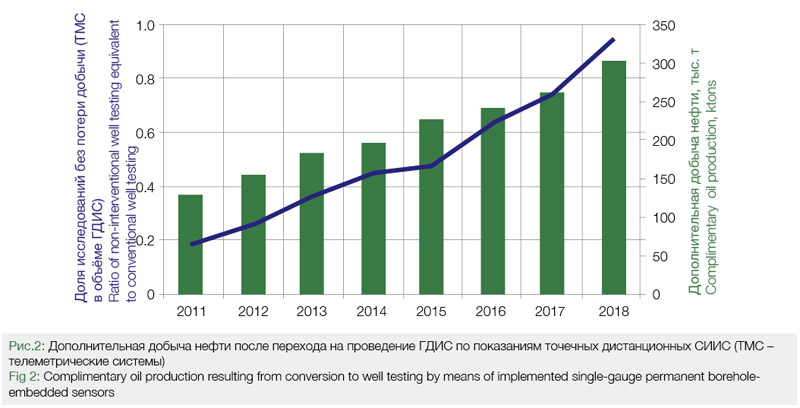

At this stage, the implementation of simple single-gauge remote wellbore sensors led to multiple oil production savings by eliminating losses that had resulted from long-term shutdowns of production wells (Fig. 2).

Gazprom Neft was the first company in Russia to implement this innovative technology and the Yuzhno-Priobskoe field was chosen as a testing facility. Implementation of the technology allowed for: abandoning bottomhole pressure detection out of dynamic levels which resulted in wrong results; performing well tests on almost 100% of operating well stock; estimating well interference (observation well testing), dynamics of skin-factor and bottomhole pressure. Company’s experts defended in ‘Rosnedra’ Central Commission for Reserves (protocol #3820 dated 14.09.2006) a technology for replacement of long-term pressure and level build-up curves’ acquisition with long-term level stabilization and short-term level build-up (during routine stops of electric submersible pumps) curves’ acquisition. This technology was later registered as a patent. Taking the Yuzhno-Priobskoe field as an example (annual oil production in 2018 comprised more than 11 409 thousand tons) where annual complimentary oil production due to implementation of single-gauge wellbore sensors is estimated at 880 thousand ton. It can be concluded that optimization of oil production driven by the technical means that have been already deployed cumulatively results in 7.7% of field oil production. Components comprising economic benefit are the following: optimization of pumps performance (potential pumps capacity was estimated out of dynamics of data obtained by wellbore sensors) – more

than 1.8%; selection of candidate wells for refracking taking into account interference of offset wells (estimated data obtained by wellbore sensors) – more than 1.3%; leveling of oil displacement and redistribution of water injection (including reduction of injected water volume in order to exclude water breakthrough due to self-induced hydraulic fracturing) – more than 1.8% (not taking into account effect of non-efficient injection decrease); target boosting of reservoir pressure maintenance system – 1.7%; reduction of direct oil production losses due to switching from acquisition of pressure and level build-up curves to real-time acquisition of level stabilization curves – not less than 1.1%. At this stage apart from single-gauge wellbore sensors providing wellbore hydraulic measurements, there was also implementation of autonomous remote multiple single-gauge sensors each consisted of a flowmeter, water-in-oil meter, thermometer and pressure gauge; they were installed at different depths in vertical and directional wells (usually at the top of co-produced oil formations). Remote data transmission from these multiple-measurement devices (for example if ‘Sprut’ (‘Octopus’) design developed by ‘Geofizika’ research and production company was implemented) has been achieved by 2 ways:

1) In production wells – a power supply cable sits inside a pump telemetry unit is connected to a string of sensors; the latter is suspended below the electric submersible pump within a perforated zone;

2) Injection wells, with dual injection equipment, a separate additional cable is used.

Unconventional oil deposits produced mostly by horizontal wells with multi-stage fracking have been identified as optimum candidates for performing the studies with distributed fiber-optic systems.

This type of single-gauge-distributed wellbore sensors deployed at the Yuzhno-Priobskoe field with wells equipped with Y-tool bypass systems which allowed targeted monitoring of producing wells equipped with multizone completions. This permanent geomonitoring resulted in reliable quantitative data regarding multiphase fluid movement and composition (under conditions of pumping-assisted production of formations); and variations of the filtering parameters within produced oil formations; unevenness of reserve recovery of a multi-zone reservoir; occurrence of intracolumn fluid migrations after a well shutdown. Starting from 2014 during next stage of implementation of permanent wellbore sensors for geomonitoring (including distributed fiber optics systems for thermal monitoring DTS and indicator-based (tracer) systems for monitoring flow profile and composition) horizontal wellbores with multi-stage fracking have been subjected to field testing.

For a detailed description of the results, refer to work [3] from Gazprom Neft experts’ conclusions regarding new approaches for remote distributed monitoring and their commentaries for delivering equipment with distributed wellbore sensors in horizontal wells that have been implemented at Gazprom Neft assets. The delivery of fiber optics sensing cable systems deployed through the tubing, of a reduced diameter, has its advantages for long-term monitoring while delivery via a coiled tubing should be applied for short-term monitoring. By the end of 2018 Gazprom Neft fields had the following systems deployed for field testing: fiber optic thermal monitoring system (DTS) – at 15 wells; fiber optic acoustic systems DAS – at 3 wells; fiber optic systems for bottomhole pressure control – at 2 wells; single-gauge-distributed indicator-based systems – at 8 wells.

From the point of view of the country’s energy security, the transition to a controlled and supervised approach to the production of hydrocarbon raw materials is guaranteed, which ensures guaranteed design levels of oil production, especially at fields with unconventional reserves produced by horizontal wells with multi-stage fracking equipped with smart completion systems including permanent wellbore-embedded sensors.

Practices for optimizing technology within the geophysical monitoring of horizontal wellbores, multilateral horizontal wellbores and horizontal wellbores with multi-stage fracturing should be primarily intended to:

• Performance analysis of wells with multi-stage fracking: validation of production at separate intervals/ports (estimation of their contribution

to total production rate and flow composition), location of hydraulic fractures within a whole horizontal wellbore and study of their parameters, detection of possible flaws with the BHA completion (for example packer leakage);

• Operational decision-making aimed to increase the wells productivity (cuttings removal from a wellbore, selective multi-stage re-fracking, shut-off water- or gas-breakthrough zones) based upon data describing current fluid movement profile;

• Estimation of the formation’s level of reserve depletion, identification of dead intervals, location of well-pattern zones with bypassed oil based on analysis of fluid movement and injectivity profile time-based logs for horizontal wellbores.

Unconventional oil deposits, requiring multi-stage fracking have been identified as optimum candidates for performing the studies involving distributed fiber-optic systems. If long-term monitoring in horizontal wellbore is considered, then this type of permanent downhole measuring systems has several substantial advantages over conventional ‘single-run’ well logging suites:

• Ability to install sensors below pumping equipment’s hanger directly inside horizontal wellbore for a long term (i.e. for an overhaul period or longer);

• Realtime measurements within the entire wellbore (some reduction in sensitivity of thermal sensors is compensated with big volumes of data gathered immediately after well production starts);

• Significant cost savings due to limit absence for amount and frequency of tests whilst reaching minimum values of their specific cost (especially if many wells are being studied simultaneously);

• Ability to pull out pumping equipment during well remedial works without the need to remove measuring sensors from horizontal wellbore (if inductive breakers are used in telemetry or electrical submersible pump of reduced size is used which is installed at tubing using wireline);

• Ability to integrate permanent wellbore sensors with a system for controlling downhole equipment (‘active ICD in Smart Well’ concept). Cost of permanent distributed measurement system for a horizontal wellbore is comparable to a cost of performing single hi-tech well logging. However, this equipment allows for permeant remote monitoring of wells performance for the long term (months or years).

Up to 2019, based on data analysis and classification of results obtained by permanent downhole sensors, in conjunction with results from digital modeling using thermo-hydrodynamical simulators, justifications have been established for basic bottomhole parameters (pressure, temperature, multiphase flow). This allowed for the development of required procedural [2] and regulatory documents (M-01.05.01.05-01. Recommended practices for conducting wellbore studies – geophysical logging. – 2018; M-01.05.02.01-01. Recommended practices for conducting wellbore studies – remote measurements and well testing. – 2017) for their subsequent wide introduction within oilfields at Gazprom Neft. In addition, recommended practices and time constraints have been established for validated hi-tech downhole monitoring systems [3]. Thus, despite several stages of technology implementation that have been already been completed and the clear economic benefits that have been achieved, a goal for the establishment of a sophisticated digital system for wellbore geomonitoring at Gazprom Neft fields is still in the list of the technology development program’s primary objectives.

Between 2012-2018 the following results have been achieved: worldwide market research has been performed and the most useable and cost-efficient wellbore sensors have been defined; step-by-step field testing at Gazprom Neft production assets have been performed in various technical and environmental conditions; procedural guidelines and algorithms have been developed; requirements for development of backbone networks for permanent geomonitoring within the company’s assets have been justified. It must be noted that at the time when Gazprom Neft experts started working on this comprehensive project there weren’t any similar commercial products available in Russia, while the cost of overseas commercial systems was much higher than the cost of the system developed by Gazprom Neft. A substantial part of measuring tools and equipment was radically changed by contractors based upon adjusted technical specifications that included cost reduction among other requirements.

Technical and economic indexes (key performance indicators) of a system for remote hydrodynamic and geophysical monitoring

The implementation of remote geomonitoring has allowed for a few direct and indirect benefits. KPIs were calculated based on production indexes for 2018 in 2 ways:

1. Separately for Gazpromneft-Khantos LLC asset – Yuzhno-Priobskoe field, where the calculation is based on economic effect stated as complimentary annual oil production due to the following factors:

a) Reduction of direct oil production losses caused by well shutdowns required for performing scheduled well testing (frequency and coverage are defined by regulatory document M-01.05.02.01-01) replacing the conventional logging pressure and level build-up curves implying long-term idle time of wells with realtime acquisition of level stabilization curves performed by single-gauge permanent wellbore sensors – 1.16% from total field production;

b) Selection of candidate wells for re-fracking based upon bottomhole pressure and skin-factor data obtained by permanent wellbore sensors. In 2018 on

a monthly basis approximately 22 wells were subjected to re-fracking; no-good candidate wells (statistically 16%) were excluded and replaced with wells selected upon well testing data obtained by permanent wellbore sensors. On average re-fracking at current field resulted in 10 tons/day of production increase, consequently effect of permanent wellbore sensors comprised 1.35% of total oil production.

2. For the other assets of Gazprom Neft only the economical effect which measured in an incremental annual oil production due to (a) component mentioned above was accounted for. Total annual net cash flow resulted from complimentary produced oil due to development and implementation of the system for remote wellbore geomonitoring amounted to 2.17 bln RUR. This calculation can be considered as being a conservative estimation because it doesn’t consider neither the operation costs savings nor the indirect effects of single-gauge wellbore sensors installation.

Prospects for future implementation of the remote monitoring system

Currently most Russian oil companies produce assets with unconventional reserves. Comprising of 50% and more of their total production. Smart completions of hi-tech wells and remote acquisition of bottomhole data provide significant benefits due to operating cost reduction and oil production savings. Further efficiencies increase with wireline logging and well testing at hi-tech horizontal wellbores together with the overall efficiency increases with the development of assets with unconventional reserves which can be attributed to conversions from single-run wellbore logs to long-term monitoring with permanent sensors distributed all over the wellbore. At present the most advanced technology that utilize fiber optic allowing remote temperature measurements within the whole well profile and by single-gauge-distributed systems based on fiber Bragg grating. Single-gauge-distributed indicator-based wellbore systems, as proven in their field tests aren’t reliable enough and seem to require a significant improvement.

In order to implement distributed permanent wellbore sensors within a wide range of oilfields, application guidelines and technical requirements being created as part of the Corporate Technological Strategy program. Upon completion of this stage it’s expected to form guidelines for implementing this technology in any horizontal well being drilled. As a way forward innovative wellbore sensors are under consideration including distributed hot-wire anemometry on a basis of fiber optic sensors (distributed DTS in combination with single-gauge measuring elements based on fiber Bragg grating) developed in conjunction with the Institute of Fine Mechanics and Optics, and multi-single-gauge heating elements.

Conclusion

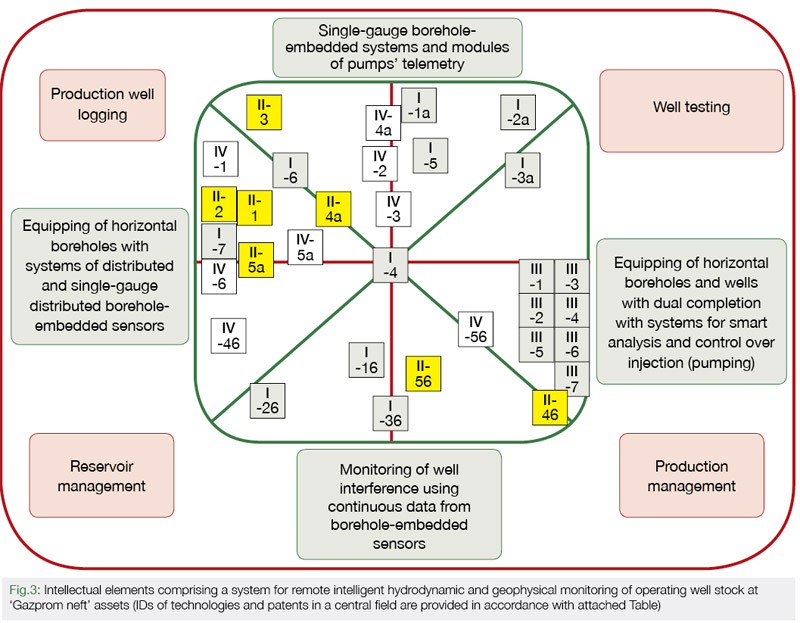

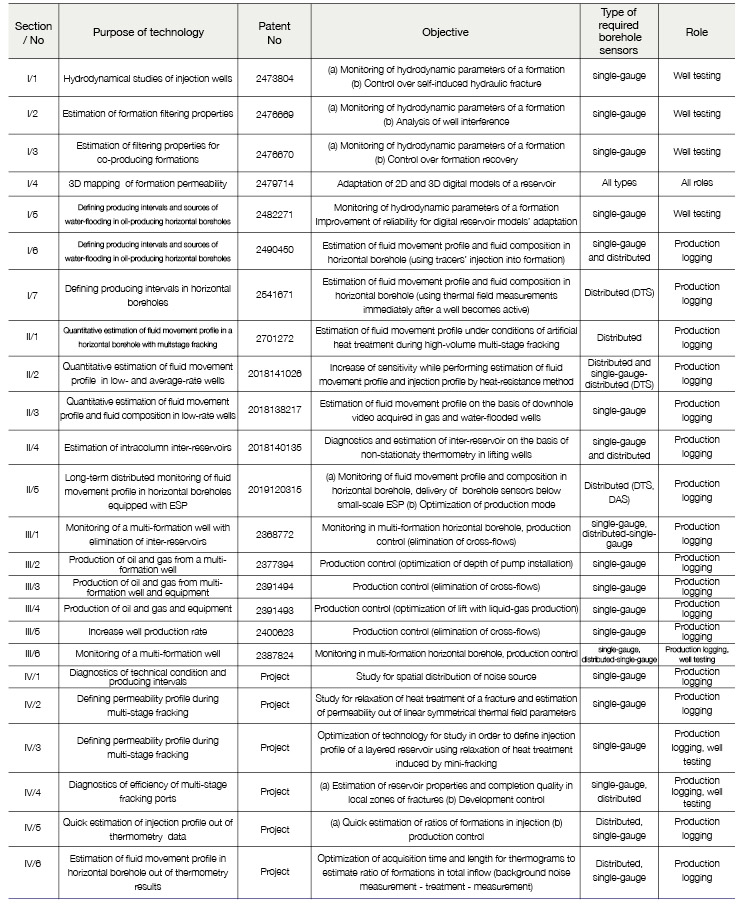

The security of energy supply, on a national scale, dictates the need for a wide conversion to permit a controlled and supervised approach for the production of raw hydrocarbons which enables planned oil production levels especially at fields with unconventional reserves produced from horizontal wells with multi-stage fracking completed with smart completion systems including permanent wellbore-embedded sensors. It’s worth mentioning that technological and software innovations and patents are being developed by Gazprom Neft affiliates and are of the utmost importance. Fig. 3 illustrates authors’ approach to the intellectual scope of the system for remote monitoring. The science and Technology Center of Gazprom Neft currently holds a block consisting of 7 patents (Section I of Table), 5 actual applications for an invention submitted to Rospatent in 2018 (Section II of Table) and 6 related patents in joint with Gazpromneft-Noyabrskneftegazgeofizika LLC (Section III of Table); aside from this it’s planned to produce and to draw up a significant amount of complementary intellectual elements (Section IV of a Table).

References

1. Kremenetskiy M.I., Ipatov A.I., Statsionarnyy gidrodinamiko-geofizicheskiy monitoring razrabotki mestorozhdeniy nefti i gaza (Stationary hydrodynamic-geophysical monitoring of the development of oil and gas fields), Moscow – Izhevsk: Publ.of Institute of Computer Science, 2018, 796 p.

2. Ipatov A.I., Kremenetskiy M.I., Kleshkov I.S., Experience in the application of distributed fiber optic thermometry for monitoring wells in the company Gazprom Neft (In Russ.), PRONEFT. Professional no o nefti, 2017, no. 3, pp. 55–64.

3. Billinchuk A.V., Ipatov A.I., Kremenetskiy M.I., Sitnikov A.N., et al., Evolution of production logging in low permeability reservoirs at horizontal wells, multiplefractured horizontal wells and multilateral wells. Gazprom Neft experience (In Russ.), Neftyanoe khozyaystvo = Oil Industry, 2018, no. 12, pp. 34-37.

Authors

A.I. Ipatov, D.Eng.Sc.,

M.I. Kremenecky, D.Eng.Sc,

A.A. Pustovskikh, Cand. Sc.,

I.S. Kaeshkov, Cand. Sc. Scientific and Technological Center of Gazprom Neft (Gazpromneft – NTC LLC)

D.Yu. Kolupaev (Gazpromneft-Khantos LLC)