Gazprom Neft: Drilling Digitalization

Since the beginning of 2018, Gazprom Neft PJSC has been testing and implementing digital technologies and Geo-Supervision services during well construction operations, which has opened new potential for well construction techniques and the organizing and managing of drilling operations within the region [1]. Following on from the first ever tender and contract for Geo Supervision services in well construction, the system has now been implemented at three drilling sites, integrating the engineering and operational sphere of the contractors and drilling crews.

The new strategy outlined by Gazprom Neft, PJSC, for the period to 2030, is aimed at enhancing the quality and speed of decision-making through the introduction of digital technologies, correlating with major task such as oil production.

With current practices, achieving oil production growth without any radical change in drilling technique and technology, as a minimum, requires the doubling of the drilling unit fleet, which would considerably reduce the economic efficiency of any field development (Fig.1).

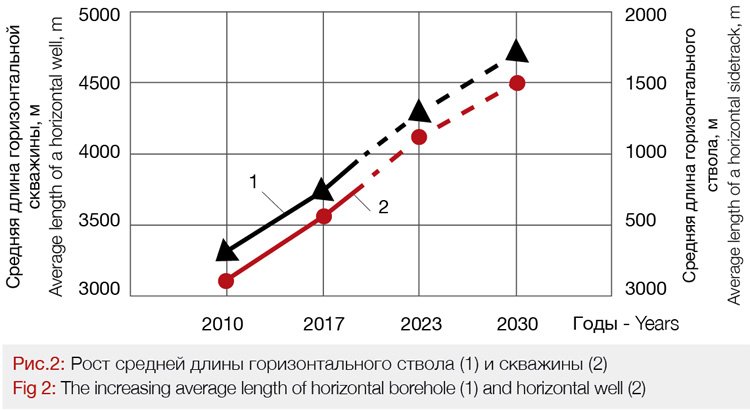

Current trends show horizontal wells are increasing in length to 4500m. The replacement of the older drilling units with more powerful rigs is required, and this can be combined with the reequipment of the existing fleet with automated drilling units (ADU). Drilling of horizontal wells is forecast to exceed 50% of all the development drilling operations in 2021, and it will continue to grow. [2].

The higher level of well complexity, especially in the projects dealing with hard to recover oil reserves, including oil recovery from kerogen, a solid organic compound of the Bazhenov Suite, requires the development of science-coupled technological solutions for the optimisation of drilling processes, based on a self-adapting system built on integrated digital platforms and multi-disciplinary and cross-functional teams with all the employees of the contracted organizations involved in the implementation of drilling projects [3, 4 ].

Complementary to the retrofitting of the drilling fleet with ADU’s, to efficiently drill fields and increase oil production without any the need for additional drilling unit fleets, companies will need state of-the-art digital technologies, software, IT-specialists and a new approach to the managing of drilling operations, based on the integration of geosupervison and a drilling crew within the integrated command space of a Mobile Operational Center.

Terms and definitions related to drilling digitalization, which are not more than three years old, are more and more commonly seen in the scientific and industrial lexicon [5]:

The digitalization of drilling is an effective way to enhance labor efficiency, based on a digital station for mud logging, operated by a Geo-Supervisor and a drilling crew.

Geo-Supervisor is a specialist IT professional based on the integration of knowledge in the following specialties: geophysics of well mud logging and drilling supervision.

Geo-Supervision is the supervision of drilling, integrated with a digital station for mud logging, to provide an effective real time monitoring of conditions, equipment and operating procedures, and real time on-site decision-making.

Drilling crew is a team composed of contractor employees representing various specialties of engineering activities that are coordinated by a drilling supervisor into a hierarchical structure with the view to manage preparatory work prior related to drilling, well extension, geosteering, borehole reaming and cleanouts, well logging and geotechnical studies and the preparation of well boreholes for the running the casing, cementing and implementation of other jobs within the integrated space of a Mobile Operational Center.

The goal of Geo-Supervision is to enhance the efficiency of drilling oil and gas wells by integrating service contractors into the process of transitioning to digital systems – to manage operating processes at a drilling site, based on innovative platform of integrated space and the interaction between contractors and a drilling crew.

The major goals of Geo-Supervision are as follows:

1. Enhancement of the quality of geotechnical studies;

2. Enhancement of the efficiency of Geo-Supervision due to the release of time which a drilling supervisor spends on reporting activity;

3. Optimization of reporting from well logging services and Geo-Supervision, due to their integration;

4. Optimization of the interaction between employees at a drilling site due to the integrated space of a Mobile Operational Center;

5. Reduction of Non-Productive Time during the operating of drilling equipment and well bore design due to software, which enables real-time monitoring of processes, based on drilling geomechanics and “digital duplexes” [6].

Geo-Supervision mobile station is equipped with a digital well logging station, matching the national standard and a Mobile Operational Center which provides an integrated space drilling crews to work from.

The Geo-Supervision Digital Station elaborated on the basis of modern technologies, includes:

• digital sensors, capable of storing factory calibration and having unique identifying codes;

• digital technologies for data communications, video monitoring, telephony;

• a system for real-time monitoring of operating procedures and the monitoring the condition of drilling equipment.

The system of data gathering includes only protected and licensed cross-platform software. The Geo-Supervision Digital Station monitors the quality and consistency of data (AD converter database codes which are not editable, GPS/Glonass data gathering time synchronization, registration of events, and the status of data gathering server, etc.). The configured module of handling the WITS and WITSML protocols works both for data transfer and for data reception, to integrate outside communication devices and services into the data gathering system (cementing monitoring station, well logging, geosteering, etc) with the possibility of viewing data from all the participants within the process, including the data on a driller’s display.

The Geo-steering digital station has the following capacities:

• Remote monitoring and control of the data gathering system. The database is optimized for storing information on hard drives, as well as for data transfer through low bandwidth Internet-connection channels.

• Uploading Project data into a cloud system and synchronizing them there. The regular back-up of project data for any computers, connected to a local area network.

The Geo-Supervision Digital Station is:

• equipped with digital talk-over system for the participants involved in the process (including the driller and off-site users) with the possibility of both direct phone communications and intercom telephony, including the function of recording conversations.

• Equipped with the system of active degasation of mud in the explosion-proof version.

• Capable to exclude any data loss during cut-offs at the drilling site communication line, or during any problems with the server of datalogger, for at least 1 hour (data buffering in data loggers at drilling sites).

To increase the efficiency of managing contracted service companies, pilot testing of Geo-Supervision was launched on the 2nd of April, 2019, integrating a Mobile Operational Center, well logging digital station and supervision.

The Tailakovskoye oil field, has a complex geology for drilling, is located five hundred kilometers from the operations base of “Slavneft-Megionneftegas” PJSC, and functions practically in an off-line basis, which requires separate liability from drilling people.

Their qualification must be high enough to maintain failure-free drilling of deep wells with a high level of complexity, with a horizontal sidetrack extending up to one kilometer through Jurassic formations.

The launch of the digital supervision on the basis of a Mobile Operational Center and a drilling crew was carried out from the office of “Gaspromneft STC”, LLC by

I.F. Rustamov, Executive Director for design-and-functional support of the “Gaspromneft STC”, LLC assets, and V.V. Kulchitskiy, President of the “Research and Design Center for Gas and Oil Technologies”, the research supervisor for development of digital technologies applied in well construction management (Fig.1).

The integrated service means transition of the employees representing service contractors (a drilling crew) from their distant drilling site vehicles to a Mobile Operational Center with an open layout. Such transition is imposed with the expediency of interaction between the members of a drilling crew within an integrated space, when preparatory work is carried out for drilling, well deepening, reaming and flushing operations, geosteering, geophysical studies and well logging, for preparation of a well borehole for running the casing and for cementing operations. The Mobile Operational Center is placed next to a drilling unit; it significantly saves space, providing some increase in operating efficiency of specialists [7].

In the first phase, an assistant Geo-Supervisor works jointly with a drilling fluid engineer who examines boring sludge, and gathers, analyses and stores the geologic data.

In the second phase, a Geo-Supervisor operates the digital well logging station, analyses information, and, jointly with a supervisor, makes operating decisions.

In the third phase, a drilling foreman’s workstation is located next to the supervisor, and next to them, the geosteering engineers have space with their well trajectory control station. Workspaces for young specialists as probationary employees and new technology test engineers are also provided here.

All of the contractors, involved in the work on the drilling site, will delegate their specialists to work within the Mobile Operational Center to perform their services, jointly discuss any operating decisions being made, and analyze them. The joint work within the Mobile Operational Center inspires active interaction between the service contractors, and it also stimulates the exchange of reliable information. Digital sensors provide high-precision control of all the well operation parameters used in the process of well construction with a minimal measurement errors, while software tools, in due time, signal about any deviations, and optimize the process of preparing and reporting materials. The work within an integrated space allows deeper communications between during “brain storming” session, letting them quickly resolve business problems and make operating decisions. A supervisor in such Mobile Operational Center creates an atmosphere of fellowship, choosing a format of communication to meet production objectives, while the electronic telecommunication facilities serve as tools for coordination of key decisions with headquarters of a customer. (Fig.1, a).

As the target depth of the well was reached, the geologist in the oil company’s Drilling dispatch room, going by the well logging cuttings data and well logging telemetry, which indicated high permeability and porosity of the penetrated oil bed, gave orders to consider chances of extending the 900 meter horizontal sidetrack by 200 or 300 meters. The drilling crew, composed of a supervisor, drilling foreman, Geo-Supervisor, drilling fluid engineer, geosteering engineer, and production technical limit (PTL) engineer entered upon this decision making (fig. 2, b):

As a result of the five-minute “brain storming” session, the following limiting conditions were determined by the crew, and the following risks were outlined in case such orders were implemented:

Supervisor: the drilling unit is not equipped with any top drive system, which complicates shaping the well shaft and provision of face output, and this increases the risk of stuck pipe.

Drilling foreman: it is necessary to order the delivery of supplementary drilling equipment and the casing for liner string, which would require some time.

Drilling fluid engineer: it is necessary to prepare 40 cubic meters of drilling fluid to reduce the density.

Geo-Supervisor: Drilling time is going to increase by a day and a half, and it is necessary to schedule additional callipering of the well shaft.

The arguments, based on calculations and field experience of the drilling crew members, made it possible to give up the idea of extending the horizontal sidetrack and exclude the vivid risks of complications and breakdowns. Indeed, when the drilling was conducted, tools had seizure in place and the drilling footage went down.

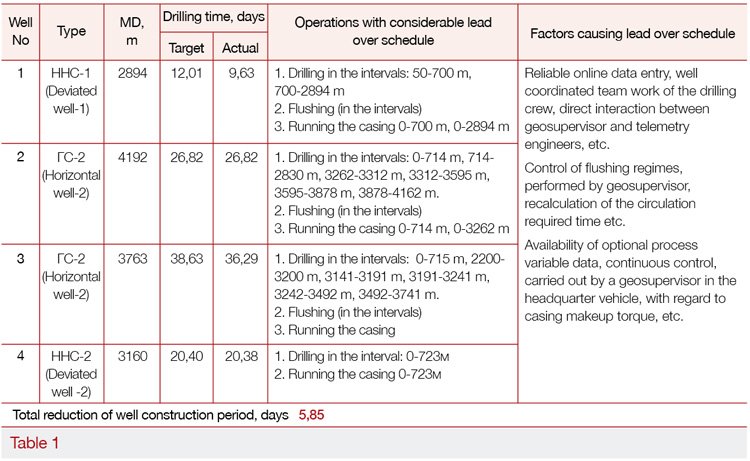

The first deviated well was drilled for 9.6 days with the lead over work schedule by 2.4 days. The second horizontal well, 4192 m deep, having the length of horizontal sidetrack of 962 m was drilled with acceleration of 1.1 days (see Table 1). The following outcomes of the Geo-Supervision pilot test were obtained at the well pad #88 of the Tailakovskoye field, according to the minutes of the scientific and technical council meeting dated 16.07.2019: the well construction period was reduced, the quality of drilling operations increased, complications and breakdowns were avoided, and the probability of any technological and managerial risks had considerably decreased.

A determining factor, when transitioning to digital technologies, is testing new technical and technological solutions, software, communications, logistics and the training of drilling operation employees (drilling crew and service contractors). The geo-supervision, employing a Mobile Operational Center, makes it possible for a supervisor to efficiently manage the drilling procedures due to reallocation of authorities of the specialists involved in the work on a drilling site, due to integrated management of the processes, and operative decision-making.

Key Performance Indicators of the managerial Geo-supervision:

1. Freeing of a supervisor from deskwork.

2. Ruling out any paperwork or data manipulations on the part of service contractors.

3. All contractors are in sight: it is clear who is busy with what and how much.

4. Minimized time for decision-making.

5. Obtaining integrated knowledge of allied services.

6. Creation of an environment, which is friendly to testing new equipment and technologies.

7. Forming conditions for digital long-distance interactive training on the job for the personnel reserve of “Gasprom Neft”, PJSC and drilling services.

The interaction between specialists of service companies, participating in well construction under geosupervision, is carried out on the basis of regulations setting standard requirements for specialists of contracted organizations, involved in geosupervision of drilling operations as part of a drilling crew.

Conclusions:

1. Field application of geosupervision forms highly-qualified teams of specialists having advanced leadership and management skills and competencies in techniques and technology of drilling, including expertise in the field of digitalization of well logging, geosteering and automation.

2. The mobile station of geosupervision as much as possible contributes to testing new equipment and technologies of well drilling, software, well casing program and design, well construction elements and infrastructure, including forms of labor management and production control, i.e. performing the functions of a drilling test site.

3. The geosupervision station is initially used as a digital Test site for long-distance interactive training of students on the job, for probation of young specialists and for additional occupational training.

4. Equipping a Mobile Operational Center with instrumentation for video conference calls would enable holding meetings with the office and drilling crew.

5. Digitalization of well drilling would prepare the transition of drilling contractors and service companies to the use of automated drilling units and would provide cost-effective oil production growth.

List of References:

1. S.A. Ilichev, V.V. Kulchitskiy, V.P. Spiridonov and others. “Digital Geosupervision of Optimized Well Design Drilling”. Neftyanoye Khozyaistvo, #1-2019, pp.10-13.

2. RPI: Dynamics of the drilling market in 2017 inspires optimism. ROGTEC. April 24, 2018, pp. 16-27.

3. A.V. Bilinchuk, I.F. Rustamov, E.Yu.Bulgakov, and others. “Principles of Building Integrated Systems for the Management of Operating Activities by the Example of a Drilling Control Center of the “Gasprom neft” company grouping”. ROGTEC. Russian oil and gas technologies. #54 – September 2018, pp.36-44.

4. V.V. Kulchitskiy, A.K. Parkhomenko, S.A. Ilichev and others. “Adaptive System of Well Drilling on the Basis of Integrated Digital Platform. Patent for Invention RU №2703576. Priority dated 18.01.2019.

5. V.V. Kulchitskiy “Supervision of the Oil and Gas Well Construction”. Practical field publication. M. Veche. 2019, 367 p.

6. V.V. Kulchitskiy, S.A. Ilichev, Ya.S. Naseri, M.D. Demin “Research of Correlation between the Torque Moment and the Reacting Power Forcing on the Tool Threaded Joints of Drilling Pipes”. Gazovaya Promyshlennost’ #1 – 2020.

7. V.V. Kulchitsky, S.A. Il’ichev, V.L. Alexandrov and others. “Drilling Crew” Popular Science film. “ Multimedia laboratory of NIPTs GNT, 2019.

Authors:

I.F. Rustamov, Executive Director for the Design & Functional Support of Gazpromneft STC, LLC Assets

K.V. Kulakov, Director for Development of the “Drilling and Downhole Operations” Function of Gazpromneft STC, LLC

S.A. Ilichev, Deputy General Director, Well Construction, Gaspromneft-Orenburg, LLC

V.V. Kulchitskiy, President of the R&D Center for Gas&Oil Tech JSC