Gazpromneft NTC: From Digital to Intelligent Fields

Rising costs associated with the development of new oil and gas fields in the face of fluctuating demand for hydrocarbons are forcing subsoil users to develop and implement new efficient technologies that reduce the cost of production. The remoteness of new fields from the existing infrastructure, the commissioning of new production targets and their connection to the existing field facilities system, as well as the harsh climatic conditions at play make the management of oil and gas assets more and more complicated. This requires optimal technological decisions aimed at eliminating risks that influence the effectiveness of management decisions. Computer-based information technologies supporting the oil and gas industry have been on the rise since the beginning of 1980 [1]. By the end of 2000, they had evolved into an array of individual software tools used for modeling reservoirs, piping networks, and oil and gas treatment facilities, as well as for financial and economic modeling of assets. The evolution of digital field technologies proceeded from simple to complex: from measurements, recording, analysis, and aggregation of field data to analytical systems that solve problems across the entire field, being linked together by a unified data gathering network.

From the early 20th century to the present time, the two factors that have gained principal importance for ensuring breakthrough advances in finding optimal field development and operation solutions are the acceleration of data processing and the evaluation of sustainable feasibility of solutions through intelligent technologies [2]. Such computer information systems make it possible to automate the collection, filtering, storage, and processing of data, to describe the physical processes at work, to predict hydrocarbon production, and to visualize the key parameters for management decisions. The main challenges that come in the way of those designing such systems are how to control large pools of oil-field data and to ensure high-quality processing and intelligible visualization of the same.

From 2003, leading oil and gas companies and their research centers got busy developing a wide range of new methods for field information management [3].

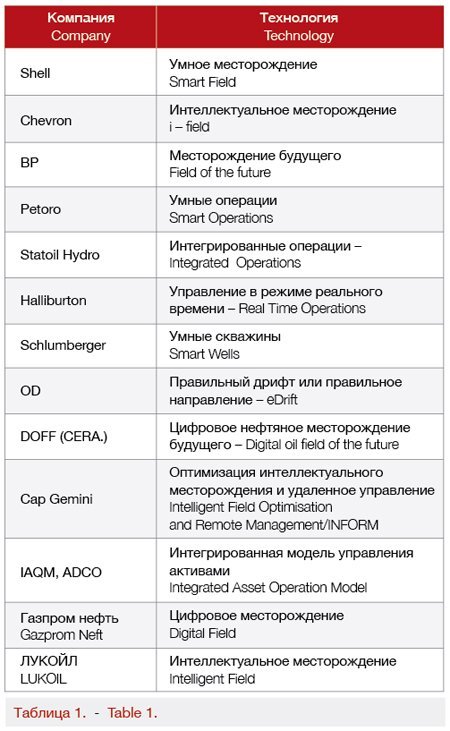

The new-gen technology based on integrating a combination of hardware and software tools into the production processes of oil and gas companies has been given various names and has had its elements configured in a variety of ways (see Table 1).

Each company comes up with its own definition of this technology based on an understanding of its current needs for methods of solving production problems. The literature offers many definitions of this concept, including the following:

• an intelligent field is a dynamic system of interconnected technologies and business processes that ensure an increase in the economic efficiency of all the elements of production and management of oil and gas assets [4, 5];

• a digital field is a software package that comprises a suite of applications making it possible to describe the field behavior on a computer [6];

• an intelligent field is a process of generating added value in oil and gas assets by creating a cycle of data collection, modeling, decision-making and related performance [7];

• an intelligent field is a system of oil and gas field operations management, which includes a set of business processes aimed at optimizing production and reducing financial losses by timely identification of problems and rapid decision-making by multidisciplinary teams based on data obtained in real time [8].

Nevertheless, a precise definition that would highlight the essence of this technology does not yet exist, since its ideal architecture must provide for the emergence of artificial intelligent systems, which is not yet possible. However, some modern developments in information technology and high-tech equipment create the conditions for exercising cybernetic control over individual elements of the field. One recent trend is the widespread use of systems known as the Smart Well, the Smart Oil Field, Integrated Modeling, Integrated Activity Planning, etc. The intelligent field should be equipped with software that conforms to cutting-edge developments in information technology.

The effectiveness of the digital field, as a combination of intelligent systems, is due to the close integration of intelligent equipment and analytical information products into production business processes, such that, whenever an abnormality is detected, those integrated solutions will provide recommendations for eliminating possible risk. The quality of such solutions is ensured by combining operational data for all the field’s systems with an integrated asset model supplemented by analytical libraries, which will enable experts to analyze a particular process system and will issue suggestions on how they can optimize it and what losses it can sustain in the future (proactive protection). In the absence of digital field management systems, information is collected and used after an event has occurred, i. e. when the problem already exists, which means that trouble-free field operations may be at risk, and complications may arise (see Fig. 1) [9].

INTEGRATED FIELD MODEL

The Digital Field technology binds together all the stages of commercial exploitation of an asset. At the core of this technology is an Integrated Field Model (IFM), ideally one possessing algorithms for receiving and processing data from remote field development control systems. An IFM will include mathematical models of the reservoir, fluids, wells, and surface facilities of the field, all constructed based on the totality of field data available. An IFM makes it possible to integrate models of the well and its gathering system with larger models of the reservoir and field facilities, as well as to update the model in real time. Based on an IFM, you can automate your surveillance/monitoring processes and predict the operation situation for each component of the field’s systems while avoiding laborious, manually-intensive processes. An IFM is constructed with a view to increasing the effectiveness of each individual system as well as of the asset as a whole, considering the way its systems affect each other. An IFM provides an opportunity to reasonably assess the current operational state of the systems, to foresee possible issues, and to suggest measures to prevent them.

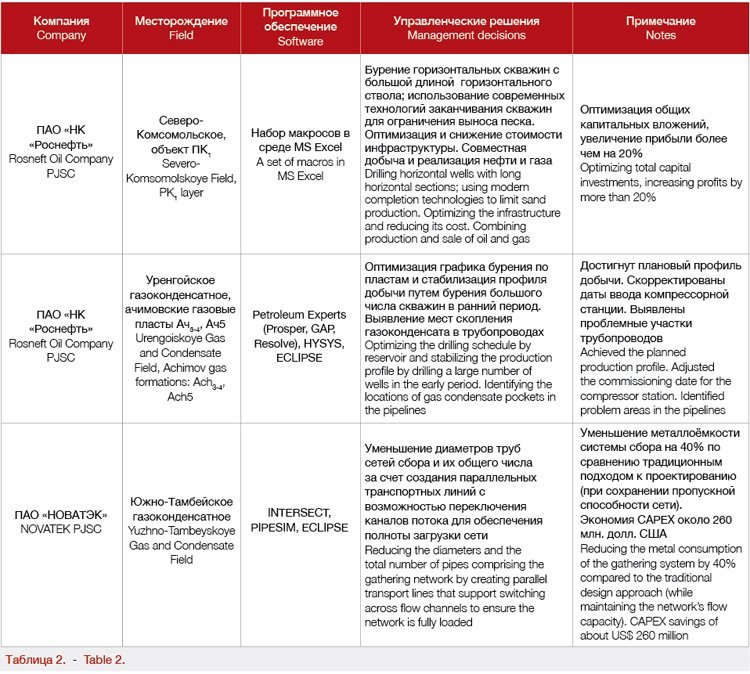

The concept of IFM is inextricably linked with that of integrated design, which first emerged in the 1960s, and whose primary purpose was to ensure comprehensive optimization of well operation processes while streamlining the performance of surface installations, pumping equipment, and other facilities during the modeling of oil field development [10]. Today, it is effectively complemented by IFM tools—programs that integrate all the core disciplines of the asset (geology, development, drilling and completion, oil production, facilities construction, economics, environmental concerns, risk analysis) for effective field exploitation planning from the business point of view [11]. The IFM has already proven its effectiveness in supporting decision-making in Russian companies (see Table 2).

Today, however, field modeling practice is limited to individual geo-hydrodynamic, oilfield engineering, and economic modeling tools, which are used far and wide. They have become an integral part of planning for oil and gas field development and performance optimization activities as well as a toolkit used for the calculation of process parameters when drafting design and engineering documents for field development projects. One major disadvantage here is the lack of a unified field model, which would include all the elements of integrated planning.

Geo-hydrodynamic modeling (GHDM) tools are good at describing a reservoir’s development targets, but an attempt to use them comprehensively to analyze the entire field will cause difficulties. It is known, for example, that field-specific development projects demonstrate an imbalance between the fluid volume required for the operation of the reservoir pressure maintenance (RPM) system and the excess water accumulated at the nodes of the gathering system, which makes the design of surface facilities more complicated [12]. This is due to the lack of coordination between the development projects and the facilities construction projects. If ever there is any data exchange between the system components being designed, it is maintained in the form of spreadsheets that do not take into account how individual field elements affect each other, and how uncertain their parameters are. When technology solutions or injection modes change, this will affect the performance figures for one system but will leave the other one unchanged, because the spreadsheets are not connected to the system. A material deficiency of such a process is that the elements are modeled at one single point in time, which is unacceptable for analyzing the system at another point and calls for an adjustment of the inputs for the development history. Thus, the traditional GHDM method cannot take into account the dynamics of field development (how the flow rate changes in an existing well and as a result of drilling new wells, how oil production increases after specific well-work activities (“GTM”), etc.). The lack of interconnection between the GHDM tool and a field-wide gathering system can lead to significant complications, such as irregular drilling or overestimated / underestimated equipment performance.

INTEGRATED FIELD MODEL TOOLS

In order to eliminate or minimize complications that may aggravate the field performance and to increase the sustainability of a design decision against the uncertainties at work, we must synchronize the processes used to elaborate the field’s development targets and their infrastructure. This approach can be implemented using IFM and requires that the following IFM components be set up for a digital field:

1) algorithms for collecting, storing, structuring, validating, and filtering field data from various sources;

2) tools for modeling all elements of the integrated field system (GHDM, wells, gathering system, treatment system, economics);

3) integration of engineering data analysis methods based on their processing in models with decision support algorithms.

The development of data processing algorithms means setting up communication channels to and from oil-field telemetry systems, chemical analysis laboratories, drilling rigs, and other information sources present in the field, and maintaining real-time communications in them. An integrated field system modeling tool means a specialized software package that is used by experts specializing in geology, drilling, development, facilities, and production at the company’s Research and Engineering Center. Those experts use the online data and specialized software available to them to create an IFM and adjust it for the development history. Next, the updated IFM elements, enhanced with libraries of information processing algorithms, are used to help experts in the oil field by following their work in real time and making suggestions on how to optimize the operating process parameters of the field systems based on technical and economic constraint indicators.

IFM tools make it possible to evaluate an asset’s growth prospects and RoI potential at different points in time. This IFM function is becoming especially popular in the face of high volatility in oil prices. An investment in IFM construction (if the IFM is correctly implemented as the core of a digital field) will, thus, help secure transparency and faster decision-making during oil production processes.

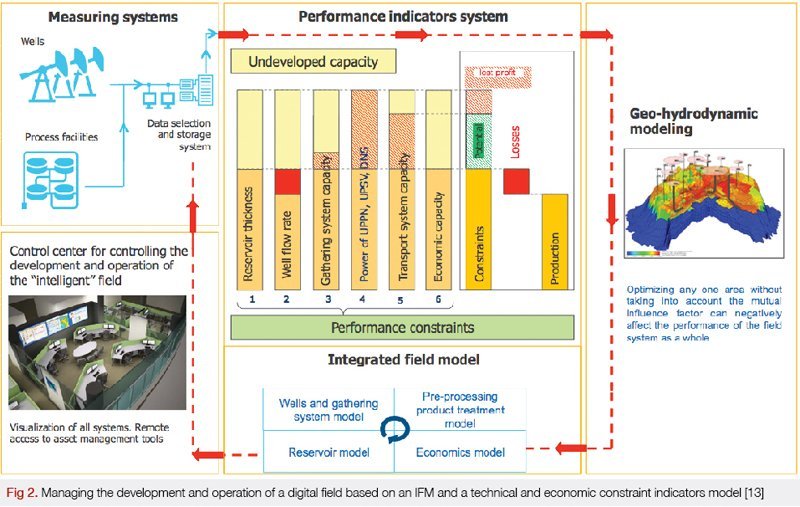

If we want the IFM core of the digital field to work, we should transform the technique of how our employees, from technical specialists working directly in the field to analysts at the company’s Research and Engineering Center, do their work. In addition to modernizing workflows, special attention must be paid to employee motivation based on the field’s key performance indicators. By integrating those key performance indicators with a technical and economic constraints model to control our operation modes and with analytical IFM tools to help prepare management decisions, we will be able to reduce the risks of financial losses. If an employee takes a personal interest in achieving the digital field’s key performance indicators, this will speed up their proactive responses that will prevent complications from occurring. With such a system, the IFM becomes a tool for reducing the geological and technological uncertainty of the field parameters, and the constraints model with key performance indicators motivates employees to thoroughly study the field and search for methods to increase oil production at the lowest cost (see Fig. 2).

CONSTRAINTS MODEL

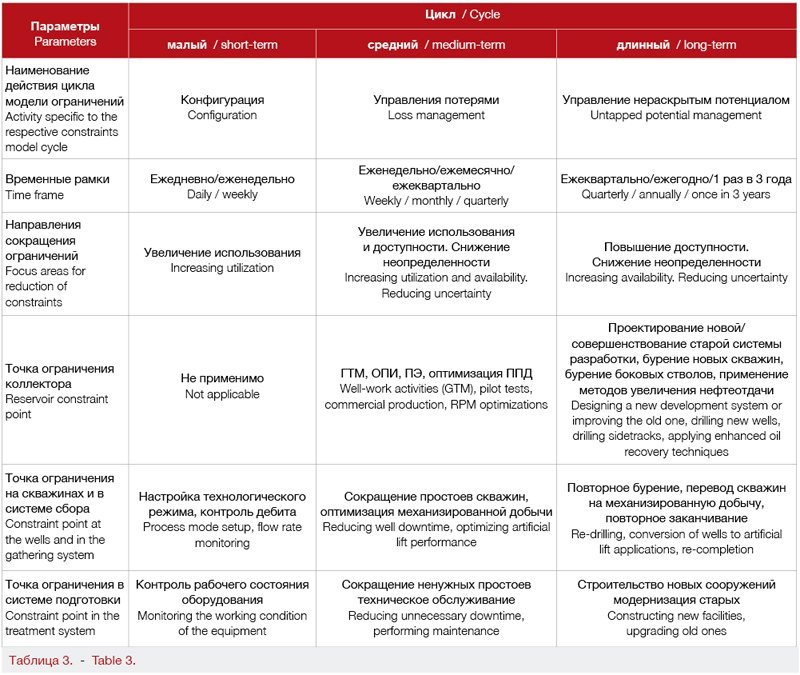

A constraints model, also known as a technical and economic constraint indicators model, linked to the IFM at its constraint points, makes it possible to implement the short, medium, and long-term asset management cycles (see Table 3).

Short-term cycle— that configures the IFM, is carried out daily / weekly at the constraint points attributable to the wells and the oil gathering and treatment system by monitoring the flow rate and the process mode configurations of the production equipment. Medium-term cycle—manages losses and is carried out weekly / monthly / quarterly at the constraint points attributable to the reservoir, the wells, and the oil gathering and treatment system by planning and conducting well-work activities (GTO), pilot tests, commercial production activities, RPI optimizations, and reducing well downtimes. Long-term cycle—manages the untapped potential of the asset and is carried out quarterly / annually / once in 3 years at the constraint points attributable to the reservoir, the wells, and the oil gathering and treatment system my designing a new development system, drilling new wells, re-drilling, converting wells to artificial lift applications, re-completion, building new facilities and redeveloping/upgrading new ones.

In Gazprom Neft PJSC, parts of the medium-term cycle and the entire long-term cycle for asset management decision-making are implemented via conceptual field-geology and field-development design at the Assessment and Selection stages [14]. A key element of this system is the integrator, which integrates modules with the following functions: well planning (WellPlanning); solving optimization problems for the reservoir, wells, and surface facilities (ECLIPSE, PIPESIM, HYSYS); cost engineering (Merak PEEP). The integrator makes it possible to optimize the search for solutions in field development and facilities construction at the strategic and tactical levels of asset management decision-making.

The sustainability and effectiveness of IFM application are made visible if the simulation results and the field data converge. Where the source information available for calculations at the Assessment and Selection stages of the project is not sufficient, the iteration cycle of the conceptual field-geology and field-development design process must be accelerated. However, the acceleration of the process will result in information losses at IFM constraint points. In this case, if you link the constraints model to the conceptual design process, the process management methodology will remain unchanged (see Fig. 3), but such an approach will enable you to make constraint point-specific adjustments to the IFM integrator settings at any stages of the Assessment and Selection stages. Here, the integrator will not only act as integration software linking together individual conceptual design tool modules but will also become a tool for managing constraints in an asset.

Each stage of constraint points management will be implemented with a cycle frequency aimed at boosting oil production, increasing oil recovery rates, improving NPV and PI, reducing operating costs and uncertainties, and minimizing risks. Shorter cycle times will speed up the decision-making process.

CONCLUSION

The relationship between the IFM and the constraint points management cycle in the constraints model is a continuous-action methodology for finding sustainable asset management solutions. This methodology synchronizes the processes of obtaining, processing, and analyzing information on field-development and infrastructure-building targets and is based on an acceleration of cycles of constraint point-specific input data acquisition through the use of software and hardware tools and algorithms in Gazprom Neft’s production processes. Applying such an accelerated decision-making process, structured using the IFM constraint points, in the form of a constraints model results in increased economic value of the asset.

BIBLIOGRAPHY

1. By Ian J. Hardy, Gordon P. Wetzel. Automated Production Systems //SPE 10005. – MS. – 1982.

2. Оптимизация добычи: от продуктивного пласта до пункта подготовки нефти и газа // Э. Барбер, М.Е. Шиппен, С. Баруа [и др.] / Нефтегазовое обозрение. – 2008. – Т. 19. – № 4. – С. 22–37.

3. Маргелов Д.В. Месторождение на ладони – инновационный взгляд на перспективу интеллектуальных месторождений // Инженерная практика. – 2010. – №9. – С.43–46.

4. Власов А.И., Андреев К.В., Поплыгин В.В. Потенциальные возможности создания интеллектуальных месторождений в Группе компаний «ЛУКОЙЛ»// Газовая промышленность. – 2014. – № 7. – С. 43–45.

5. Гульдемонд Э., Акда Л., Андронов М. Организация и управления ИТ для «Умных месторождений» // SPE 160557. – RU. – 2012.

6. Инженерное программное обеспечение // Материалы презентации компании Petroleum Experts. – http://itps.com/uploads/files/Petex/20IPM/20Brochure/20RUS.pdf.

7. Оптимизация процессов управления добычей нефти при внедрении технологий «интеллектуального месторождения» на Самотлорском месторождении / С.Д. Шевченко, В.А. Навозов, Д.В. Миронов [и др.] // SPE 161978. – 2012.

8. Березина А.А., Череповицын А.Е. Экономическая концепция нефтегазового «интеллектуального» месторождения // Нефтяное хозяйство. – 2014. – № 14. – С.14–15.

9. Еремени Н.А. Управление разработкой интеллектуальных месторождений нефти и газа: в 2 кн. Кн. 1. – М.: РГУ нефти и газа имени И.М. Губкина, 2011.

10. Гричлоу Г.Б. Современная разработка нефтяных месторождений – проблемы моделирования. – М.: Недра, 1979. – 303 с. publications, devoted to PVT-modeling, grows with every year, the complexity of models increases. On the one hand, this helps to increase the accuracy of the forecast and to adopt an optisolution in the design and development of deposits, on the other – often slows the process of preparation of PVT of data

11. Integrated modeling of the El Furrial field Asset Applying Risk and uncertainty analysis for the decision making // L.M. Acosta, J. Jimenez, A. Guedez [et al.] // SPE 94093. – 2005.

12. Гришагин А.В. О проблемах интеграции системы пласт – скважина – обустройство – экономика на примере проекта разработки Западно-Коммунарского нефтяного месторождения // Научно-технический вестник ОАО «НК «РОСНЕФТЬ». – 2009. – № 1. – С. 30–35.

13. Власов А.И. Умное месторождение для оптимального промысла // Материалы журнала медиапортала сообщества ТЭК. – 2014. – № 5. – С. 38–43.

14. Интегрированная модель для комплексного управления разработкой и обустройством месторождений» / Р.Р. Исмагилов, М.М. Хасанов, Ю.В. Максимов [и др.] // Нефтяное хозяйство – 2014. – № 12. – С. 74–76.

REFERENCE

1. Hardy I.T., Wetzel G.P., Automated production systems, SPE 10005-MS, 1982.

2. Barber E., Shippe M., Neftegazovoe obozrenie, 2007–2008, URL: https://www.slb.com/~/media/Files/resources/oilfield_review/ors07/win07/optimizing.pdf

3. Margelov D.V., The deposit on the palm – an innovative perspective on the prospects of intellectual deposits (In Russ.), Inzhenernaya praktika, 2010, no. 9, pp. 43-46.

4. Vlasov A.I., Andreev K.V., Poplygin V.V., Potential opportunities for the creation of intellectual deposits in the LUKOIL Group (In Russ.), Gazovaya promyshlennost’, 2014, no. 7, pp. 43-45.

5. Gul’demond E., Akda L., Andronov M., IT Governance and Organization in Smart Oil Fields (In Russ.), SPE 160557-RU, 2012.

6. http://itps.com/uploads/filesPetex/20IPM/20Brochure/20RUS.pdf.

7. Shevchenko S.D., Navozov V.A., Mironov D.V. et al., Oil production process optimization resultant from intelligent field technologies implementation in Samotlorskoe field (In Russ.), SPE 161978, 2012.

8. Berezina A.A., Cherepovitsyn A.E., Economical conception of oil&gas smart fields (In Russ.), Neftyanoe khozyaystvo = Oil Industry, 2014, no. 4, pp. 14-15

9. Eremin N.A., Eremin Al.N., Eremin An.N., Upravlenie razrabotkoy intellektual’nykh mestorozhdeniy (Management of the development of intellectual deposits), Moscow: Publ. of Gubkin Oil and Gas State University, 2011, Part 1, p. 9.

10. Crichlow H.B., Modern reservoir engineering: a simulation approach, Prentice-Hall Inc., New Jersey, 1977.

11. Acosta L.M., Jimenez J., Guedez A. et al., Integrated modeling of the Furrial Field Asset applying risk and uncertainty analysis for the decision taking, SPE 94093, 2005.

12. Grishagin A.V., On the problems of integration of the reservoir—well system—arrangement—the economy by the example of the West-Kommunarskoye oil field development project (In Russ.), Nauchno-tekhnicheskiy vestnik OAO “NK “Rosneft’”, 2009, no. 1, pp. 30-35.

13. Vlasov A.I., Smart field for optimal oil field (In Russ.), Zhurnal-daydzhest EnergyLand.info, 2014, no. 5, pp. 38-43.

14. Ismagilov R.R., Khasanov M.M., Maksimov Yu.V. et al., Prospects of energy optimization on Gazprom Neft JSC objects with use of hydrocarbons (In Russ.), Neftyanoe khozyaystvo = Oil Industry, 2014, no. 12, pp. 74-7.

AURTHOR

A. I. Vlasov, A. F. Mozhchil

Gazpromneft NTC LLC, RF, Saint-Petersburg

Gazpromneft Science and Technology Centre (Gazpromneft NTC LLC)

Published with thanks to Gazprom Neft & PROneft Magazine