Gazprom Neft: Optimising Multistage Hydraulic Fracturing in Challenging Reservoirs

Effective well stimulation with hydraulic fracturing requires indepth engineering and technological research. This paper shows various ways of optimizing multistage fracturing operations in reservoirs with weak barriers with low stress contrasts. One of the solutions is to optimize the existing guar fluid systems to control the fracture height. The following solutions were applied to achieve the maximum effect: gradual decrease of polymer concentration, application of low-viscosity fluids and combined «pad» stages. Additional operations were carried out in order to optimize the pumping schedule and make it more rapid. To achieve the maximum clean out of the fracture, the concentration of the enzyme breaker was gradually increased. Hydraulic fracturing with a non-polymer fluid system (surface active agent) was chosen as an alternative stimulation approach. To minimize the risks associated with screenout, multistage completion system with reusable sleeves have been used. The system is controlled by a special CT-deployed key and bottomhole pressure monitoring. Additional control methods included microseismic monitoring and different logging operations. The analysis from the actual oil production rate showed that these approaches maximized the efficiency of the stimulated wells.

Introduction

Gazprom Neft’s asset portfolio includes several fields which are characterized by the absence of distinct lithological barriers for gas and water. Hydraulic fracturing is not efficient without in-depth engineering studies and utilizing the latest technologies. Successful field commissioning in the Yamal region requires implementing the optimal solutions. This paper describes the various scenarios for the optimization of hydraulic fracturing. The analysis of the actual performance of the stimulated wells showed that a successful solution was finally identified. The integrated approach developed by the company’s specialists allowed the company to optimize hydraulic fracturing and thus increase the wells productivity.

Fluid and Fracturing Design Optimisation Testing

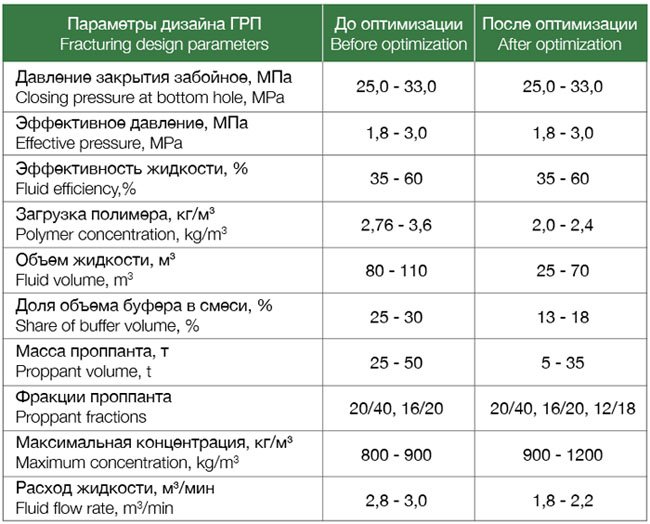

In Western Siberia, one of the tasks for reservoirs with close proximity to oil-gas and water-oil contacts and low stress barriers is the need to control the height of fracture in order to avoid the fracturing of non-target intervals. Technologies with low-polymer modified agents or surfactants have not yet become widespread due to the higher costs and harsh equipment requirements. Therefore, the obvious solution is to optimize the existing guar fluids in order to reduce the concentration of the polymer and to use low-viscosity fluids as a buffer and/or sand-bearing fluid [1]. In the present case, it was decided to start optimizing the fluids and fracturing design by a gradual decrease the polymer concentration and increasing the pump rate (reduction of the buffer volume, increase in the maximum concentration of proppant and decrease in fluid rate). The first tests were carried out in directional wells. The design of these wells prevents the risk of an accident due to the proppant settling in the liner in the horizontal section. After obtaining positive results, it was decided to perform an injection in the horizontal wells completed with multistage fracturing assemblies [2]. The polymer concentration and main reservoir characteristics before and after the optimization are presented in the table. Initially, the viscosity of the cross-linked fluid was 800 mPa⋅s, which is due to the high fluid loss into the formation matrix.

The high viscosity of the fluid prevented the risk of screen-out and guaranteed the conductivity of the fracture. However, the height of the fracture also increased which led to the risk of gas and water infiltration. Hydraulic fracturing was further optimized by reducing the polymer concentration and increasing the concentration of the enzyme breaker to clean the fracture from the polymer residues and, consequently, increased the residual conductivity of the fracture. This enabled a significant reduction in the polymer concentration without increasing the accident rate – from 3.6 to 2.2 kg/m3. As a result, the viscosity of the cross-linked gel has been reduced to an average of 400-450 mPa⋅s. In total, 370 well operations were performed in the project, the share of complications (screen-out) was less than 5%, which was a very good indicator. Most of the complications were related to technical propblems (equipment operations), such as deviations in the injection of the proppant (proppant concentration spikes) and chemical agents. Facture height control was carried out to validate the chosen approach – micro-seismic monitoring, which physically evaluates the efficiency of the operation, not only in terms of the production parameters or the results of the hydraulic fracturing simulation. Figure 1 shows the comparison of the fracture height calculations via the fracturing design and micro-seismic monitoring. The data from the simulation and the micro-seismic monitoring have been validated in well operation without signs of fracture breakthrough into non-target layers [3].

Pilot Operations for Optimising Fluid and Fracture Design

In addition to the testing of the fluid and fracturing design optimization, pilot operations injecting viscoelastic surfactants were also conducted. Viscoelastic surfactant fluids have good sand-bearing capacity at a reduced viscosities (about 250 mPa⋅s), but very high demands are then placed on the equipment. In addition, viscoelastic surfactants are much more expensive.

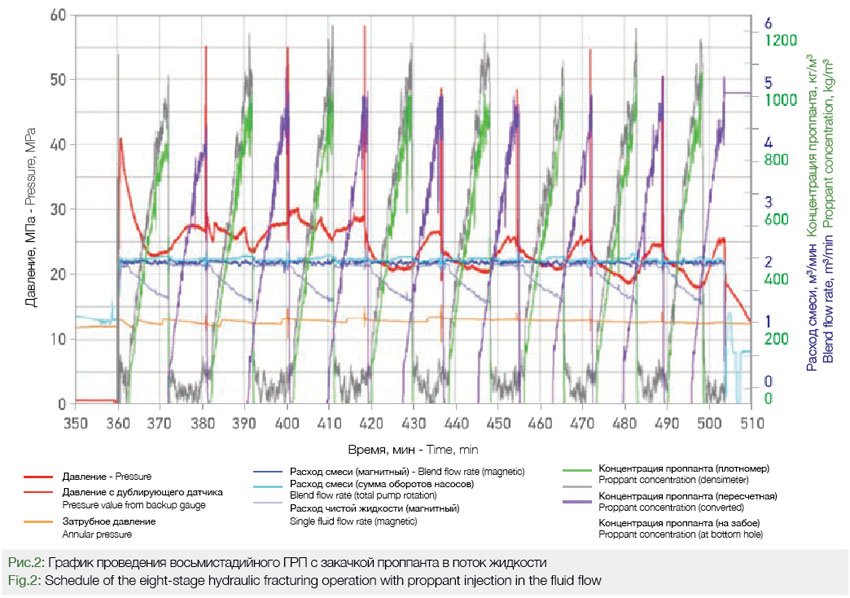

Nine well operations were carried out, the share of complications (screen-out) with this technology was 25%. The main reasons for the complications was the unwillingness of the contractor to perform the operations with this fluid. The well’s performance was evaluated by a dimensionless productivity index normalized to the production rate after one fracturing stage. This fracturing technology with viscoelastic surfactant fluid has been proven to be efficient. However, this technology is not widely used due to the high cost and high percentage of complications as compared to the guar-based fluid technology. In order to minimize the risks of breakthroughs during hydraulic fracturing when injecting 8-10 tons of proppant, a ball-drop tool has also been utilized. This tool enabled eight stage fracturing without stopping the injection, which has proved its efficiency. As a result, the unproductive volume of the fluid pumped into the formation is reduced by several times (the fluid volume is reduced by 30-40% due to the cancellation of pumping tests for each fracturing stage and the reduction of the fluid volume during pumping). The duration of eight fracturing stages is also reduced (duration from the time the fracturing fleet arrives at location is reduced by almost half). A significant overall time reduction has also been achieved. For example, pumping of 10 tons of proppant per stage as part of eight-stage fracturing was completed in 2 hours (Fig. 2).

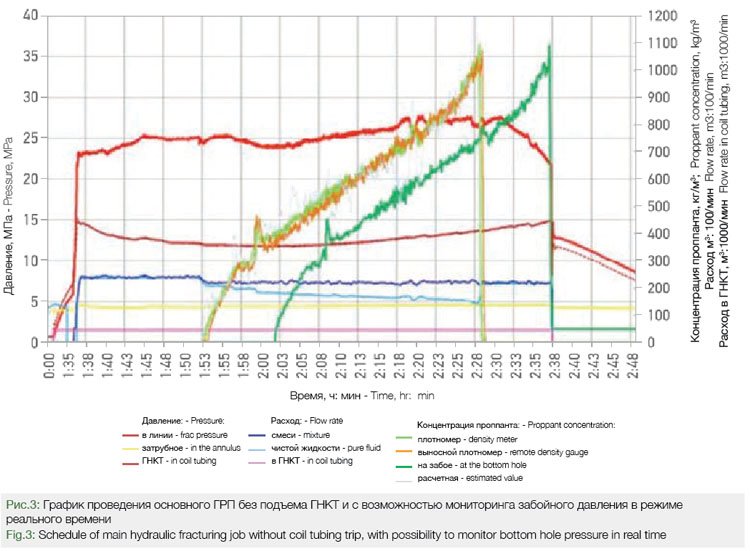

However, when pumping 8-10 tons of proppant per fracturing sleeve, there is a risk of complications from the activation ball for the subsequent sleeve which has already been dropped into the well during proppant injection into the stimulated formation interval. In case of screen-out, the presence of the ball in the tubing string seriously hampers further work in the well [3]. In order to minimize these risks multistage fracturing completion configurations with reusable CT-operated sleeves have been implemented. Fracturing fluid is pumped through the annular space between tubing and coiled tubing with a CT-deployed key below the target frac port. This dispensed the “unnecessary” runs for each stage and provided the unique ability to monitor the bottomhole pressure inside the coiled tubing in real time (Fig. 3).

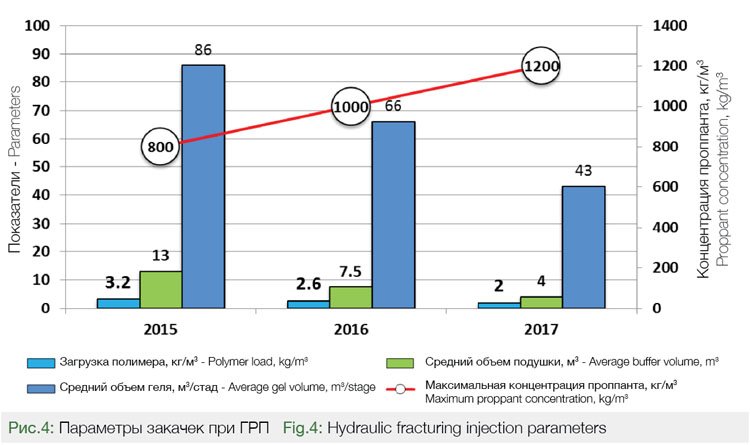

This made it possible to evaluate the efficiency of proppant pack in the fracture during operations and to propose well-reasoned optimization changes to the pumping program. After fracturing the port is closed, which eliminates additional clogging of the newly treated interval and facilitates the proppant removal from the stimulated frac port into the wellbore during the next stages. It was decided to replicate this technology within one area of the field. Implementing all the described stages of fluid and fracturing optimization technologies resulted in the fracturing injection parameters shown in Fig. 4. In addition to reducing the polymer content in the fracturing fluids, Gazprom Neft has implemented the method of pumping combined buffer pills (linear + cross-linked gel) with a constant decrease in the concentration of the cross-linked fluids without changing the volume of the buffer fluid. It is possible to pump fully linear buffer fluid for reservoirs that do not have the risk of a breakthrough in the non-target interval. In Western Siberia operations, the fluid was injected into low porosity and permeability reservoirs at a depth of 2350-2650m. The efficiency of the cross-linked fracturing fluids in these reservoirs reached more than 60%. The positive results and experience were subsequently adapted and transferred to reservoirs with a risk of a breakthrough in gas-oil and water-oil contact. These reservoirs are characterized by relatively high porosity and permeability, depth 750-780 m. The efficiency of cross-linked fluid in these reservoirs reached 45%.

Fluid injection optimization in these reservoirs enabled a proppant concentration of 200 kg/m3, fraction 16/20 for fluid based on linear gel, and proppant concentration of 1400 kg/m3, fraction 12/18 – for fluid based on cross-linked gel.

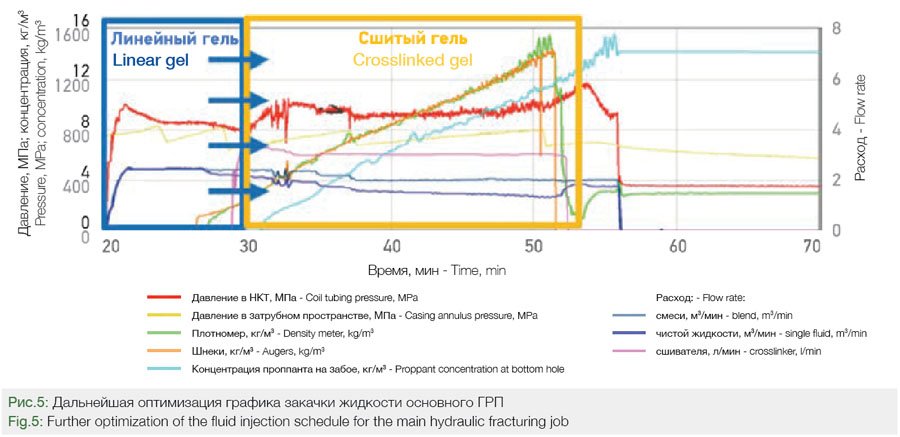

The first horizontal well to test this approach was completed with five ball-drop sleeves with a horizontal section length of approximately 1000m. The increase of the linear gel content in the buffer stage was carried out gradually step by step. During the fracturing of the fifth stage, linear fluid was used both at the buffer and proppant pumping stages up to the proppant concentration value of 200 kg/m3. Further injection with gradual increases of proppant concentrations up to 1400 kg/m3 was carried out with the fluid based on cross-linked gel with a concentration of 2.4 kg/m3. In addition, the pumping rate was reduced from 2.4 m3/min during the buffer stage to 2.0 m3/min by the end of the operation. The average proppant volume was 30 tons per stage. Oil production exceeded expectations by 25%. The optimization of fluid, fracturing technology and injection program is yet to be completed and will be further developed to determine the optimum ratio of linear and cross-linked components of the gel (Fig. 5).

It is planned to reduce the polymer concentration to 1.8 kg/m3, increase the maximum proppant concentration up to 1600-1800 kg/m3. It is also planned to use larger proppant fraction 10/14.

Conclusion

Gazprom Neft’s specialists provided a successful technological approach for the development of hard-to-recover reserves in Western Siberian fields with reservoirs with close proximity to oil-gas and water-oil contacts and low stress lithological barriers. Solutions for hydraulic fracturing in reservoirs with close proximity to oil-gas and water-oil contacts were tested and implemented while maintaining technological success without increasing the cost of the operations. These solutions include reduction of the concentration of guar polymer, the application of a ball-dropping tools, hybrid fracturing design and full-bore ball-free completion technologies. The efficiency of the optimized technologies is confirmed by the actual production of the stimulated wells. This enables the prospect to replicate these technologies at fields with the same or similar conditions.

Reference

1. Sugaipov D.A., Bazhenov D.Yu., Devyatyarov S.S. et al., Integrirovannyy podkhod k razrabotke neftyanykh otorochek Novoportovskogo neftegazokondensatnogo mestorozhdeniya (In Russ.), Neftyanoe khozyaystvo = Oil Industry, 2016, no. 12, pp. 60-63.

2. Yudin A., Sypchenko S., Gromovenko A. et al., First in Russia large-scale implementation of the channel fracturing technology in horizontal wells (In Russ.), SPE-187932-RU, 2017.

3. Kazakov E., Vereschagin S., Kichigin A. et al., Precise fracturing: Increasing number of stages and reducing treatments size in oil rims of Novoportovskoe oil field (In Russ.), SPE-187680-RU, 2017.

4. Kuvakina M.S., The combine completion of the wells for development oil rims (In Russ.), PRONeft’, 2018, no. 4, pp. 44-47, DOI: 10.24887/2587-7399-2018-4-44-47.

Published with thanks to Gazprom Neft & PROneft Magazine

Authors:

E.G. Kazakov, I.G. Fayzullin, E.F. Sayfutdinov,

Gazpromneft NTC LLC, RF, Saint-Petersburg

A.A. Korepanov, Gazpromneft–Yamal LLC, RF, Tyumen

N.V. Chebykin, Gazpromneft–Khantos LLC, RF, Khanty-Mansiysk

A.Yu. Konopelko, Messoyakhaneftegaz JSC, RF, Tyumen