GEA Separators Help Quenching the Worldwide Oil Thirst

GEA centrifugal separators for conventional and non-conventional crude oil treatment

Thanks to technological progress and the development of new oil reserves, crude oil will remain the most important source of energy and raw material for the global economy in the coming decades. According to Statista the global oil production has risen steadily over the past fifty years – to a peak of around 94.72 million barrels per day in 2018. This means that daily production has roughly tripled over the same period. Rising global consumption, particularly in the emerging economies of China, India, Brazil and Mexico, require more efficient technologies and new ways to handle also heavy-to-extract oil wells. The role of non-conventional crude oil production and hard to recover oil reserves becomes more important.

GEA centrifugal separators are the efficient, state of art solution for crude oil treatment. They play a key role in unconventional crude oil treatment. More and more oil companies are turning to unconventional potentials such as deep-sea oil, oil sand, and heavy crude oil (HCO). Even resources that have already been developed still offer considerable untapped potential: the conventional deposits exploited by primary methods are only depleted on average by about 35 percent, depending on the properties of the deposit and crude oil. Yields can be increased there by up to 60 percent with a thermal tertiary process. This method has also proven to be effective in the extraction of heavy crude oil. Hot water or steam is injected into the reservoir via a horizontal well to enable the high-viscosity heavy crude oil to flow after it is released from the reservoir rock. The oil is collected via a second horizontal well, channelled to a pumping system and then conveyed to the surface for further processing with GEA centrifugal separators.

Oil producers choose GEA centrifugal separators for efficient crude oil treatment in extremely challenging conditions

The processing of heavy crude oil places high demands on technology and methods. These oil deposits are often in environments with difficult working conditions. The oil field in the Timan-Pechora Basin, located in the Republic of Komi on the Arctic Circle in northern Russia, is one of the greatest examples demonstrating that GEA centrifugal separators easily master these challenges. One of the largest oil producers in Russia produces heavy crude oil in Timan-Pechora at temperatures below 40 °C minus in winter. The oil is processed with the help of eight GEA centrifugal separators to an exportable quality with a solids and sediment content (BS&W) of less than 0.5 percent – and that in just two stages. The eight disc-stack centrifuges with discontinuous solids discharge have been commissioned in 2016. They are designed for the processing of heavy crude oil with a specific gravity of 16 degrees API (965 kg/m3). If required, the centrifuges can also process higher densities or modified for produced water treatment.

GEA separators for efficient heavy crude oil processing in the best export quality

The heavy crude oil, extracted from the reservoir with steam at a temperature exceeding 300 °C, is first pumped into above-ground tanks. There, using chemical additives as an emulsion breaker, coarse solids and water settle in the tank. Through a smart tank management, the heavy crude oil is pre-conditioned until certain feed parameters for the centrifuges are achieved. If predefined parameters are met, this oil mixture is sent to the centrifugal separators for processing. Depending on the degree of exploitation of the deposit, the levels of water and solids such as sand, change in the oil produced. The GEA centrifugal separators are designed for these fluctuations, for example, a water content of 5 to 40 percent. Compared to conventional gravity separators, this ensures fast, continuous processing with significant advantages for the operating company: smaller, space-saving tanks for pre-separation and significantly reduced production time up to ready-for-sale heavy crude oil in the best export quality.

GEA – best quality for long service life even under the harshest working conditions

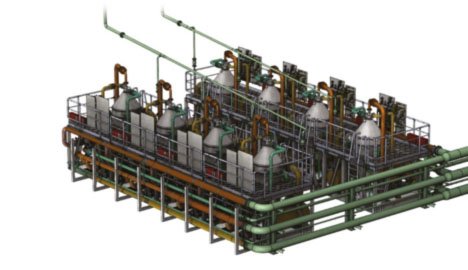

The GEA OSE and ODB centrifugal separators guarantee long service lives combined with top performance, even under the harshest operating conditions with fluctuating oil qualities. This is where the more than 50-year GEA expertise from oil sand processing, which has gone into the development of the centrifugal separators, pays off. For example, in wear protection: all parts coming in contact with the product in the rotating bowl are lined with a tungsten carbide layer. This layer is very resistant to the abrasive action of sand and provides an excellent basis for long service life. Another advantage for the operating company is the installation of the eight centrifugal separators in a compact system design. The building for this only requires a small footprint which takes up 12 x 40 m of floor space. In addition, with the machines working in parallel configuration, a continuous 365/24 production time is ensured since individual centrifugal separators can be maintained at any time without interruption of production or lost capacity.

This heavy crude oil processing method with GEA centrifugal separators provides oil processing companies with high productivity and efficiency right from the start. This is due to the flexibility and optimized life of the system. In 2017, a total of over six million barrels of exportable heavy crude oil with a BS&W share of less than 0.5 percent could be extracted from the North Russian oil field. And GEA engineers are working together with the customer to continuously increase this output through further process optimization.

Image 1: Heavy crude oil dewatering with high g-force centrifugal separators from GEA. (GEA)