Geo-Supervision: the Thorny Path of a Single Innovation

With this publication, we will continue our series of articles looking at the management-related segment, of oilfield services, called supervision. Since the publication of our first article in April’s 2017 Issue of ROGTEC Magazine [1], little has changed fundamentally in terms of the key players, market size, and operating principles in our industry. One of the promising areas for further development of supervision is combining or supplementing it with other types of oilfield services. One new type of service implemented to date by NIPTs GNT is geo-supervision, which is all about enhancing traditional supervision with measuring instruments and systems. As a result, the quality of such supervision goes up to a fundamentally new level.

This article uses the specific example of geo-supervision to demonstrate the thorny and convoluted path, from the inception of an idea to its commercialization, which the oilfield service businesses must tread in order to implement the innovations that their client companies require so badly.

The Birth of Innovation

The idea to combine traditional supervision with instrumental monitoring was born from the hands-on drill site experience of field supervisors managing the drilling processes and crews in charge of maintenance of the surface logging units which measure the key drilling parameters. It seemed easier and more logical to concentrate these two types of oilfield services in a single pair of hands. But, unfortunately, the two had to go their separate ways in Russia: they are provided by different contractors, procured in separate tenders, subjected to separate sets of requirements. Often enough, this results in a paradoxical situation at the drilling site: the field supervisor, who manages the drilling process and assumes full responsibility for its results, must make decisions relying on the ‘eyes and ears’ of someone else, i. e. the surface logging contractor, whose quality and integrity are beyond the supervisor’s control.

Figuratively, this is easy to imagine this situation as a car whose dashboard was placed in front of the passenger, not the driver (Fig. 1). That way, the driver (supervisor) is supposed to control the car (drilling processes) without seeing the dashboard, being compelled to rely entirely on the passenger (the surface logging contractor) communicating the readings on the display to them. In this case, the driver will always have doubts about all sorts of things, starting from the poor qualifications of the passenger, who can easily misread a parameter or two, and ending with false representations intended to mislead the driver. It is, thus, quite reasonable to move the dashboard back to the driver.

And it was this line of reasoning that helped shape the final shape to the concept of geo-supervision – i. e. supervision enhanced with inspection and measurement instruments as well as analytical tools for real-time objective monitoring of the processes (Fig. 2).

The effectiveness of the new types of services is achieved by adding an additional feature – process parameter monitoring. Consider the day that the mobile phone was equipped with a camera, this is a good example of a well-known product receiving an extra feature or augmentation.

The reason behind the choice of a new, separate name, geo-supervising, is to help and identify the new service types to distinguish it from the other, traditional oilfield services. Securing the authorship of the new idea was made possible by patenting the key elements of the system include a mobile surface logging unit for the geo-supervisor and a optimization suit software to integrate and monitor the work flows. At the same time, active efforts began to promote the concept of geo-supervision in industry-specific publications across the region [4, 5].

Implementing Innovation

We decided to share our concept of geo-supervision with our existing Customers, whose projects are the main playing field for NIPTs GNT’s supervision activity. Fortunately, one subsidiary company (SC) of a major Russian VIOC was open to the idea and concept of improving their operations. They took the liberty to let NIPTs GNT carry out some pilot tests (PT) at their project sites. This was conducted at the Contractor’s expense and using the Contractor’s own materials and equipment.

Results of Implementation

In March 2016 JSC “Research and Design Center for Gas and Oil Technologies” began implementing a pilot testing (PT) program for administering geo-supervision during well servicing and workover operations (WSWO) at the facilities of one of the Subsidiary Companies of a Russian VIOC. A characteristic feature of this service is the combination of three standard types of services during the performance of WSWO:

• Mobile WSWO supervision – the activity focused on managing the work of service entities contracted or subcontracted to perform the respective well intervention;

• Registration and monitoring of fluid parameters during WSWO – studying the parameters of drilling and cleanout fluids;

• Registration and monitoring of geotechnical process parameters during WSWO – studying the geotechnical process parameters during WSWO.

An analysis of the current WSWO activities, at the well sites of Subsidiary Company, made it possible to highlight the main operations that require special supervision, as they are conducted, and the physical parameters that required careful measurement. As a result, the standard mobile workstation of the WSWO supervisor was equipped with a fluid injection monitoring unit (SKUTP-1) to measure the parameters of the fluid injected into the well through a delivery line, recording. its pressure, temperature, density, and flow rate. Figure 3 shows a photograph of a mobile geo-supervision station mounted on a NIVA pickup truck.

The very first tests carried out under the PT program at several well sites promptly revealed the main causes of high accident rates during WSWO. In particular, WSWO service contractors were interrupting, or otherwise not complying with, their prescribed process work flows, using faulty equipment and underperforming pumps, failing to use adequate amounts of drilling fluids in their operations.

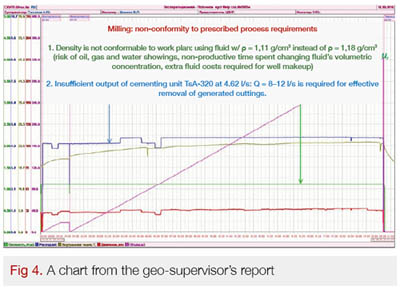

Figure 4 shows a sample chart from the geo-supervisor’s report that made it possible to quickly identify any deviation from the work plan and non-conformity to the prescribed process requirements.

The synergies from combining supervision and injection parameters did not take long to produce results: the supervisor’s orders to remedy the faults were issued to the Contractor, coordinated with the Customer, and monitored immediately. Yet another success was achieved by preventing any misrepresentation and fraudulent reporting by the WSWO service contractor.

The statistical materials obtained in the initial tests made it possible to analyze and systemize the nonproductive time during WSWO. In addition to the time spent directly working on the remediation of non-conformities and defects, the WSWO contractor would exceed the standard time prescribed for the performance of process flow tasks and would stand idle awaiting delivery of materials, special machinery or equipment. The results of the first series of experiments were used to prepare action plans and recommendations for well servicing entities.

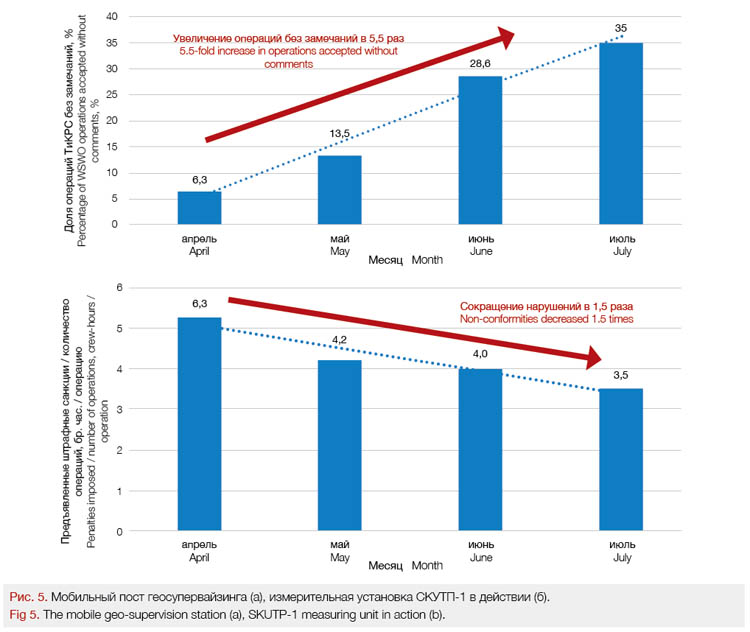

Subsequent developments towards introducing the concept of geo-supervision at the well sites made it possible to achieve a significant improvement in the quality of WSWO operations over time (Figure 5). In particular, there were now fewer deviations in the density and volume of the injected kill fluid from the respective design target values. WSWO crews were now going to greater lengths preparing for each process step: less time was spent for preparatory work, and there were fewer deliveries of unprepared or defective equipment requiring in situ repairs.

Obviously, the positive effects of geo-supervision have been achieved precisely because of the combination of the following features:

1) providing the supervisor with a certified and calibrated high-accuracy software and hardware measuring apparatus whose measurement data would constitute conclusive evidence for non-conformities;

2) timely remediation of non-conformities and monitoring the results of such remediation directly at the work site;

3) influencing the well servicing contractors in a prompt and effective manner.

If all the services listed above which were performed separately, by different contractors, no such effects would be seen.

Commercializing Innovation

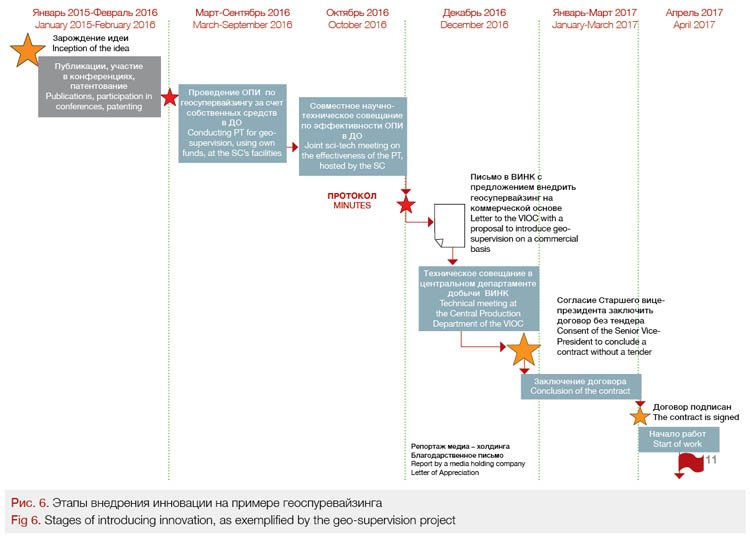

Significant positive feedback and results were demonstrated after the TP program . The effects of introducing geo-supervision were discussed at a joint sci-tech meeting, with positive feedback supplied by the team members from the Subsidiary Company who took park in the project. The next stage would be a full scale launch across the SC with the geo-supervision system. NIPTs GNT contacted the Central Production Department of the VIOC with a proposal to introduce geo-supervision across the organization

After an internal review the VIOC decide to proceed with the implementation of geo supervising having analysed the benefits of the systems and deciding to roll the project out across the company

After the PT, one system was fully launched in 2017. After this projects implementation and execution the company again reviewed the operation performance. Based on this review the project was renewed and expanded to 4 geo supervising stations. The entire thorny path of this innovation from the PT stage to

the conclusion of a commercial contract is shown

in Figure 6.

Conclusion

The results of the implementation of the innovative idea to strengthen supervising by instrumental control tools (geosuperveying) have proved their effectiveness. For example, only one geosuperveying post for an incomplete year of work, at a cost of 12.3 million rubles, allowed VIOC to save about 40 million rubles by imposing penalties on the contractor for the WSWO Contractor. In the future, the work of geo-superversing monitored the WSWO Contractor, reducing accidents and unproductive time by 12%.

The effects realized by implementing the innovation were so valuable the Subsidiary Company shot a separate video for their corporate television channel about how this geo-supervision innovation was

adopted [6].

Our experience of introducing innovation to a Russian VIOC, as exemplified by the geo-supervision project, has made it clear that oilfield service companies should be ready, at the first (PT) stage, to carry out pilot work using their own funds and resources. Worse still, whether or not PT will be initiated by the VIOC may sometimes be a matter of chance or good fortune. What plays the main role here is interest on the part of the potential Customer and the personal ambitions of its mid-tier managers that stimulate them to adopt new technology, sometimes exceeding their official powers and risking negative consequences for their career on account of their own initiative. However, even obtaining positive and outstanding results does not guarantee that the oilfield service company will be able to successfully commercialize its innovation in the future. The outcome here may entirely depend on the internal coordination procedures at work in the specific VIOC, where sometimes the decision to implement an innovation depends on the opinion of just one person from the top management.

Bibliography

1. Щебетов А. В. Супервайзинг как бизнес: дешево и сердито. ROGTEC. – Апрель 2017. – С. 64–73. (A. V. Shchebetov. Supervision as a business: cheap but good. ROGTEC. – April 2017. – P. 64–73.)

2. Certificate of state registration of a computer program No. 2017611562, Software Suite “ARM Geosupervayzera,” registration date: February 6, 2017.

3. Patent for Invention re. Application No. 2016148006, “A mobile surface logging unit for the supervisor.” Priority as of December 7, 2016.

4. Кульчицкий В. В., Щебетов А. В., Пархоменко А. К., Даутов И. И., Яскин С. А., Кондратьев В. В., Телков О. П. Геосупервайзинг – прогрессивная система управления качеством внутрискважинных работ //Управление качеством в нефтегазовом комплексе. – 2016. – № 4. – С. 12–16. (V. V. Kulchitsky, A. V. Shchebetov, A. K. Parkhomenko, I. I. Dautov, S. A. Yaskin, V. V. Kondratyev, O. P. Telkov. Geo-supervision – a progressive system of downhole work quality control // Quality Management in the Oil and Gas Sector. – 2016. – No. 4. –P. 12–16.)

5. Аппаратно-программный комплекс геосупервайзинга бурения и внутрискважинных работ. Кульчицкий В. В., Щебетов А. В., Пархоменко А. К., Гришин Д. В., Насери Я. С. // Оборудование и технологии для нефтегазового комплекса. – М.: ОАО «ВНИИОЭНГ», 2017. – № 2. – С. 55–59 (A hardware and software system for geo-supervision over drilling and well intervention work. Moscow: JSC “VNIIOENG,” 2017. –No. 2. – P. 55–59.)

6. Instrumental supervision at the fields of Western Siberia. A video report by a media holding company. https://www.youtube.com/watch?v=FkpOgtlRjTk&t=14s

Author:

A. V. Shchebetov: Manager at JSC “Research and Design Center for Gas and Oil Technologies” (NIPTs GNT)