How Tool Joint Build-Up And Extension Affects the Structure and Physical Properties of the Tool Joint and Drill Pipe Body Friction Weld Zone

The construction of oil and gas wells produces considerable wear and tear on the outer surface of drill pipes, especially those operating in horizontal sections, therefore various tool joint build up techniques have been used for both the repair of the outer diameter and to extend the tool joint.

During welding operations to extend the tool joint, the tool joint build up layer overlaps the friction welded areas and the heat affected zones of the upset section of the pipe and joint. The effect of the applied build up wire on the base metal and the friction weld zone has not been sufficiently studied.

This study was targeted to determine the impact and role of the build up wire on the formation, structure, and mechanical properties of the low-alloy pearlitic steels.

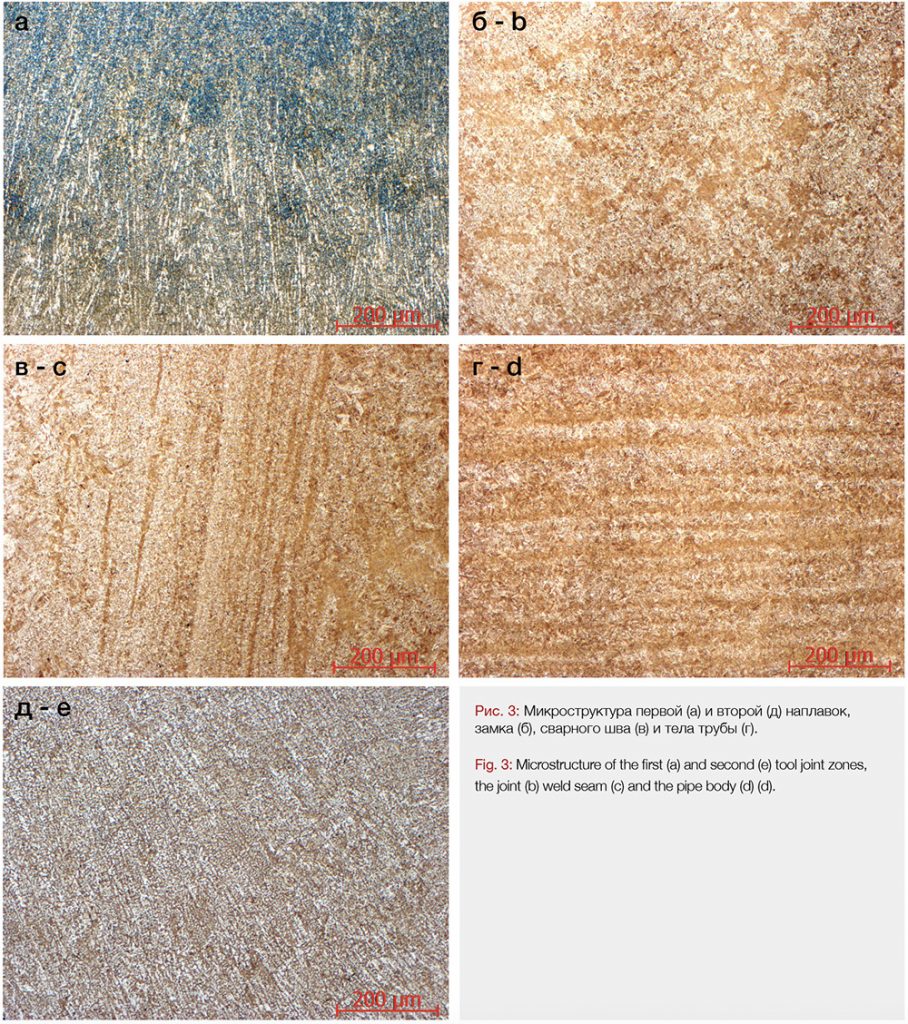

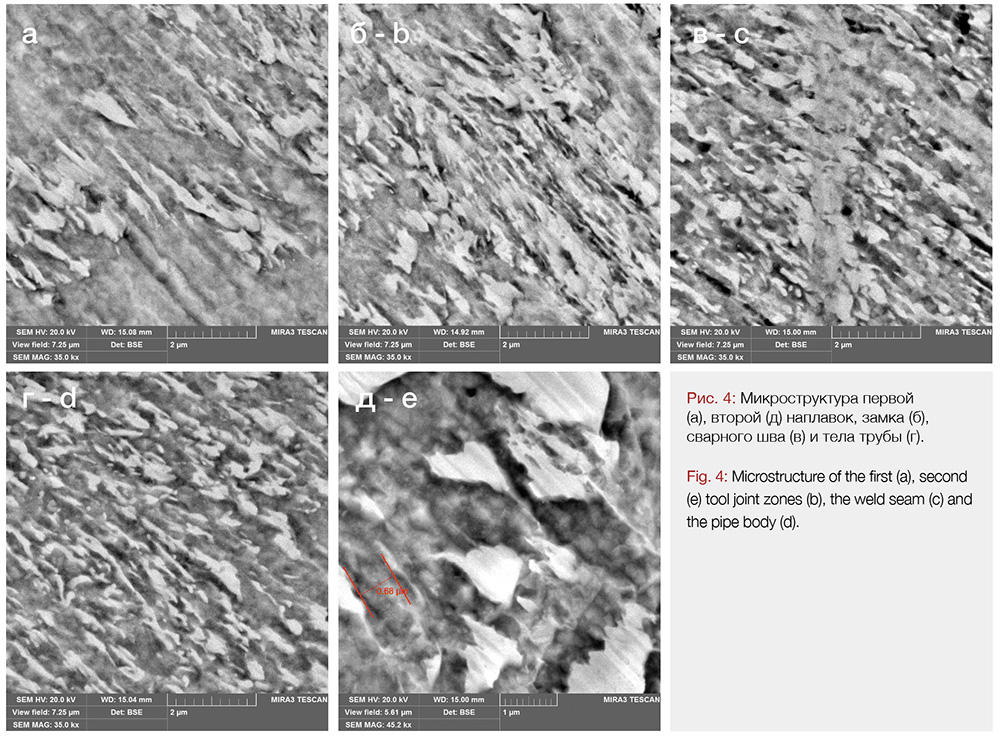

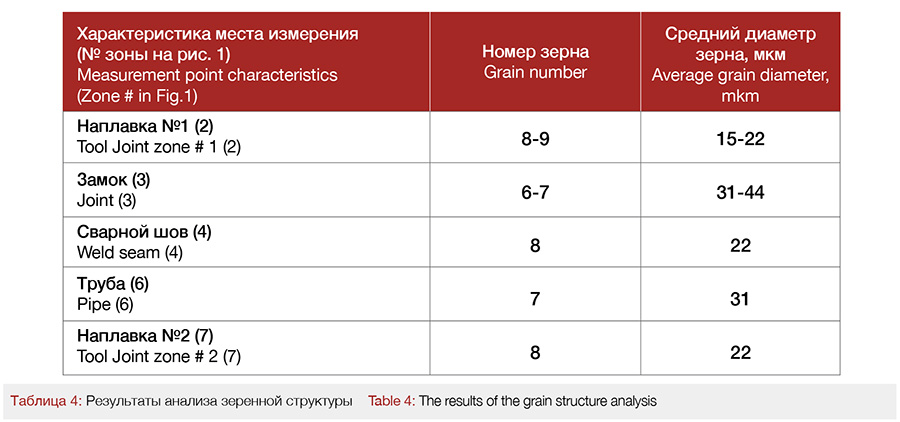

Research has been conducted on the structure of the build up zones, the friction weld zone, the overlapping heat affected zones of the build up area and the friction weld. It was discovered that the overlapping zones had a low influence on the mechanical properties. The mechanical properties did not vary much before and after the tool joint was connected to the pipe body. The grain size and the interlamellar spacing were also determined. The size of the structural elements of the plates, near the second (outer) facing layer, were almost one and a half times smaller than the size of the laths and interlamellar spacing in the different parts of the elements, however, the plate-like structure of pearlite remained unchanged, and the number of ferrite fields was insignificant.

Introduction

The structure and composition of steel has a significant influence on the processes of welding and tool joint build up wire application. Most of the fluids in oil fields have a dissolved CO2 and H2S presence. The task has thus been set to obtain a robust, reliable and homogeneous steel structure, with increased corrosive resistance.

Pipes are usually manufactured from Fe-Mn-Si-(V) alloy, steel types 09G2S, 20F, 09GSF, 17G1C, 14G2 that do not have the feature high levels of mechanical properties and low corrosive resistance for CO2 phases. The maximum resistance to corrosion and mechanical failure was demonstrated by steel type 08HMFA, whose properties can be also slightly increased improved with microalloying.

Drill pipes are manufactured from steel types 32G2, 38HGMA, 40HGMA and 40HN2MA. The structure of low carbon steels used for welding are ferrite-pearlitic (FPS). The FPS of a jointthe friction weld and the heat affected zone (HAZ) were measured after welding in wide range of heating temperatures and cooling rates. Steels with carbon content of up to 0.25-0.3%С ensures high-quality friction weld zones, uniform distribution of the pearlite and ferrite sectors in the core of the weld and in the HAZ.

An efficient way to increase the strength is the use of pearlite-type steels (PS). For low-alloy steels, the strength increase Δσ due to the increased part of pearlite, can be determined using the following expression (1)

Δσ=2.4П, (1)

where П – is a volume fraction of the pearlite component, %.

Another factor determining the strength increase is PS dispersiveness. Pseudopearlite is formed in alloyed steels with lower carbon content than it is in the eutectoid composition.

The quality of drill pipes depends on two basic parameters: corrosion resistance and structural integrity. The structural composition of steel determines its serviceability. The durability of the product is very much determined by their its design.

Pearlite-type steels (PS) have higher strength compared with FPS, and friction welding is a preferred method for connection connecting them together.

Work objective: to determine the HAZ structure, the core, facing and areas of its connection with a pipe surface as a result of friction welding using the pearlite- steels.

Research and Test Methodology

The build-up wire was applied to a SBT-89х9,35 drill pipe tool joint, strength group S135, using a Castolin DS-XM welding unit, with a pipe rotator and length travel stepper motor manufactured by PLATINUM-Service, allowing an automated application. A 3mm build-up wire was used with a Ar/15-25CO2 gas mixture.

The coulometric method was used to analyze the carbon and sulfur content, using an online analyzer АН-7529М (for carbon) and type АС-7932М (for sulfur).

The composition of the steel was determined through chemical testing and X-ray spectroscopy, using a Mira 3 TESCAN Oxford Instruments X-Max electron microscope.

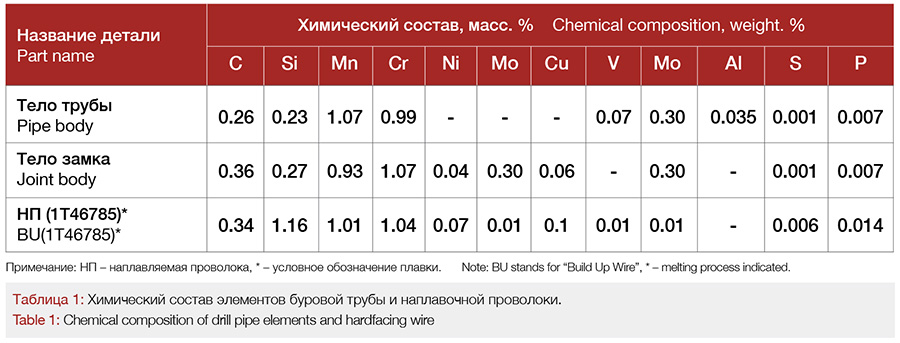

The chemical composition of the material of the parts under study is presented in Table 1.

To determine the mechanical properties of the drill pipe upset end, friction weld, the build up layer and the base metal, tensile tests were carried out for fivefold longitudinal test specimen type III #7 using a tensile test machine type UEM-10T (УЭМ-10Т) under room temperature, the load application rate of 5mm/min, and recorder scale of 25, in accordance with GOST 1497-84, taking into account ASTM A370 requirements; through the tensile impact test for standard specimen type 11 under the temperature of +20 ОС using impact testing machine type КМ-30 in accordance with GOST 9454-78, taking into account ASTM E23 requirements; through the Brinnel hardness test, in accordance with GOST 9012-59; through the Rockwell hardness test using cone indentation, GOST 9013-59; through the micro-hardness test using PMT-3 device, in accordance with GOST9450-71; through the metallographic analysis, using Neophot-32 instrument and digital inverted-stage microscope Zeiss Axiovert 40MA; through the submicroscopic analysis, using HitachiS-3400N and PhenomProX.

Review of the Results

As it follows from Table 1, low-alloy steels, similar by their composition and mechanical properties, were used for manufacturing the pipe body and the tool joint, featuring rather high tensile strength ( at a level of 1000 MPa) and KCV of not less than 120 J/cm2 , Table 2.

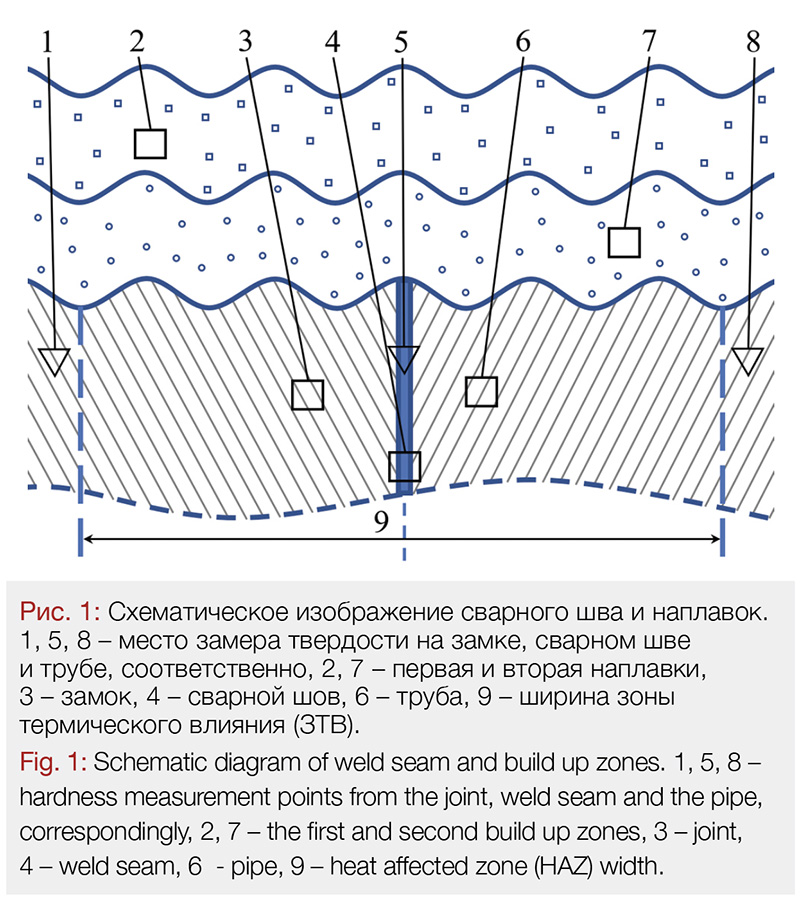

Schematic diagram of weld seam and build up zones is illustrated in Fig.1.

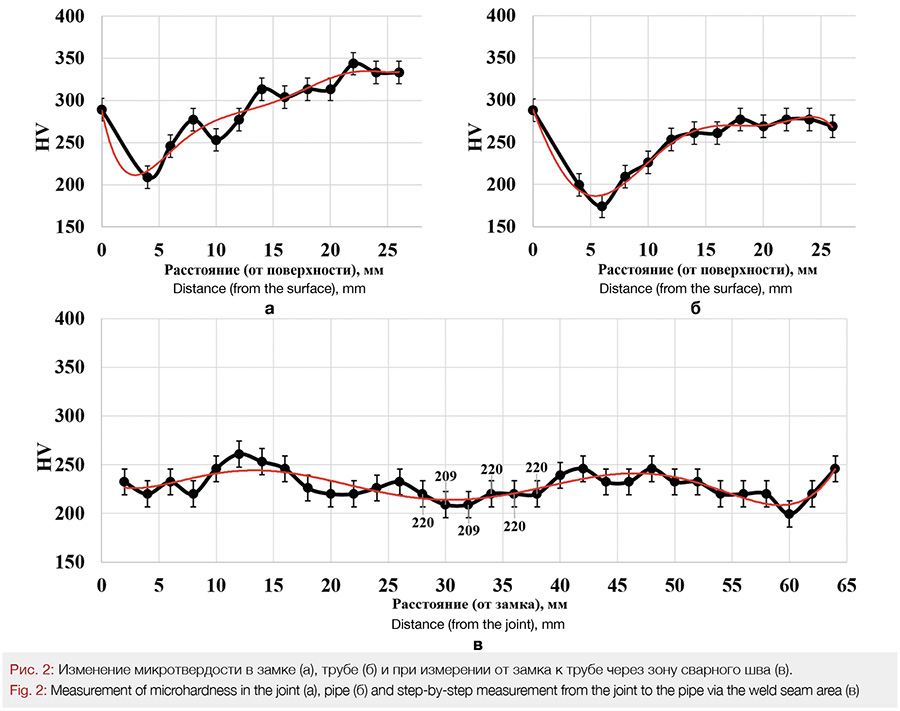

Measurement output data for mechanical properties during tensile test, hardness profile (Fig.2) and KCV indicated that the steels have the pearlite-type structure.

Hardness in the surface adjacent zone of the build up layer shows 290 to 300 HV which can be explained by the high cool-down rate of the puddle and by the sorbito-pearlitic structure that formed. The values uniformly decrease in the mid zone of the applied layer which is conditioned by cooling.

Hardness uniformly increases from the applied layer to the tool joint and the pipe body material up to 280-340 HV, see Fig.2, (a,b); hardness variations can be also observed in the heat affected zones. Hardness in the HAZ stays at 260-280 HV, the minimum hardness value was determined at a distance of 6 mm from the outer surface of the tool joint.

Hardness lengthways measurements, Fig.2 (в) carried out in the base metal throughout the entire test specimen revealed that, when performing friction welding, the weld zone did not differ much by hardness from the other areas. The microhardness value in the HAZ of the weld seam was in the range of 209 – 220 HV. Some changes could be observed both microscopically and visually, Fig.3, 4. A little increase in hardness near the surface and heat affected zones can be explained by higher cooling rate.

The following data of the structure were obtained from an electron microscope investigation Fig.4, Table 3.

The average effective grain size varies within a narrow range of 15 mkm in the applied layer top zone, to 44 mkm in the base metal zone, see Table 4. The result fits in well with the mechanical testing outputs.

It should be noted that no defects of metallurgical character like discontinuity flaws, microfissures, pores etc. were detected in the structures under study.

Conclusions

Friction welding has a negligible influence on the structure and hardness profile in the heat affected zones.

The build up wire application strongly affects the hardness profile in adjacent areas but it makes it possible to maintain the pearlite-type structure. Judging by the results, the hardness of the ferritic and pearlitic steels conforms to the rule of additivity, with consideration given to the dispersiveness of pearlite.

The high cooling rate of the surface following the application is the cause of the formed sorbito-pearlitic structure in the build up layer, which transforms into the pearlitic one in the areas away from the surface.

The selected build up application modes have no marginal impact on the structure of the friction weld and its heat affected zones (HAZ), no cracking occurred.

The research into the influence of tool joint build up wires on the structure and properties of drill pipe makes it possible to repair the pipe without negatively affecting its characteristics and to extended its run life.

On the other hand, a promising way to extend the lifetime of the tool joint is to apply a hardbanding wire to further protect the tool joint. Hardbanding is a wear resistant protective metal layer, applied to the external surface of the drill pipe tool joint.

The tool joint build up and extension will not be required for most of the drill pipes if the pipe owners implement proper monitoring of the hardbanding layer condition and height, followed the existing technical procedures, and inspecting their pipes regularly.

List of References

1. A.A. Babenko, V.I. Zhuchkov, N.I. Sel’menskikh, A.G.Upolovnikova Structure and properties of 17G1S-U low-carbon pipe steel microalloyed by boron. Higher Education News. Iron and Steel Industry. – 2018. Vol 61. – Issue 10. P.774-779.

2. М. Caltaru Tribological characterization of the drill pipe tool joints reconditioned by using welding technologies / М. Badicioiu, R. G. Ripeanu, А. Dinita, М. Minescu, Е. Laudacescu. // IOP Conf. Series: Materials Science and Engineering – 2018. Vol. – 295 012010. doi:10.1088/1757-899X/295/1/012010.

3. L. Han. A new method to determine the required impact toughness for petroleum drill pipe used in critical sour environment / F. Hu, H. Wang, Y. Feng, H. Li// Procedia Engineering. – 2011. Vol. – 16. P. 667-672. doi:10.1016/j.proeng.2011.08.1139.

4. H. Yan Failure Analysis on Fracture of a S135 Drill Pipe / Z. Xuehu, B. Zhenquan, Y. Chengxian// Procedia Materials Science. – 2014. Vol. – 3. P. 447 – 453. doi: 10.1016/j.mspro.2014.06.075.

Author

Sergey Laptev,

Deputy Director, Business Development, Platinum-Service LLC