Technology Roundtable: Intelligent Well Completions

1. Intelligent well completions or ‘smart’ wells enable operators to acquire data, monitor and remotely control well operations for maximum productivity. What is the degree of this technology implementation in Russia and what operators are currently using it?

Weatherford: Intelligent well completion is an integrated package featuring complex design and including control tools, inflow or conformance control devices in dual completion/dual injection systems, downhole monitoring systems (in various zones and sidetracks), as well as control and emergency shut-in systems. This comprehensive package enables automation and optimization of reservoirs or target developments at a local level, as well as standalone or remote-control operations.

There is currently slow but positive movement toward implementing this technology by both Russian and foreign operators. This is due to the development of new offshore and remote fields, with challenging geology, hard-to-recover reserves and assets that require innovative approaches — beyond conventional drilling and construction operations. Companies producing hydrocarbons at the Russian continental shelf (in the Sea of Okhotsk, Caspian Sea and Barents Sea) are currently developing ‘smart’ wells with specific design features.

While the number of complex, intelligent completions may be limited right now, most oil and gas producers are already using a simplified version of this method: the installation of a downhole monitoring system that includes pressure and temperature sensors, distributed and distributed/point temperature profiling and downhole flow meters.

Halliburton: At present, intelligent well completion systems are relevant for many Russian fields and are used to some extent by most major oil and gas companies carrying out development activities in the Russian Federation. Due to depletion of easily recoverable hydrocarbon reserves, as well as the need for development of more and more new fields located in hard-to-reach areas, it is becoming obvious that it is necessary to change approaches to field development in order to maintain the required production level. One of the key solution elements is the introduction of intelligent well completion systems allowing monitoring and control of the well operation throughout its service life and therefore carrying out continuous development optimization.

2. Is it possible to increase the degree of this technology application and to enhance its potential in Russia?

Weatherford: The degree of technology adoption depends on several key factors, which will determine what types of intelligent systems are implemented. These factors include:

- objectives;

- level of complexity;

- feasibility of implementing the selected completion system considering the engineering, technical and geological conditions of the well construction and design;

- cost of imported equipment and the high-quality components required for a successful operation;

- oil price;

- sanctions policy;

- import substitution policy;

- limited capabilities of Russian suppliers to provide intelligent well completion services.

If the conditions are favorable and if we succeed in overcoming certain technical challenges and budget limitations, then the potential of this advanced technology in Russia can be significantly increased.

Halliburton: We certainly have our features, such as climatic conditions, availability of existing infrastructure required for the introduction of these technologies as well as technical equipment of the personnel involved in the equipment operation process. However, all these are not an unsurmountable obstacles for the introduction of intelligent well completions. More and more oil and gas companies get convinced in reliability and efficiency of this solution after its application. If initially systems allowing only monitoring of individual parameters of producing wells were introduced, now operators introduce systems allowing monitoring of operation parameters of both the whole well and its individual intervals. The next stage of development will be the construction of intelligent fields. The Russian market definitely has a great potential, and Halliburton intends to take the most active part in its development, thus increasing its share in the sphere of intelligent well completion.

3. Are technology costs prohibitive in Russia, and what cost saving possibilities are offered by intellectual well completions?

Weatherford: The technology itself is flexible. The costs and production results of a well completed through intelligent methods greatly depend on the manufacturing quality of its components.

Weatherford offers a competitive system equipped with permanent downhole monitoring systems, with a service life spanning the whole operational life of the well; electronic systems, from basic to multi-zone; and multilateral configuration. This integrated package enables remote and continuous operations with high accuracy and without any operational interference, which results in a significant reduction of operators’ work-over expenses, manual labor, operating personnel and equipment.

Halliburton: The answer to this question and determination of feasibility of introducing intelligent well completions in each particular case requires integrated approach and participation of a wide range of experts both from the operator and the service company. Introducing this system, you get the access to a wide range of real-time information as well as the capability to control each well interval in process of its operation without the need for well intervention which saves time and significantly reduces the risks inevitably arising during workover. Information received from a group of wells can be centralized and used not only for current optimization but also for short-term planning of the field development for the purpose of increasing the total cumulative production and recovery factor. In addition, this technology will allow enhancing waterflood system efficiency by means of optimal distribution of chemical injection by formations in wells exposing multiple deposits. Also, it is necessary to take into account that efficient development of multiple reservoirs is virtually impossible without intelligent completion. Therefore, regardless of significant costs, the use of this technology will maximize the companies’ capabilities to provide efficient production.

4. What are the advantages of a ‘smart’ well for an operator?

Weatherford: One of the key intellectual completion tools is a permanent downhole monitoring and control system, which provides high accuracy monitoring over extended periods (up to 25 years!). This component is really necessary in an intellectual completion, and most operators have already enjoyed its benefits.

To start with, a ‘smart’ well equipped with monitoring systems enables an operator to decrease operational costs, to optimize production and to manage the whole field. The higher the number of wells, the greater economic effect will be achieved.

Halliburton: Using intelligent completions, an operator obtains a lot of various benefits. Productivity enhancement is of great importance and provides financial advantage and maximum return on investments (ROI). The operator also receives additional capabilities to evaluate productive formation, which allows optimization of production and waterflood system. Other important advantages include production from several formations, zonal isolation, control of production rate from different intervals and enhancement of artificial lift efficiency. For example, using downhole temperature and pressure monitoring systems, it is possible to optimize ESP’s operation mode, analyzing differential pressure and flow rates. In water injection wells exposing several formations, using the system of monitoring and control of injection into each formation, it is possible to increase the efficiency of waterflood systems significantly, having reduced the risk of premature water breakthrough in high permeability formations and eliminate low voidage replacement in low permeability formations.

5. Is it possible to implement intellectual well completions at existing fields? Does it happen in Russia or worldwide? Why yes, or why not?

Weatherford: Implementation of intellectual well completions at existing fields depends on the following:

- field development stage, as the first question that arises here is about the tasks to be solved by such systems;

- geological and physical reservoir properties as well as physical and chemical properties of produced/injected fluids;

- uniformity of the displacement/injection front;

- field development method;

- candidate well and wellhead design.

The challenge posed by wells that have been already drilled, completed and put into production is that the newer, more advanced equipment used in intelligent completion systems is most often incompatible with the original well design.

Other factors include:

- well completion method (single-stage or double-stage);

- equipment installed in single wells, well pads or the field in total;

- well construction costs when putting new reservoirs or development targets into production.

All the above factors are related both to the technical aspect (equipment in one well or a group of wells) and the financial aspect, as they will impact the economic feasibility and cost effectiveness of the intelligent well completion. Operators can take the decision to implement intelligent well completion only after consideration of all the parameters.

It should be noted that digital and optic downhole monitoring systems based on various combinations of pressure and temperature sensors are being actively implemented worldwide, including Russia. Such systems are used both individually and as part of various downhole pumping equipment.

Halliburton: Intelligent well completion systems have been introduced to existing fields. In the workover process, oil and gas producing companies can decide to changeover to intelligent completion systems and compare production rates in the future as well as use this data for a more comprehensive evaluation of productive formation. In some cases, the advantages of intelligent well completions become obvious for operators at the initial stage of the project when the operator faces contingencies or does not receive planned production rates. It may be caused by changing of reservoir properties in process of development or many other problems the most optimal solution to which can be achieved with a help of intelligent well completions. At present, in many mature fields in Russia and all over the world, operators are starting to introduce intelligent well completions as they start realizing their advantages.

6. Accuracy of data received from a ‘smart’ well is the key to its performance. How do you convert the obtained data into accurate information for the central control room?

Weatherford: The data accuracy depends on the metrological performance of downhole sensors (digital, quartz and fiber optic). High response frequency (sampling frequency), together with stable readings and high measurement repeatability, enables transmitting initial data to the control room without any data losses. The data, digitized directly in the control and acquisition unit, are further transferred via digital communication channels using noiseless coding protocols; this effectively prevents losses of important operational real time data transferred to the central control room from the well. Data from permanent monitoring systems are often transferred at high rates to the data acquisition and averaging systems of third parties.

Halliburton: Halliburton intelligent well completion systems are not just equipment, they can perform the function of an advisor on enhancement of productivity and efficiency by using hardware and software system which allows analyzing real-time data at a new level. Halliburton uses the most progressive technologies and equipment in its work. For example, ROC™ downhole temperature and pressure monitoring system with the following pressure measurement parameters: error – 0.015% of full scale, achievable resolution – less than 0.055 kPa/s, repeatability accuracy – less than 0.01% of full scale, deviation – less than 0.02% of full scale per year. Temperature measurement also meets the highest requirements: error – 0.15 C, resolution – less than 0.005 C/s, repeatability accuracy – less than 0.01% C, deviation – less than 0.1 C per year. These figures confirm that using our well completion systems, operator will get accurate data which then can be used for production process optimization. In addition, software filtration algorithms which are components of

DecisionSpace Production™ software platform within the framework of «Intelligent Field» implementation are used for fighting interference in received signals which inevitably occur during data transmission and distort useful signal. The platform includes different functional modules which allow choosing filter for each signal, performing integrated validation of incoming measurements including generation of indicators of integrity and correctness of downhole measurements for further startup of automated procedures for updating of inflow models and correlation of the well lift when producing with open flow or ESP.

7. How does a ‘smart’ well change the well operating parameters to increase its flow rate?

Weatherford: With regard to an individual case or a single well, a smart completion does not have a direct effect on production enhancement as it is not a flow enhancement tool. Such systems are designed to maintain high production rates (ideally – of dry crude oil) for a long time, with uniform and maximum reservoir production levels by means of isolation and production from separate zones (without any extra intervention expenses).

With regard to well clusters and blocks of intelligent well completions within the field, it is fair to say that smart completion promotes maximum production – approaching the maximum oil recovery factor specified in the Field Development Project – by means of stable and continuous production of dry crude oil and low water-cut oil. Naturally, this holds true if there are no significant complications due to factors not considered during candidate well selection, such as water cones at the fields with active bottom water or gas breakthroughs, which call for isolation of certain intervals or sidetracks. Even in such cases, intelligent completions enable continued operations without the extra interventions typical of standard completions.

All changes in well performance are recorded by permanent downhole monitoring systems, which detect changes in downhole parameters and production anomalies in multilateral wells. These changes are reviewed and respective actions are taken.

Halliburton: Using intelligent well completion systems provides full understanding of the reservoir and the opportunity to enhance oil and gas recovery by means of changing specific downhole equipment parameters. These two advantages are the key to maximizing production. In addition to the above advantages, it is also necessary to take into account the equipment reliability, information accuracy, understanding and control of multiple downhole parameters and conditions which altogether allow maximizing production. As a result, production increase is what intelligent well completions provide.

8. What solutions for ‘smart’ wells do you offer for operators?

Weatherford: Currently Weatherford offers a wide range of well completion tools from the simplest to the most complex ones, which minimize costs, reduce risks and optimize production. Instead of adjusting old technologies to new and more challenging conditions, our Company offers a portfolio of state-of-the-art high performance technologies and solutions.

To attain the goals set by the operators, Weatherford applies an integrated approach to well completion which involves collaboration between Well Construction and Well Completion experts.

We offer a wide range of permanent downhole monitoring technologies, including the OmniWell™ system. OmniWell provides real time reservoir monitoring for the lifetime of a well. The system includes several types of solutions and monitoring:

• nGAUGE™ – optical and quartz pressure/temperature gauges rated for 30,000 psi/206 MPa and up to 572°F/300°С; which are also widely used as separate

systems for standard monitoring tasks;

• nTHERMAL™ – optical and distributed multipoint Bragg grating sensors as a universal solution for thermal monitoring;

• nPHASE™ – full-bore downhole optical flow meters configurable for single-, two- and three-phase flows and installed anywhere in the well regardless of its path;

• nLINK™ – electrical or optical cable in various configurations;

• nFORM™ – flexible data control, acquisition, storage and transfer complex for various operating conditions.

In addition, we offer a monitoring solution for two-stage completions: IWWMC, a technology of downhole fiber-optic connector/contact (optical wet-mate connector) for sand control and gravel packing applications.

Our offering includes radio-frequency identification (RFID) technology, which helps reduce the number of trips and interventions. Nearly all our tools are compatible with RFID technology, which enables remote and selective operation of certain tools. A programmed RFID tag is simply dropped into the well where it reaches the completion tool and modifies its operating parameters according to the downloaded program.

Moreover, our Company has developed several downhole intelligent completion technologies including open-hole and cased-hole completion tools. Annulus casing packers with various setting mechanisms and channels for cables and control lines are used to improve open-hole completion efficiency, as well as Inflow Control Devices (ICD and AICD technologies); conventional, premium and expandable screens; gravel packing technologies; liner hangers and packers of various design (both standard and with a bore for cables and control lines); casing accessories, including roller protectors for extended

reach wells, etc.

Technologies for cased-hole completion include:

- Optimax™ safety valves-currently more than 7,000 valves of this series are installed worldwide;

- intelligent packers of various modifications;

- Renaissance™ system for regaining well control in case of safety valve damage or failure;

- OptiBarrier™ bidirectional mechanical RFID activated isolation valve;

- UltraLift™ system for gaslift wells.

We also offer tubular running solutions providing cost efficiency, safety and well integrity at all stages of the operations.

Halliburton: One of the key aspects in designing and introduction of intelligent well completions is reliability, therefore, in addition to generally accepted industry standards, Halliburton has developed its own, often more stringent, standards, compliance with which provides reliability of each system element. Moreover, at each stage of manufacturing and introduction, we use a specific quality control system providing the customer with not only achievement of a short-term result in accordance with the approved plan, but also the equipment life ensuring achievement of the desirable result as a whole. Upon completion of the introduction process, all the lessons learned are considered when developing the next generation of intelligent well completion solutions and technologies. Such an approach to improvement of reliability allowed us to become the leading supplier of intelligent well completion technologies on the market.

Halliburton intelligent well completions can be used for the following applications:

- Automatic control for gas lift systems

- Deep-water well construction

- Horizontal well construction

- Multilateral well construction

- Multistage hydraulic fracturing

- Temperature and pressure monitoring

- One or multiple interval flow rate control

- Zonal isolation

- Chemical injection

All the above technologies allow operators to increase cumulative production along with reduction of capital and operating expenditures under the most difficult conditions all over the world.

9. Speaking about prospects, will smart completion technologies be implemented at the majority of new fields?

Weatherford: The need for this technology must be considered in light of the current situation in the industry. To create positive technological and economic effects, simple and complex smart completions must be incorporated into the design from the very initial stage. The process of selecting candidate wells for smart completion is not just an analysis; it’s a hard work that requires building complex models and developing various scenarios that account for the changing properties of the produced fluids, reservoir and development target during field development.

Because many smart wells have already been brought into operation, we have accumulated extensive experience. Therefore, this information can be jointly considered by several parties – the operator, its design institute and the service contractor which will carry out the project – before implementing a smart completion.

Various companies use smart well technologies worldwide; therefore it is necessary to consider the capabilities of each supplier in this area and to evaluate all possible solutions. This will eliminate unnecessary limitations when selecting the supplier and the technology. Current intelligent completion technologies are characterized by high flexibility: operators can select from complex intelligent well completions (i.e. for multi-zone and multi-lateral wells of various categories) or simple assemblies with a downhole monitoring system to facilitate reservoir monitoring. A full-field completion operation may be implemented depending on the field, the development method and other key parameters.

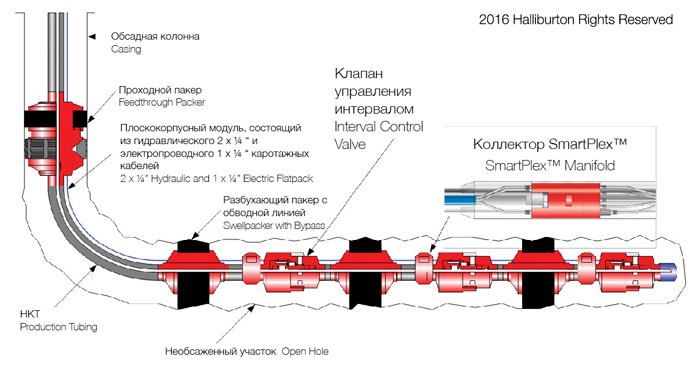

Halliburton: Development of the most gas and gas condensate fields should start with the construction of intelligent wells if possible. In this case operator gets all the required information on the reservoir at the very beginning of its development. Examples of using monitoring systems at the initial stage of development can be observed in Yamal region as well as in offshore wells of Sakhalin and the Caspian sea. Further on, with the correct use of the information obtained and considering the capability to operate wells in different modes, operators will be able to prevent a lot of problems which may arise at later stages of development. It should also be noted that intelligent well completion technology is actively developing and along with the enhancement of reliability of the systems, the costs required for their manufacturing and installation go down which certainly has a positive effect on their introduction prospects. A good example of cost optimization is SmartPlex™ system developed by Halliburton which allows controlling up to 12 zones using just 1 electrical and 3 hydraulic lines. Depending on the setting depth, this system allows reducing the smart well construction costs by up to 30% thanks to reduced number of hydraulic lines, surface equipment and simplified X-mas tree design.

Ural Munirov

Weatherford

Ural Munirov is a graduate of the Ufa State Petroleum Technological University. He joined Weatherford 5 years ago. In 2011 he started his career as a Field Engineer in the Production Optimization group at the Noyabrsk branch; in 2013 he was transferred to the company’s Moscow office and took the position of Project Engineer.

Ural has more than 10 years of experience in the oil and gas industry, focusing in well testing, multiphase flow measurement and subsurface well monitoring.

Maxim Karpov

Halliburton

Maxim Karpov graduated from the Faculty of Geology at Lomonosov Moscow State University in 2002. His total length of service in the oil and gas industry exceeds fifteen years, and the geography of work covers Russia, Kazakhstan and the USA. Maxim has substantial experience in testing and completion of wells, including application of intelligent completion systems. He currently holds the position of head of the Russian Completion Tools Business Development.