In this interview, we talk to Diego Ferrandes, global business director and regional head for Drillmec, widely considered one of the world’s leading manufacturers of next generation automated drilling rigs and premium drilling equipment.

We discuss Drillmec´s recent successes, regional localization efforts in Russia and its development across the Caspian.

Please give our readers an overview of your role within the company and Drillmec´s key activities across Russian and the Caspian.

I am the Marketing Manager at Drillmec, but since 2006 I´ve also overseen our business activities across Russia and the FSU. We delivered our first rig to West Siberia back in 2001, which is still in operation today and now, we are proud to have over 70 active rigs working across the entire Russian region carrying out Drilling operations, Sidetracking, W/O, both onshore and offshore.

It is important to note that Drillmec is also manufacturing advanced drilling equipment and during the last decade we were able to sell 60+ Top Drives packages either electric or hydraulic and 80+ Mud pumps in the range of 800 to 2200hp, in the Russian alone.

Drillmec is also recognized as a leader within the offshore market and as such, we have gained a lot of experience in the Caspian Sea, where we are present since 2009. Our drilling rigs are located in the Kazakh, Azeri and also the Russian sector of the Caspian Sea, where we recently took care of the delivery of 2000hp drilling facilities on 2 ice resistant platforms operating in the Filanovsky project.

Despite the challenging period during the last couple of years, we were able to achieve great results, selling five 225-ton mobile drilling rigs and 3 hydraulic fully automatic drilling rigs. The mobile rigs are already operating, while the first of the 3 automatic rigs will start working in the first half of the year in Noyabrsk.

This last contract for us is a crucial milestone for Drillmec, since we are delivering for the very first time in Russia, a fully automatic drilling rig completely winterized, mounted on an echelon system – an amazing result which was possible to achieve thanks to the close cooperation with our client’s technical team. This provided us with lots of suggestion to better fit our advanced technology to the arctic climate and to be in full compliance with Russian standard regulation.

Russia has been long living under EU/US sanctions, aimed mainly at unconventional formations and deep water. What impact, if any, have these sanctions had on Drillmec business?

The short answer is no real impact at all. The sanctions are not ideal for anyone in this sector, international or Russian, but as you mention, they are targeted towards very specific projects and areas.

Drillmec has built up long partnerships with our regional clients and work closely with them all to ensure all projects are delivered on time and in accordance with local and international laws and regulations.

Drillmec have our own facilities across the region, including our rig factory in the FSU, which ensure smooth regional operational processes and as such, the said EU sanctions do not affect our regional operations or business.

Localization is key and something Drillmec have been working on for some years. How are these ongoing efforts and what are your long-term localization plans?

Correct, ever since Drillmec opened the Russian market we started to think about a localization plan and several steps have been already concluded:

- having a factory in the FSU since 2010 where we produce all the steel parts of the rigs to be delivered in the former Soviet Union.

- we have several temporary warehouses, opened on the request of our clients in strategic location to ensure quick delivery of spare parts and assistance.

- we have a training center equipped with portable simulator, dedicated to the CSI clients, opened in Kazakhstan.

- in the last few years, we also reinforced our aftersales team which is available across the country 24/7. We have about 30 field engineers available to help our clients on standard maintenance, commissioning, rig up and are ready for any request of intervention on site. All our field engineers are Russian natives with a strong experience in the oil & gas and all of them have been trained in Italy on Drillmec products.

- additionally, we are now opening new warehouses in the regions our new rigs are operating in, plus a workshop in west Siberia where Drillmec products can be overhauled and retrofitted by our technicians.

Another step forward we made during the last period regarding localization is related to the strong relationship we have established with several reliable Russian Manufacturers. These were suggested to us and accepted by our client, who cooperate with Drillmec to complete the full scope of supply on the rigs, for the equipment which is not produce by Drillmec. For all the equipment not manufactured by Drillmec, an accurate technical analysis has been carried out by our engineers, to approve and adapt it to our drilling facilities.

Drillmec produces a range of equipment, including next generation fully automated rigs. What are the latest technologies/advances within Drillmec rigs? How do they suit the Russian, regional markets?

Yes, it is true, Drillmec has been the pioneer in automation and robotization of drilling rigs, as from the beginning, we always gave strong priority to ESG criteria while engineering new products.

The HH hydraulic automatic rig is the perfect example, a fully automatic drilling rig that while operating can keep away all the employees from the line of fire. In fact, our first HH rig was produced way back in 1995 and over the years thanks to our experience and expertise in this field, we added new features bringing the rig from a semi-automatic mode to a completely automatic one.

The last step to consider the rig fully automatic, was made based on the request of our Russian client which desired a fully automatic operation, including whilst while running the casing. This last innovation has been recently implemented on the rig and will speed up the drilling operation even more and reduce NPT to the absolute minimum.

The Drillmec R&D department is constantly working on new products and improvement of existing ones, the last and unique product released by our team is the Stinger; a robotic manipulator that can automatically make RIH and POOH operation, off line build up stand and rack it back the pipes and additionally can pick up and lay down pipes from/to the power catwalk. Such a system is pretty common within the offshore market, but for the first time will appear onshore thanks to the small dimension and light weight that make it possible to install it even on small and narrow rig floors.

We are seeing a big push to “digitalize” the entire well cycle, using real time data to increase planning and operational efficiency. What steps are Drillmec taking to keep up with the digital revolution?

Drillmec is leaning heavily on the power of machine learning to digitalize, and therefore facilitate, everyday monitoring and maintenance tasks. This is clear in the, now operative, Prorig Data Management System which allows rigs to be connected to a single platform where data can be monitored and stored for backup. The Prorig Analytics module allows advanced insights into the workload of rigs and equipment like remaining life, predicted failures, and efficiency optimization. The system also implements a Transfer-Learning property that allows it to learn from different rigs and self-improve its predictions.

Is it correct that you will soon be launching a new “Bio-Metric“ system into the Drillmec simulator and training programs? Please tell us about this very interesting technology, how does it work and what will be its applications?

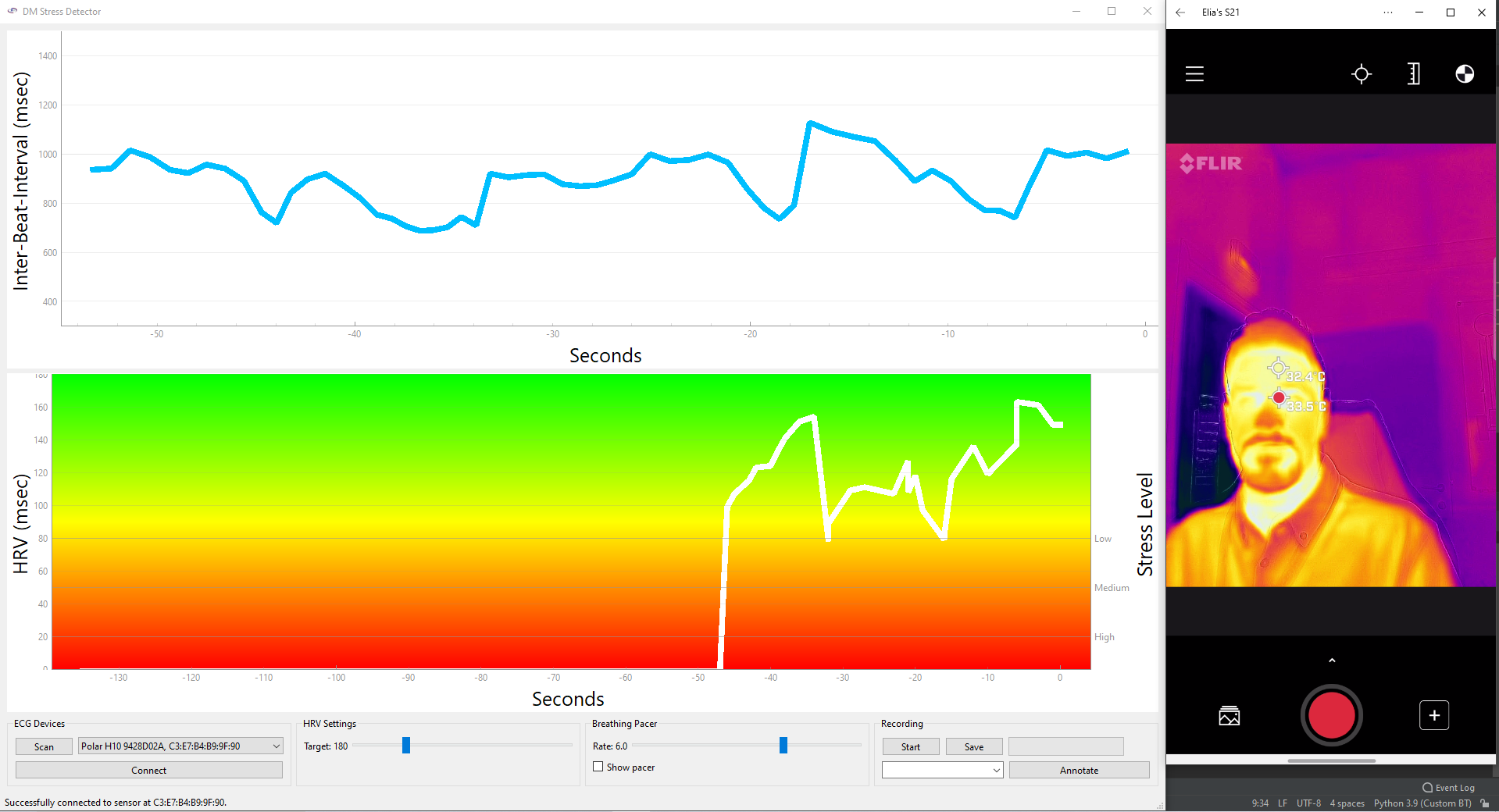

The Drillmec Biometric Stress Monitor is a package that may be used to improve training or interface designs. It uses a proprietary machine learning algorithm developed in collaboration with the psychology department of the University of Modena and Reggio Emilia. By monitoring a few parameters like the heart rate and skin temperature, the system can detect operator stress, be it due to an emergency situation, low awareness, or confusion with controls and procedures. Then once the moment of stress is detected and correlated to the task at hand, specific training can be implemented to improve operator response and reduce stress. In the same way, confusing instructions or interfaces may be redesigned to help reduce stress.

How do you see the rig market for Russia in the coming years? What specific rigs are you targeting for your local customers?

The Russians trend to drill more complex wells with higher production rates and this will probably lead to a requirement for more advance and reliable drilling rigs – able to perform in such environment to avoid jeopardizing the projects. Moreover, the proportion of horizontal wells drilled has increased quickly and this will probably bring the selection of more powerful rigs during the next few years.

We already saw a recovery in drilling activity during 2021 and the same is expected to continue, driven by several projects that are designed to increase gas output. So, if we take in consideration projects such as Vostok Oil, Kovytinskoye, Utreneye or Kharasaveyskoye just to name a few, we forecast a measured growth of activity during the near future.

We are confident that Drillmec can contribute on this recovery scenario considering the high technological complexity of the projects to be developed by local companies and our ability and experience in managing and dealing with such complex operations.

Regarding rig sales, Drillmec have recently secured some key contracts with Russian operating companies. Can you explain what type of rigs you have agreed to sell and why were they were specifically chosen?

I already mentioned the two most important contracts recently signed between Drillmec and Russian companies. The first for 5 mobile drilling rigs, those are fully electrical rigs able to be connected directly to the local grid and implement most of the latest technologies developed by Drillmec and thanks to the cooperation of a local manufacturer, selected by the client, we were also able to be more competitive pricewise.

The second contract includes 3 Fully automatic drilling rigs, in this case the client selected our rig for several reasons. An example was to follow the tender requirement. The bidder had to prove to be able to skid the rig within a pad or from well to well, to rig up and rig down, to perform drilling operation and to commission the rig within certain strict thresholds. As a result, the Drillmec HH rig fully satisfied, meet, and even exceed client requirement.

Another remarkable point to underline was the desire from the client to intervene during the engineering process bringing their suggestions, based on their experience of the local environmental condition, standard rules, and standard way to work. At Drillmec, we have been open and flexible from the beginning and working directly with the client ensured we fully satisfied their requirements. The result has produced an advanced, high tech, fully automatic drilling rig perfectly adapted to the Russian standard.

In this way, to be open to accept the possibility to modify and adapt our standard product, was another strong point which convinced our client to choose Drillmec.

Drillmec is recognized worldwide as not only a leading manufacturer of advanced rigs, but also premium drilling equipment. What drilling equipment are you successfully selling into Russia and what benefits is this equipment bringing to your customers?

Having touched on this previously in my first answer, the core technologies and most sophisticated components produced, in-house, by Drillmec are: Electrical and Hydraulic top Drives, Mud Pumps, Power Tongs/Iron Roughnecks, Power Catwalks any other kind of pipe handlers (including Stinger) as well as a vast range of standard equipment such as rotary tables or mud systems.

For the Russian market, as already mentioned, we have been very successful within the Top Drive sector and there are several key reasons our clients choose Drillmec Top Drives:

- easy to rig up with different kind of mast thanks to the small dimension and versatility.

- very reliable, field proven with minimum NPT recorded.

- a long reference list, from all over the world including extreme arctic climates.

- quick delivery time. Since our top drives are very popular with our clients, we take the calculated risk and ensure they are under production on speculation to shorten the delivery time to a minimum.

- finally, our Drillmec top drives are very competitive on price.

Drillmec has long established ties in Azerbaijan and has secured some recent contracts. Please explain your business in Azerbaijan and what rigs will Drillmec be supplying to that market in the coming years?

Drillmec sold its first rig in Azerbaijan back in 2014, it was our first offshore HH-300 Automatic rig. A 300 short ton pull up capacity rig which has been placed on a fixed platform in the west Absheron field. Our client (Socar-AQS) choose this rig as it was the only one which meet their requirement in terms of total dry weight and dimension since the platform was quite old and pretty narrow. The rig has been moved on different platform on the same field and has reach several records for drilling and casing running speed. Few years later a 3000hp rig fully equipped as been purchased by the same client and bring to operate in the Umid field.

Lastly, we recently finalized a new contract with a subsidiary of Socar-AQS, and are now building a new 3000hp drilling facility which will be delivered in Q4 2022.

Over the last years Drillmec has been developing “Training Services” including “Drilling Simulation”. How is this sector of business doing and is it offered to the Russian market?

We have increased our training activity greatly during the last couple of years, either in the field, the classroom or remotely. This exiting result was achieved thanks to a very experienced, smart, proactive, and creative training team which is never satisfied by the “status quo” and always looking for innovative solutions to satisfy our clients.

In our portfolio we include from the most traditional training for drilling, well control (for which we are IWCF IADC certified) and Well integrity, to the most advanced and unique products in the market such as: Advanced Well Control, Biometric Stress Monitoring, Kick Monitoring system and IOT Predictive Maintenance just to name some.

Each lesson can be carried out using the well control simulator or Drilling rig full scale simulator to enjoy a comprehensive Digital twin experience. Huge interest has been already shown from our Russian clients and even though we have already confirmed a busy training agenda for the 2022, clients can keep booking training courses whether they own/operate a Drillmec rig or not.

How do you see Drillmec´s business developing in the region over the short to mid-term?

As already mentioned, we trust in the continued recovery of drilling activities and we are sure our industry, Drillmec included, will benefit from. It is difficult to forecast how quick it will happen, but positive signs are coming out from important projects such as Vostok oil for which we are sure Drillmec can provide his own contribution. In short and mid-term, we will have the target to increase our after sales activities in which we recently make a lot of investments, in order to be able to serve our clients in all the Russian territory.

Thank you!