MOL GROUP Russia: Implementing the ‘Technical Limit’ System to Improve Efficiency in Workover Operations

Russian oil and gas companies have been implementing the Technical Limit methodology for about 10 years to improve the efficiency of various operational stages of well construction and workover, from drilling to production.

Gazprom Neft has already written about their experiences of implementing this solution to improve their efficiency within this publication [1].

In this article, we will discuss the successful implementation of the Technical Limit methodology during the current well workover program by BaiTex LLC, the Russian division of MOL Group, which operates the Baytukansky field on the border of the Orenburg and Samara regions.

The case study is of interest since a wide range of Technical Limit tools were implemented. Including the fact that the system was introduced and implemented during the COVID-19 pandemic restriction period.

The Task at Hand

Baitugan is a mature field (the development of which began in the 1930’s). BaiTex LLC needed to carry out routine maintenance and workover promptly and cost-effectively in its large, 500+ well, field.

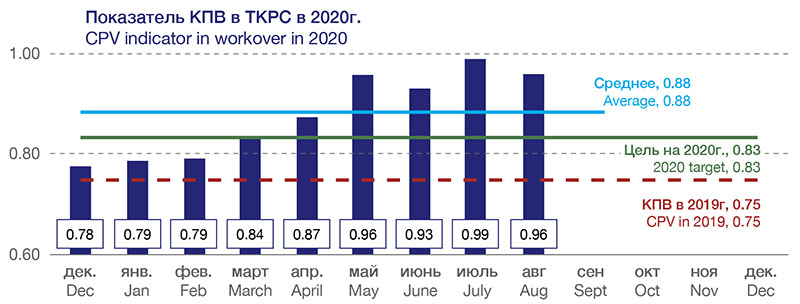

In 2019, the Performance Time Ratio for the contracted well workover services was 0.75, i.e. only three-quarters of the time that the team spent on well repair the customer actually paid for. The rest of the time was not paid for due to various downtime incidents and tasks exceeding the standard time permitted for operations.

BaiTex saw the potential in improving the efficiency of the workover operations as the average KPI for the region was estimated at 0.85. To solve this problem, it was decided to introduce the Technical Limit program into workover operations.

Evgeny Lapshin, Executive Director of MOL Group for Russia and Kazakhstan

In recent years, our company has made great strides in improving our drilling efficiency. Our team of drillers, using their skills and methodology of the Technical Limit program, have reduced drilling times by 46% in 4 years.

We saw the need for improvement in workover operations, and we understood that this would be our next target. By the end of 2019, we launched a project to improve workover efficiency.

In order to ensure these improvements, it was important that the following conditions be met:

A systematic approach had to be taken, i.e. a set of interconnected activities covering Technical Limits was conducted. All the participants in the workover process were involved including both the management and production teams.

● The changes had to be sustainable, so that the tools and methodologies implemented became entrenched and an integral part of our production culture.

It had to be mutually beneficial. Having benefited from the changes for ourselves as a Customer, it is important for us that both the service contractor and especially the employees would be interested in achieving the desired results.

The Focus is on Continuous Improvements

The Technical Limit program is based on the Deming cycle of, “Plan, Do, Check, Act». The cycle has been adjusted since WW II and is the basis of the continuous improvement system.

The project approach was used to implement the initiative to improve the efficiency of workover operations in MOL Group and BaiTex. The project was set to last 10 months, from November 2019 to August 2020.

This is good example in implementing comprehensive productivity initiatives. Also, as expert support in the launch of the Technical Limit tools, Artem Borisov, who has many years of successful experience in implementing similar projects, was involved in the project.

The project team knew their roles. Within two weeks, diagnostics were carried out, a work plan for the project was drawn up, and work commenced. The plan highlighted 5 main areas: (1) tools in the office, (2) tools in the field, (3) monitoring and control tools, (4) Management and Communications System, (5) The development of competencies and leadership.

Roman Kozlov, Project Manager, Drilling Manager MOL GROUP Russia

We didn’t want to reinvent the wheel when implementing a project to improve the efficiency of workover operations. Our drilling team had excellent efficiency enhancement tools: well planning, day depth schedules, operational flow charts, shift planning meetings. We wanted to adapt these tools to workover operations.

As a result, we defined the procedures and implemented monthly workover planning (similar to the drilling plan), a detailed workover schedule based on standard time norms (similar to the day depth schedule), and many other tools.

Not all the implementation went smoothly. At first we thought we would need quickly produce a high-quality workover schedule per well and that this would be a difficult task to complete. However, quite swiftly we solved this with the help of a simple Excel spreadsheet, and now at the beginning of each repair the foreman gets an accurate plan of work, calculated strictly according to standards. Based on this plan, he determines with the crew the operations for each shift, after the repair they provide the team with feedback and a summary. We also get important statistics about the duration of individual workover operations and information about the causes of any deviations in the plan.

Crew Motivation

One of the key problems during well service operations was the low motivation of the contractor’s crews. Ordinary employees had low wages, there was no connection between work performance and pay. One of the first tasks of the project was to fix this.

Oleg Kondratiev, the head of the contractor’s workover team, had already worked out the principles of crew motivation. With the support of BaiTex management, the contractor was persuaded to implement a transparent and results-based incentive system. At first, no one was sure that this system, even if it were launched, would work for more than a month or two. Result: since January 2020, the system has worked like clockwork, it now has the trust of all the employees.

The principle is simple: a CPT* level of 0.70 is set, at which the previous basic salary level is paid. For each additional unit of CPT 1% is added to their salary. Additionally, the supervisor assesses the contribution of each employee by assigning him a Labor Participation Coefficient (LPC), which can increase or decrease depending on their performance. These simple and well-known motivational tools have allowed workers to take home 20-25% more money. The effectiveness is enhanced by implementing consistent and transparent wage calculations.

As Oleg Kondratyev notes, now workers minimize any downtimes, knowing how they affect their salary. When incidents do occur, they are solved and eliminated as soon as possible.

*CPT – Standard time to calendar time ratio

And Then There was COVID

During the program, in March, all the established work patterns and progress were suddenly stopped by the outbreak of the coronavirus pandemic. All the face-to-face interaction and training, the development of field workers through feedback, brainstorming, group sessions and discussions ceased. And all this took place in the context of the disastrous impact of the collapse of oil prices…

However, no-one wanted to stop and step back from the objectives of the program, and it was necessary to urgently restructure the system and ways of working. By early April, a remote work scheme was developed and implemented, in which all the blocked activities were transferred online. There was only one problem: how to implement the system in teams who are in remote locations with poor communication networks?

Under these conditions, excellent leadership was shown by BaiTek’s workover service team which was headed up by Alexander Ryndin. Under the leadership of his deputy V. Borzenkov, the role of the project’s workover supervisor quickly changed. According to the initial implementation plan supervisors and workover specialists were supposed to be trained in efficiency improvement tools throughout the course of the project. Then the Covid travel restrictions came into force between the regions, so this training approach had to be adjusted. After a month of distance learning, the workover supervisors changed from apprentices into mentors: they began to train the foremen in efficiency improvement tools, monitor their quality, and providing feedback. In other words, they undertook the role that third-party consultants and experts have been brought in to do, at a cost and as standard practice, on other projects.

All these actions allowed the project team to get back on track quickly enough to implement the project systems.

Oleg Toropchin, CEO of BaiTex LLC

The workover efficiency project has provided us with a good impetus to start addressing a known problem that we had. The team’s efforts gave us great results.

It also helped us that at the very beginning of the program we clearly defined what the project participants were responsible for, identified their Key Performance Indicators (KPIs), and began to monitor them regularly. In the beginning, it was unusual for individual managers to plan their actions to achieve the KPI’s in the coming months. Now, operational planning is more focused and has become part of the norm. Constantly looking ahead to improve the efficiency of well service operations has become part of our culture.

In general, our communications have become more transparent. We have become clearer with operational risks and safety. I welcome it when subordinates speak openly about the problems that exist, and we address without delay, the issues in which they need help.

Results

After 9 months of the project, the results exceeded the original targets. The CPT value for workover operations is approaching 1, which initially seemed unobtainable even to the most experienced workers.

In many areas of work there has been a qualitative improvement shift. Visual monitoring tools which show work performance allowed the customer to keep an overview of the whole project on one radar. It is gratifying that the key performance reporting is conducted by the workover supervisors who determine the use of the Technical Limit system in the teams. As the supervisors joked, they can now introduce efficiency improvement tools, based on wage renumeration, in other companies involved in workover.

During the project, over 20 new systems were implemented and consolidated in all areas.

For Evgeny Lapshin all of this happened due to one important principle: the results are beneficial to all participants. The customer’s wells are repaired within the shortest possible time frame. The salary of the service companies crews increased by a quarter. At the same time, workover service company’s revenue from BaiTex for the services rendered increased by more than the increase in staff costs. And all together, the employees of the customer and service company have acquired and consolidated their skill sets to conduct their work more effectively. This means that there will be further improvements still to come in the future.

Artem Borisov, expert on productivity and leadership development

In terms of the number of systems implemented, their quality, timing of the implementation, and the challenges we faced along the way, it was a unique project. Nevertheless we were able to implement and deliver, to a high standard, a lot of what we initially planned to achieve on time.

I believe that the main factors of success for us were:

● Continued support and leadership involvement throughout the project. Both Yevgeny Lapshin, Oleg Toropchin and other sponsors attended all the key meetings and business reviews, demonstrating the importance of management support for such projects so that they can achieve the set targets. In every instance they supplied the necessary support.

● The key project participants were more or less familiar with performance-enhancing tools and time was not wasted on «converting» them to the concept of continuous improvement. There was only the need to remind on certain things, to put them in a single system, and support of the management team help grease the wheels of the whole implementation.

The Appetite Comes with Eating

Whilst improving the efficiency in workover operations, the project team tried to assist with the use and implementation of the Technical Limit system to other applications – in the selection of wells for geological and geotechnical measurement (GTM).

The process of GTM well candidate section was initiated and optimized, the criteria and process to evaluate the effectiveness of GTM, with analysis and lessons learned were defined. To improve efficiency further new team members were involved.

In summary and noting the success of the project, Evgeny Lapshin listed the following important tasks:

1. To ensure all the implemented performance enhancing tools and systems remain in workover operations and other related areas;

2. Select new areas where performance enhancing tools can be implemented to bring further value to the business.

And in solving the second task, the workover project team trained in performance improvement will provide expert support to their colleagues.

References:

1. Zorina S., Ragouline A., Borisov A. Gazprom Neft Launches an Ambitious Programme to Improve Drilling Efficiency: ROGTEC Magazine #43, 2015, o. 39-50