NNTC Research & Development Center: Integrated LWD, Mud Logging and Geomechanical Surveys While Drilling in the Nizhnevartovsk District

This article presents the study of an integrated approach to drilling process management with the aim to optimize and reduce well construction time. It demonstrates successful integration of well construction design and technology aspects. The described experience is unique for Russian companies and based mostly on Russian techniques.

Introduction

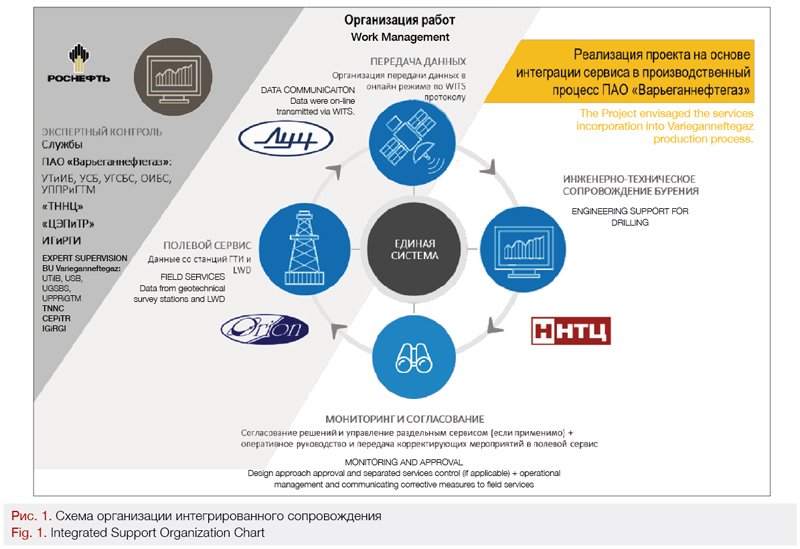

Nowadays more wells require a deeper and more comprehensive technological approach to planning and construction of the wells. Today’s design concepts make it possible to solve a wide range of tasks to mitigate risks and to eventually reduce the time for well drilling and completion. However, such solutions are often strictly restrained to segments and not coordinated on both the operation level and decision making level. To handle such inconsistency, an integrated approach to drilling support was applied with the following envisaged:

• Pre-engineering geomechanical and technological modelling in order to select and optimize the drilling parameters;

• Engineering and technological support for DD;

• LWD;

• Geosteering and Petrophysics survey

• Mud logging;

• Stress-strain properties and wellbore stability models adjustment based on acquired logging data and implemented for subsequent drilling operations.

The project was performed within a unified system and supported by RN-Varieganneftegaz and the Rosneft design institutes TNNC, CEPiTR, IGiRGI.

DD and LWD

The applied LWD tools included the Russian LWD complex LOOCH-M-2014 designed to obtain a complete set of drilling parameters and to provide quick and accurate conclusions in order to evaluate the reservoir’s poro-perm properties and lithological differentiation. The following survey and logging methods were used:

• Gamma-Ray (GR);

• High-Frequency Induction Logging – VIKIZ Analogue (HF IL);

• Compensated neutron-neutron logging (CNNL);

• Gamma-gamma density logging (GGDL);

• Directional survey.

Depending on the tasks, the complex modules are available for lateral logging (LL), annulus pressure logging, acoustic logging, and other geophysical logging techniques. LOOCH-M-2014 complex logs the following process parameters: circulation rate, pipie pressure, lateral and longitudinal vibrations.

The complex is subject to continuous modifications in the design and in view of recent geophysics measuring techniques. For example, registration of the azimuth density and micro lateral logging (producing images) data is integrated. It will enable the collection of important data on the structural behaviour of the formation in the wellbore, which is a high priority for geonavigation. With density and/or resistivity contrasts available, it will be possible to evaluate more accurately the local structural angles, localize well position in the log, and detail and adjust the 2D model. Images are also used to determine the structural elements and the fracture orientation, which is very important for carbonate logs sections. An acoustic profile logging module will be soon introduced to log the well bore profile. Thus it will be possible to consider the LWD qualitative technological peculiarities and to set up a liner packer running position. The plan also includes step-by-step design and integration of acoustic logging, drill-bit and gamma-gamma litho-density logging.

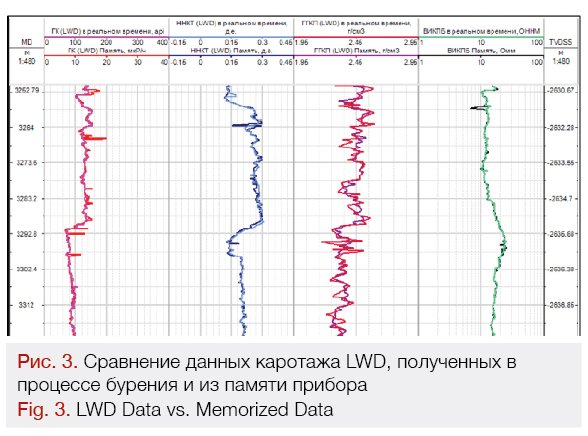

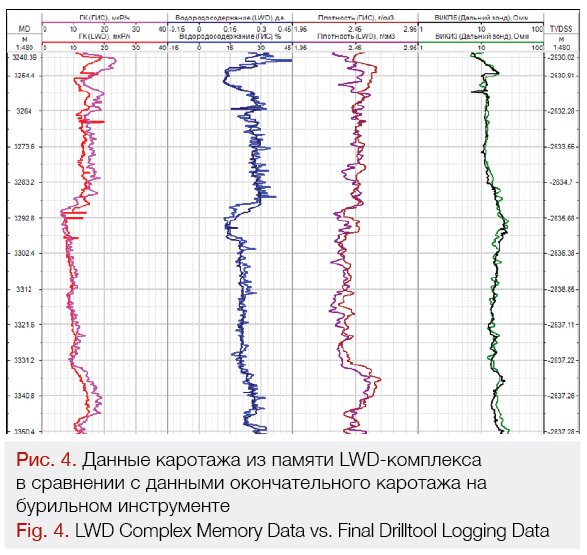

LWD LOOCH-MK-2014 complex Size 172mm was used while drilling the production string interval of pilot directional well (bit Ø 220.7mm), and Size 121mm for horizontal sections (bit Ø 155.6mm). The LWD tool is fitted with a hydraulic communication channel. Its speed and a decoding system gives a stable good on-line signal during geophysical logging whilst drilling at a rate of 40 to 60 m/h. This is confirmed by comparing tool memory data with final pipe-conveyed logging result.

In addition, each logged well interval was subject to wireline or pipe-conveyed logging with the same techniques applied.

The comparison shows a high level of repeatability for all techniques, while the variances do not exceed measurement errors or these are caused by geological and technological conditions due to different time of logging.

Geological Survey

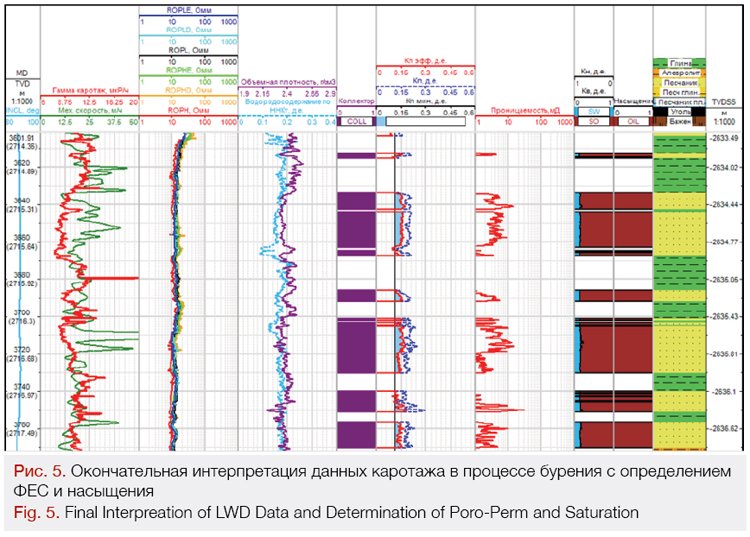

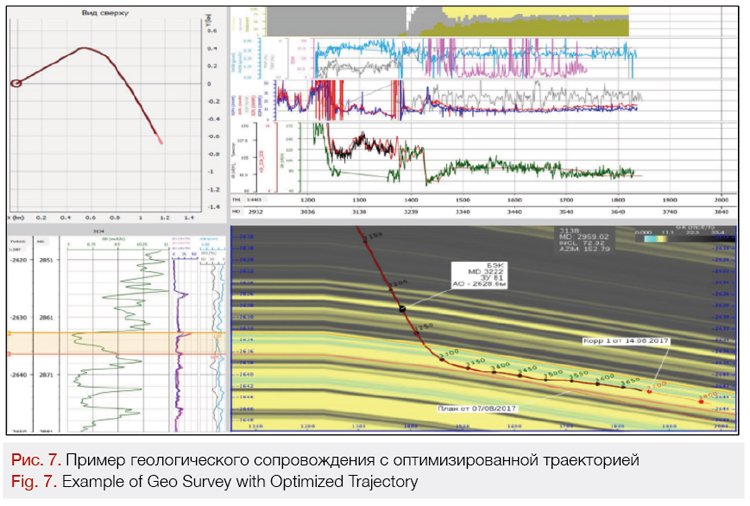

The LWD tool makes it possible to perform a petrophysical evaluation of the reservoir and saturated fluid properties not only after drilling but also while drilling on realtime basis.

The target horizon at the field under development are YuV1 reservoir in Vasyugan Suite composed of light-gray to brown, fine-grained sandstones; sandstones interbedded with siltstone and claystone layers. The sandstones are oil-bearing and characterized by lateral and vertical heterogeneity that makes horizontal tracking difficult. Based on logging data interpretation while drilling directional and pilot wells, oil-saturated interlayers were singled out: effective thickness up to 4m, porosity 12 to 18%, permeability 10 to 20 mD and oil saturation 51 to 66%.

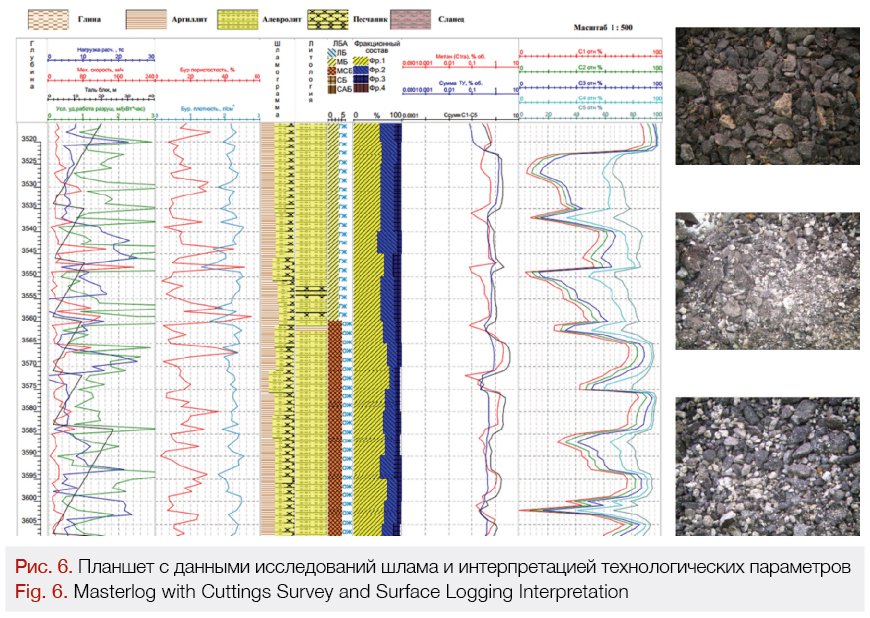

Enhanced analysis of the drilling parameters and cuttings was also performed. Power logging techniques enabled acquiring pseudo-petrophysical parameters (drilling porosity and density) that reflected characteristics of rock interacting with a bit. In addition to widely used methods, the enhanced study of cuttings included measurements of density, carbonate content and fractional analysis.

With described techniques and LWD data interpretation, UGSBS engineers timely optimized the trajectory and track the well in oil-saturated rock that has better reservoir features.

Geomechanical Survey while Drilling

To reduce risks while drilling, a1D geomechanical survey was performed including: Analysis of a priori information and pre-drilling geomechanical and a wellbore stability models, adjustment of models while drilling basing on the LWD data and technological studies, post-drilling geomechanical model basing on the logging memory data.

The main complicated intervals occurred in unstable shales in the bottom part of Megion and Georg Suites.

Modeling and successive model calibration resulted in proper mud density determination.

While drilling the production interval and pilot well, the recommended mud density was 1,20 to 1.23 g/cm3 which increase to 1.25 when approaching the unstable shale horizons. For the horizontal section, the recommended mud density was 1.09 to 1.12 g/cm3.

In addition, the trajectory was studied to determine the wellbore stability. It was discovered that the drilling program expected the horizontal well location to be close to the maximum fracturing stress that affects both rock stability in the borehole environment and the hydraulic fracture propagation. Unfortunately, the considerable drilling azimuth deviation requires more time for and deeper elaboration of design. However, the trajectories were optimized as much as possible to minimize well construction risks.

Priori stability models were based on the projected well trajectories and further improved by adjustments of geological environment, geomeсhaniсs and trajectory changes.

The geomechanical models correspond to the actual data; the procedures performed at this stage reduced problems while drilling and trip operations by 30%.

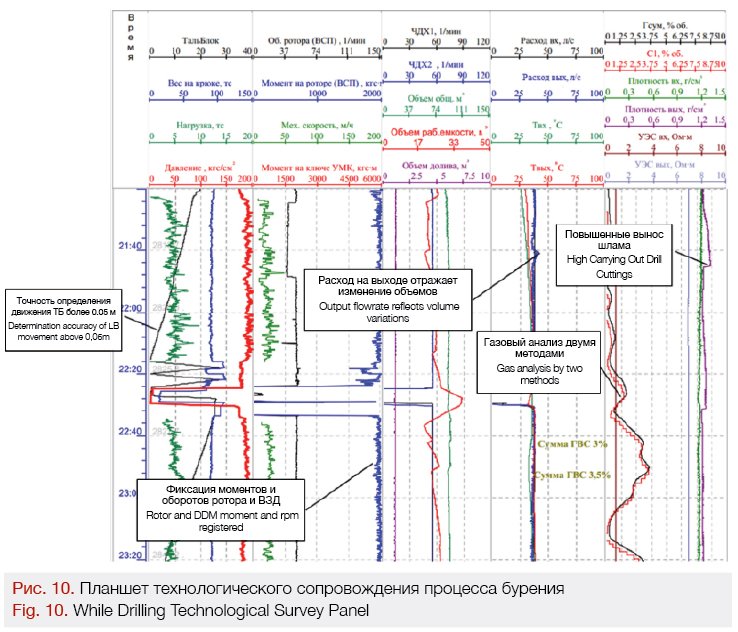

Technological Survey while Drilling

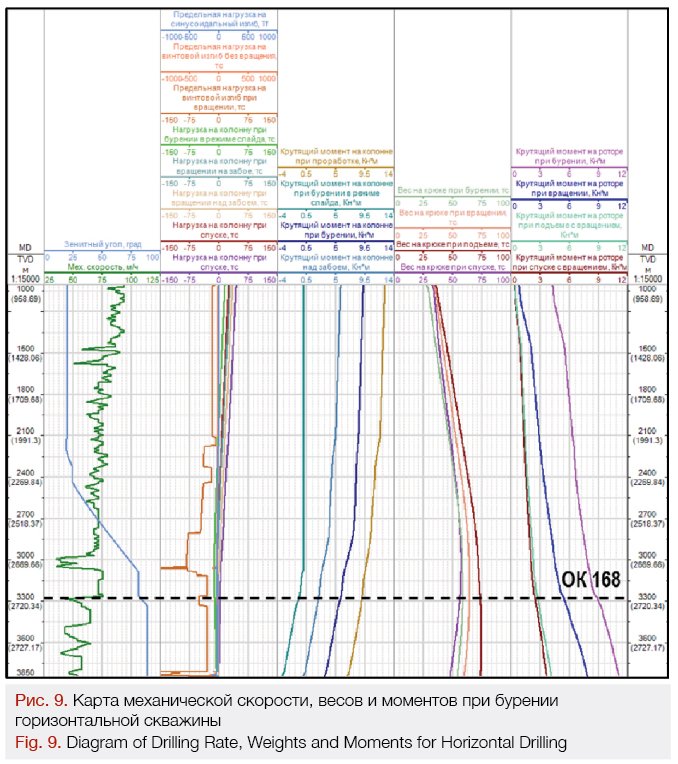

The technological survey included a priory calculations of penetration rate, weights, torgue and loads during well construction and technological survey with state-of-art process controls used on the rig site and in the LWD system. The most operating problems related to the Frolov and Georg Suite intervals. In the intervals, high vertical heterogeneity of the mechanical properties (demonstrated by geomechanical model) altered the rock’s contrast mechanics, including strength. This resulted in high transverse vibrations while drilling (up to 30G vs. 10 maximum allowable), even damaged BHA, high wear and tear of bits and centralizers.

Vibration data from downhole tools and surface data monitoring allowed to establish drilling parameters (WOD, tool rpm) which would reduce the vibrations by 5 to 10 times.

Also, it was possible to identify an interval in the top of Georg Suite where drop in ROP was expected due to the high strength properties. The interval existence was confirmed while drilling.

Conclusions

The performed analysis of engineering and organizational solutions and achieved results demonstrate how important it is to apply integrated approach, create full-scale system and provide comprehensive and close interface between all disciplines.

These works led to the following conclusions:

• LOOCH-M-2014 LWD system supply open hole logging data while drilling for geological, petrophysical and other interpretations, also used for conclusions and reserve calculation;

• Geological and technological survey according to all standards will help timely anticipate or eliminate drilling problems;

• Geomechanical modeling in case of sufficient set of drilling data will facilitate determination of optimal drilling parameters, trajectory and mud properties for successful drilling.

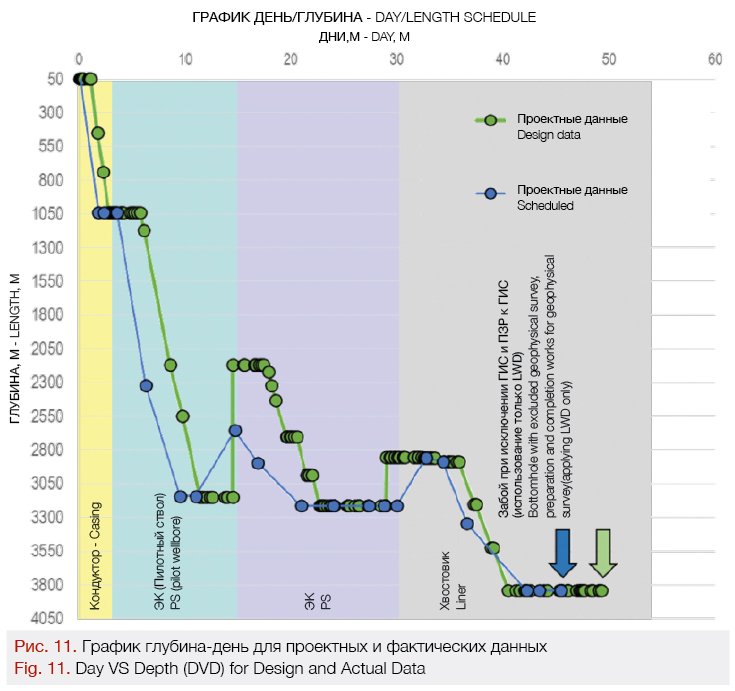

Such factors coupled with the efficient system will considerably reduce well construction time. At this stage, single well construction period has been already reduced by:

• 1.6 days vs. the estimation;

• 5.3 days vs. standard approach with logging in open hole

With the technology elaborated and permanently applied, the planned construction days saving will be 3.8 and 7.4 days respectively.

References

1. Resistivity LWD Tools and Interpretation / K. Kayurov, V. Eremin, M. Epov, V. Glinskikh, K. Sukhorukova, M. Nikitenko // Petroleum Industry. – 2014. – No. 12. – P. 49–55.

2. Resistivity LWD Tools and Techniques / V. Eremin, Yu. Volkanin, A. Tarasov // Karotazhnik – 2013. – No. 4. – P. 62-69.

3. E. Lukianov Petrophysical Drilling Simulation as Basis of Geo Survey Data Interpretation. – Novosibirsk: Istoricheskoe Nasledie Sibiri Publishing House, 2015. – p. 312.

4. Synopsis of Petrophysical Functions in 1D Geological-Geomechanical Simulation for Wellbore Stability while Drilling / K. Toropetskiy, V. Ulyanov, G. Borisov, R. Kurmangaliev, N. Kayurov, V. Arzhantsev // Automation, Telemetry and Communication in Petroleum Industry. -М.: VNIIOENG, 2016 – No. 12. – P. 31-44.

5. 1D Physical-Mechanical Modeling and Solving Problem for Well and Near-Wellbore Stability / K. Toropetskiy, N. Kayurov, A. Cheremisin, M. Lushev, M. Samoilov, V. Ulyanov, G. Borisov // Automation, Telemetry and Communication in Petroleum Industry. -М.: VNIIOENG, 2016 – No. 11. – P. 29-41.

6. Enhancing Geo Survey Capabilities / E. Lukianov // Karotazhnik – 2008. – No. 5. – P. 42-59.

7. Well Construciton Survey Technology / K. Toropetskiy, N. Kayurov, V. Eremin, E. Lukianov, V. Ulyanov , G. Shevtsov // Automation, Telemetry and Communication in Petroleum Industry. -М.: VNIIOENG, 2017 – No. 12. – P. 4-15.

8. Penetration rate performance of bits / Warren T.M. // SPE Drilling Engineering. – 1987. – No. 2. – Pp. 9-18. – doi:10.2118/13259-PA.

9. Theory and applications of a new generalized model for torque and drag / Aadnoy B.S., Djurhuus J. // Society of Petroleum Engineers. – 2008. – doi:10.2118/114684-PA.

Authors:

N. Kayurov1,5, E. Dontsov2, A. Lyudinovets, A2. Gadiulin3, A. Prokhoshin4,

V. Eremin1, A. Korobeynikov6, V. Ulyanov5

SPE «Looch»

Varieganneftegaz

Expert Support and Technical Development Center

TNNC Tumen Oil Scientific Center

NNTC Research & Development Center

Orion Consulting and Services Ltd