NovosibirskNIPIneft: Constructing the Smart Field

Abstract

In this paper the issues of obtaining and processing data for various concepts behind the smart fields were reviewed. It gave consideration to the major issue of establishing feedback mechanisms to manage hydrocarbon production and key resources in the field, that is, the data reliability issue. The paper demonstrates a way to assess the reliability of the measurements through information analysis of the data flows acquiring from the instrumentation. It examines the primary factors which largely influence the reliability of the field data. The paper suggests a technique and algorithms to shore up the reliability of the acquired information and to keep uncertainty in the field data down to support a range of geological and technological solutions that will increase the exploration maturity of the field as a hydrodynamic object.

Issue of Field Data Reliability

These days there are a number of hydrocarbon production issues that drain operator profits. High uncertainty in the data used for decision making is one of them [1]. Chiefly it is uncertainty in the field geology and unreliability of the field data and in particular measurements of flow rates per phase. Currently the performance data is used mainly to monitor the current equipment status and select its operating conditions while some efforts are made to use this information to optimize the equipment utilization [2].

This data also contains the essential field information related to the hydrodynamics of a geological object, the oil and gas reservoir. When supplemented with well logging, well testing, pressure build-up curve, level build-up curve, fluid sampling, etc., which are currently conducted sporadically, this research would

supply wide-ranging information about the hydrodynamic properties of the oil and gas reservoir.

Metering Systems. Since this paper talks about the reliability of the data obtained by surface measurements we would like to begin with the key characteristics of the metering systems used (Western Siberia with its extensive multiple drilling pads uses mainly group metering stations, GMSes), their major advantages and disadvantages and impact on the reliability of measurements. If we review the conditions of the typical oil fields at the later stages of their operation with almost entirely marginal wells it will become obvious that the financial parameter, the cost of the measuring unit per oil well, is the central factor for selecting the measuring tool.

For our purposes all measuring systems can be divided into 3 groups:

1. Two-phase separators that determine water cut with a water cut meter or by laboratory testing of the fluid samples. Advantages: Low cost and simple construction. Disadvantages: Measurement discreteness and extremely low accuracy for high gas volume factor and high dependence on human component. The powerful influence of the above mentioned factors, on the reliability of the measurements does not provide for the adequate accuracy of measurements.

2. Three phase separators. Advantages: Relatively high accuracy of individual measurements. Disadvantages: High cost, bulky construction, measurement discreteness and need for highly qualified employees. Such devices often also do not support the required accuracy of the measurements.

3. On-line flow meters. Advantages: High accuracy of measurements and continuous measurement capability. Disadvantages: Extremely high cost, need for highly qualified employees that further boost costs. Such devices meet the requirements for reliable measurement but their use is economically justified only for high rate wells. By the same token they are not practical for Russian circumstances. Dependence on the human component is also not canceled out.

Composition of the borehole fluid should be determined by the flow meter, that is, with no interference in the flow and phase separation, based on measuring the physical properties of the medium which differ significantly among its individual components. A definitive interrelation between the measured physical properties and composition of the fluid is generated based on a preliminary calibration results with slip effects factored in.

Composition monitors can be, for our purposes, split up in several groups contingent upon their measured fluid physical properties:

- Electrophysical meters including measuring of permittivity and electrical conductivity. The directly measured parameters are electric properties of a sensor filled with fluid: capacitance and / or conductivity; full impedance; resonance parameters for standing waves; absorption factor for super high frequency EMI, etc.

- Radioactivity meters including measuring of ionizing radiation absorption factors: γ-rays (Daniel, Schlumberger, Haimo) or neutrons.

- Optical meters including measuring of IR transmission and / or scattering factor (Premier Instruments).

- Acoustic meters including measuring of acoustic wave travel velocity and acoustic wave attenuation, Doppler shift, etc.

Electrophysical and radioactivity sensors are highly sensitive to fluctuations in water salinity since electrical conductivity and absorption hugely depend on salt content. A disadvantage of electrophysical and optical sensors to some extent is their low sensitivity to the liquid hydrocarbons / water ratio at high gas content. Thus such meters can be used either together with a composition meter of another type which identifies specific gas content or as part of the two phase separator flow meter where liquid is separated from gas. The majority of industrial multiphase flow meters employs a combination of component scanners with different physical principals applying independent measurements to mutual adjust them and determine the flow structure.

Summing up the above, we get that the metering systems and metering techniques currently cannot ensure a uniform reliability of the obtained data given the financial considerations the higher the accuracy of the metering system, the higher its cost and lower its financial efficiency. For this reason, the development of the existing data collection systems based on the subsurface telemetry systems (STS) and group metering station (GMS) is from both perspectives of data processing technique and equipment upgrade.

Reliability of Field Data. Summing up the above information on the metering systems we can state a primary as well as a dual problem related to the wellhead measurements. Let us suppose that we are interested in the accumulated daily production of one well. We write the following formula for the double component three phase flow if we assume a constant gas ratio (which is true for the majority of

producing wells):

Where:

![]() is the daily measurement for the accumulated phase j (that is, j=1.2 since we have two phases: water and oil),

is the daily measurement for the accumulated phase j (that is, j=1.2 since we have two phases: water and oil), ![]() is an instanteneous rate of the ith well for this phase

is an instanteneous rate of the ith well for this phase

Since no instantaneous measurements are available the integral in the right hand member of the formula is replaced with a product of the hourly accumulated product measurement times the specified time period Δt in hours:

![]()

Where: ![]()

are an average accumulated daily well performance for liquid and average saturation for such phase respectively ![]()

are empirical parameters that impact the reliability of these measurements

f1: Human component that entails adherence to the measurement schedule including compliance with the set time periods and work scrupulousness (no fictious records), measuring accuracy including following the activity sequence, purposeful information distortion, or exaggerated production, etc.

f2: Technology factor that covers the metering unit error along with potential leakage, stray flows in the manifold, reciprocal actions of the wells, unstable pump system operation, etc.

f3: Hydrodynamic factor that comprises the fluctuating operation of both individual wells and the field as a whole.

The reliability of the obtained information is hinged upon the listed factors each of which affects the total measurement error. Despite the high accuracy of the recent metering systems they cannot rule out all the three above mentioned factors but only lessen the technology and / or hydrodynamic factor while obviously not redressing the human component.

Then the primary problem is to minimize three factors that directly impact the reliability of measurements for a well or a well cluster. It is possible both technically and mathematically by utilizing the special algorithms outlined below. The dual problem is to recover the values of three factors depending on time with a known exact total of each phase ![]() that will allow us to calculate production for each well. Solution of the primal and dual problems is essential for increasing the accuracy of metering in oil and gas production, creating reservoir models, etc.

that will allow us to calculate production for each well. Solution of the primal and dual problems is essential for increasing the accuracy of metering in oil and gas production, creating reservoir models, etc.

Information System

The error in the different measurements is a term that traditionally belongs to metrology. This field reduces error mainly though technical measures: equipment advances but much less so through measuring techniques [3]. When measuring such a complex characteristic as multiphase multicomponent flow at the wellhead of a producing oil or gas well the issue of error is primarily related not only to the perfection of the measuring instruments but the reliability of the created physical model for the measured fluid and the device. Thus it is reasonable to examine not the error of well rate measurements but reliability of the measured information [4].

Periodic continuous rate measurements are utterly important for settling the issues related to oil and gas field development both locally and for the field as a whole. We would like to emphasize that there is an apparent relationship between the error and resolution of the measuring system and its cost. That’s why the problem of determining the reliability level of information on well rates, accumulated production and other characteristics measured and identified with various devices is top-of-the-agenda. Such devices are represented by a wide range of diversified measuring systems based on both mixture separation and rate measurements for each component and a vast number of multiphase measuring instruments that operate with no interference with the flow. The most common instruments are the GMS’es simultaneously connected to several wells via a hydraulic switching system and supporting measurements with a toggled intermittent operation. Such metering systems normally contain separators within them but multiphase flow meters can be used as well.

Since data interpolation between measurements makes a sizeable addition to the overall information picture we suggest that quantitative assessment of metering system efficiency is rooted in the information theory. The most practical approach for identifying informativity of the production monitoring system is a probabilistic one using entropy as an information content measure, that is, the number of bits required for coding a variable value so that it meets the accuracy criterion [5]. It is clear that the source of information is a change in the production system performance. In this view, information flow from the production system I (t, δ, Δt) is a function of time (t), the required resolution of the monitoring system (δ) and a time lag between measurements (Δt). Generally speaking, the monitoring system does not support sensing all the information about the changes in the production system so the information losses dI should be calculated to numerically compare the efficiency of different monitoring system [6]:

![]()

Where:

![]() is steps in time,

is steps in time, ![]() is a time period between measurement;

is a time period between measurement; ![]() is the instrument resolution;

is the instrument resolution; ![]()

is the information flow of the instrument ![]() is the information sensing function that factors in event superposition and takes on a value of

is the information sensing function that factors in event superposition and takes on a value of ![]()

Where: pi is the probability of occurrence for the set value ![]()

The ultimate goal of flow metering system design is to maximize ![]() to minimize the information losses dI which are linearly proportional to the method error of the monitoring system.

to minimize the information losses dI which are linearly proportional to the method error of the monitoring system.

Since information is generated upon any changes in the production system the information capacity of the monitoring system can be boosted by performing measurements only on the wells with changes. It will help to satisfy one of the crucial requirements to the measuring system: the opportunity to accurately determine time of any event occurrence, the reasons behind it, location of the source within the field, and assessment of its scale.

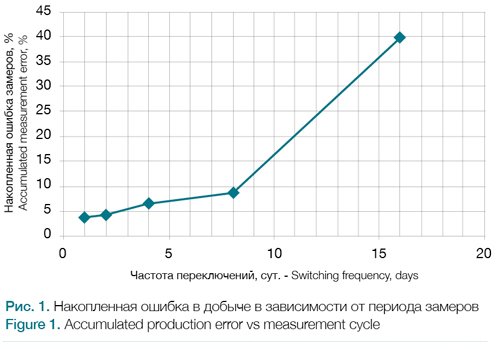

Measurements with switching between events. Up-to-date GMS’es are meant for performing measurements on several wells within one cluster but errors brought about by information omissions in such a case will pile up since √n, where n is the number of wells and a total error of the accumulated production, will upsurge.

The solution to this problem is to increase the frequency of switching between the wells. Yet this frequency is, in fact, limited by both serviceable life saving considerations for the hydraulic switch and a duration constant for separation. Any events in the wells will be identified with a time lag comparable with a duration of a complete switching cycle for all the wells in a cluster.

We performed an information simulation study for a system of hydrodynamically related facilities where events of a certain type were prescribed. Since all the flow properties in such a system can be calculated and are known to any predetermined accuracy and timing resolution we have an approximation of a perfect measuring system with an unlimited information capacity. We further reviewed an approximation of an actual metering system recording a limited or incomplete information range with a deliberately reduced timing resolution and noises of various nature added. Continuous thermobarometry at the wellhead supplemented with a low accuracy flow measurements and, finally, some data for the itemized component rates from the GMS hooked up via a hydraulic switch were selected as the measured parameters.

As an illustration, Fig. 1 shows a correlation between an error in the accumulated production for a well system and a cycle of the GMS switching between them. Mathematical simulation demonstrated that the metering system with an event switch can have a one order lower total error for the accumulated production thus eliminating the need for equipping each well with costly meters since only one high accuracy cluster flow meter is sufficient. Additionally, such metering system cuts the wear of the hydraulic switch (isolation valves) down to a required minimum.

Conventional algorithms based on exploring correlations in the measured data [7] and identifying fractal characteristics of time functions [8] as well as state-of-the-art algorithms rooted in the competitive similarity function [9] that supports factoring in of quantitative assessment of various data accuracy can be used to identify events by gauge readings

Field Data Analysis and Processing System

Another important aspect of system building is a study of field information containing a large amount of omissions and incorrect values to create a consolidated data structure which is ready for further use.

Despite the shortcomings of the existing measuring systems such data can be mathematically processed to deal with a range of issues. A distinctive feature of the tested solutions is an integrated approach to field data including their analysis as a function of time and not only as instantaneous or average values.

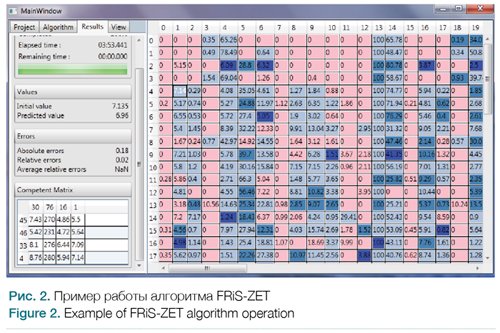

Data filtering and interpolation. Data can contain a large amount of omissions and errors. The FRiS-ZET algorithm based on the competitive similarity function [9] to fill in the omissions and identify erroneous data is suggested as a solution. The algorithm operates in the following steps:

1. The most competent rows and columns are selected to fill in the element from the original M*N size object / property matrix, which will later form a competent submatrix consisting of the m, m ≤ M, rows and n, n ≤ N, columns.

2. In the second step the parameters in the formula used to predict the omitted element are adjusted automatically and an expected error of the omitted element prediction is assessed.

3. The element is directly predicted.

The software package in Fig. 2 calculates the competent matrix (in its lower left part) and makes a prediction for each cell. The algorithm can operate in either ways: by filling in the omissions in the tables or checking the filled out cells for their alignment with the common patterns of the data array (potentially incorrect data are highlighted with darker color in Fig. 2).

The advantage of the algorithm is the use of the competitive similarity function that, from the entire data array, selects only a small competent part most suited for filling in a particular empty cell or identifying errors in the already completed matrix [10] and adds a reliability checks for the generated prediction based on the compactness value of the competent matrix involved in the element prediction. It helps to boost the speed and accuracy of the algorithm operation compared to its existing alternatives.

This data processing stage ensures generation of data with an equivalent error that can be used for further calculations and developments: to create correlation models, monitor and identify events, build hydrodynamic models, search for linked objects, analyze data with statistical estimates, etc.

Further use of data. Preliminary data preparation and selection of the representative “hydrodynamic events” will allow producing more solid and consolidated data arrays that can be used for solving high level integration issues related to process optimizing.

Summary

The smart field is created through building and fine tuning a feedback system for the execution units and measuring systems for its flawless operation. This paper attempts to approach the issues of forming the smart field basis including software package development to implement the expert system and multiphase flow metering system to ensure the least information loss during measuring. We plan to further clarify all of these issues including data processing algorithms and an information approach to the measuring system assessment.

References

1. Baikov I. R., Smorodov Е.А., Akhmadullin K. R. Reliability and efficiency analysis techniques for hydrocarbon production and transportation system. – M.: OOO Nedra Business center, 2003. – 275 p.: ill.\

2. Weatherford. LOWIS™ Life of Well Information Software. http://www.ep- solutions .com/solutions/Software/LOWIS.htm

3. espWatcher. A service for remote real-time surveillance and control electrical submersible pump systems. http://www.slb.com/content/services/artificial/submersible/espwatcher.asp.

4. Real Time Optimisation Approach for 15,000 ESP Wells S. Zdolnik, A. Pashali, D. Markelov, M. Volkov//SPE 2008.

5. Shneiderman B. Tree visualization with Tree-maps: A 2-d space-filling approach. ACM Transaction on graphics. – 1992. – Vol. 11. – № 1.

6. Zagoruiko N.G. Applied Approaches to Data and Knowledge Analysis. 1999

7. Methods of Recognition Based on the Function of Rival Similarity N. G. Zagoruiko, I. A. Borisova, V. V. Dyubanov, and O. A. Kutnenko Sobolev Institute of Mathematics, SB RAS//MATHEMATICAL THEORY OF PATTERN RECOGNITION.

8. Ryazantsev A. E. Phase Meter for the Oil-Water-Gas Mixture (MMIF Interra, 2011)

9. Ryazantsev A. E. The FRiS- ZET omission filling algorithm for empirical tables and its use for solving data analysis issues in oil and gas fields, (MNSK, 2012)

10. http://math.nsc.ru/wwwzag/

11. Jeffery I., Higgins D., Culhane A.: Comparison and evaluation of methods for generating differentially expressed gene lists from microarray data, BMC Bioinformatics, 2006, 7:359. (http://www.biomedcentral.com/1471-2[9]5/7/359)

12. Ryazantsev A. E. Intellectual expert system for field data analysis and streamlining oil and gas production. The Smart Field: International Practice and Modern Technology, International Research to Practice Conference. May 10-11, 2012

Vladimir Ulyanov, Ph.D.,

Technical Director, NovosibirskNIPIneft

Toropetskiy Konstantin,

Leading Expert, NovosibirskNIPIneft,

Anton E. Ryazantsev, CEO, RC TSC