NovosibirskNIPIneft: Recommended Drill Fluid Selection in the Vend-Cambrian Deposit in Eastern Siberia

Overview

The work defines the methodological aspects of selection and expert analysis of the optimal drilling fluids (RDFs) for producing reservoirs deriving from geotechnical and the geological characteristics of the development. The works were performed in pre-salt carbonate and terrigenous reservoirs of the Vend-Cambrian deposits of the Nep-Butob Anticlise in Eastern Siberia.

Introduction

The involvement of low-permeable carbonate and terrigenous formations of Eastern Siberia (Nep-Butob Anticlise) in the commercial development process was started relatively recently. Since the final goal of the exploratory wells is to determine the commercial value and petroleum potential of the field under exploration, it is necessary to ensure a high quality penetration into the producing reservoirs. In view of the complicated geotechnical and geological formation; pre-salt carbonate and terrigenous reservoirs, abnormally low reservoir pressure and temperature, saline reservoirs, selection of muds for primary penetration, it is a rather complex task [1-9].

The purpose of this work was to perform the research works for the selection of the optimal drilling fluids (RDF) for the producing reservoirs deriving from geotechnical and geological characteristics of the target formation. The research work focused on obtaining the experimental data for making effective technical decisions based on the preservation of the producing reservoir collecting properties in the process of prospecting/appraisal and exploration well construction. Experiments were conducted with drill fluid samples from different manufacturers. They were focused on the physical and chemical properties of the drill fluids and their compliance with samples of reservoir fluids and rocks.

Based on geotechnical and geological conditions, including the producing reservoir geological & physical characteristics and formation, mineral composition, saturation, wettability, porosity and permeability, the following general requirements for the drilling fluids were defined:

1. High quality penetration into the producing reservoir (preserving the initial permeability);

2. Consideration of the possible presence of ALRP local zones — 3-4 MPa lower than hydrostatic pressure (RDF density is lower than 1.05 g/cm3);

3. Consideration of the cavernous-porous-fractured nature of voids in the opened producing intervals formed by carbonate rocks to minimize the penetration zone;

4. Consideration of highly mineralized reservoir water (up to 400 g/L) and presence of crystal salts in the cut or in the porous space (salination);

5. Prevention of clay soil (clay, argillites, etc.) swelling and sloughing;

6. The fluid must be suitable for pumping at low temperatures (15-25°С) typical for such reservoirs.

7. The drill fluid design parameters must conform to the following values within the producing reservoir drilling interval: density – 1.03-1.06 g/cm3; viscosity – 40-60s; water loss – 2-4 cm3/ 30 min.

Procedure

The laboratory research cycle comprised the following sequence:

1. Determination of physical properties of the reservoir rocks, including mineralogical analysis, the porous space structure, and wettability, namely:

-Carbonate content determination by gas-volumetric method when reacting with hydrochloric acid;

-Determination of the clay component mineralogical composition by X-ray spectral analysis;

-Determination of the porous space with the raster electronic microscopy;

-Porous channel dimensions and geometry determination by method of optical microscopy of thin rock sections;

-Wettability index determination;

-Determination of clay minerals’ tendency to swell in consequence of hydration;

2. Determination of physical and chemical properties of the drill fluids as per API RP13 [10-11], boundary tension, emulsification, and scale depositing index when exposed to reservoir fluids:

-Density, funnel and plastic viscosity, static and dynamic shear stress; water loss index, filter cake thickness; pH value; liquid and solids content; aggregate stability index.

-Determination of boundary tension between immiscible fluids by drop volume method as per GOST R 50092-97 [12] using a laboratory instrument – stalagmometer.

-Preparation and dynamics of emulsion breaking, determination of the whole emulsion electrical stability.

-Determination of tendency to form a solid (insoluble) sediment when mixing liquids.

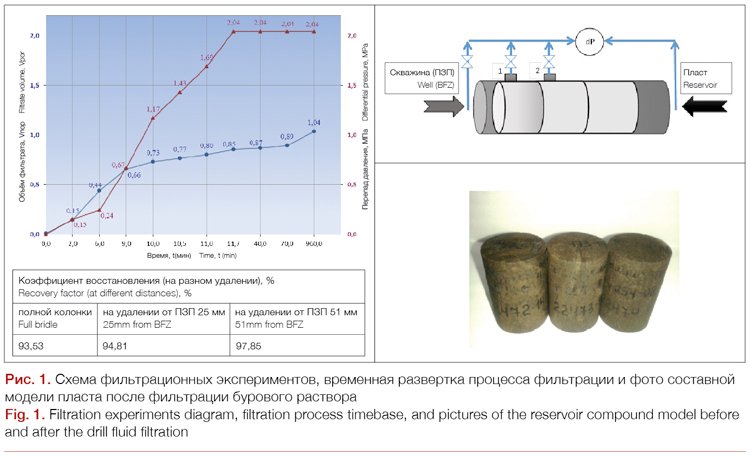

3. Determination of reservoir damage (recovery factor) during filtration experiments conducted under pressure-temperature conditions as per OST 39-235-89 [13] (Figure 1):

-Kperm1 in the process of filtration through the reservoir compound model in the direction “reservoir-well”, pumping at least 3-5 porous volumes of the core model.

-Process fluid injection in the direction “well-reservoir” at differential pressure corresponding to the expected overbalance pressure during penetration.

-Kperm2 in the process of filtration in the direction “reservoir-well”, pumping at least 5-10 porous volumes of the reservoir compound model.

-Permeability recovery factor β = (Kperm2/ Kperm1)·100%.

-Clogging area estimation during measurement of differential pressure at different distances from the drill fluid delivery point.

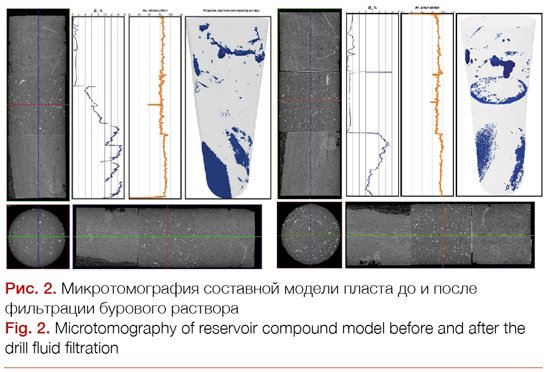

4. Determination of porous space change in the process of drill fluid filtration though rock specimens (Figure 2):

-Microtomography of the reservoir compound model in the initial state and after exposure to drill fluid.

-Comparative analysis of the porous space model before and after the drill fluid effect on the reservoir compound model.

Preparation of reservoir compound models (RCM):

-3-5 cylinder specimens with a diameter of 30 mm and total length ≥ 10 cm;

-close permeability values (difference < 50%);

-belonging to producing or potentially producing interval and lithotype;

The samples are extracted with toluene, saturated with reservoir water to create residual water saturation, and resaturated with hydrocarbon liquid (kerosene) as per GOST 26450.0-85 [14].

For the OBM with the highest permeability recovery factor some insignificant changes in the reservoir model structure are observed: decreased matrix porosity compensated by increase of the caliper component caused by elution of salts. It is in a good agreement with insignificant change of permeability after the drill fluid filtration.

Output

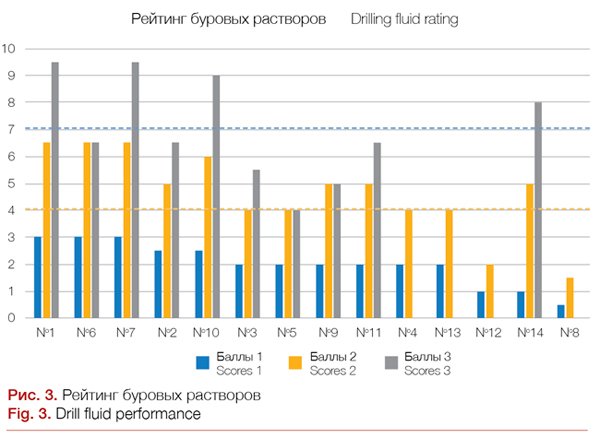

There are dozens of companies in Russia that render drill fluid recipe selection and drill fluid delivery services, including divisions of drilling companies, international service companies, and Russian independent companies. We have analyzed 14 samples of drill fluids, including: Inhibited potassium chloride bio-polymer WBM, diesel fuel/mineral oil base OBM with/without organic bentonite as well as emulsion muds.

We have adopted a scoring system (Table 1) to estimate the drill mud quality depending on compliance of laboratory test results with the established requirements.

Scores1 – final rating in rheology (density, FV, ПФ), Scores2 – final rating in rheology and phys.-chemistry (surface tension, emulsion formation, scale depositing, emulsion formation), Scores3 – final rating in rheology, phys.-chemistry, and filtration characteristics (filtration recovery).

Conclusion

Only 4 of the 14 drill fluid samples were recognized as optimal to be applied at the target sites (3 for terrigenous reservoir and 1 for carbonate reservoir). All these fluids are characterized by low density 1.025 – 1.14 g/cm3, viscosity 50-90 s, water loss 0.5-3.5 cm3/30 min, and filtration recovery factor 87-93%. These drill fluids have the following common features:

− oil base (mineral oil or diesel fuel);

− water phase, emulsion mud ionic strength adjuster (calcium chloride);

− marble bridging / weighing agent of different size (5 µm median);

− gelling agent (organic bentonite);

− additives, rheology and filtrate return adjusters, hydrophobizator, and other surfactants;

For the purpose of RDF final selection it is also necessary to consider a number of economic and technological factors, such as:

– easy preparation, availability, and logistics of the mud components;

– the cost of reactants and their delivery to the site, storage terms, conditions and volumes;

– possibility of regeneration and repeated use;

– environmental friendliness and safety of the components being used.

References

1. Angelopulo O.K., Podgornov V.M., Evakov V.E. Drill fluids for complicated conditions, M.: Nedra, 1988. -135 p.

2. Gray G.R., Darley H.C.H. Drill fluid composition and properties, M.: Nedra, 1985.

3. Ryazanov Y.A. Drill fluid encyclopedia, Orenburg: Letopis, 2005. 664 p.

4. Darley H.C.H., Gray G.R. Composition and properties of drilling and completion fluids, Gulf Professional Publishing, 1988, 643 p.

5. Drilling Fluids Processing. Handbook, ELSEVIER, 2005, 666 pp.

6. Skalle P. Drilling Fluid Engineering. 2011. 125 p.

7. Antonov K.V., Lukmanov R.R. Polymer drill fluid influence on the quality of producing reservoir penetration and informational value of well log geophysical study, Tyumen: ZapSibburNIPI. 1996

8. Kiselev K.V. Physical and chemical processes of acid solution interaction with poor oil deposit rocks. Author’s abstract, Tyumen, 2004, 27 pages.

9. Usachev E.A. Modeling of process fluid filtration into the reservoir bottomhole formation zone in the course of the well construction. Author’s abstract. Tyumen. 2002. – 110 p.

10. RD 39-00147001-773-2004. Methods of drill fluid parameters control, 2004, 138 p.

11. API RP13, Recommended Practice for Laboratory Testing of Drilling Fluids.

12. GOST R 50097-92. Surface active agents. Determination of interfacial tension. Drop volume method.

13. OST 39-235-89 Crude oil. Method of relative permeability determination in laboratory conditions in the course of joint stationary filtration.

14. GOST 26450.0-85. Rocks. Methods of collecting property determination.

K. Toropetskiy, V. Ulianov, G. Borisov.

K. Toropetskiy: Leading Expert, NovosibirskNIPIneft;

V. Ulianov: Ph.D.in Engineering, Technical Director of NovosibirskNIPIneft;

G. Borisov: Ph.D. in Physics and Mathematics, Director General of NovosibirskNIPIneft.