PJSC NK Rosneft and Schlumberger Develop a Local High-Tech Drilling Equipment Market

The First Use of Russian neutron-density tool in a Triple Combo BHA at the oilfield of LLC «RN-Uganskneftegaz» for drilling of optimized casing design wells

Introduction

To improve well construction efficiency Rosneft has been successfully implementing two-string wells design for several years now [1]. The approach is quite innovative, it excludes a whole stage in well construction cycle, in particular the running of the 178mm production casing. Two sections of the production casing and liner are combined into a 178/140mm casing. This approach helps to reduce the well construction time by an average of 7 days. One of the key stages, which contributes to the efficiency of this type of well construction, is the use of high-tech equipment in the BHA (Bottom-Hole Assembly), including a Rotary Steerable System (RSS) and an LWD (Logging While Drilling) tool for formation evaluation in the real time. Originally, only international equipment was used. However, over the past few years, Russia has implemented an import substitution strategy and oil & gas companies are looking for locally made and manufactured Russian high-tech directional drilling (DD) and LWD equipment [4]. This article describes the successful experience of localizing such technologies for Rosneft.

Successful Integration of the Russian Neutron Density Logging Tool into the BHA

Oilfield service companies have been actively developing BHA’s which are 100% Russian-made. One example of a successful implementation is the integration of the Russian nuclear logging tool. Tools manufactured by CJSC NPP Energia were chosen for this purpose. The tools were developed in 2017 and are included in the register of technologies approved by the Expert Technical Board of the State Committee for Mineral Reserves (Protocol No. 6 of 07/29/19). The expert Board assessed the quality and completeness of the measurements. However, to unlock the tools geosteering and operational petrophysical analysis measuring potential, it was necessary to integrate it with high-speed telemetry. This challenging task was handled by the GEOFIT Product Center. For more than 30 years GEOFIT has successfully manufactured drilling service equipment and continuously invests in Research and Development. Their engineering team designed an unique real-time connection module, that combined the logging tool with the high-speed telemetry system. The development of the module made it possible to fully integrate a Russian nuclear tool into the bottom hole assembly, providing the acquisition of density and porosity data in real time for geosteering and proactive reservoir characterization. The high speed telemetry tools can send downhole data to the surface using mud pulse telemetry with a bit rate up to 12 bit/sec without compression (up to 50 bit/sec with compression.) The connection module made it possible to fill this channel with CJSC NPP Energia Tools LWD121-2NNK-GGKLP (4.75”) / LWD172-2NNK-GGKLP-3GK (6.75”) measurements. In real terms, the bit rate transmits to the surface 5 curves and density images in real time with a data density of about 3 data points per meter.

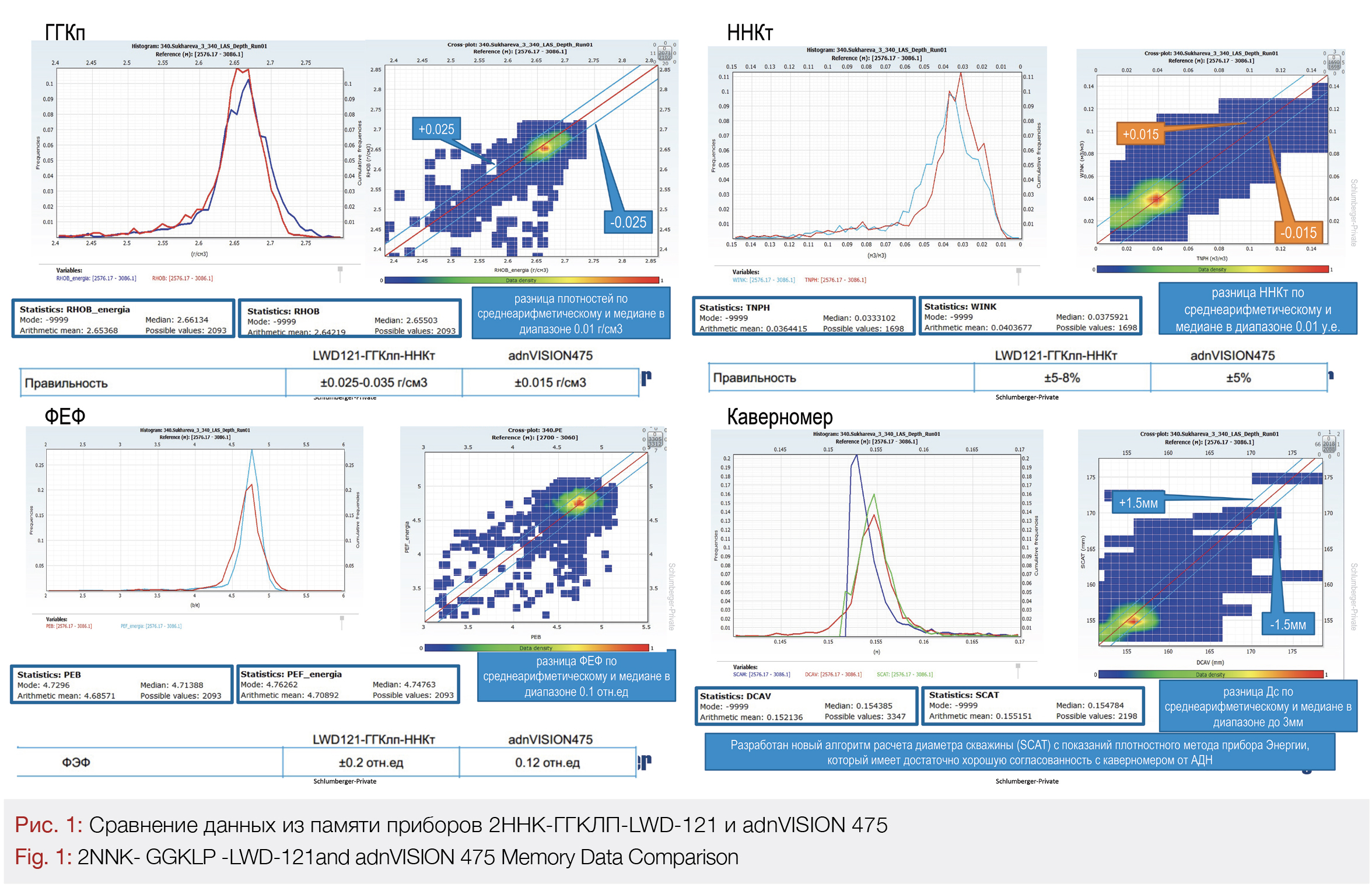

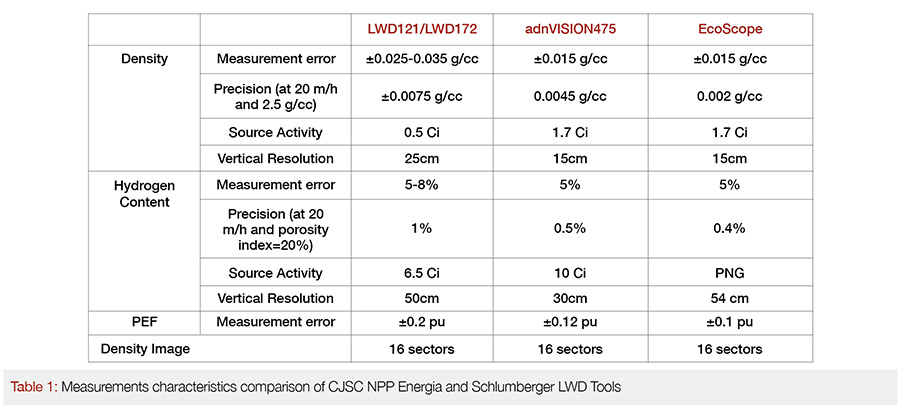

In April 2019 the first carbonate pilot test of the LWD121-2NNK-GGKLP (4.75”) tool, in connection with a Schlumberger neutron-density tool, adnVISION, in the was held. The comparison of the memory data from both tools, such as: density, porosity, density image, caliper showed a convergence within the nominal margin of error. The comparison of the measurements specifications of the tools is presented in Table 1.

Currently this technology has been successfully deployed for in more than 20 wells (three- and two-string designs) for Rosneft. The tools are available in two sizes – 121mm and 172mm.

In Russia, the use of radioactive sources for nuclear LWD Tools must comply with the highest safety standards to ensure employees health and safety. Standards, procedures and technical decisions for handling radioactive sources used in nuclear tools are now at different deployment stages. Also, modifications in the tool’s design are being implemented together with tool’s manufacturer. For example, neutron source plugs and handling tools have been modified for faster source handling operations and reduced personnel exposure time, the tool’s stabilizer wear resistance has been increased with the addition of laser cladding, the organization of the calibration facility and the calibration methodology optimization was improved, as well as the creation of regular equipment verifications and source integrity and photo inventory auditing.

Special training programs for field and technical personnel were organized at the Schlumberger Training Center, Tyumen, together with CJSC NPP Energia. In addition, a special knowledge repository was created, which consolidates technical information on the NPP Energia LWD tool, including the most recent updates on procedures, firmware, technical regulations, lessons learnt on failures and other important information.

Successful Deployment of LWD172-2NNK-GGKLP-3GK Tool Together with Multilayer Bed Boundary Detection Tool for Drilling Two-String Wells at a Rosneft Field

After successful jobs with Russian neutron density tools for a three-string well it was decided to apply this experience when drilling a two-string well at RN-Yuganskneftegaz field’s. In such wells the production casing and liner are combined in one casing and are run together. The section for combined casing is drilled in one bit run. On the 4th of February 2021 the first two-string well using a Russian neutron-density tool and multilayer bed boundary detection tool was drilled.

The objective was to drill a two-string well in the oilfield of LLC «RN-Uganskneftegaz» (Jurassic age formation) with geosteering.

The two-string well was composed of the following open hole sections:

• 11 5/8 inch section [295,3mm] for conductor casing till 1137m MD (measured depth)

• 8 11/16 inch section [220,7 mm] for combined casing till 4411m MD

Total length of 220.7 mm HS interval was 3274m. Section was drilled within one bit run. Oil based mud (OBM) with a density of 1.32 g/cc was used.

As mentioned previously, drilling two-string wells reduces the well construction time by 7 days on average compared to a three- string well.

There were two main objectives when drilling this well:

Petrophysical: oil reservoir rock characterization while drilling. The volume and quality of the data should be high enough for a reliable localization of the productive intervals and the well completion design.

Geological: real-time geosteering. The objective was to proactively adjust the well’s trajectory to achieve the optimal position within the best section of the reservoir. The data should help proactively assess the structure and well’s location relative to the productive and unproductive layers.

• The petrophysical objective was achieved by a set of azimuthal bulk density and neutron measurements from the LWD172-2NNK-GGKLP-3GK tool, while

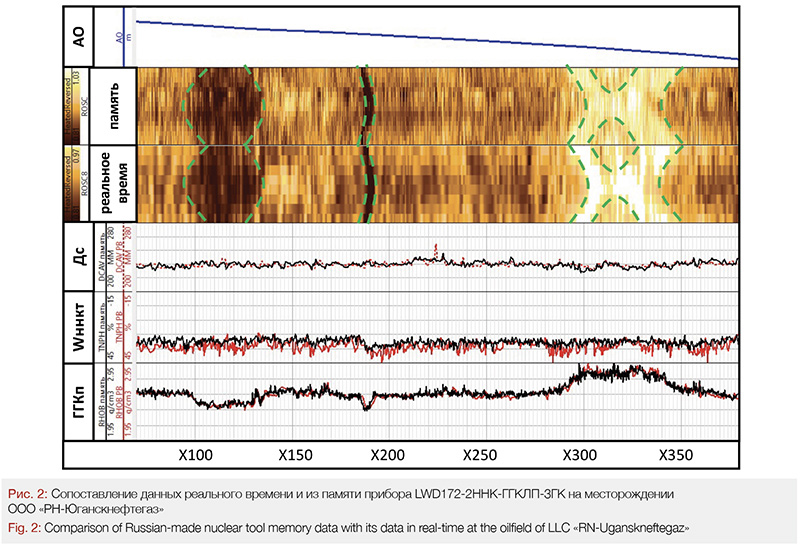

the gamma-ray and resistivity measurements were obtained from the bed boundary detection tool. Based on the available petrophysical sediment model, it was possible to perform the formation evaluation of the YUS2 reservoir in real time. The existing complex made it possible to reliably estimate the porosity, permeability and water saturation coefficients in reservoir conditions. The Russian nuclear tool memory data compared to its data in real time is presented in Figure 2.

• The geological objective was defined by the complex reservoir structure of the target layer YUS2, confined to the Tyumen suite. This layer is characterized

by the lateral variability of rocks and is represented by alternating sandy-silty rocks and shales. Despite the relatively large reservoir thickness, the effective

thickness varies and can be as low as 2-4m. Thus, it is very important to ensure high-quality geosteering in the horizontal wellbore. The horizontal section was designed in the direction of the wing of the structure. Consequently, continuous bedding monitoring was required to ensure efficient reservoir penetration.

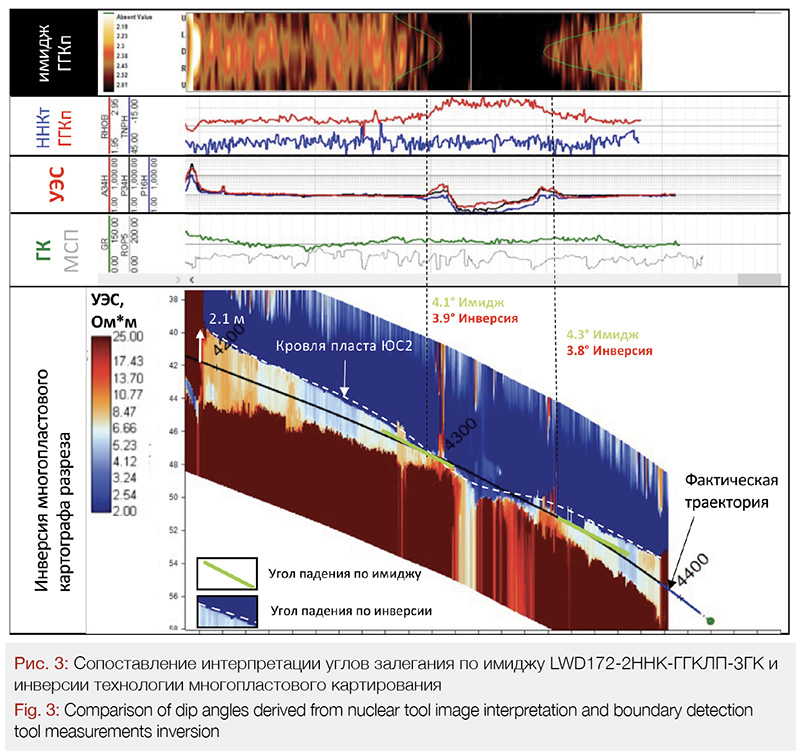

This objective was achieved with the help of density image measurements from a nuclear tool and directional electromagnetic measurement inversion from a multilayer bed boundary detection service. Density images helped to define the formation’s dip angles and the inversion helps define the distance to the bed boundaries. In addition, tracing the bed boundaries using the boundary detection tool can also be used to estimate dip angles. This allows to evaluate the quality of the density image interpretation by comparing the different measurements and providing the conclusion about the application of the density images for geosteering. The comparison of inversion data from multilayer bed boundary detection tool and interpretation of density images in real time showed good convergence of the calculated dip angles (Fig. 3). This means that quality of density image data from the Russian neutron-density tool is considered satisfactory for geosteering. All measurements were available in real time due to connection of the nuclear tool with a high-speed mud-pulse telemetry.

Both objectives were successfully achieved. The set of measurements helped to demonstrate not only the ability to determine the reservoir rock properties in real time, but also the possibility of geosteering using density images dip interpretation in real-time. The combination of LWD172-2NNK-GGKLP-3GK and multilayer bed boundary detection tool would improve net-to-gross (NTG) to 25% in same formation environment.

Density Image

The geological objective was successfully achieved, among the other things, due to the measurements of the density image. Density images provides an outline of the measured properties changes along the circumference of the well. This data is extremely important for geosteering, because it provides information about the dip angles of the structure. Image measurements are not just a simple integral parameter, but an array of data.

It’s crucial to transmit such a significant amount of data to the surface reliably. This objective is traditionally achieved using a combination of two solutions – the use of high-speed downhole telemetry (> 4 bit / s) and data compression algorithms. Image arrays are presented in 16 channels. Each channel (sector) represents a density value with an angle of 22.5⁰. To compress such arrays a Discrete Cosine Transform (DCT) algorithm is used and it is similar to JPEG compression.

Array fragments of 16×16 pixels were taken, encoded and divided into packets, which are transmitted in a row via downhole telemetry. This increases the information compression efficiency several fold.

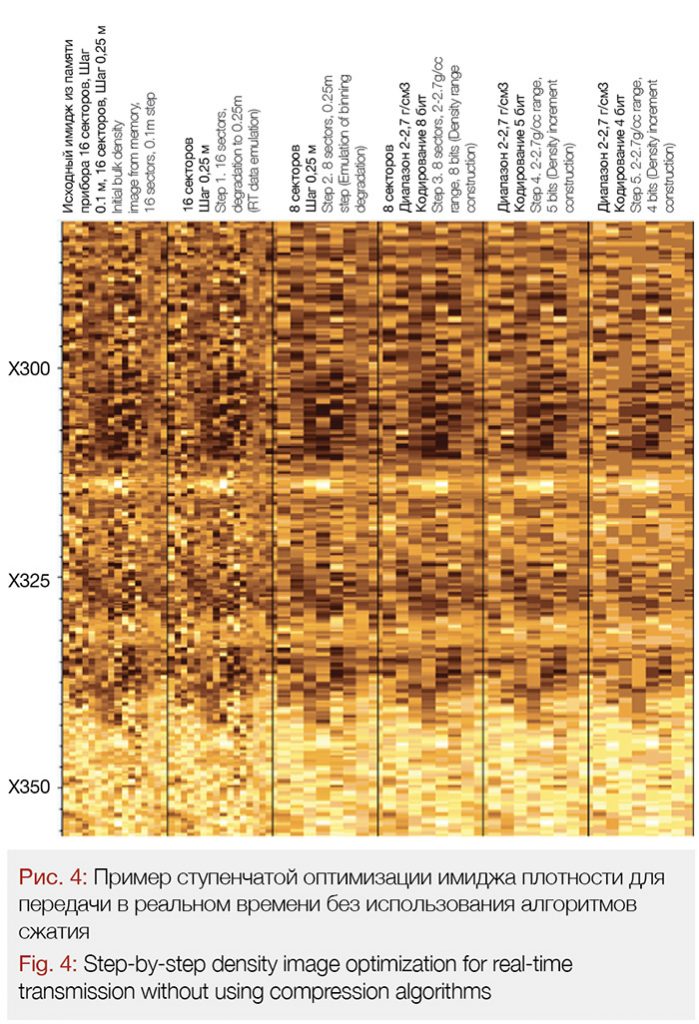

During the implementation of Russian radioactive tools, the project team faced the absence of built-in density image compression algorithms. Implementation takes resources and time. When the compression algorithms are absent in real time, all channels have to be transmitted as separate curves, which will inevitably lead to insufficient real time data density.

At the initial stage of the neutron-density tool’s implementation, an interesting solution was proposed that made it possible to transmit an acceptable quality of the density image without the need for compression algorithms. To implement the transfer of the density images without compression, it was decided to optimize the array itself. In other words, it was necessary to reduce the size of the array to a minimum. At the same time, the minimum size must be sufficient to fulfil the geological objective – the estimation of structure’s dip angles in the drilling direction. The optimization was conducted step by step and the result was controlled at each stage:

Step 1. Reducing the sector size from 16 to 8 sectors. This allowed a reduction in the size of the array by 2 times

Step 2. Reducing transmitted value size (or bitness). This allowed optimization of the size of the transmitted parameter by two times more: from 8 to 4 bits. Optimization of bitness was achieved by narrowing the measurement range and reducing the measurement discreteness. To be precise, if we have in mind the idea of the expected measurement range, then there is no need to reserve all possible density values, but to narrow the range by reducing the bitness.

To reduce the discreteness, the principle of practical sufficiency was also used. It is necessary to have such discrete values so that the layers can be identified on the log. In other words, if the layers are sufficiently contrasting, then there is no need in having too sensitive image – the processing result will be

the same.

This allowed a 4 fold reduction in the amount of transmitted data whilst still achieving the same quality of the compressed image. All mathematical transformations are conducted in real-time in the connection module, which was mentioned earlier in the article. An image optimization example is presented in Fig. 4 The solution satisfied the objectives, nevertheless the next step was to implement the density image compression algorithms to be able to transmit 16 sector density images in real time.

It is worth mentioning that at the time of writing this article, a 16-sector density image real time solution was tested and implemented while drilling two-string well.

Results

When deploying new geophysical equipment the primary objective is to evaluate the data quality and confirm the declared characteristics. The radioactive tools manufactured by CJSC NPP Energia have successfully passed the comparison test against their foreign analogs.

An integrated approach for drilling two-string wells using Russian technology and multilayer bed boundary detection tools ensured that the well construction time was optimized and improved the KPIs. The main results and conclusions are the following:

1. The first successful independent run using a Russian nuclear tool in real time, for a two-string well was performed without using a foreign back-up analog in the same BHA

2. Radioactive logging tools LWD172-2NNK-GGKLP-3GK (6 «) and LWD121-2NNK-GGKLP (4.75») are fully compliant with the required characteristics. Their deployment can be scaled up for a wide range of industrial use.

3. Proactive geosteering using a Russian radioactive tool and multilayer bed boundary detection service, while drilling wells at the oilfield of LLC «RN-Uganskneftegaz», can potentially increase the NTG by 25%.

Conclusion

Russian localization in the oil and gas industry is developing smoothly and it is a natural process that enables cost savings and a reduced dependence on any imported equipment. It also helps to bring the production capacities closer to the customer and create new local products that meet and exceed the requirements of the Russian market.

The NPP Energia nuclear logging tool in the BHA is a vivid example of the symbiosis of the best Russian solutions and advanced Schlumberger technologies, which helps implements the program of import substitution and localization in the oil and gas industry in Russia. Since this radioactive tool was successfully deployed, the Russian drilling market has obtained a fully domestic triple-combo BHA which is aiming to expand accessibility and efficiency of high-tech drilling service for Russia-based oilfield companies.

References

1. Rosneft: Reducing Drilling Time – Combined Production String and Multi Stage Fracturing Completions R. Giniatullin, V. Kireev, E. Pilipetc, R. Gazimov D. Krepostnov, M. Mishakov (NK Rosneft), R. Galimullin, V. Khlebnikov, P. Medvedev (RN-Center of Expertise and Support) // ROGTEC – 2017. – № 48. – p. 14–22. https://rogtecmagazine.com/wp-content/uploads/2017/04/01-PJSC NK Rosneft -Reducing-Drilling-Time-Combined-Production-String-and-Multi-Stage-Fracturing-Completions.pdf

2. Rosneft. Drilling two-string well has reduced well construction time by 7 days

https://www.slb.ru/upload/iblock/da1/15_dg_7732_integrated_PJSC NK Rosneft _vankoskoye_rus.pdf

3. Presentation «Logging while drilling using LWD121-2NNK-GGKLPand LWD172-2NNK-GGKLP-3GK tools developed and manufactured by NPP Energia for calculation of oil and gas reserves» Chermenskiy V.G., Emelyanov A.V., Mezhenskaya T.E., Vorobyev A.N. (OOO NPP Energia)) Velizhanin V.A., Kryuchatov D.N., Isyangulov R.U. (OAO “Kogalymneftegeofisica”)

https://power-np.ru/f/nvs_lwd_energy_sept_2019.pdf

4. Sakhalin Energy Investment Company used first in project history Russian PDM. http://www.sakhalinenergy.ru/ru/news/5937/

Authors

Bokarev A.Y., Leontyev D.S., Mingazov A.N., Golovanova L.S., Akhundov M.G (Schlumberger), Grebnev P.V. (LLC «RN-Uganskneftegaz»), Chetverikov D.M. PJSC NK Rosneft