RN-Nyaganneftegaz: Well Intervention Candidate Selection at the Krasnoleninskoe Field

One of the major tasks of the oil and gas field development is to maximize the oil recovery factor (ORF) at minimal cost. The solutions adopted in the field development design need to be optimized, taking into account the actual reservoir performance. Well intervention is a prime tool to improve mature field control and production development efficiency. An integrated approach to Well Intervention planning allows for the improvement of the reservoir and field development efficiency.

The implementation of an integrated approach to the Well Intervention planning is conditioned upon the following:

• Depletion of easy-to-recover reserves and, thereby, necessity of hard-to-recover reserve production applying various techniques of individual zone stimulation;

• Degradation of the candidate wells and efficiency of repeated Well Intervention;

• Large number of wells requiring Well Intervention.

Obviously, the rifle (well after well) approach to assessing the potential of particular Well Intervention jobs does not allow timely selection of candidate wells, since this is labor-consuming, especially when we speak of the unique and major fields, where the operating well stock often numbers in the thousands of wells. Such fields require integrated approach to assess if the wells qualify for Well Intervention. This shall include:

1) Integration of the field geological information;

2) Justification of the candidate well selection criteria for a particular Well Intervention job;

3) WI risk assessment;

4) Candidate well prioritizing based on the obtained complex parameters;

5) Estimation of the well production potential and Well Intervention economic feasibility study.

Individual well assessment is the common approach to Well Intervention selection for the medium and small fields. This method is very time-consuming in case of a large well stock, so the wells are prioritized applying filters based on a set of criteria. However the above approach is not always successful, as the wells are not assessed comprehensively. In this regard, the following tasks were carried out to improve the approach to candidate well selection for a particular WI job as part of this work.

1. Identify the main factors (criteria) affecting the WI success (failure) in certain field conditions.

2. Assess the oil production increase potential using actual data on the well operation and reservoir simulation models that are appropriate as to the information quality and scope.

3. Develop the integrated WI program taking into account identified criteria and applying mathematical calculations (criteria-based prioritizing).

Implementation

Multiple parameters in various categories should be analyzed and considered to minimize risk of erroneous candidate well selection for the WI job: geological, process and economic [1].

It is proposed to use the mathematical tool allowing selection of the candidate wells for a particular WI job with regard to the identified criteria. This tool is developed based on the Microsoft Excel 2010 and Visual Basic for Applications (VBA).

The main advantage of using this technique is considerable time saving compared to the expert appraisal techniques commonly applied to solve similar tasks. Testing of this method in Talinskoe License Area (LA) of Krasnoleninskoe Oil and Gas Condensate Field (OGCF) featuring hard-to-recover reserves proved its efficiency and allowed a multiple increase in the number of matching WI jobs. So, during the project life cycle, Tyumen Petroleum Research Center specialists selected about 650 candidate wells and received subsoil user’s approval for hydraulic fracturing (HF), bottomhole treatment (BHT) and reservoir conversion and commingling (C&C) jobs.

Special attention was given to identification of the main criteria to be considered when deciding on WI. These were identified across the spectrum of criteria applicable to the selected WI job, taking into account the field particularities (geology, infrastructure, etc.). Thus, the first stage involved the integration of the best WI practices, identification of criteria applicable to certain WI jobs followed by grouping thereof.

The criteria for candidate well selection for the most common WI jobs performed in the field had been identified in the process of work. For example, the following criteria are to be considered when deciding on the WI feasibility:

- Residual oil reserves in the well drainage area;

- Performance of the adjacent wells, including recent WI results;

- Candidate well performance;

- Reservoir energy state;

- Performance of the adjacent injection wells;

- Number of HF jobs;

- Date of the last HF job;

- Effectiveness of the last HF job;

- Difference between the cumulative oil production in the candidate well and average oil production in adjacent wells;

- Well serviceability or possibility of bottomhole cleanout in the killed wells [2, 3].

The following criteria serve the ground for deciding on reservoir C&C:

- Initial recoverable oil reserves in the reservoir to be converted or commingled localized in the well drainage area;

- Candidate well performance;

- Start-up rate in the adjacent wells;

- Reservoir energy state;

- Well serviceability or possibility of bottomhole cleanout in the killed wells [4, 5].

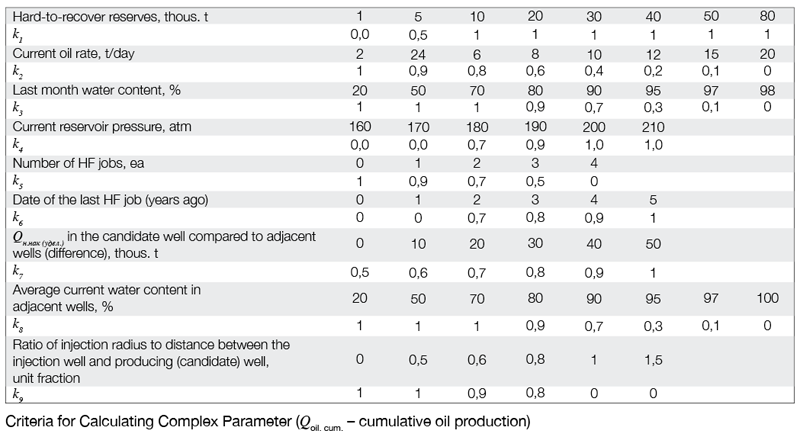

Wells are selected based on the complex parameter which is the function of several criteria. This parameter is a product of partial criteria having weight k, which is the value of the criterion. Criteria weight is determined based on the past WI analysis results. The function is expressed as follows:

K = k1.k2.k3.k4.k5…kn.

When the parameter common to all wells under consideration is found and the results are prioritized, one can identify the most promising candidate wells to be included into WI program.

Application in Practice

The HF job planning in Talinskoe LA of Krasnoleninskoe OGCF as described below can serve an example of the calculation application. The number of wells is rather large: total stock counts more than 5000 wells. The individual analysis of all wells would take a long time, therefore certain data might not be relevant after the analysis process is completed. Moreover, some essential parameters may be omitted.

The proposed calculation technique eliminates the necessity for time-consuming manual WI selection, automatically accounts all factors and prevents criteria omissions which may be the case when applying candidate well expert appraisal method.

The Talinskoe LA reservoirs feature both favorable and unfavorable factors with regard to HF. Favorable factors include high density of the residual oil reserves and material reservoir permeability heterogeneity. Unfavorable factors include presence of zones with low energy characteristics, high water content at individual sections due to injected water penetration through highly conductive intervals (presence of super reservoir). Thus, the criteria meeting the identified factors were used when calculating the complex parameter. Numerical values of weights used for complex parameter calculation are specified in the Figure below. These were applied for the calculation and criteria prioritizing for HF purposes.

For example, a study of all the past HF jobs in the field showed that energy state of the reservoirs is a key factor that affects the oil rate increase. So, with a reservoir pressure of less than 190 atm (19 MPa), the oil rate increase is not satisfactory. As a result, the weight was set to 0.9 for the reservoir pressure of 190 atm (19 MPa) and to 0 for the reservoir pressure of 170 atm.

Similarly all criteria were analyzed and weights were set based on the results of the study .

Candidate wells qualifying for HF were selected and justified based on the results of automated well prioritizing and subsequent individual analysis of those wells featuring the max. values of the complex parameters. Currently the subsoil user approved about 650 jobs, 110 of which were completed in the period of January 2014 through December 2015.

The average start-up oil rate constituted more than 8 t/day meeting the target figures and validating the approach’s effectiveness.

The project economic effectiveness is a combination of two factors: 10% work efficiency improvement and 5 times labor input reduction.

Conclusion

- The tool for WI selection and prioritizing based on multi criteria assessment was proposed.

- The tool was tested in Talinskoe LA of Krasnoleninskoe OGCF. About 650 jobs were approved by the subsoil user following the results of the tool use. More than 110 jobs were completed in 2014-2015.

- This tool can be applied to select candidate wells for a large range of WI jobs. Additional criteria that take into account particularities of the field or part thereof can be used in the process of work planning.

- Integrated approach to assessment of production and process parameters of the candidate wells shall be applied to maximize WI effectiveness.

- Use of mathematical tools allows consideration of several parameters at a time, minimize labor input and plan optimal procedures to increase the hydrocarbon production rate.

References

1. Tolstonogov A.A., Assessment of WI Effectiveness in the Oil Production Sector // Fundamental Studies, 2014, No. 11(1), pp. 150-154

2. Economides M., Oligney R., Valko P., Unified Fracture Design. Bridging the Gap between Theory and Practice, Orsa Press, Alvin, Texas, 2002, p. 262

3. A Reference Manual for the Design Development and Exploitation of Oil Fields: edited by Gimatudinov Sh.K., Moscow: Nedra Publ., 1983, p. 455

4. Zheltov Yu.P., The Development of Oil Fields, Moscow: Nedra Publ., 1986, p. 333

5. Umetbaev V.G., Workover Action in Well Operation, Moscow: Nedra Publ., 1989, p. 217

T. I. Mashkantseva , A. V. Knyazev, A. G. Olyunina (Tyumen Petroleum Research Center)

S. P. Kanaikin (RN-Nyaganneftegas)

The article was published in the ROSNEFT Scientific and Technical Newsletter (Nauchno-technicheskiy Vestnik OAO “NK “Rosneft”) No.1, 2016, pp.34.