Rosneft: Reducing Drilling Time – Combined Production String and Multi Stage Fracturing Completions

History of Success

RN-Yuganskneftegaz (RN-YuNG) is a major oil company, and part of NK Rosneft. Formed in 1977, it has 26 oil fields under development located in Khanty-Mansiysk, Western Siberia. RN-YuNG has also been developing relatively new fields such as Priobskoe and Prirazlomnoe that feature a relitively low depletion of reserves and are developed using the most advanced and effective technologies. These fields are of strategic importance as they form a major part of the overall oil production of Rosneft, and the drilling and commissioning of new wells is an important task for the Company. In 2013, the Well Construction Department initiated works on optimizing horizontal drilling, including completions for multistage fracturing (MSF).

Traditionally, RN-YuNG drills wells on a Master Contract basis. The average drilling time was approx. 42 days (by the end of 2013) for a standard 3-string horizontal well, 4000m deep with a 1000m horizontal section. The first optimization cycle allowed us to significantly reduce the drilling time for existing well designs. The main organizational and technological modifications included:

- LWD for the horizontal section.

- Optimized mud composition.

- New conceptual approach to wellbore preparation for liner running. i.e. using reaming technology.

- Optimization of the drilling parameters in all well’s sections.

- Switching to “separate service” model.

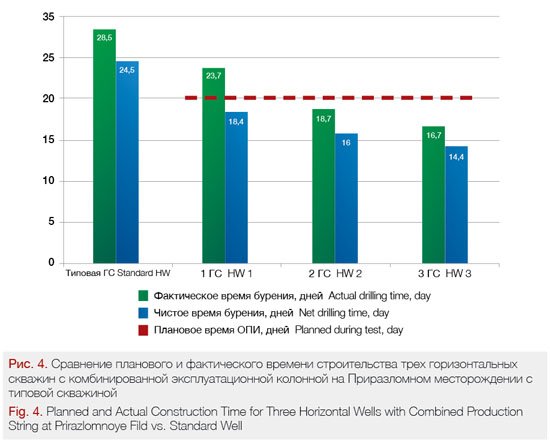

Thus in 2016 the average actual time of horizontal drilling was 28.5 days for the Prirazlomnoe field while the net drilling time is 24.5 days (excluding downtime). Consequently, the drilling cycle was selected to optimize a standard well design.

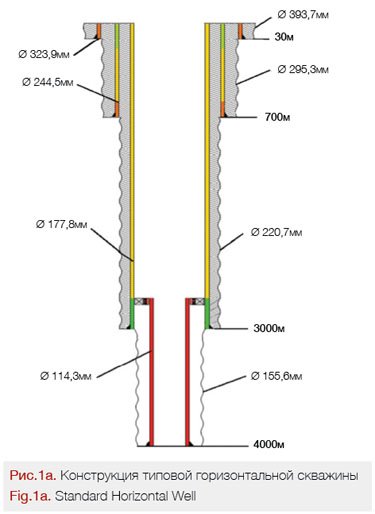

A RN-YuNG, a standard horizontal well with MSF completion (Fig. 1a) looks as follows:

- 324mm surface pipe; is run vertically down to 30 m to prevent wellhead washout, isolate weak rock and prevent pollution of the surface water-bearing stratum.

- 245mm conductor pipe; is run vertically down to 1100m to isolate weak rock, prevent kicks and install a BOP to safely complete oil-bearing reservoirs while deepening the well for the production string.

- 178mm production string; is run vertically down to approx. 2490m to isolate unstable clay rock of BS4-5 producing reservoir for further accident-free horizontal drilling to 1000m.

- 114mm liner with MSF equipment; is run to the producing reservoir for wall lining, installation of MSF equipment and further operation of the well.

The design of BS4-5 producing reservoir in Akhskaya suite consists of alternating sandy and clay rock and is oil-saturated through the entire interval. The absolute depth top is -2372m. The average total thickness of the target interval is 8 m in the drilling area.

On the Way to Success

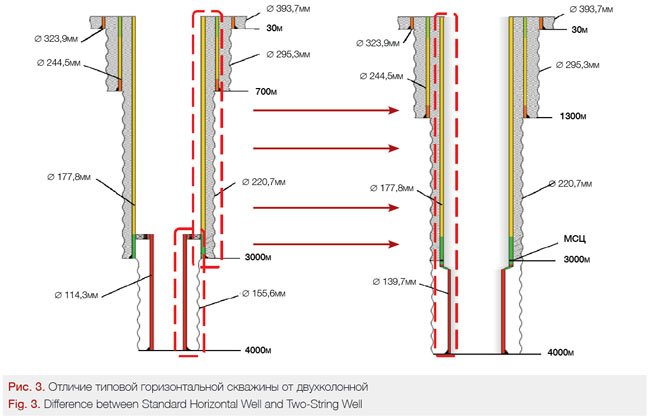

To implement the second stage of increasing drilling efficiency, the Company refused the standard approach of drilling design and conceptually reconsidered the standard horizontal well design in view of the experience that we have accumulated, including the Company’s foreign projects (RN Cardium Oil Inc). The Well Department had analyzed global experience, searched for non-traditional solutions and, in order to reduce the well construction cycle, considered a new approach to well design that would exclude an entire stage in the drilling cycle, in particular, running and casing the 178mm production string. In this concept, two sections for the production string and liner are combined into a 178/140mm production string. This approach enabled 17 days’ drilling cycle.

Once all feasibility calculations were completed, it was decided to test and drill the first 12 horizontal wells in the Prirazlomnoe and Priobskoe fields of RN-YuN using this new design method.

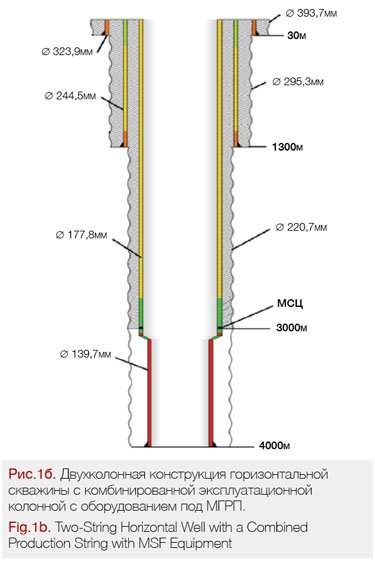

The two-string horizontal well (Fig. 1b) consists of the following sections:

- 324mm surface pipe is run vertically down to 30m to prevent the wellhead washout, isolate weak rock and prevent pollution of the surface water-bearing stratum.

- 245mm conductor pipe is run vertically down to 1100m to isolate weak rock, prevent kicks and install the BOP to safely complete oil-kicking reservoirs while deepening the well for the production string.

- 178/140mm combined production string is run for wall lining, installation of MSF equipment and further operation of the well.

The basic advantages of the well design:

- Drilling the section for the combined production string to the design bottom in a single trip. 127mm drill pipe laydown or 102/89mm drill pipe assembly is not required.

- Drilling the section for the combined production string without changing the mud.

- BOP re-assembly is not required.

- Hydraulic testing of the drill pipe is not required prior to running the liner or replacing the BOP pipe rams for the 102/89 mm drill pipe.

- HWDP assembly is not required to gain the required load on the liner while running.

- Running the section of the production string and liner at the same time.

- Well maintainability is not affected with regard to sidetracking.

Project Control

To mitigate process risks, and considering the lack of experience on similar projects in the Russian Federation, the Project Testing Team invited RN-YuNG, RN-Center of Expertise and Support and Schlumberger engineers to join in. In view of the concept perspectives to be implemented by the Company, the Project control was executed by the Technologies and Engineering Directorate of the Well Department and personally by the Department Director.

Drilling and Completion Technologies and Engineering

While planning the Project, several options were thoroughly studied for each area of focus, risks were evaluated and optimal ways of implementation were selected. The following was decided:

- Drilling under the conductor in the interval with the curvature parameters to reservoir entry point and further drilling to the target bottom on the horizontal section

with use of hydrocarbon-base muds (OBM) with a single free fall. - Utilizing a rotary steerable system and LWD tools and 220.7mm PDC drill bit. This BHA is used to drill the 245mm casing, drilling and prepare the borehole for running the combined string using the back reamer.

- Calculating and selection of the effective process parameters of Fast Drilling to gain record-breaking penetration rates.

- Running the combined string that comprises of the 140mm casing in the horizontal interval and a further 178mm casing string to the wellhead. The completion comprising of the MSF is sized respectively.

- Cementing the combined string in the 178mm casing interval through the cementing collar.

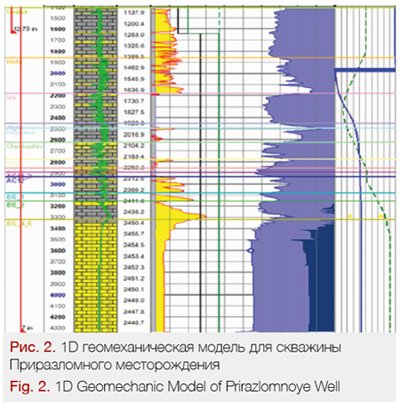

- Geomechanic modeling prior to drilling and adjusting the model during the drilling.

The main difference (Fig. 3) from the previous technique is that the 178×9.19 production string is combined with the completion for 140×9.17mm casing.

MSF completion with the combined production string is similar to the completion utilized for standard wells.

The difference is that the equipment is sized for 220.7mm open hole and 140mm casing. After drilling, the inside diameter (ID) of all completion elements equals to the ID of the 140mm casing. To speed up the well commissioning, soluble balls are used for the fracturing ports.

Cross-Disciplinary Interface

The following engineers participated in cross-disciplinary planning and Project execution:

- NK-Rosneft

- RN-Yuganskneftegaz

- RN-Center of Expertise and Support

- RN-Burenie

- Schlumberger

For the Project purpose, the drilling string was upgraded to use OBM and slurry drying equipment.

RN-Center of Expertise and Support provided great input for the Project’s success while providing 24/7 monitoring of the drilling process.

Results

The first three wells drilled showed that the well design with a combined production string is the most successful. The best horizontal drilling construction rate was 16.7 days for the Prirazlomnoye field, so the construction period was 41% of the average construction period for standard horizontal wells, which is 28.5 days (Fig. 4).

1. The well design with a combined production string and MSF completion was proven to be successful

2. The interval of the production string and liner was drilled by a single trip.

3. NK Rosneft has successfully completed runs of 178×140 mm combined strings with MSF completion equipment for the first time.

4. RH-YuNG successfully used OBM completion fluid for the first time.

It should be noted, that drilling times can potentially be further reduced due the experience gained on this project in reducing downtime and the optimization of the technical processes.

Based on the results that we achieved, we decided to promote this technique with a combined production string and MSF completion throughout Rosneft.

Authors

R. Giniatullin, V. Kireev, E. Pilipetc, R. Gazimov D. Krepostnov, M. Mishakov (NK Rosneft),

R. Galimullin, V. Khlebnikov, P. Medvedev (RN-Center of Expertise and Support)