RPI: Split Service Efficiency Management in Drilling: Approaches to Enhancing the Key Tools

The article continues and amplifies the key topic of “The Russian Drilling Market in 2017: The Market Outlook and Management Challenges”, from ROGTEC Issue 48 (2017).

The drilling process management systems efficiency enhancement requires the creation of adequate tools; such as time and resource consumption standards for the particular operation and entire well construction and reconstruction.

A piece of good evidence that illustrates the importance of a systematic approach to well construction efficiency management is the level of costs related to oil production, keeping up and increasing efforts to curb costs that are currently prohibitively high in the Russian oil production industry.

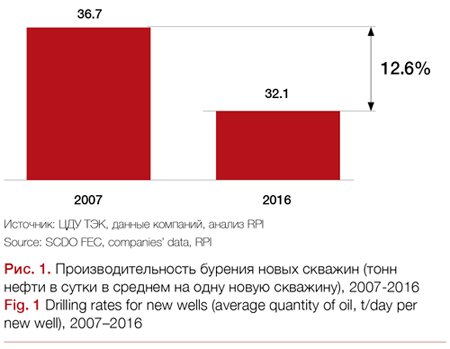

According to official figures, in the last 10 years (2007–2016) the drilling rates in terms of average oil rate per new well was reduced by 11.9% (Fig. 1) while the drilling costs per unit (per 1m penetration) for the same period increased 2.3 times (Fig. 2). At the same time, the overall percentage of horizontal wells increased from 11% to 36% becoming a “life buoy” for oil industry in general. However, this increase was not enough to overcome the decreasing trend in well production rates in full.

This situation is due to the fact that oil production in Russia is mostly concentrated on the fields which are at a late stage of operation. Under these circumstances the production rates are usually increased by construction and reconstruction of wells that have significantly larger wellbore area of contact with productive reservoir in comparison with traditional ones. The profile of these wells is more complicated and construction requires more time, materials, agents, expensive technologies and equipment. Another point is that the wells with this complicated profile are constructed in newly developed fields that often have the hard-to-recover reserves where construction of conventional wells is not reasonable from financial point of view.

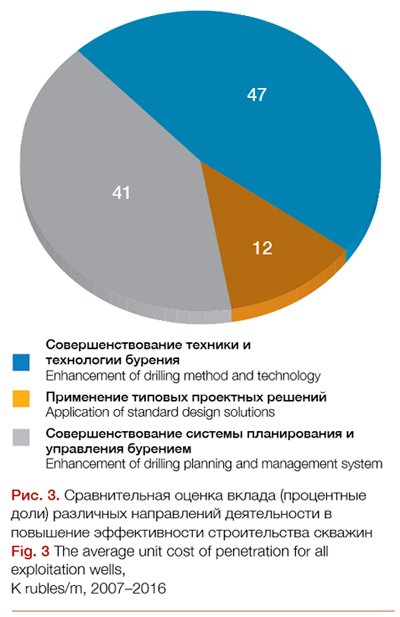

As has been already mentioned in our previous article [ROGTEC 48], at the present stage of the industry development, the enhancement of business management systems is one of the key ways to increase efficiency of drilling operations (Fig. 3). The efficiency of drilling operations hereinafter refers to the costs related to well construction per ton of products recovered from the well.

Enhancement of planning and management processes is possible provided the availability of efficient tools. In particular, these tools include the regulatory documents. The system of regulatory documents in the construction industry is a collection of interrelated documents incorporated by the competent executive and governing authorities, companies and organizations that perform the construction of wells and are the clients and consumers for the corresponding services. The tools that have a fundamental influence on well construction efficiency include the following:

• Pricing and cost estimating system

• Well construction time rating system

Let’s review each of them in details.

Pricing and Cost Estimating System

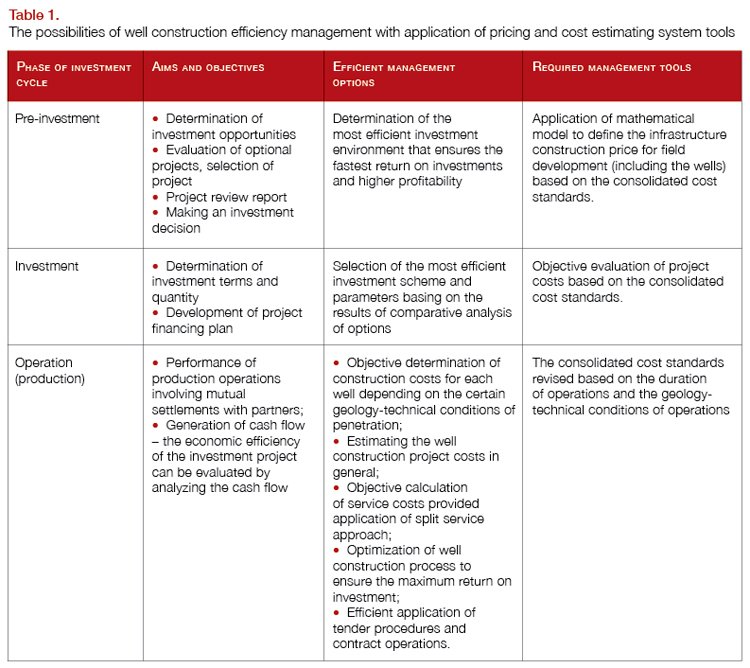

See Table 1 for possibilities of well construction efficiency management with application of pricing and cost estimating system.

According to Table 1 the consolidated cost standards make an essential element of the pricing and cost estimating system. Their generation is accompanied by a range of challenges caused by the existing system of relations between the clients and contractors engaged in well construction.

Since a well is an object of capital construction project the town-planning legislation that regulates pricing aspects should be followed during construction. Currently, the well construction costs are determined by preparing the estimates within the scope of project documentation. It is reasonable to ask if these estimated costs really suit the current actual situation and how they are agreed with further operations performed at drilling site as well as with contract and actual price.

In the vast majority of cases, the estimated cost of modern wells is determined based on the cost rating standard of 1984, where the methodological basis of this process is VSN 39-86 “The guidelines for the scope and procedure of design and estimate documentation development, agreement and approval for oil and gas well construction” and the legal basis is made of collections of itemized construction estimates and unified regional unit rates for engineering structures and construction works (SNiP 4-2-82 Book 49 “Oil and gas wells” and SNiP 4-5-82 and Book 49 “Oil and gas wells”, respectively). The index concept used in the estimates is really simple. The prescriptive common indexes established for the whole estimate in general are changed to more actual costs. However, the application of indexes is often limited to changing to the price level to that of 1991. Further actualization up to the so called “going-rate” prices takes place more rarely.

Some developers of estimate documents use a mix of prices. The estimated costs for the main stages of work (preparation and derrick installation, well drilling, casing and productivity testing) are determined applying the basic price rates of 1984 (1991) while the present-day types of operations and services (geophysical survey, telemetry, drill bit, supervising, etc.) that are not available in the prescriptive base, are related to the miscellaneous costs at the going rate of prices according to partners’ data.

Finally, some design organizations develop the estimate documentation by applying the going-rate prices. It seems that these estimated costs should be the most suitable for real market conditions and useful for further stages of investment and construction process. However, this pricing approach is associated with a serious problem – there is no regulatory basis for the items of these estimates. So, the estimated costs cannot be checked by the client and may not be consistent with the contract prices claimed by the contractor.

In general, the analysis of estimate documentation for well construction reveals that the scope and content thereof have almost nothing in common with the mandatory requirements of RF Government Decree N 87 dated Feb. 16, 2008, while generation and distribution of costs in the estimates do not comply with the advanced technological structure of capital investments into the objects of capital construction project (including the wells) These are the following main contradictions between the existing structure of cost estimates for well construction and present-day regulatory structure of estimated price:

• The labor costs are distributed between the estimates (the chapters of summary estimate) and cost items. It’s impossible to extract and evaluate the estimated labor costs in the existing structure of well construction cost estimate without additional calculations.

• Depreciation of drilling equipment in the estimates is calculated based on the standard rates of depreciation and turnover ratio that are currently invalid and have no effect. The actually used models of equipment are replaced with the most similar analogues under the cost

rating standard of 1984 (1991).

• Allocation of burden costs and planned accumulations as separate chapters of Summary Estimate according to VSN 39-86 “The guidelines for the scope and procedure of design and estimate documentation development, agreement and approval for oil and gas well construction” makes it impossible to draw up the estimated costs of construction-preparation stages (if applicable), derrick installation, well drilling, casing and productivity testing.

The estimates do not reflect the costs of certain organizations that participate in well construction.

In general, the rates used for preparation of estimates and, consequently, the whole estimate documentation do not reflect the advanced design solutions, methods of performance of certain operations and services, or actually applied materials and equipment. The cases below are just few good examples of price estimating procedure that is still used in the industry being inadequate under the current market conditions.

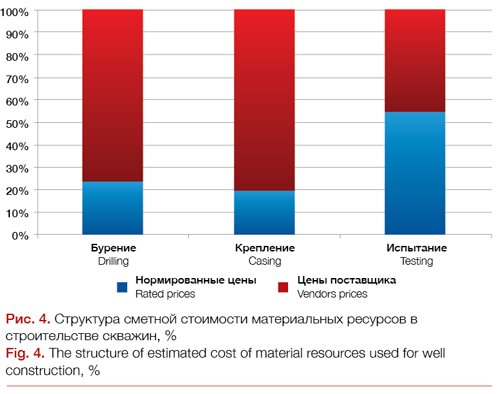

For example, as proved by the structure analysis [2], in the overall structure of well construction costs defined by any developer of estimate documentation used for well construction by NK Rosneft, the percentage of materials that are not available in the cost rating standard significantly increases the percentage of rated materials. When the cost of material resources is not covered by the cost rating standard it is determined by applying one of the following approaches: either basis indexation (the indexes are applied to the costs under the cost rating standard) or resource based approach (basing on the current price lists with back indexation to the basic price rates). For the average structure of relative estimated cost of material resources used for well construction depending on the estimation approach refer to Figure 4.

The omissions found in the estimates can be illustrated by the labor cost structure. Often, this cost item is recognized as “Miscellaneous works and costs” while actually these costs make up 40–95% of total labor cost structure – this does not reflect the current conditions for generation of labor costs for workers who participate in well construction.

The diagnostics of well construction pricing system makes it possible to define the approaches that can be used right today to enhance the related management tools.

• Estimation of well construction costs at the going rate;

• Application of rate- or project-based approaches or both of them to estimate the construction costs;

• Transformation of estimate documentation forms considering the options of estimated cost distribution between the separate stages of construction, types of work and services;

• Development of procedure to prepare the modified estimates for the client to issue the tender estimate for well construction;

• Arrangement of construction cost monitoring systems including monitoring of structure elements;

• Development of procedure and forms to define the actual construction costs.

We suppose that the implementation of the above proposals will make it possible to ensure a higher efficiency while estimating the costs for construction of wells as object of capital construction project and enhance cost management control by the clients under the 21st century market conditions.

Time Rating System for Well Construction

Another approach for the enhancement of well construction efficiency management is the application of time rates for performance of particular operations and construction of entire facility.

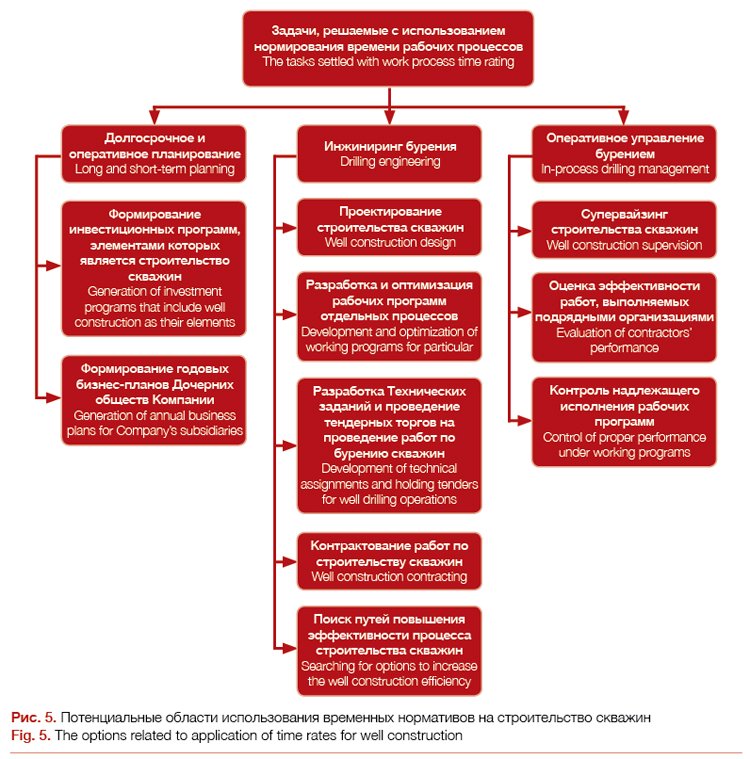

Each type of operations performed during well construction is a complicated work process that can be divided into simple work processes. Each work process has its own technological content, organizational structure and applied equipment. Simple work processes can be further subdivided into the following components: operations, methods and, finally, actions. It is evident that simplification of work processes should be defined by the possibility to solve the tasks set for the developers of normative documentation. Refer to Figure 5 for the options related to application of time rates for well construction.

The uniform time standards for oil, gas and other mineral well drilling were approved with Decree N 81/5-86 issued March 7, 1986 by USSR State Committee for Labor and Social Problems and the Secretariat of the All-Union Central Council of Trade Unions. The standards were valid 1987–1991. This regulatory document was developed by the Central Regulation and Research Office of the Ministry of Oil Industry of the USSR in cooperation with Bashneft Production Association’s regulation and research office of the Ministry of Oil Industry of the USSR along with regulation and research organizations and companies of the USSR Ministry of Oil Industry, Ministry of Gas Industry and Ministry of Geology under methodological supervision of Central Bureau of Labor Standards [3].

The uniform time standards were developed based on the following materials:

• Photo and time observations;

• Equipment passports and specifications;

• The results of labor management evaluation and enhancement arrangements.

In 2000 VNIIOENG’s labor economics laboratory, in cooperation with Bashneft NK regulation and research office and with OJSC Gazprom and Rosneft NK regulation and research organizations and companies, participated in developing the addendums to the uniform time standards for oil, gas and other mineral well drilling. The collected book was valid till 2005 [4,5].

From the time of implementation of the above books, the well drilling conditions were significantly changed. Absolutely new equipment and technologies appeared to construct oil and gas wells, e.g. new types of Russian and foreign drilling rigs, top drives, rotor systems, PDC drill bits, etc. Furthermore, the profiles of new wells became rather complicated. The directional wells have been supplemented with horizontal ones including wells with large length of horizontal section and multilateral wells. Another factor that requires different time for performance of the same technological operations, is the specific geological and technical conditions of well construction in new fields.

When the opportunities and possibilities for the most efficient application of rating system are considered, arrangement of required rating tools for in-process drilling control and management can be set as a primary goal.

With reference to the tasks listed in Figure 5 the conclusion can be made that rate setting for simple work process is not reasonable. Another option of the well construction process breakdown is the development of consolidated time rates. Such consolidations ensure the efficient settlement of tasks as well as contribute to the decrease of labor costs with an increase of rate setting efficiency.

One more rate setting aspect, which is important from a methodological point of view, is a source of information on actual time consumption for particular stages of well construction and technological operations. As stated above, the photo and time observations became the only source of such information for development of The uniform time standards. Despite of numerous advantages (accuracy, precision), this method requires substantial labor costs. Such circumstance significantly restricts the possible scope of measurements and, consequently, decreases the accuracy of the results.

An alternative option is application of experience-based and statistical method of rate setting. This method of time rate setting requires information on main operations executed during well construction including the time consumed for the performance of these operations.

The detailed information is summarized in structured fashion during the performance of the following operations that are typical almost for all drilling projects:

• Supervision;

• Instrumental monitoring of the well drilling process with a geological and engineering survey stations.

According to the occupational standard no. 256, the drilling supervisor in the oil and gas industry who performs technological control and management of well drilling process keeps the Client informed on the drilling production progress [6]. As such, the scope of supervision services includes the generation of a supervisor’s report. The document contains an end-of-day report including:

• Short description of operations for 24 hours;

• Daily balance of productive and nonproductive time consumed for performance of main operations and, correspondingly, downtime.

Analysis of the supervisor’s reports that describe the well construction control process with Rosneft NK PAO proves that the content of this document is often limited to the information on time consumed for performance of operations per day. However, it does not reflect the number of such operations. So, information like this cannot be used for experience-based and statistical analysis.

According to RD 153-39.0-069-01 the geophysical survey of oil and gas wells includes the operation of geological and engineering survey stations. They are intended to control well conditions at each stage of construction and commissioning. A technological task to be settled with the application of geological and engineering survey stations is identification and determination of process operation duration. Hence, during the instrumental monitoring of the well construction process and further manual processing of reference information the specialists of the geological and engineering survey station and the supervisor develop a geological and engineering survey station’s report.

The report contains a “Time Observation” section with sequential time observation for each operation performed during construction of wells.

The analysis of information received from geological and engineering survey stations with reference to 270 RN Yuganskneftegaz’s wells during in-process drilling control has proved that the consolidated time rates that are accurate and adequately describe the actual process of well construction and can be received provided correct processing of statistics. Then once developed consolidated time rates could be continuously updated to remain adequate and reflect the changing drilling conditions and well penetration technology.

In this way, the information that is available with oil production companies can become the basis for the generation of such management tool as the consolidated time rates for well construction provided correct processing of this information.

RPI is a specialist consulting company covering the fuel and energy industry of the Russian Federation, CIS, Central and Eastern Europe countries. Additional Information: www.rpi-consult.ru,

research@rpi-research.com or +7 495 778-9332.

References:

1. “The Russian Drilling Market in 2017: The Market Outlook and Management Challenges”, ROGTEC publication no.48 (2017).

2. V.N. Gnibidin, M.V. Zhitkova, O.V. Didkovskaya, M.V. Ilyina, A.V. Bakan. Diagnostic results of the current pricing system at the stage of well construction and ways of its improvement. NK Rosneft Science and Technology Bulletin. Attachment 1, 2014. “Oil Industry”, M.,

page 71-75.

3. The uniform time standards for oil, gas and other mineral well drilling. M., Institute of Labor Research, 1987.

4. The uniform time standards for oil drilling.

Part 1. M.- 2000. – p. 376.

5. The uniform time standards for oil drilling.

Part 2. M.- 2000. – p. 227.

6. RF Ministry of Labor and Social Protection Order N 942n dated November 27, 2014 On approval on occupational standard “The drilling supervisor in oil and gas industry”

Victor Gnibidin, Ph.D, Technical Sciences, Samara State Technical University Sergei Rudnitskiy, RPI