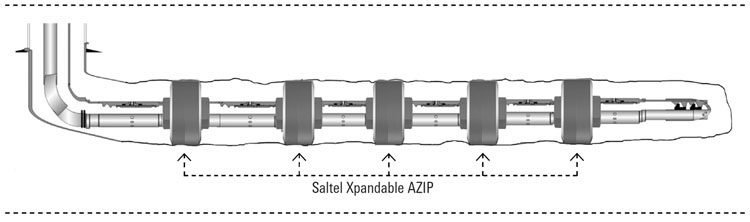

Saltel Widens Xpandable Steel Packer Footprint with New Installation of 5 AZIP Packers Between Active Inflow Control Devices, in Libya

Rennes, 28th Feb 2019. Ageing horizontal wells from the Zelten field (Sirte Basin, Libya) tend to face excessive water breakthrough. The client experienced the case in his open hole porosity producer well. Production tests showed a severely reduced oil rate of 210 barrels of oil per day (BOPD), and underlined an increase in the water cut from 50 to 80% on natural flow. Schlumberger recommended a workover to recomplete the well with active in-flow control devices (ICD) and open hole packers, to reduce drastically the water cut, and take control of the production. Saltel Xpandable AZIP Packers were selected to ensure long term zonal isolation between active inflow control devices. The AZIP packer sets instantly unlike fluid-dependent swellable packers requiring longer setting time. It also offers longer seal contact lengths than mechanical packers, and guarantees better deployment success rates to True Depth (TD). Schlumberger recommended the following recompletion string: ■ 5in x 7in Liner hanger with Liner top packer ■ Five Saltel Xpandable AZIP-W 4.5in ■ Twelve Premium Port ICDs The packers were successfully expanded and set at 5,000 psi. The workover was effective and allowed recompleting the well with ICD and Xpandable AZIPs. The client benefitted from effective means of shutting off watered out zones, reducing water inflow and getting control of the well production. Associating Xpandable Steel Packers with active inflow control devices is a worldwide first made concrete and effective in the Sirte Basin in Libya. Saltel Xpandable Steel Packers have been installed in various regions and applications, such as reservoir compartmentalization, acid stimulation, multiple stage and off-bottom cementing, cement backup, Plug and Abandonment, and open hole ball drop multistage fracturing. Their global success rate currently peaks at 97%, and new developments and qualifications are led consistently through a continuous improvement process, to meet the various requirements from the field. |