Schlumberger: CemSYS System

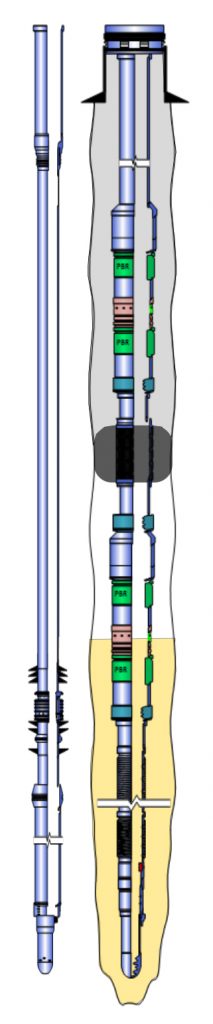

CemSYS System is designed to compiles stand-alone screen or gravel-pack completion with production casing installation and cementing into single run.

Operating principle

Screens, open hole packer and production casing are to be installed by single run. Open hole packer is activated to split open hole into two intervals. If necessary, gravel pack may be pumped first into lower interval, than production casing may be cemented.

Tool features

New design was made possible by developing of special CemSYS tool, which provides:

- Washdown while running in hole

- Gravel-packing and cementing in single run

- Reverse-out pumping to wash out excess slurry and cement after pumping operations

- Positive indication of the tool positions

- Anti-swab effect

CemSYS System can be utilized for gravel pack purpose (CemPAC) as well as for stand-alone screen completion (CemSAS) with cementing of production casing or without, which gives wide range of combinations.

System benefits

- Reducing the number of runs and therefore decreasing the rig time.

- Elimination of the production casing cement plug drill-out.

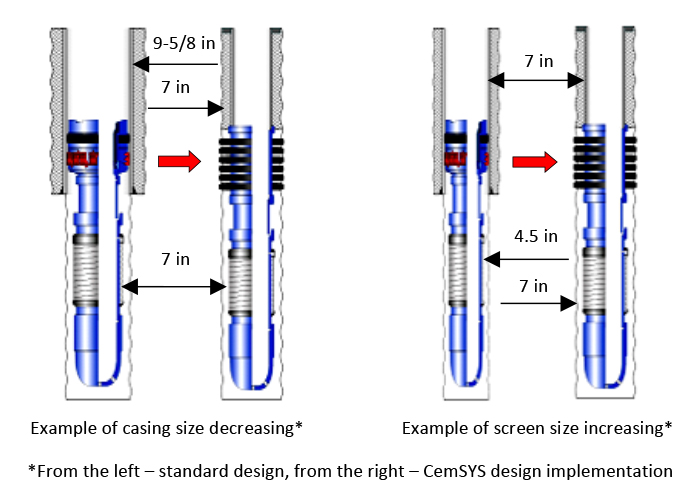

- Decrease of metal and cement consumption volumes if standard design was improved with production casing size reduction.

- Increase of filtering area, production and creating more opportunities for well intervention if standard design was improved by maximizing screen size.

Applications

- Stand-alone-screen completion

- Gravel-pack

- Cementing

- Onshore and offshorewells

- Vertical and deviated wells

- Open-hole

Benefits

- Rig time reduced

- Eliminate drill-out plug operation

- Materials and cost saving

- Production increase

Features

- Washdown capability

- Single-trip gravel-pack and cementing

- Reverce-out capabilities

- Positions indication

- Anti-swab effect