Short-Term Well Operation (STWO) as Effective Method of Shale Oil Extraction

Kuzmichev N. P. Petroleum 21st Century LLC, Almetyevsk

A surge in the production of shale oil in the United States over the past decade caused oversupply on the world oil market. Between 2005 and 2013, oil production rose from 5.18 million to 7.44 million barrels per day. In December 2014, it reached a record level of 9.118 million barrels per day [1]. The supply of oil on the world market has exceeded demand. Oil prices have plummeted by 50 percent. These are challenging times for oil companies which as it is are facing problems due to higher costs of oil production as a result of deterioration of the reserves structure [2]. The situation is extremely dire for shale oil producers. For them, reducing the cost of oil production is a matter of life or death. In late 2014 and early 2015, many companies have significantly scaled back their drilling operations [1]. Some went bankrupt.

In 2015, oil production in the United States did not grow as rapidly as in 2014, but thanks to the pace gathered it still continues to grow. In the next couple of years, the production is likely to stabilize at 10.2-10.3 million barrels a day and then will decline. Analysts strongly believe that the current oil prices are unlikely to rise noticeably in the next five or even ten years. [1]. Therefore, reducing the cost of oil production in order to increase profitability is the most important issue for today’s oil industry.

The “shale revolution” happened thanks to innovations in oil production particularly improved technology of horizontal drilling and multi-stage hydraulic fracturing [3-5]. In the last 15-20 years, the cost of production of shale oil has been reduced significantly as a result of improvement of these major wellbore drilling technologies. With high oil prices, profitability of shale oil production was fairly high. Yet, with the current oil prices, the technological level of many shale projects is not high enough. Even worse, further improvement of the aforementioned wellbore drilling technologies is virtually impossible. To reduce further shale oil production costs, we need new approaches and new solutions at all technological stages of oil production, not just in wellbore drilling.

In fact, it is possible to significantly reduce drilling costs, especially horizontal drilling, by using electro-drilling. As the old adage says, “If you can’t stop it, lead it,” so Russia has good chances to compete with western oil and oilfield service companies in shale oil production technologies. That’s because electro-drilling was widely used only in the Soviet Union, and the technological and organizational know-how achieved still remains relevant. Moreover, there are new ideas that could bring electro-drilling to a new level. But to achieve this ambitious goal, Russia’s oil industry needs to go beyond words and actually embrace innovative development.

Mass production of shale oil was constrained not only by geological issues related to deposit structure specifics, their study, reserve estimation, etc., but also by poor technologies of processing the raw materials extracted [3-5]. Today, there are industrial-scale technologies for ex situ and in situ processing. There are also experimental technologies, which are being improved both in laboratory conditions and in the field. However, breakthroughs in shale oil processing or shall oil wellbore drilling are unlikely.

One of the attempts to find new ways to reduce the cost of shale oil production was a US$5 million investment in Texas-based Propell Technologies made on February 24, 2015 by Cyprus-based Ervington Investments [6], whose ultimate beneficiary is Russian billionaire Roman Abramovich. Propel Technologies is the owner of Novas Energy USA which specializes in increasing profitability of shale oil and gas wells by using the latest pulsed plasma exposure (PPE) technology. Interestingly, Novas Energy USA, the owner of PPE technology, has Russian roots [7].

The PPE technology is a method of bottom hole treatment. We may say that this is one of the methods of enhanced oil recovery (EOR). Previously, no such technologies were used to reduce the cost of shale oil production. Reportedly, it is showing some good technological results [7]. Without the information about the cost of this technology, it is hard to evaluate its economic benefits. Yet, judging by the size of investment in this project, economic benefits do exist and are significant.

It is quite interesting that, unlike Russia, where the PPE technology is considered as one of the EOR methods, the United States see it as an alternative to multi-stage hydraulic fracturing. Hydraulic fracturing has two serious non-technical drawbacks: potential environmental impacts and extensive water use. This is why shale oil production in the United States mainly occurs in sparsely populated areas with ample water resources. It is expected that the PPE technology will solve these problems and allow access to shale oil deposits, which currently are not justifiable or not possible to develop [James Stafford). Roman Abramovich Invests $15M in New US Fracking Technology. Posted on Tue, 24 February 2015. http://oilprice.com/Energy/Crude-Oil/Roman-Abramovich-Invests-15M-in-New-US-Fracking-Technology.html].

The success of the PPE technology is another factor affecting the future of shale projects. We have yet to see if large-scale introduction of pulsed plasma exposure will have a big enough impact. There is another way, short-term well operation (STWO) technology that will definitely make shale oil production feasible, even with the current oil prices. This well operation method is based on the mechanized production of oil. The idea to use STWO in shale oil production is a vivid example of an innovative solution to the problem of reducing the cost of shale oil production.

STWO is well known and widely used in Russia and abroad. For those who are not well familiar with it, we recommend to read “Short-term oil well operation,” section “Extraction and industrial preparation of oil” at www.oilforum.ru [8]. Here, for the sake of brevity, we shall merely summarize the most important advantages.

The main competitive advantage of STWO for the shale oil industry is 10%-30% reduction of oil production costs, proved during the extraction of crude oil. It is achieved thanks to increased oil production and time between workovers, reduced electricity and equipment needs, lower costs of well exploration and technological operations aimed at increasing flow rates. STWO is the most effective way for mechanized oil production from wells with low and medium flow rates [9].

A unique feature of STWO is minimization or complete elimination of negative impacts of virtually all the major factors complicating well operations [10]. STWO is the only method of oil extraction from wells with simultaneous exposure to several complicating factors. STWO is a universal method of reducing the cost of oil extraction from complicated wells.

In order to demonstrate the effectiveness of STWO in the extraction of shale oil, we have to highlight some specifics of its extraction, which complicate shale well operations, reduce time between workover and, ultimately, adversely affect the production costs. These include [11]:

» Large variety of physico-chemical properties of formation fluids;

» Abnormally high fracture gradient;

» High reservoir temperature;

» Calcium scale deposition in completion and surface equipment;

» High GOR (Gas-Oil Ratio);

» Significant solids production.

Short-term well operation (STWO) allows dealing with all the complicating factors and reducing the cost of shale oil production by increasing time between overhauls [10].

But perhaps the most interesting things about developing shale oil deposits, thanks to which STWO will become widely used for shale oil extraction, are rapid and significant reduction of flow rates and much shorter periods of cost-effective operation, compared to crude oil fields [12]. Reduced flow rates require changing the design of production equipment and even artificial lift methods (electric submersible pump, or ECP instead of sucker rod pump, or SRP), in the case they are not caused by wear and tear or failure of equipment, resulting in increased costs. Additional costs are associated with poor predictability in the flow rates at shale oil deposits, which also leads to unscheduled changes in the production equipment design. This increases shale oil production costs, which are high as it is.

STWO has unique technological capabilities that are critical for the extraction of shale oil: for example, it allows you to increase the extraction unit’s performance by 3-5 times, and even more so after the transition to continuous operation [9]. And it happens automatically. In addition, in horizontal wells, ESP’s can operate deeper than beam units and operate with higher-pressure drawdown, allowing increasing well flow rates.

As of the end of 2014, there were 8,000-10,000 STWO oil wells in Russia. As of August 2014, Gazpromneft-Khantos had more than 800 STWO wells, or 40% of the total number of approximately 2,000 wells [13]. The economic benefit in 2012-2013 was about 1.2 billion roubles. Rosneft had 1,722 STWO wells in January 2014 and 2,361 wells in August [14]. There were plans to bring their number to 3,700 by the end of 2014, i.e. the number of STWO wells more than doubled in just one year.

Due to its high economic efficiency, STWO is fast becoming one of the main methods of oil production. Low oil prices and their low volatility help to speed up this process.

The future of shale oil production depends on a holistic approach to the choice of technology at all stages of development and exploitation of shale deposits, from exploration to processing. Production cost minimization seems to be the main factor behind the key technology selection criteria. Mechanized oil production methods, especially STWO, can and should play a significant role in this process.

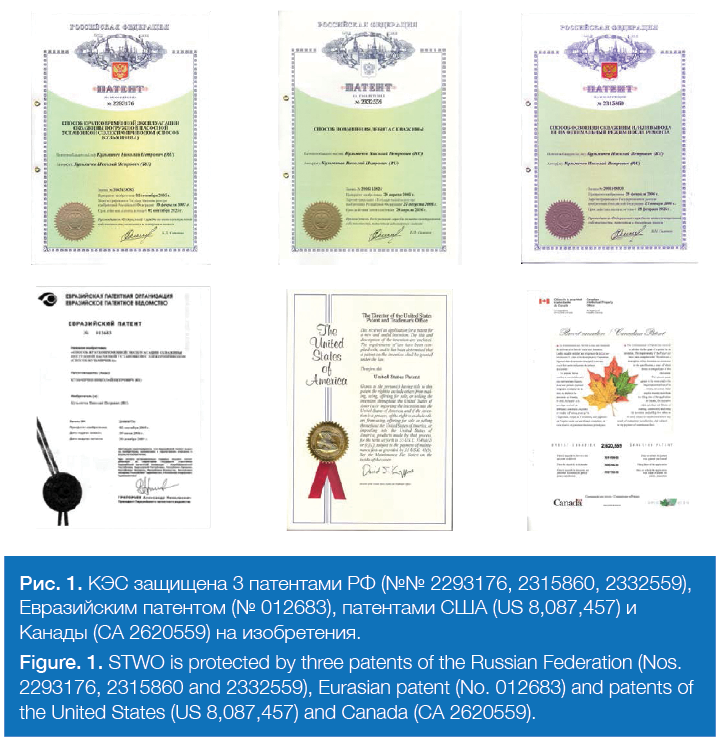

STWO is protected by various patents for invention including three of the Russian Federation (Nos. 2293176, 2315860 and 2332559), Eurasian patent (No. 012683) and patents of the United States (US 8,087,457) and Canada (CA 2620559). STWO has good export potential. With such oil production technologies, Russian oil companies can operate on the global market without fear of competition with foreign companies.

Technologies such as STWO can put Russian oil and oilfield services companies technologically on a par with their foreign competitors. This was clearly expressed in the speech of Russian President Vladimir Putin at a meeting of the Presidential Council on Science and Education on June 24, 2015: “…If we can become a leader in several key areas, if our partners depend on Russian technologies, and we are able to quickly absorb and use the achievements of others, then this interdependence will seriously strengthen our position and we will be treated as equal by other members of the global technological development and will not be exposed to various risks.”

Bibliography

1. Michael Overchenko. “How the United States Changed the Global Oil Market.” Vedomosti,15.12.2014.

http://www.vedomosti.ru/librarv/articles/2014/12/15/kakssha-perekroili-mirovoj-neftvanoj-rynok

2. Guy Chazan. “Production or Profits?” Vedomosti, # 3407 of 13.08.2013. http://www.vedomosti.rU/newspaper/articles/2013/08/13/dobycha-ili-pribvl#ixzz2tr2JQbfl

3. D. Grushevenko, E. Grushevenko. “Shale Oil – a New Challenge for the Energy Market?” Information and analytical survey of the Center for the Study of the Global Energy Markets. November 2012, Institute of Energy Studies, Russian Academy of Sciences.

http://www.eriras.ru/files/spravka_slanc_njeft.pdf

4. Morariu D., Averyanova O. U. “Some aspects of oil bearing capacity of shale: conceptual framework, evaluation methods and search for oil extraction technologies” // Oil and Gas Geology.Theory and Practice, 2013. v. 8, # 1. http://www.ngtp.ru/rub/9/3_2013.pdf

5. Arutyunov T.V., Arutuynov A.A. “Methods and technologies for hydrocarbons extraction from shale deposits.” Scientific Works of Kubansky State Technological University, # 1, 2015. http://ntk.kubstu.ru/file/314

6. EvgenyKalyukov, Ivan Tkachev, Alena Sukharevskaya. “Russian Businessman Gains Control Over Technology That Could Change the United States Shale Oil Market.” RBC, 25.02.2015.

http://www.rbcdailv.ru/industrv/562949994116651

7. Dmitry Mungalov. “To the Last Drop: How to Squeeze Shale.” Skolkovo Fund website, December 9, 2013.

http://sk.ru/news/b/news/archive/2013/12/09/do-poslednev-kapli-kak-vvzhat-plast.aspx

8. James Stafford. Roman Abramovich Invests $15M In New US Fracking Technology. Posted on Tue, 24 February 2015. http://oilprice.com/Energy/Crude-Oil/Roman-Abramovich-Invests-15M-in-New-US-Fracking- Technology.html]

9. Topic “Short-Term Operation of Oil Wells”, section “Extraction and Industrial Preparation of Oil” at www.oilforum.ru. http://www.oilforum.ru/topic

10. Kuzmichev N.P. “Short-Term Well Operation – Innovative Oil Extraction Method.” Report at the international scientific and practical conference “Innovations and Technologies in Exploration, Extraction and Processing of Oil and Gas,” Kazan, September 8-10, 2010. https://db.tt/1mmxMwvB

11. Kuzmichev N.P. “Short-Term Well Operation – Unique Method of Dealing with Complicating Factors.” Oil and Gas Exposition, # 4, 2012. http://runeft.ru/upload/iblock/fa8/fa8302543969955956fc4cd314e8806d.pdf

12. Chirkov V.L., Sonich V.P. State of Geological Exploration of Bazhenov Formation on the Territory of Surgutneftegaz. http://www.ncintech.ru/files/28-09-2010/1-prsnt-chirkov.pdf

13. Alexeev A.D. “Bazhenov Formation: Searching for Big Shale Oil in Upper Salym.” Part 1. ROGTEC,# 34, August 2013. https://rogtecmagazine.com/wp-content/uploads/2014/09/02_SPD-The-Bazhenov-Formation-Big-Shale-Oil-in-Upper-Salym.pdf

Part 2. ROGTEC, # 35, January 2013.

https://rogtecmagazine.com/wp-content/uploads/2014/09/02_The-Bazhenov-Formation-in-Search-of-Big-Shale-Oil.pdf

14. Lutfullin R.R. “Integrated Approach to Improving Energy Efficiency of Mechanized Equipment at Oil Wells of Gazpromneft-Khantos.” First practical conference “Oil Production: Energy Efficiency 2014,” October 2-3, 2014, Moscow. http://www.ngv.ru/ngv-technologY/dobYcha-nefti-energoeffektivnost/

15. Kaverin M.N. “Analysis of ECPs Operating Intermittently.” Engineering Practice, # 11, 2014. http://lib.glavteh.ru/publicationreader/808/?folder=demo#page/1/mode/1up

16. Speech by Vladimir Putin at a meeting of the Presidential Council on Science and Education on the topic “New Challenges and Priorities in Science and Technology Development in the Russian Federation.” Moscow, Kremlin, June 24, 2015

http://kremlin.ru/events/president/news/49755