SSC Hardbanding Report

Tribological test results for wear resistant hardbanding

The primary cause of drill pipe tool joint wear as it rotates in the open well bore is the presence of a hard rock layer in aggressive geological formations. Drilling in such severe operating conditions results in the wearing of the outside diameter of the tool joint and of the entire drill stem. To protect the drill pipes, and to extend their service life, a wear-resistant hardband is applied onto the tool joint surface.

Hardbanding is a wear-resistant protective metal coating, arc welded onto the tool joint surface, in order to extend its service life and to reduce casing wear.

In 2014, the Siberian Service Company JSC started to use hardbanded drill pipes. At first there were just a few sets hardbanded within the scope of a pilot operation project. The number of hardbanded drill pipe sets grew as the benefits of hardbanding became know.

In view of the wide range hardbanding wire grades available in the Russian market, a natural question arises as to how to make the best choice and selection based on the price/quality ratio in order to avoid using inherently less effective hardbanding wires. For the purpose of an unbiased and independent evaluation of wear-resistant qualities of hardbanding wires from Russian and foreign manufacturers, MTService LLC and SSC JSC have conducted a number of tests.

Apart from hardbanding specimens, these tests were extended to an alternative technology of tool joint protection against wear – a specimen hardened by the electromechanical processing (EMP) method.

Electromechanical processing is a method of wear resistance, strength, and endurance limit improvement based on passing the industrial frequency (50 Hz) electric current through the «tool-surface» interface area with simultaneous surface plastic deformation of the parts (current 400 – 3000 A, voltage 1 – 6 V).

For testing purposes the accredited service companies rendering hardbanding application services provided specimens of the commercially produced drill pipe tool joint SBT 89 (tool outer diameter 127 mm) of strength grade G-105 with 76.2 mm wide and 2.38 mm high hardbanding with standard applications.

There were 10 tool joint specimens prepared, in total, for the tests. Their overall view is provided in Fig. 1:

0. Initial, w/o hardbanding;

1. Duraband NC, Postle Industries;

2. OTW-12Ti, Castolin Eutectic;

3. ARNCO 350XT, Arnco Technology Trust;

4. NP 57, Interpro;

5. NP 58, Interpro;

6. ASM NGN-GS, АСМ – Special hardbanding materials;

7. OTW-13СF, Castolin Eutectic;

8. Electro-mechanical processing (EMP);

9. BoTn 3000, Hilong.

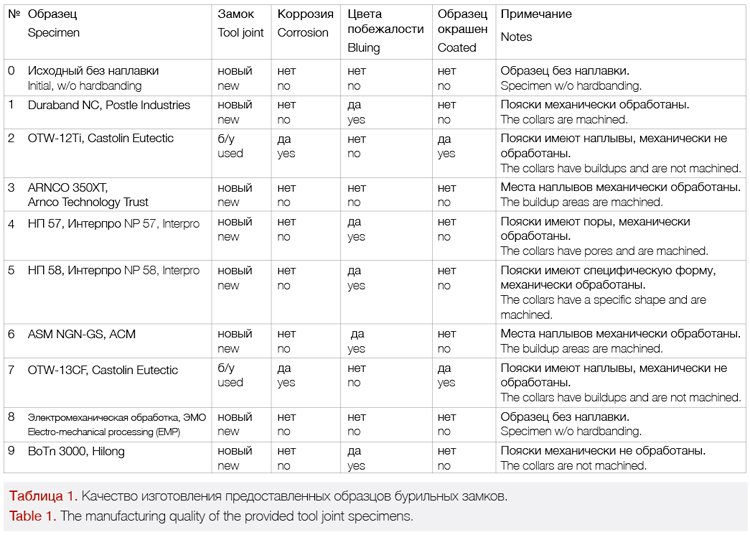

The specimen appearance and the hardbanding application quality are provided in Fig. 2 and summarized in Table 1

There were 2 types of tests:

1. Test No. 1 as per ASTM G65 – simulation of the tool joint rotation in the open well bore.

2. Test No. 2 as per API 7CW (Casing Wear Tests) – simulation of the tool joint rotation in the casing.

As such these two types of tests have enabled us to reasonably evaluate not only the specimens resistance to their own wear, but also their effect on the abrasive wear of the casing.

Test No. 1 as per ASTM G65

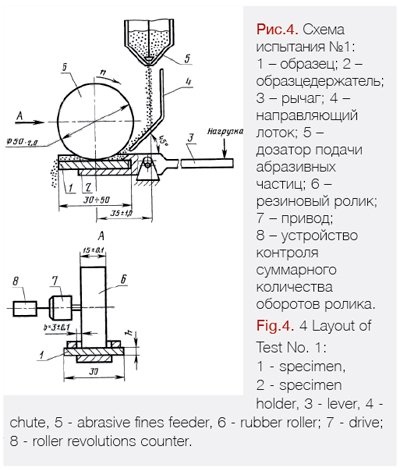

The purpose is to determine the wear resistance of the specimen surface layer exposed to abrasive particles delivered to the friction zone and pressed against the specimen by a rotating rubber roller.

Wear resistance was evaluated using a test bench implemented as per GOST 23.208-79 «Ensuring of wear resistance of products». See the test bench overall view in Fig. 3 and the test layout in Fig. 4.

Prior to testing, at least 4 specimens were made from the provided drill pipe tool joints to perform the test as per ASTM G65. All specimens were machined to size tolerance grade 7 and surface asperity class not less than 7.

The abrasive material with grain size 16 µm (or 16P) had been provisionally sieved and dried in ovens to ensure moisture content of 0.15% maximum.

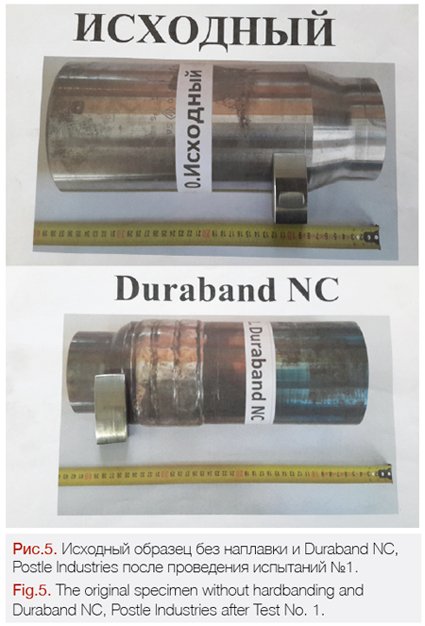

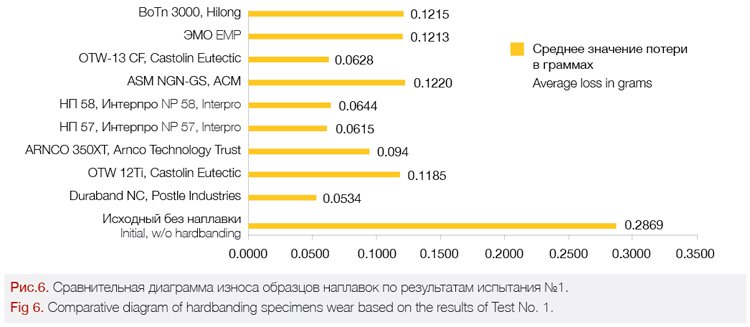

The prepared specimens were tested on the bench. The test duration and the specimen wear measurement frequency complied with standard ASTM G65 (from 20 to 30 minutes depending on the measured hardness of the specimen). 3 specimens of each hardbanding type were tested. The averaged test results are provided in the diagram (Fig. 6). The wear was evaluated by weighing each specimen before and after the test.

The results of the hardbanding wear tests performed on the commercially produced tool joint materials prove the efficiency of all tested Russian and foreign specimens (Fig. 6). The hardbanded specimens have worn 2.5 – 3 times less than the the original tool joint without wear-resistant hardbanding. In general, a direct dependence of wear resistance values on the hardbanding material hardness persists.

The hardbanding materials NP 57 and NP 58 from Interpro, Russia, have exhibited the wear resistance matching the best tested international brands Duraband NC (Postle Industries) and OTW-13СF (Castolin Eutectic). Nevertheless NP 57 and NP 58 still require perfection of the hardbanding application technology and improvement of the finished coating quality.

Proceeding from the results of Test No. 1 as per ASTM G65, we come to the conclusion that the industrial success of using the hardbanding application technology is based on the actual efficiency of the tool joint and the entire pipe body protection, allowing for extension of the drill stem service life.

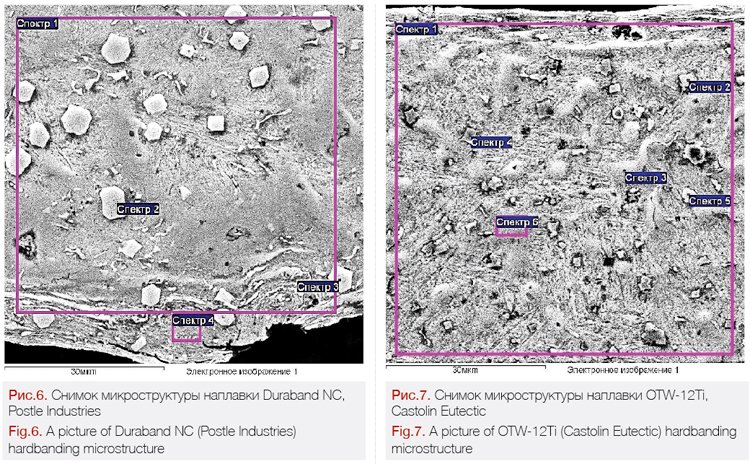

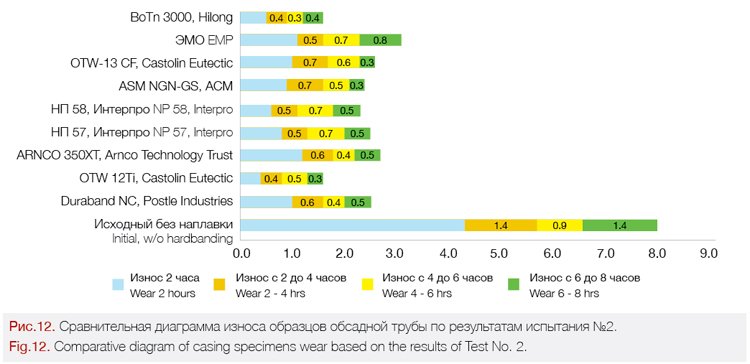

Metallographic examination of hardbanding materials

In addition to the test program, the hardbanding materials were subject to chemical analysis as per GOST R 54153-2010, using the universal laser atomic emission spectrometer SPEKS LAES.

The hardbanding material assay shows carbide stabilizing elements (Cr, Ti, Al, V, Nb, Mn) unevenly distributed across the metalized coating; they increase hardness and combine with carbon to form single or complex carbides having high hardness and at the same time maintaining sufficient viscosity.

Test No. 2 as per API 7CW (Casing Wear Tests)

The purpose is to determine wear of the casing string rubbing against the hardbanding specimen surface layer with abrasive material fed to the contact zone.

The bench for Test No. 2 (Fig. 9) was assembled on the basis of a compact lathe machine subject to some modification:

The bench for Test No. 2 (Fig. 9) was assembled on the basis of a compact lathe machine subject to some modification:

• A variable frequency regulation system was installed to maintain the required and accurate rotation rate (155 rpm).

• A leverage mechanism was added to achieve the parameters required for pressing the hardbanding specimen against the casing.

• Drilling mud was fed to the contact zone (density 1050 – 1080 kg/m3) with controlled abrasive particles content 20 g per 1 liter of drilling mud.

The layout of Test No. 2 is shown in Fig. 8. A pair of specimens (the specimen and the counter-specimen) were made for each type of hardbanding to be tested.

The specimen was a fragment of 245 mm casing with wall thickness of 11 mm, manufactured as per API 5CT standard. The counter-specimen was a fragment of hardbanding.

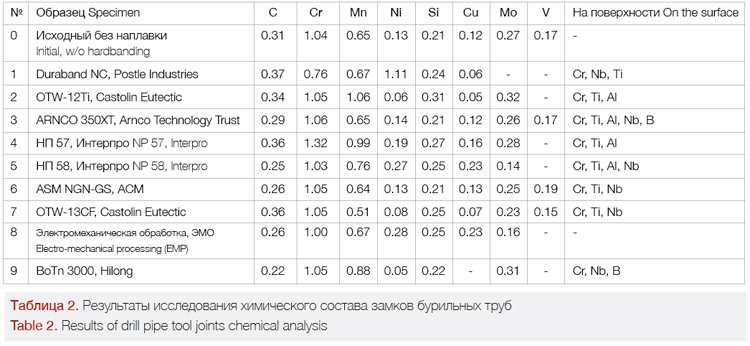

The prepared specimens (Fig. 10) were tested on the bench for 8 hours. The current wear of specimens and counter-specimens was measured every 2 hours. One specimen of each hardbanding type was tested. The averaged test results are provided in the diagram (Fig. 12). The wear was evaluated by weighing each specimen of the casing before and after the test.

The prepared specimens (Fig. 10) were tested on the bench for 8 hours. The current wear of specimens and counter-specimens was measured every 2 hours. One specimen of each hardbanding type was tested. The averaged test results are provided in the diagram (Fig. 12). The wear was evaluated by weighing each specimen of the casing before and after the test.

Test No. 2 as per API 7CW (Casing Wear Tests) proves the efficiency of Russian and foreign hardbanding materials used for casing protection against wear caused by contact with the tool joint. Wear resistance of the casing contacting the hardbanding applied onto the tool joint surface is more than 5 times higher than that of the casing contacting the initial specimen without hardbanding. At the same time the dependence of wear resistance values on the hardbanding material hardness persists, i.e. the casing specimen is less worn by materials with relatively low hardness (Fig. 12).

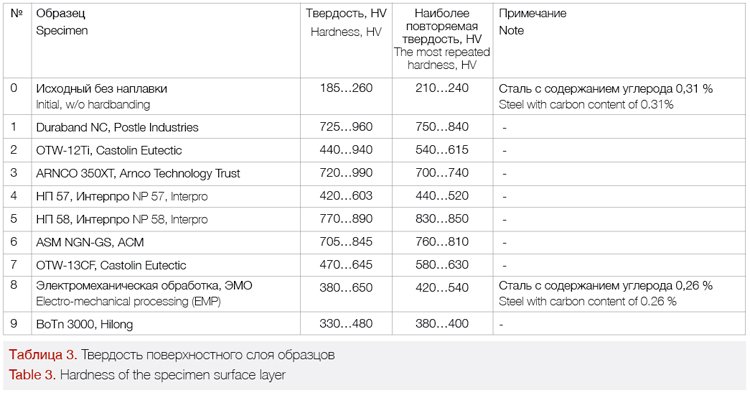

Metallographic examination of tool joints

In addition to the test program, the tool joint materials were subject to chemical analysis as per GOST R 54153-2010, using the universal laser atomic emission spectrometer SPEKS LAES MATRIX. The examination results are provided in Table 2.

Table 3 shows the results of surface layer hardness measurement on the initial, EMP-hardened, and hardbanded tool joints. Hardness was measured by Vickers method on polished sections, using the EMCOTEST DuraScan microhardness tester under loading of 100g.

The chemical composition of the materials used in tool joints from Russian and foreign drill pipe manufacturers reveal a considerable diversity of steel grades with regard to carbon content (0.22…0.37).

Such considerable diversity of steel grades used for tool joint production has an adverse effect on wear resistance of the tool joint surface as well as on the thread connections — the weakest point of pipes. Along with low hardness 210…260 HV and strength of the thread, it reduces wear resistance of thread connections and necessitates their recovery at pipe control shops. The thread connection durability issue is the «bottleneck» in the life cycle of a drill pipe with hardbanded tool joints (but this issue is beyond the scope of the performed examinations).

MTService LLC conclusion on the test results

These two tests demonstrate how difficult it is to achieve versatility of hardbanding materials, but the situation becomes still more complicated, when drilling contractors use drill string assemblies with different hardbanding types. So it is recommended to select for tool joints such hardbanding materials that have showed the best average results. Based on the test results, these materials are: Duraband NC (Postle Industries), OTW-13СF (Castolin Eutectic) and Russian materials NP 57 and NP 58 from Interpro, provided that the latter are applied using a technology of proper quality.

Compared to hardbanding application technology, the EMP technology has yielded some lower, but still comparable results. As an alternative to hardbanding, the EMP technology is able to improve the tool joint wear resistance and to ensure safety of the casing through the tool joint surface hardening.

Apart from the tool joints, the EMP technology may be used to improve wear resistance of the drill pipe external and internal thread, using the same equipment. The hardening process does not require any hardbanding consumables or shielding gases.

The cost of EMP equipment is comparable with the cost of a mobile plant for wear-resistant hardbanding application. EMP operations are performed on metal cutting machines, and the operating capacity is equal to hardbanding application time.

Oleg Fomin, Chief Drilling Expert, Siberian Service Company JSC

SSC JSC thanks the MTService LLC team for high quality of the performed hardbanding test works. MTService specialists have fulfilled their assumed obligations with due diligence, thus proving their reputation. Within several months, almost «from scratch», they managed to build the test bench to perform tests as per API 7CW standard (Casing Wear Tests). The tests were conducted on schedule with full photo and video documenting of each work phase, while engagement of research staff from Bauman Moscow State Technical University leaves no doubts about the unbiased and independent nature of the performed studies.

The results of the performed tests will be used for future selection of cost effective wear resistant hardbandings at the stage of procurement of new drill pipe sets.

Sergey Kuznetsov, Technical Director, Technomash LLC

We have participated in hardbanding testing performed by MTService to analyze the properties of our products against other hardbanding manufacturers.

Such studies help to facilitate development and implementation of innovations aimed at improving our product quality.

The studies method and qualification of the specialists clearly demonstrate the fairness of the results.

Unfortunately, our Company has participated in the test of only one hardbanding specimen BoTn-3000.

Technomash and MTService have agreed to test the entire BoTn hardbanding range produced by HILONG.

Test results will allow us to develop new products and upgrade BoTn-1000, BoTn-3000 and BoTn-5000 hardbanding that have been in service for a long time.

Don Bishop, Director, Business Development, Arnco Technology

Arnco Technology is extremely encouraged by the amount of time and attention being given the manufactures of hardband alloys by leading names within the Russian Federation’s drilling sector. While we view the SSC Hardbanding Report as a step in the right direction, we encourage the customer, and by larger measure, the industry, to continue to improve the testing methods used to evaluate hardband samples in the laboratory. Since the mid-1990’s, our company has worked with the testing houses known around the globe as pioneers of hardband performance analysis. Arnco itself has contributed greatly to the discussions that have sought to form and improve the methods used in conducting the casing wear test, originating from the Drilling Engineers Association (DEA-42) to the modern day Stress Engineering API Spec 7 CW as well as the ASTM 65 test. Throughout their development what we have come to know is that the process takes time. We also know that it is not simply the casing wear percent that is the final tool for Operators as they model their drilling program, rather, it is a number of additional experiment outputs derived from the test that ultimately feed the algorithms used to model potential outcomes of a modern day well.

While laboratory benchmarks are important in creating a minimum “apples to apples” comparison across products, we cannot stress enough the importance of a field trial to determine overall hardband performance. No two wellbores are the same, and drilling variables are numerous. Arnco remains steadfast in our claim of providing the industry with the highest quality and most durable casing friendly hardband alloy on the market. We appreciate the continued consideration from members of the Russian drilling sector, and look forward to becoming the hardband of choice for customers across the industry.

Mikhail Baranov, Chief Executive, ASM – Special Welding Materials Ltd

On behalf of ASM – Special Welding Materials Ltd, I would like to thank you for invaluable experience and information we have received during performance of trials by your company. Unfortunately, the article is limited to the pure results of trials and measurements while it would be great to know also the opinion and comments of specialists as well as the positive and negative characteristics of each material and, particularly, our product.

Our life requires further development and continuous improvement of materials. So, we will be glad to participate in such comparative trials again.

Alexey Sadovnikov, General Director, MTService LLC

The test results obviously demonstrate that the use of an unprotected tool joint is IMPERMISSIBLE.

The tests have also proved the alignment of hardbanding brands for onshore drilling in the market.

Two aspects shall be emphasized in the coming years:

• The Chinese brands: only one grade of Chinese hardbandings was present in the test. It may be a result of low awareness of the manufacturers. But the Chinese brands are still making aggres-sive and persisting moves, and believe me, they’ve got something to offer. The fact they hit the Russian market with their integrated drill pipe plants proves that they can spring a mine to the market of wear resistant hardbandings.

• As to Russian brands: Can they really compete with the foreign manufacturers? The good physi-cal results of tests are a kick off. They need focus on stability of an application technology and extend the regional coverage.

Roman Ignatenko, General Director, Interpro-Tyumen LLC

I’m very glad that testing has been completed and must admit I’m really satisfied with the results of PP-NP 58/3 and PP-NP 57. We have spent a lot of time – a year and a half – to reach this goal. As for the comments we will consider all of them and do our best to resolve them accordingly. As the saying goes, there’s always room for improvement.

We do appreciate the competence, patience, reasonable conclusions and comments of specialists who have performed testing.

Alexey Shilovskiy, Deputy Director, Castolin Eutectic

We are very grateful that our products have been chosen for this test. The results again proved that Hardbanding alloys developed by Castolin Eutectic, are one of the best on the market. We achieved these results due to our investments in our own production and R&D centers, which develop and test our new products and also through our very stringent quality control systems. For example, our gas shielded, flux cored alloys, OTW, have been tested on active field components, under the most extreme drilling conditions and they were approved according to set industry standards and customer approvals, e.g. NS-1 and NS-2 standards from the Fearnley Procter Group, who specialize in testing materials, equipment and services for the oil and gas industry.

Colin Duff, Director, Hardbanding Solutions

We are very grateful to SSK for organising the first major study of hardband materials in Russia. The use of casing friendly materials like Duraband has grown quickly in the Russian drilling industry, and this report shows some of the reasons why. However, laboratory testing of this nature can only be used as a guide to show some aspects of the performance of each material. We would strongly recommend taking into consideration other vital factors such as reliability of the material, and technical support offered by the manufacturer.

Reliability in this case refers to a material that will not crack or fail, particularly after the second or third application. Many welding wire manufacturers can produce a product that will be wear resistant. The difficulty comes in producing a material that is both wear resistant and reliable, when applied to high-carbon tool joints. Very few have succeeded in achieving this. To claim that a material is comparable with Duraband, because it comes close to achieving the same wear resistance figures, is not accurate. This is especially true when some of the wires mentioned presented serious defects on the first application submitted for this test, and that’s before reapplication is considered. The consequences of using a material that will crack and fail are significant repair costs and downtime. On average, Duraband NC is applied and reapplied to more than 1000 drill pipes in Russia every month, it never cracks and it never fails.

Today in Russia, with modern drilling technologies and methods, drill pipe is required to do more than ever before. Wells are deeper, they are drilled faster in order to keep the cost of drilling low, and a greater number are directional. The hardbanding, like Duraband NC, should be applied crack free and defect free to new pipe and for its entire working life, in order for the owner to gain the most benefit from hardbanding.

** Since this report was published additional wires have been tested and these can be seen here