SSC: Supplemented Tribological Test Results for Wear Resistant Hardbanding

This article follows on from the technical report first published in ROGTEC Issue 49, SSC: Hardbanding Report, which covered SSC’s wear resistant hardbanding test for domestic and foreign wires.

A detailed description of the test method, equipment and test benches used, and a conclusion on the test results were published in this earlier article.

This publication is a summary of the results combined with the further tests on the specimens provided by Hilong (BoTn 1000, BoTn 3000, BoTn 5000) and NOV (TCS-Ti, TCS-XL).

Finally, the following hardband wires were abrasion and wear tested, including the new specimens:

0. Initial, w/o hardbanding;

1. Duraband NC, Postle Industries;

2. OTW-12Ti, Castolin Eutectic;

3. ARNCO 350XT, Arnco Technology Trust;

4. NP 57, Interpro;

5. NP 58, Interpro;

6. ASM NGN-GS, АСМ – Special hardbanding materials;

7. OTW-13СF, Castolin Eutectic;

8. Electro-mechanical processing (EMP);

9. BoTn 1000, Hilong;

10. BoTn 3000, Hilong;

11. BoTn 5000, Hilong;

12. TCS-Ti, NOV;

13. TCS-XL, NOV.

The specimen appearance and the hardbanding application quality are shown in Fig. 1. 2 different tests were performed with the same equipment as the previous testing:

1. Test No. 1 as per ASTM G65 – simulation of the tool joint rotation in the open well bore.

2. Test No. 2 as per API 7CW (Casing Wear Tests) – simulation of the tool joint rotation in the casing.

Test No. 1 as per ASTM G65

The purpose is to determine the wear resistance of the specimen surface layer which is exposed to abrasive particles delivered to the friction zone and pressed against the specimen by a rotating rubber roller.

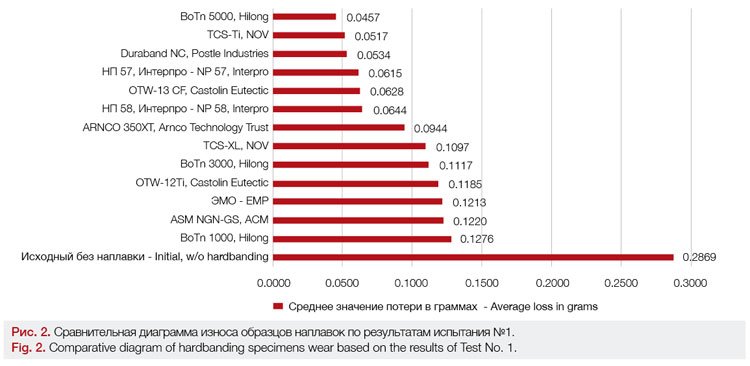

Three specimens per hardbanding wire were evaluated using a test bench constructed in accordance with GOST 23.208-79 Providing Wear Resistance to Products. The averaged test results are provided in the diagram (Fig. 2). Wear was evaluated by weighing each hardbanding specimen before and after the test.

Test No. 2 as per API 7CW (Casing Wear Tests)

The purpose is to determine the wear of the casing string rubbing against the hardbanding specimen surface layer with an abrasive material fed to the contact zone.

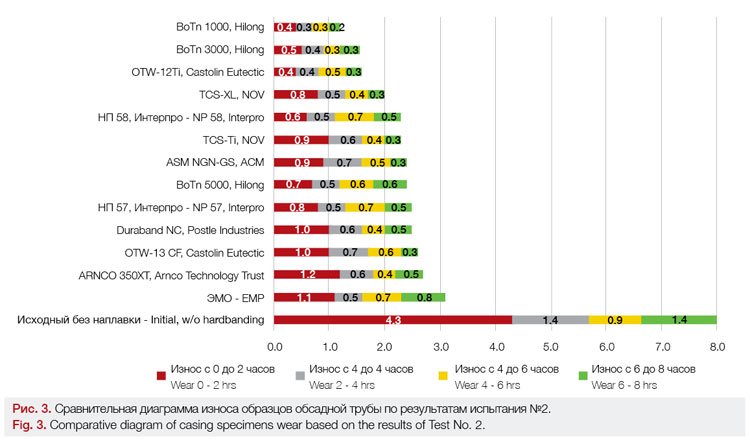

One specimen of each hardbanding type was tested. The averaged test results are provided in the diagram (Fig. 3). The wear was evaluated by weighing each specimen of the casing before and after the test.

Conclusion on the Test Results

The results of the hardbanding wear tests performed on the commercially produced tool joint materials (the abrasion resistance test as per ASTM G65) prove the efficiency of all tested specimens. In general, a direct dependence of wear resistance values on the hardbanding material hardness persists. This test very favorably showcases the TSC-Ti, BoTn 5000, and Duraband hardbanding materials that have shown the best results among the tested specimens.

Tribological test No. 2, the test as per API 7CW (Casing Wear Tests), also supports high performance of the hardbanding materials. Wear resistance of the casing contacting the hardbanding applied onto the tool joint surface is more than 5 times higher than that of the casing contacting the initial tool joint without hardbanding. Further, a relatively low hardness of materials invokes less wear on the casing specimen.

Authors:

A. Sadovnikov – General Director, MTService LLC

S. Fedorov – Doctor of Engineering, Professor, Bauman Moscow State Technical University

L. Fedorova – Doctor of Engineering, Professor, Bauman Moscow State Technical University.

Yu. Ivanova – Candidate of Engineering, Associate Professor, Bauman Moscow State Technical University.

O. Fomin – Chief Drilling Specialist, Siberian Service Company JSC