Supervision Management: Divide & Conquer!

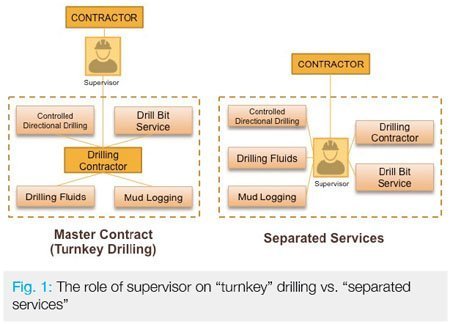

This article is the final installment of a series of ROGTEC articles (1,4) and is devoted to oil related services and managing well construction, well services and workover, and supervising services. We are going to cover the modern trend of managerial supervising, which has emerged due to transition of most of the oil and gas companies to the drilling contracting principles of “separated services”. The difference between contracts based on a “turnkey” principle (or master contract) is that each service company receives a separately signed contract for providing specialized services, including contracts with the drilling contractor. On the other side, managing several contractors at the drilling site, at any one time, requires considerable efforts from the Customer to provide and coordinate their actions and the quality of their work. If a drilling company, as the general contractor, was coordinating all the processes, when turnkey drilling contracts were used, today the supervisor becomes the central interlink between the management (see the Figure 1) and the service providers. It’s the quality of the supervisor, and their leadership, and organizational abilities, that results in properly managed project. Eventually the supervisor is the person responsible for delivering a high quality well, which is drilled on schedule, without accidents and complications, without any environmental impact and incidents, and within the planned cost (budget).

The Basic Functions of Managerial Supervision

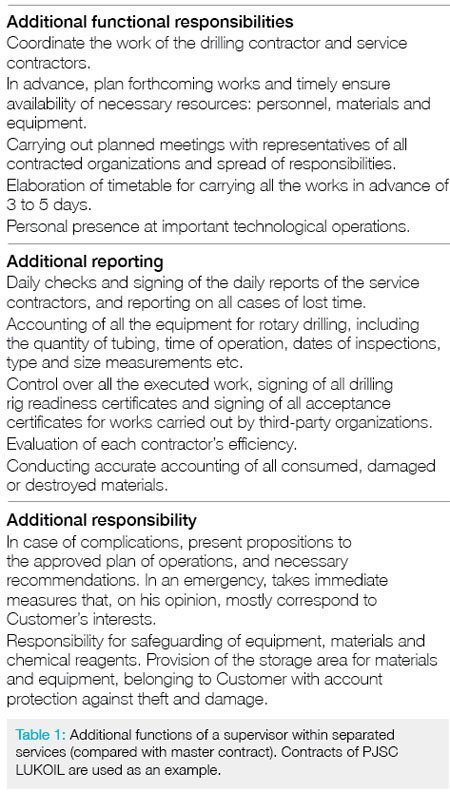

Quite naturally, the transition from a “controlling” supervising to “managerial” supervising function immediately changed the functional duties of a field supervisor on site. This adjustment can be traced in the contracts for the rendering of supervising services and the lately adopted standards from the oil and gas companies for operations under the separated services contract model (Table 1).

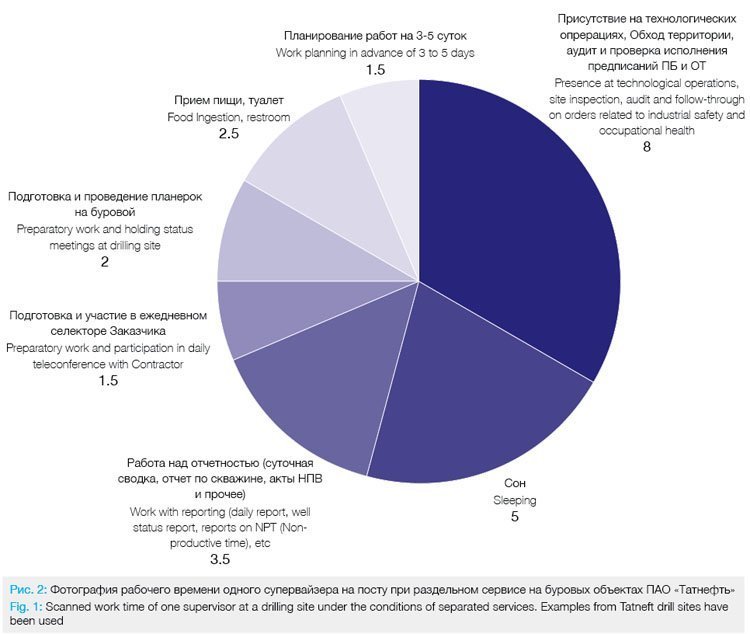

As we see it, the major feature of the managerial supervising is related to coordination of the work of service contractors which is expressed in the daily planning of operations and advanced planning for the next 3 to 5 days. The process of organizing, meeting with the service contractor and keeping the project on course, has become obligatory for the supervisor. The frequency and quantity of reporting, at the managerial supervising level, has materially increased since it is necessary to keep track of time, usage and availability of equipment and materials. The responsibility of a field supervisor is rising sharply as well. These include accountability for the safeguarding of equipment and materials and financial liability deriving from signing the acts of acceptance performed by the service contractors. Alongside with that, the new additional responsibilities do not eliminate the old supervising requirements that existed with the master contract principle. As before, supervisor must personally control all the important technological operations and keep thorough audits of the contractors abiding by the rules of industrial safety and occupational health.

The analysis of the field supervisor’s work load, for managerial supervising, indicates that should they complete all of their additional functions results in a 19-hour working day (Figure 2). Therefore, one supervisor at a drilling site cannot cope with all the tasks assigned to him. For this reason, practically all the oil and gas companies included the requirement of presence of two supervisors at a drilling site as an essential condition to their contracts for managerial supervision.

Another result of the new functions of managerial supervision, albeit not so evident, are the considerable expansion of competencies required from the supervisor. To plan operations and forecast situations, a supervisor is supposed to have logistical and project management knowledge. Conducting meetings and coordinating the work of several service contractors is unthinkable without possessing a minimum of managerial and organizational skills. The increased responsibility and importance of the supervisor at the drill site requires the development of communication and leadership skills. Working with financial documents and contracts requires some base knowledge of accountancy and law. It’s obvious that alongside the introduction of managerial supervision a “drilling supervisor” is becoming a separate profession, to which one has to be trained and prepared.

Manpower Requirements Under Managerial Supervision

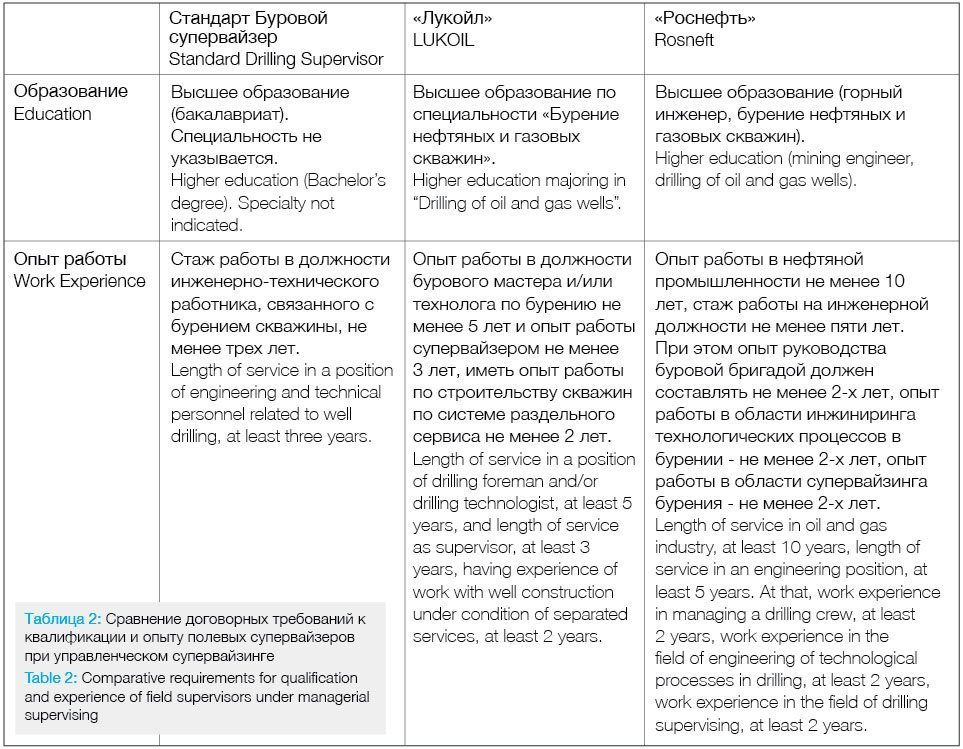

Realizing the increased complexity and responsibility of managerial supervision, many oil and gas companies, in their contracts and own internal normative documents, have strengthened the requirements for field supervisors. Before, when the most of supervising services were provided under master contracts, the experience and the qualification of the field supervisor were not very different from a the standard set in “The drilling supervisor in oil and gas industry” adopted by the Ministry of Labour on November 27, 2014. Now, when managerial supervision is introduced, each oil and gas company has established its own requirements for a field supervisor. A comparative analysis (Table 2) indicates that, in the main, these requirements have become stricter, more specific and concrete.

Thus, only a higher education is permitted for candidates majoring in “Drilling of oil and gas wells”. It is obligatory to have work experience in a position of engineering-and-technical personnel, of at least 5 years, and to be a supervisor for at least 2 to 3 years. On the one hand, the enthusiasm of oil and gas companies to set high standards for field personnel can be understood. But, as the recruitment experience of SC «R&D Center for Gas&Oil Tech.», under the project of PJSC “Rosneft” for managerial supervising [1], has shown, these formal requirements do not guarantee professional aptitude of the supervisor for working under separated services, and what is the most important, they have poor understanding as to the real situation in the labor market. Only a small percentage of specialists of the industry followed the strict carrier path of “Assistant driller- drilling foreman- drilling engineer – supervisor”. And those who followed this route are widely demanded in higher paid branches of the industry, rather than in supervising. Regarding specialists of 50 years old and above, many of them had to interrupt their carrier in the oil and gas industry in the 1990’s and devote themselves to the private sector. As before, a large percentage of the specialists have secondary specialized educations. At the same time, many experienced and qualified drilling specialists, having higher education, major in different specialties: “Field development” and “Geology”. Despite their professional aptitude, because of the formal criteria needing an education in drilling, it is impossible to enable these specialists in the managerial supervision.

Lately, the issue of the incompatibility of the contractual requirements for personnel has become a stumbling block between the oil and gas companies and the enterprises providing supervising services. The only solution of this problem would be to give up the formal requirements for experience and education and recruitment specialists, in the positions of the managerial supervisors, according to the level of their knowledge and their competencies. I’m going to cover this matter in the concluding part of this article.

Evaluation of the Effectiveness of the Managerial Supervision

The issue of the effectiveness of the managerial supervision is, probably, one of the most fundamental and complex issues. Under the master contract, the evaluation of the effectiveness of the supervision was limited to the following parameters: 1) The lack of large incidents; 2) Number of inspections and prescriptive orders handed over to drilling contractor. Many oil and gas companies were evaluating the input of the supervisors by the amount of penalties charged against a drilling contractor following the prescriptive orders of the supervisor. Based on those amounts it was oftentimes concluded on how economically “viable” the supervision was. However, to evaluate the effectiveness of supervising under the managerial supervising and measure its input into the success of drilling operations, is extremely difficult.

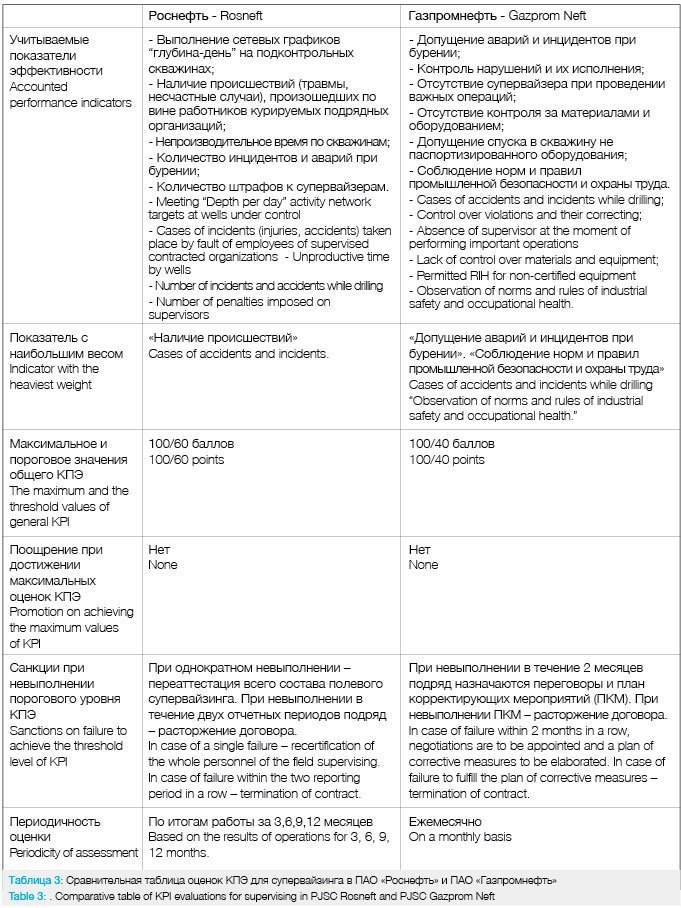

Nevertheless, practically each oil and gas company has its own system of key performance indicators (KPI) to evaluate the work of both their own supervising structures, and the third-party supervising organizations. The base of the system has been the principle of evaluation the viability of a project, once a number of key performance indicators have been achieved, account of their weighting factors: KPI= KPI 1*A + KPI 2*B +KPI 3*C…, where KPI 1,2,3 are performance indicators; A, B, C, are weighting factors. Below, we present the comparative table of the two systems of evaluation of KPI under the managerial supervising.

Overall, the evaluation of the supervising services with KPI’s has an importance. However, there are a number of controversial points which prevent this system from becoming fully operational. For instance, when calculating the NPT (non-production time) performance indicator, one operates with the total value of NPT for a specific well, including stand-downs due to weather conditions, and malfunctioning of telemetry equipment, i.e. the events over which a supervisor has no control, and these things that can impact the general evaluation in the KPI.

And still, the major hindrance to development of the evaluation of supervising by KPI is the lack of achieving the higher standards. High KPI’s do not give any financial motivation for supervising enterprise or service, they do not guarantee privileges in tender procedures. Thus, the evaluation of supervising by KPI, currently., is for guidance purposes only.

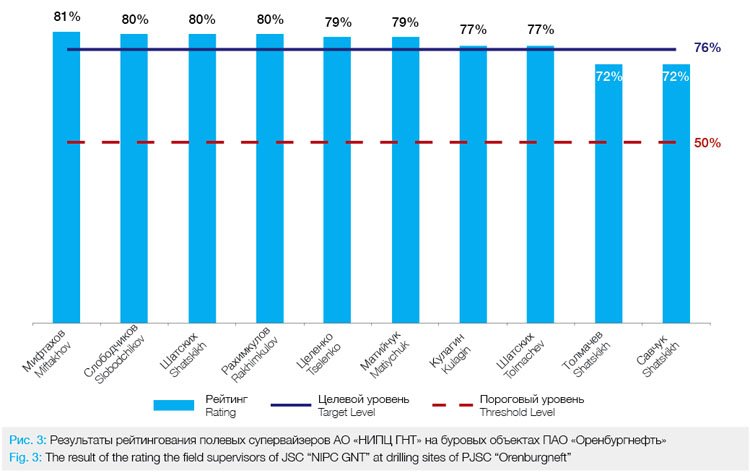

Rating the supervisors can be another example of how to evaluate the efficiency of supervising (Figure 3). The work of each supervisor is evaluated individually by many criteria, beginning with technical achievements (NPT, failure rate, acceleration, number of prescriptive orders), qualification level (results of exams and tests) and ending with subjective evaluations (quality of meetings, reports presented in conference calls, reporting).

The difference from the previous approach to the evaluation of KPI’s for the supervising service or for an enterprise overall, specific actions are taken based on the results of the individual ratings. Supervisors with the best rating received bonuses, and those with the worst one are given test period for corrective measures or get fired. Such an approach makes it possible to rank supervisors by their qualification and assign the best ones to the most complex wells. The only drawback of such ratings, one could point at, it’s the presence of subjectively evaluated parameters, which are hard to be measured quantitatively.

Further Development of Managerial Supervising

As it was mentioned at the beginning of the article, the fulfillment of functional duties by a field employee under the managerial supervising requires a set of competencies in management, planning, logistics, finances and law. As a result of this, it can be stated that, in the process of transition to the managerial supervising, the occupation of “Drilling supervisor” requires creation of a training and skills development program. The management of JSC “NIPC GNT” was the first to realize this necessity and it issued an educational license and created, within the enterprise, an educational structural division named “The Academy of drilling and oil-and-gas production supervising”. Currently there are over 350 field supervisors who have been trained in the “Academy”, majoring in various engineering disciplines of the oil and gas industry.

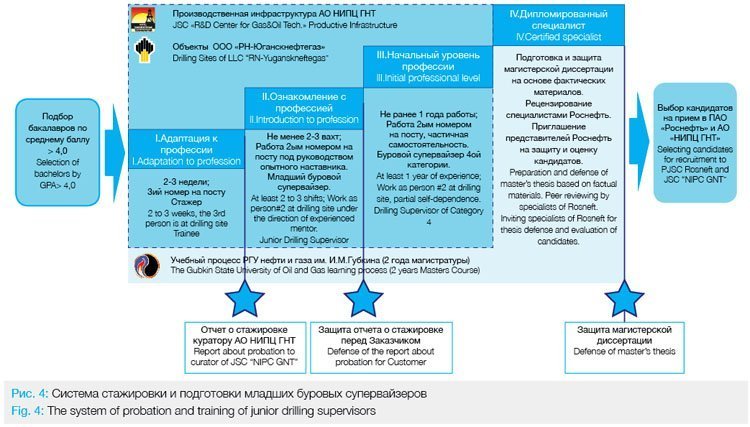

In 2017 RN-Yuganskneftegaz successfully implemented a pilot project aimed at giving practical training to undergraduates of the Gubkin State University of Oil and Gas (Figure 4). Over twenty future young specialists were on probation as drilling supervisors at drilling sites of LLC “RN-Yuganskneftegas” and then they successfully defended their thesis for their master’s degree based on the factual material and practical lessons learned on site. Many of them continued their path in supervising of oil and gas companies or within the private sector. At present we are conducting negotiations to expand this successful experience to other oil and gas companies and educational institutions.

In 2019, for the first time in Russia, an enrollment of bachelors is opening in the Gubkin State Oil and Gas University for the master’s degree program, majoring in “Drilling supervising”, jointly with JSC «R&D Center for Gas&Oil Tech.». The master’s degree programs for supervising are in plans of other educational institutions of oil and gas profile as well.

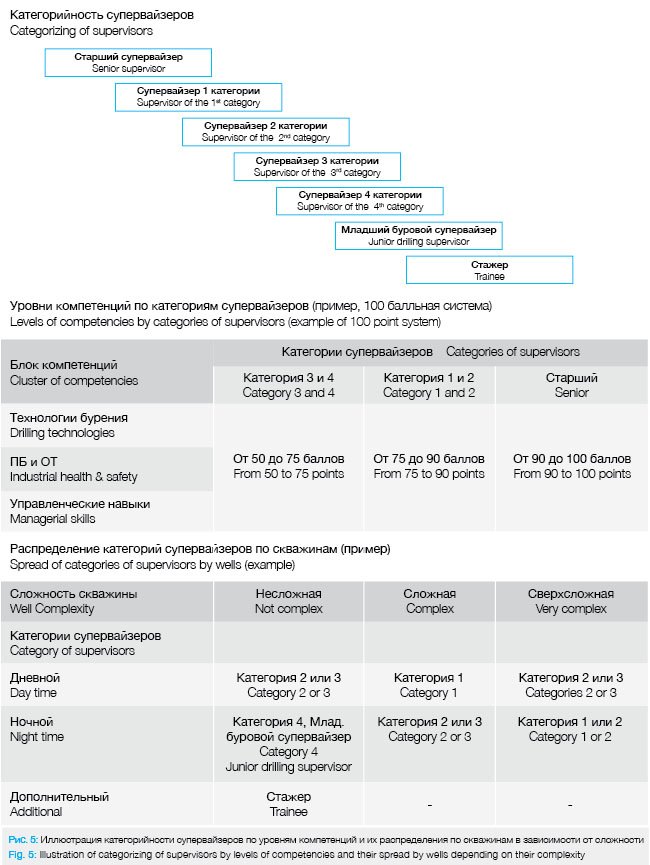

With regard to requirements to personnel under the managerial supervising, I believe that the only true way to resolve the contradictions between the contractual requirements and the existing labor market is abandonment of formal evaluation of the supervisor’s level based on information in employment record and availability of specific education. The qualification of supervisor should be evaluated by his real knowledge and competencies by means of regular tests, ratings and exams. To stimulate the development of personnel and its evaluation it is logical to introduce categorizing based on qualification (Figure 5). To accurately match the level of qualification of a supervisor to the problems addressed it makes sense to rank wells by the level of their complexity and responsibility and assign to them corresponding specialists. Such approach gives opportunity for supervising services and enterprises to provide specialists with the qualities of leaders, to train their own personnel and to respond flexibly to any changes in the labor market.

Although similar division has been already prescribed in the Statement of Requirements for the managerial supervising of PJSC “Gazprom Neft” (four levels of qualification- “Base”, “Standard”, “Experience”, “Expert” and four levels of well complexity), it is not used in practice. Similar principle of designating categories of supervisors and types of wells is still being discussed in PJSC “Rosneft”.

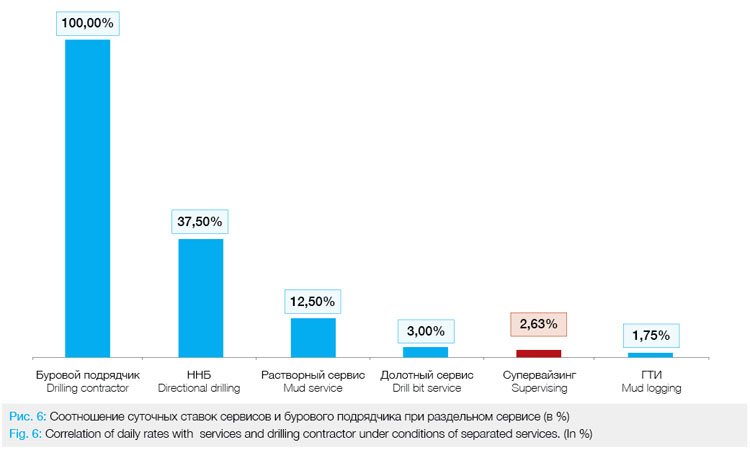

The issue of evaluating the efficiency of the managerial supervising is as much important as it is a complex one. Any managerial decision is hard to receive a quantitative evaluation. The existing systems of KPI do not work so far, since they have no promotions for high achievements. In fact, in stead of a due motivational function they play only informative role. In spite of all the advantages of individual rating of supervisors, it contains elements of subjective evaluations. The solution of the issue of evaluating the efficiency of supervising is yet to be found, but I intuitively believe that the correct answer should be searched in the evaluation of the impact of supervising on the cost of well, more accurately, in estimation of the savings achieved at the expense of acceleration, safety of operations and prompt decisions. For instance, if supervisor’s activities make it possible to reduce the drilling time by one day, the cost of supervising would multifold pay off just due to economy cut on daily rate of drilling contractor (Figure 6).

And finally, the other important way of developing the managerial supervising is introduction of innovative technologies and digitalization which would help to remove part of routine functions and provide support for supervisors in taking important decisions. We have an existing software tool «APM of Supervisor” [2], we also have a tool of technological calculations for smart phones, we introduce electronic digital assistant for making reports [3]. The concept of geosupervising – supervising, is actively being developed, enhanced with instrumental tools for monitoring parameters [4] Introduction of many other innovations, such as machine processing of video signal, electronic tags for drilling equipment, robotization of drilling rigs, would positively impact the development of the managerial supervising.

Literature

1. Schebetov A.V. Supervision Service Market in Russia: Providing Value for Money. ROGTEC – April 2017 – p. 64-73

2. Kulchitsky V.V., Larionov A.S., Alexandrov V.L., Grishin D.V. Automated work space of supervisor. (Кульчицкий В.В., Ларионов А.С., Александров В.Л., Гришин Д.В. Автоматизированное рабочее место супервайзера (АРМ Супервайзера). Certificate of official registration of the program for computer #2005612320. – RF, RosPatent, 08.09.2005

3. Kulchitsky V.V., Alexandrov V.L., Grishin D.V., Shchebetov A.V. Automated system of managing drilling supervising, current well servicing and workovers. Certificate of official registration of the program for computer #2014619243. – RF. RosPatent, 11.09.2014.

4. Shchebetov A.V. Geosupervising: Thorny path of one innovation. ROGTEC. – Number 54, 2018 – p.74-83.

Schebetov A.V., General Director, JSC «Research and Design Center for Gas and Oil Technologies» (JSC «R&D Center for Gas&Oil Tech.»)