SSC: Supplemented Tribological Test Results for Wear Resistant Hardbanding

This article follows on from the technical report first published in ROGTEC Issue 49, SSC: Hardbanding Report, which covered SSC’s wear resistant hardbanding test for domestic and foreign wires. A detailed description of the test method, equipment and test benches used, and a conclusion on the test results were published …

Technology Roundtable: Drilling Contractors

1. How can you characterize the current state of the Russian drilling market and what is your forecast for 2018? NSH ASIA DRILLING: A number of key factors affect the Russian drilling market today. First of all, Vertically Integrated Oil Companies have established their own oilfield services divisions. Today around …

SSC: Predicting and Preventing Drill String Fatigue Failure

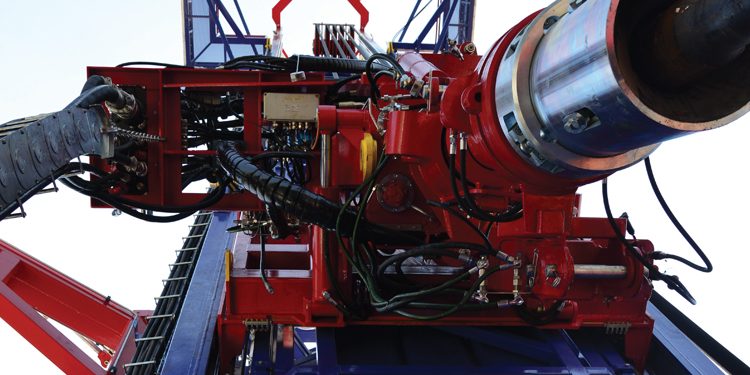

This article describes the results of an analytical study of drill string fatigue failure, prediction, and prevention during well construction. Regarding the causes of drill string failure, the API Recommended Practice 7G, para. 13.2.1 states: Most failures of drill pipe result from some form of metal fatigue. A fatigue which …

SSC Hardbanding Report

Tribological test results for wear resistant hardbanding The primary cause of drill pipe tool joint wear as it rotates in the open well bore is the presence of a hard rock layer in aggressive geological formations. Drilling in such severe operating conditions results in the wearing of the outside diameter …

RDCR Participant Update

The 1st Russian Drilling Contractors Roundtable is pleased to announce that Russia’s largest drilling contractors will be attending the event. EDC Group and SGK Drilling will be sending a large delegation as the Gold Sponsors. The Siberian Service Company (SSC), Integra Drilling, Ru Energy and Burgaz will be sending sizable …