Tatneft: New Sucker Rod Pumps Installed at Elkhovneft NGDU

The development of oil production technologies depends on the quality and scope of the latest achievements which have been implemented as part of the industrial production process, directly in the field. However, before any technology can be implemented, it needs to prove its efficiency at the pilot testing stage. The adoption of a sucker rod pumps with a 50 mm diameter plunger was one of the most significant of projects undertaken by specialists of the O&G Production Department in 2017.

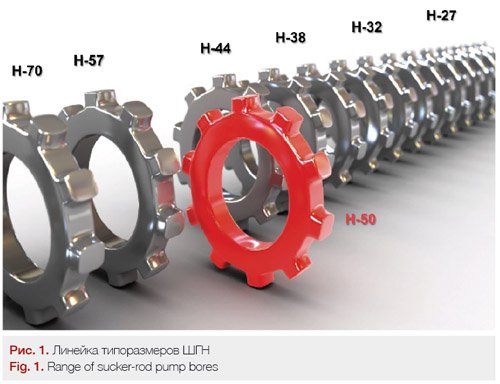

What is so significant about this size? Plunger diameter increments of 5-6 mm (reference Fig. 1) are typical of the standard range of sucker-rod pumps (ShGN) while pumps with a plunger of “intermediate” diameter i.e. 50 mm does not form part of the standard range. However, this particular diameter is sometimes required for technological reasons. When this was taken on board by specialists of Elkhovneft’s Oil and Gas Production Board (NGDU), they commenced development and testing of a pump with this new bore.

In the broad range of artificial lift systems, the most commonly used by JSC TATNEFT are sucker rod pumps. Currently, there are two traditional solutions for fluid production at a rate of 40 m3/day. These are 57 bore pumps together with a common sucker-rod pump or the use of 44 bore pumps with an increased linear pumping speed. At the same time both solutions have significant disadvantages. What is the reason?

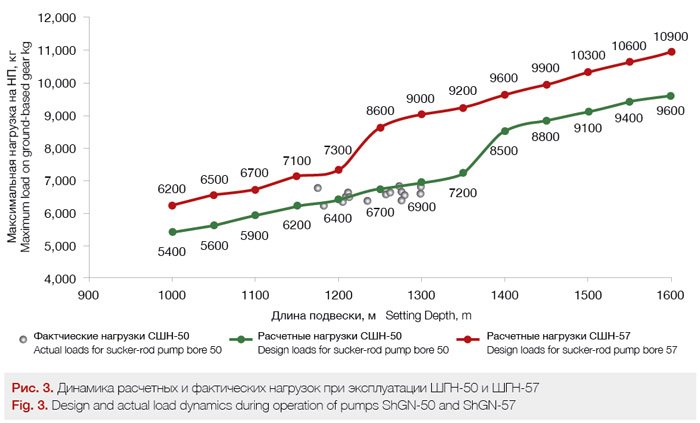

1) ShGN-57 pump has a running depth restriction due to the high hydrostatic load of the liquid column causing an overloading in the down-hole pumping equipment and surface facilities. This restricts the use of such pumps under certain conditions. Moreover, the operation of deep wells with this pump leads to additional costs related to the purchase of reinforced sucker rods and ground-based gears with a higher load capacity. All these facts together result in the low energy efficiency of the pump.

2) ShGN-44 pumps can also be used for the required well rate. In this case, pumping operations are possible provided that the pumping speed or length of stroke is increased. The first option implies excessive pumping speed, which is a negative factor from the technical, production and energy point of view. This has been proven by field experience. Long stroke equipment is advantageous from the technical and technological point of view for oil recovery. However, this is less cost efficient from the point of view of JSC TATNEFT which owns a sucker-rod pumping fleet of thousands of units.

There is a need to design equipment which is cost effective and combines the advantages of both the lifting options described above. This is aimed at ensuring the flexible control of production, to a greater or lesser extent, and to mitigate any errors when determining of the potential productivity of wells. ELKAM LLC plant, was assigned with the task of designing a pump with a plunger of “intermediate” diameter, 50 mm. The equipment was fabricated by Russian oil companies for the first time.

In accordance with pilot test program for 2017, JSC TATNEFT adopted pump 25-200-RWAM-18-4 for use at Elkhovneft NGDU’s production well. The test was performed to verify the reliability and economic and technological efficiency of the pump. A wide range of parameters were evaluated during the pilot test such as: loads imposed on ground-based gear, rod string work load, well fluctuation rates, specific consumption of power, and the reliability of equipment.

The pilot test proved the compliance of pump 25-200-RWAM with the declared specifications. No failures occurred during the control period.

One of the test results which needs to be noted is the possibility of increasing the setting depth by almost 150m, in comparison with pumps fitted with a 57 mm plunger diameter, while keeping the same size of ground-based gear. Taking into consideration the technical and (or) process restrictions related to the adoption of ShGN-57 pump, the new pump can also enhance oil production by increasing the setting depth.

It is worth also considering the pump’s configuration. Due to the need to reduce costs for underground repairs, and to increase the efficiency of threaded connections of the well tubing, JSC TATNEFT is currently implementing an ambitious maintenance program by replacing failed sucker-rod pumps, repairing the cracks and sucker rod turn-aways without lifting the tubing string. The optimum diameter and insert thin wall design of the ShGN-50 pumps comply with the new requirements, thus enabling operation of the pump within tubing with a rated diameter of 73 m and ensuring interchangeability of the pump with smaller bore pumps.

As has been already mentioned, the pump down performance is closely connected to the energy efficiency of the sucker-rod pumping unit. Previously no pump with a special plunger diameter for the well production rate range of 30-40 m3/day existed. This was compensated by a higher specific consumption of power. The field test proved this statement by reducing the daily rate of power consumption by 9,5% for the same production rate (in comparison with pump ShGN-44).

In general, as the test showed, the 25-200-RWAM-18-4 pump as a separate typical size, is technologically and economically efficient. On this basis, the company decided that at least 5% of the total sucker-rod pumping unit fleet throughout the entire Company should be earmarked for the potential usage of this particular type of pump.

In addition to the pro-active position of Company management to enhance their oil and gas production equipment and technology, the creative approach of the specialists to resolve complex tasks is an essential factor, and the team of Elkhovneft NGDU O&G Production Department does indeed possess these qualities!

Renal Islamov, Head of Oil Producion Methods and Technology Team, O&G Production Department, Yelkhovneft NGDU, JSC TATNEFT

Lenar Minikaev, Head of Oil Production Methods and Technology Team, O&G Production Department, Elkhovneft NGDU, JSC TATNEFT

Marat Timerzyanov, Lead Process Engineer of Oil Producion Methods and Technology Team, O&G Production Department, Elkhovneft NGDU, JSC TATNEFT

Lenar Karimov, Lead Process Engineer of Oil Producion Methods and Technology Team, O&G Production Department, Elkhovneft NGDU, JSC TATNEFT