TatProm-Holding Group Engineering Service for Well Completion

This article is being read and print-proofed in our classic PDF format (link)

Authors: Azat Gatiiatullin, Head of Production Service; Denis Shovkoplyas, Deputy General Director; Danil Matveev, Leading Engineer, TatProm-Holding Group

In a short period of time, TatProm-Holding Group has successfully showed itself as a strong competitor in the Russian and CIS market in well completion business. More than 3000 wells have been completed since the company began to operate in 2020. Such rapid success is the result of teamwork. The company’s Production and Technology Department takes an integrated approach to planning the operations for each customer, in accordance with the terms of reference, and then individually for each well. We perform a risk assessment and develop a set of actions to ensure that the liner reaches the design target depth. Such work includes selection of engineering solutions, RIH (run in hole) technologies, toolsets and equipment.

Horizontal wells remains the most effective and fastest way to produce oil. In the context of import substitution, TatProm-Holding Group offers solutions to successfully drill and complete horizontal wells of complex design in challenging geological conditions.

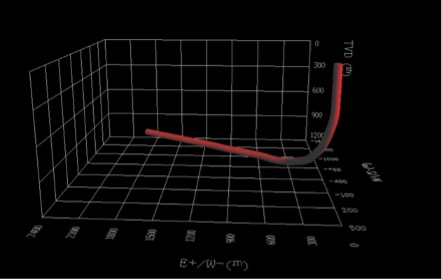

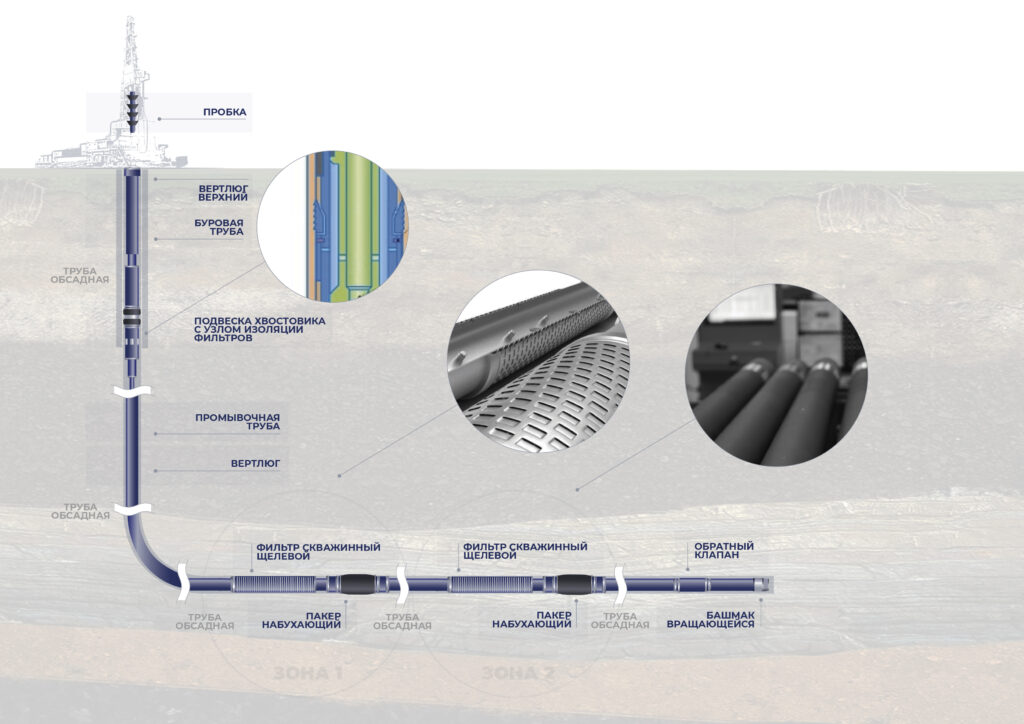

Let’s consider an example of completing a well with a horizontal section exceeding 2000 m. According to the terms of reference, the well was designed to target Cenomanian (TVD=1100 m), to be completed with a screen and a hanger of a non-cemented liner (Dia=178 mm) in a production string (Dia=245 mm) (Fig.1).

It is not an easy task to run in hole a 178 mm non-cemented liner completed with a screen at such TVD and in case the horizontal section exceeds 2000 m in length. In addition to the conventional procedure for drilling horizontal wells, presuming rotary-steerable systems, top drive and oil-based muds, Technology Group of TatProm-Holding Group proposed to run in hole PKhGMN UIF (ПХГМН.УИФ) 178/245 (hydromechanical non-cemented liner hanger with a screen isolation unit, having the option of flushing through the liner shoe); and to use of a special swivel for rotation of the liner and a swivel preventing rotation of the washpipe for its safe removal.

Work planning began by analyzing the initial well data, developing a work program with the client, and performing specialized software-based calculations:

Calculation of the bottom-hole assembly (BHA) stiffness. The calculation shows whether the BHA used for drilling and reaming ensures smooth RIH of the casing string.

Calculation of the casing depth reach. One of the key performance indicators is simulation of the liner RIH. The calculation of the depth reach includes producing crossplots of the travelling block WHO (weight on hook) vs the depth and the stress of the casing and transport strings. To assess the stability of the system, the crossplots are produced for the open hole friction factors from 0.1 to 0.5 with a step of 0.1. Often this calculation is performed twice: based on the design data during the planning and design phase, and based on the actual data before the liner RIH. In cases when the weight of the string is not enough for the liner to reach the design point, additional drill collars may be added to the transport string.

Hydraulic calculation. This calculation allows: to choose the optimal well flushing parameters for the best hole cleaning; and to adjust the equipment before RIH to prevent emergencies.

Centering calculation. Used to determine the number of centralizers and to select their optimal arrangement on the liner.

Hydrodynamic simulation. Is performed to optimize location of automatic inflow control devices and casing packers in the well.

The second step includes equipment selection. TatProm-Holding Group has a range equipment designed for successful completion of horizontal wells.

1 – Reaming shoes of various designs and form factors. The Drillable Reaming Shoe (DRS) PUR-178 (ПУР-178) consists of a rotating shoe with hard-alloy plates and a body with a multi-stage hydraulic turbine. The internal elements and the DRS cutting-and-gouging part consist of easily drillable material (Fig.2). Another unique feature of this reaming shoe is that its rotating parts can be fixed while drilling.

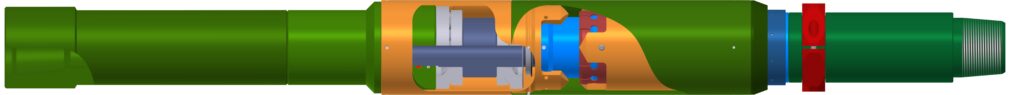

3 – Liner hangers of various modifications, types and sizes. In particular, in order to complete this well, we chose the hydromechanical non-cemented liner hanger with screen isolation unit PKhGMN UIF 178/245 (ПХГМН УИФ 178/245). This is a set of five functionally complete units housed in a single device, including:

– a hydraulic anchor;

– a hydraulic disconnection unit;

– a mechanical disconnection unit with a left-hand thread, duplicating the hydraulic disconnector;

– a hydromechanical packer;

– a hydromechanical additional packer unit.

Fig. 3 shows the assembly of the liner hanger with PKhGMN UIF (ПХГМН УИФ).

When running-in a liner with screens, the device allows to flush the wellbore while casing string RIH, jamming and when the target depth is reached. Moreover, when the bottom-hole is reached, the screen isolation unit allows to shift the well from drilling mud to completion fluid, thus saving flowback and completion time. If an oil-based drilling mud is used, the screen isolation unit makes it possible to reuse it.

4 – Swellable packers. Annulus packers with swelling elements are designed to reliably isolate the penetrated pay formation from the casing string annulus to avoid annulus communication. Activation does not require manipulations with the casing or hydraulic pressure. After the end of the activation period, when the packer elastomer comes into contact with the swelling fluid, the fluid is absorbed by the elastomer texture.

As the fluid is absorbed, the elastomer expands until the packer contacts the wellbore wall. The swelling pressure creates a strong hermetic seal that can withstand differential pressures.

5 – Well screens of various modifications and sizes. They are installed in the pay formations to screen the extracting fluid from inclusions, to prevent the bottom-hole damage, sand and other solids production in oil and gas wells, as well as to reduce wearing of the pumping equipment.

6 – VZ.178 (ВЗ.178) swivel (Fig. 4) allows rotating the transport string while liner RIH in case of increased hydromechanical, mechanical and differential resistance impeding the advancement of the liner to the design bottom-hole. In such cases, when the insufficient WOH prevents the liner RIH to the planned design depth, the tool allows to reduce the resistance of the transport string by rotating it without torque transmission to the liner. After the end of the liner RIH, the tool is locked, and in such a state the tool can transmit the torque.

TatProm-Holding always performs delivery-acceptance tests while assembling all its products at the company’s production facilities. All the tests are controlled by QAQC Service with mandatory video recording of the entire test cycle.

The final stage included service support for the equipment RIH. Highly qualified field personnel supported and supervised the liner RIH 24 hours a day, providing recommendations at all stages. 250 m before the design depth, the liner RIH was followed by slacking-offs of no more than 5 tons; at a depth of 3225 m – there was a hard slacking-off, but by reciprocating the liner and by rotation of the transport string, the interval was passed. When the liner reached the designed depth, the anchor unit was activated. Then, by creating a high pressure to cut off the brass screws, VZ.178 (ВЗ.178) swivel was activated (blocked). The next stage was the mechanical disconnection of the transportation string followed by activation of the liner top packer and pulling-out the running tool with the washpipe (89 mm tubing).

Thus, having an integrated approach to well completion servicing, TatProm-Holding Group successfully completed a well of a complex design with a long horizontal section exceeding 2000 m and a vertical section of only 1100 m. The success was achieved due to the well-coordinated work of our team and the individual approach to each well.