Technical Research Centre Management: Theory of Constraints (TOC)

Currently, the market for engineering services within exploration and production is shifting more and more towards those companies which are technical research centers (TRC) and are incorporated into the vertically integrated oil and gas companies (VIOC).

Like any other high-tech business, i.e. a business in which one of the main competitive advantages is the use of modern technologies and high-tech plants, the oil and gas business needs its own system of scientific and technical support. This is the reason to create TRC as a part of VIOC with a primary focus on the following tasks:

• Increasing the efficiency of geological exploration and reserve replacement;

• Exploitation and development engineering;

• Drilling engineering design;

• Creation of a single center of knowledge and competences;

• Training of technical specialists of the group of companies.

At present, quite a large number of manufacturing companies have implemented the principles of Theory of Constraints (TOC) and obtained successful results.

The Theory of Constraints (TOC) is a systems-management philosophy developed by Eliyahu M. Goldratt in the early 1980’s. The fundamental thesis of TOC is that the constraints establish the limits of performance for any company. This theory provides an opportunity to take a new look at some basic ideas about what to consider as productive actions and what is the real goal of cost management. An integral part of the constraint-based management technique is the so-called “continuous improvement process”. This process consists of the following five steps (or stages):

Step 1.

First of all, the major constraint in the system that limits company’s throughput or progress toward the goal needs to be identified. The constraints can be classified as internal (the production process restrictions, wrong management policy) and external (market restrictions).

Step 2.

The next step after identifying the constraint is to decide how to exploit it. The basic approach to maximizing profits is to concentrate on the release and sale of those products which provide the greatest revenue from capacity per unit of limiting factor.

Step 3.

Subordinate everything else to the above decision regarding exploitation of the major constraint. In other words, all “non-critical” operations must be subordinated to the needs of the constraint. It should be noted that compliance with the above requirement is usually not easy, since it may require a significant change in the company’s corporate culture.

Step 4.

The fourth step involves taking measures to expand the “bottleneck”, i.e. an increase in the quantitative index in which the constraint is expressed.

Step 5.

If the constraint is eliminated in the previous step, you need to return to the first step and start the process again. According to the Theory of Constraints, the management of an enterprise should never stop when a constraint has been eliminated since another one immediately arises.

Despite the successful implementation of TOC for manufacturing companies, very few papers are available on the use of TOC in the management of TRC incorporated into VIOC. According to the Theory of Constraints the goal of the enterprise and the bottleneck (constraint) which at the moment prevents the early achievement of this goal need to be defined. The constraints are those factors, processes or anything that limits throughput and prevents the system from achieving its goal.

A commercial system can have several types of constraints:

Internal resource constraint: a resource that is not able to ensure capacity in due time and amount as required by the system.

Market constraint: the quantity of orders received by the company is not enough to maintain the required growth of the system.

Time constraint: the time the system takes to responds to the needs of the market is too long and jeopardizes the ability of the company to fulfill their obligations to customers and expand its business.

First, we need to define the purpose of the TRC incorporated into VIOC. At first glance, TRC should be treated as a commercial enterprise with the primary goal of generating maximum income. However, usually the TRC incorporated into VIOC is a 100% subsidiary of the parent company and fully controlled by it. Therefore, the goal of the TRC incorporated into VIOC is completely depends on the goal set by the parent company. Thus, the progress of TRCs incorporated into VIOC in achieving the “goal” should not be measured in terms of profit earned, but in the maximum satisfaction of the needs of the holding’ group of companies with the minimum costs to the holding’s subsidiaries that use the services of the TRC.

Thus, it does not make sense to consider market constraint, time constraint (this is within the competence of the parent company’s corporate center), but it is necessary to consider those capacity or resource constraints which affect the smooth production process and make it difficult to achieve the overall goal of increasing the generated income.

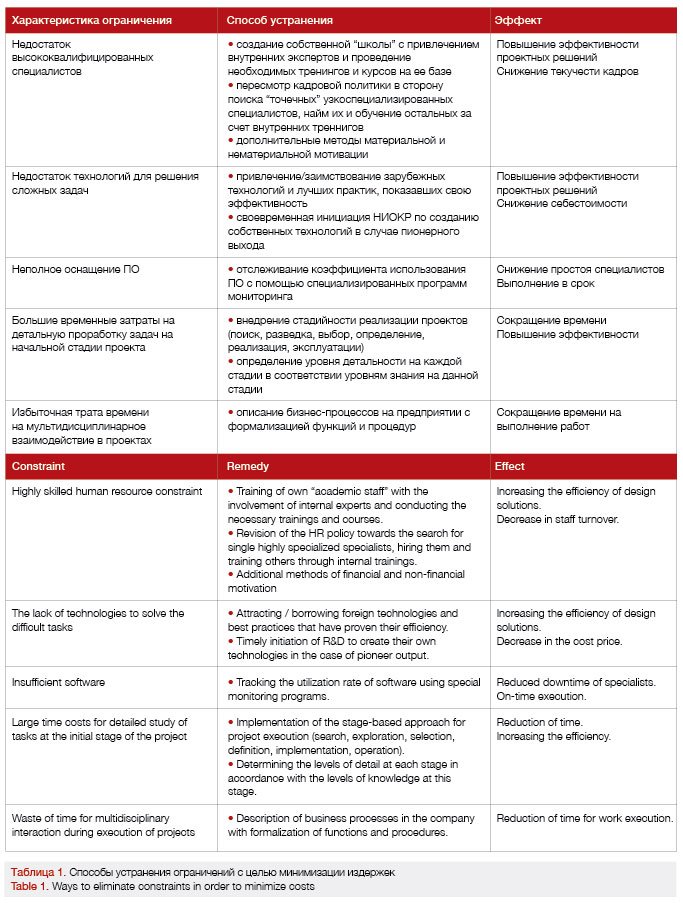

An analysis of the value-added chain of TRC has revealed the following five main types of constraints related to creation of high tech product:

1. Highly skilled human resource constraint expressed as a shortage of specialists able to perform knowledge-intensive tasks for the group of companies of the holding.

2. Intellectual resource constraint associated with a deficit in the “base of high tech knowledge and competencies”, the application of which provides high quality work results and maximum economic effect in the operating companies of the holding.

3. Tool resource constraint is a lack of high-tech tools (software) for mathematical modeling of geological exploration, development of fields, hydrocarbon transportation and preparation processes, as well as forecasting of hydrocarbon production from these fields. This is a very important resource since the results of these forecasts are the basis for investment decisions.

4. A constraint associated with the imbalance in the schedule and scope of work. The deadlines and scopes should always be in harmony, since any imbalance between them leads either to an increase in costs or to deterioration in the quality of work.

5. A constraint associated with the methods of doing business, namely, the absence of described business processes of the company, and as a result, the loss of time and quality of work caused by the ‘interdisciplinary junctions’.

The above factors determine the largest costs and make up about 85% of the structure of production costs of TRC and the level of prime cost of units of high technology products. These are the parameters of the TRC production process which are within its competence, and by improving which it is possible to achieve a reduction in the cost of production for a technical research enterprise, and subsequently also the cost of producing a unit of oil products for the operating companies. These constraints and methods of elimination with the expected effect are shown in Table 1.

In conclusion, the forecasted results of TOC application for the TRC are as follows:

1. On-time execution of projects (completion of projects as per the original schedule) increases from 50-60% to 80-90%.

2. Project implementation time is reduced by more than 20%.

3. Better communication with the Client.

An opinion editorial by A. V. Yazkov