Technology Roundtable: Drilling Fluids

1. Drilling-fluid selection remains one of the most important components of a successful well-construction operation. This results in a complicated product/system selection process. What is the optimal way to select the correct fluids for a well?

Kaz M-I SWACO: Alongside many other engineering problems, selection of a wise and optimal solution related to selection of drill fluids is, in some sense, a combination of science, art and intuition, which depends very heavily on an engineer’s knowledge. Quite often these decisions have to be taken based on poor and contradictory data, and sometimes from several conflicting options. in order to make the correct decision and satisfy the clients needs one should involve a drilling mud specialist in the well planning process as early as possible. And cooperation between the client’s engineers and the engineers of service companies should be as open and collaborative as possible. Unfortunately, year by year this goal is becoming increasingly remote. In the vast majority of cases, drilling mud specialists obtain some existing drilling program or tender conditions, where not only the type, but even the expected mud composition are strictly pre-agreed. And, of course, the budget is strictly fixed by the client. It is evident that in such situations the optimal drilling mud technology cannot be selected.

Omac Integrated: The relevance of this issue is that the selection of the correct drilling fluids system always follows from several components. In our experience, the main components are as follows: economic, technical and general organizational. In connection with the current situation in the oil and gas sector, the Client is primarily obliged to pay attention to the economic component, while taking into account the quality of the services provided. In turn, before the beginning of each project, we carefully study the case as per accumulated experience (i.e., the archival data of these projects or close details to similar geological structures), then a technical proposal (Mud Program) is compiled according to the requirements of the customer, the list of necessary products is already indicated, and then organizational points are agreed and only after this the commercial part is calculated. To date, we always carry out the entire list of the Client’s assigned tasks and contractual obligations in full. Based on the broad experience in this area, it is possible to say with full confidence that our company successfully produces a selection of a system and products for well construction and makes optimal decisions, directly in the interests of the Client.

Mirrico: The general approach to selecting the fluid takes many aspects into account:

1. Rock and geological conditions, formations, drilling pressure and temperature to have the first picture of the physical-chemical properties the circulating fluid hould have.

2. Complicated intervals to determine preventive measures in advance.

3. Well path, drilling mode, construction schedule.

4. Issues relating to the initial drilling, including preserving the cores from exploration wells.

5. Environment, additional requirements.

PSK Burteсhnologii: The following factors will determine if the drilling fluid was selected correctly: wellbore stability is kept even in complicated geological and technical conditions, maximum drilling rate and efficient wellbore cleaning are reached. You can possess a perfect drilling technique, equipment and tools, but you cannot construct a well without drilling fluid. The optimum solution for fluid selection depends on experience in drilling, integration of new drilling mud systems and further optimization. Sometimes, if you don’t have the necessary information, the optimum solution can be found by trial and error.

2. Can you describe the common problems that currently exist in the region regarding the incorrect selection of muds?

Kaz M-I SWACO: The most common and disappointing problem is the horrible quality of reservoir penetration, and the associated catastrophic deterioration in the economic performance of oil production companies, which has beenobserved during the last 3-4 years.

The second problem is the unreasonable use of potassium chloride muds as the most common and conventional solution, especially in those cases, sections and intervals, where such use is absolutely unproven and may even increase the drilling costs without any increase in efficiency. This problem is typical for this market in Kazakhstan, but is not often seen outside of the region.

Omac Integrated: Since we provide services starting from shallow to deep wells, at the projects in our region where we operate there are huge number of complications encountered during the work process. Therefore, talking about common problems associated with the incorrect selection of drilling mud is not entirely correct, because there are also geological aspects. The main problems with the incorrect selection of drilling fluids are: the inhibition process when drilling active clays, drilling a salt dome, areas with low and high reservoir pressures, and most importantly the contamination of the reservoir. First of all, to select the right type and properties of the drilling fluids, it is necessary to obtain reliable geological data. Proper selection of drilling fluid is very important, which ultimately directly affects the successful completion of the well.

Mirrico: Wrong selection of fluid is very uncommon (I do not know any such case in the last five years). Today, terms of reference (ToR) are developed by clients who specify the correct parameters and composition. The problems tend to start later. Generally, during a tender under ToR, the clients select a company that offers a lower price for chemicals without reviewing its experience. Problems then inevitably occur when the contractors show their inexperience. Thus, first trying to save on cost causes much bigger losses due to drilling problems.

I believe there is one way out of this vicious circle: Change the contract selection criteria and prioritize operational efficiency over low price. I think, if a client shares the year work scope among, say, five contractors, the year results will demonstrate the most cost-quality advantageous contractor.

PSK Burteсhnologii: Typical problems associated with wrong selection are based on the particular region. In the Perm Territory, for example, those are slides and cavings in unstable grounds, sticking of the drilling tool due to reaming with insufficient cuttings lifting, as well as lost circulation and BFZ contamination.

The most common reason for wrong fluid selection is the incomplete knowledge about the section or incomplete information about the well. Economic factors are also important – when the Client wants to save money and include a cheap mud composition, which does not meet the well conditions, in the tender requirements.

3. How can drilling muds reduce well construction costs?

Kaz M-I SWACO: First of all, we must look at the reduction in the well construction time. There are many examples, when changing the drilling mud (unfortunately, to more expensive and «complicated» mud) allowed for the reduction of well construction times by 30-35% (and with regard to drilling days – reduction of drilling time up to one month). Without any other changes in technologies (drill rig, bits, BHA , etc.).

Omac Integrated: In this case it is necessary to take into account that the well construction is a complex of related services. Various services are involved here, but drilling fluids is one of the main components due to which it is possible to optimize the well construction costs. First of all, the reduction of the construction period of the well due to the use of High-performance drilling mud systems, transparency and manageability of projects with a high degree of predictability of the result required by the Customer. Under the understanding of the general reduction of the duration, it is considered not only high mechanical rate of penetration, but also all RIH/POOH, Production Well Logging and quality cementing. High-performance systems are implemented through the introduction of new technology, skilled personnel and quality products.

Mirrico: Fluid will reduce well construction costs by:

• Reducing construction period through pro-active prevention of complications and increasing drilling rate (and therefore avoid expensive drilling equipment downtime);

• Reducing fluid waste.

In addition, minimizing formation contamination and achieving higher rates will increase profit of oil companies.

PSK Burteсhnologii: Drilling fluid will be a small part in a total well construction cost, even though it is pretty expensive. At the same time, a correctly selected drilling fluid allows reducing the well construction time due to preventing lost circulation, increasing the drilled footage and decreasing the wear on the drilling equipment. This is because the drilling team time (working day) comprises a significant part of the well construction estimate.

4. How prevalent are oil based muds (OBM) and synthetic-based muds (SBM) in the region?

Kaz M-I SWACO: Oil-based drilling muds (OBM) are used only in the three largest oil and gas projects in Kazakhstan – Tengiz (more than 20 years), Kashagan and Karachaganak. The use of OBMs in other projects and fields is quite difficult to be economically justified. However, we expect appearance of such projects by 2019-2020.

Halliburton: Water-based muds (WBM) tend to be the preferred choice due to the economic and technical requirements of the prevailing shallow and exploratory wells in the region. That said OBM and SBM are attractive options in the region on major projects that require the drilling of batch or multiple wells. For these projects, OBM and SBM systems are much more economical because the fluid can be reused.

Omac Integrated: As you know, the drilling fluids market in Kazakhstan is not large, and in particular of drilling fluids on oil based muds (OBM) and synthetic-based muds (SBM). These types of drilling fluids in our country is mainly used on big projects such as TCO, KPO and offshore. In general, these systems can prove itself in the market and has good prospects in view of the planned for drilling new deep (super-deep) wells, including horizontal wells. Our company has experience with these systems (in Azerbaijan) and in the near future plans to offer their services to potential Customers.

Mirrico: Today, these are used in offshore fields in the Okhotsk Sea, Sakhalin, Northern Caucasus and East Siberia. Synthetic and oil muds are not popular in other regions, because they are expensive and require a special infrastructure to apply them.

PSK Burteсhnologii: Nowadays, oil based muds make 30 to 40 % of drilling in the Perm Territory. They are commonly used for well construction in complicated geological and technical conditions.

5. What advantages do OBM’s and SBM’s offer over water based muds (WBM) considering their higher cost?

Kaz M-I SWACO: The main advantage is the considerable reduction of construction time in well construction time for complicated wells in challenging geotechnical and geological conditions. The above mentioned reduction in drilling time by one month was reached due to change from water based muds to oil based muds. In addition, in relevant conditions the use of OBMs allows a large increase in well capacity (however, one should be very careful, since the use of OBM may not only enhance the quality of reservoir penetration, but also have an adverse effect).

Omac Integrated: As we answered earlier, in connection with the situation in the market of drilling fluids, the client first of all pays attention to optimizing budget for the construction of the well. Therefore, this is one of the main factors hampering the widespread use of these systems in Kazakhstan. Advantages of drilling fluids OBM’s and SBM’s basis in comparison with water-based, it is not a secret that the use of these systems significantly shortens period of construction of the well, thereby helping to decrease summary cost. It is important to consider the amount of wells, drilling multiple wells in parallel are economically advantageous. The main advantages are: decrease of construction time, possibility of reusable use, decrease of liquid waste, decrease of technical water consumption, decrease of volumes of prepared drilling fluids, thereby decrease the consumption of chemical reagents and their logistics, as well as the possibility of drilling with the Abnormal Low Pressure.

Mirrico: To begin with: high stability and adaptiveness to tough rock and geological conditions and excellent stabilization of unstable shales. Another advantage, and often considered the greatest one, is the re-use of such muds and therefore reduced drilling waste.

PSK Burteсhnologii: The main and major advantage of oil based muds is their high inhibition, since the filtrate is a hydrophobic material preventing shale hydration and allowing drilling even in those intervals, where even the high-inhibited water-based muds can not ensure the required time factor of rock stability due to clay dispersion.

Oil-based muds (OBM) have proven their efficiency while drilling in large scale intervals in combination with lost circulation intervals, where low-density drilling mud is required.

In addition, the use of OBM compared to water-based muds ensures a higher quality of BHZ penetration for some certain types of reservoirs.

6. How does real time drilling data effect drilling mud selection and changes and how frequently are real time systems used in the region?

Kaz M-I SWACO: Pretty insignificantly. However, real time drilling data and, in particular, logging-while-drilling data (including ECD sensors) are critically important for early detection of wellbore instability intervals and taking some corrective actions, including change of mud density. These days such data are getting more valuable, because the number and seriousness of the problems associated with wellbore stability has grown within the last years and become the reason of downtimes, accidents, well construction time extension and cost growth in some particular fields.

Omac Integrated: The oil and gas sector is one of the flagships for the introduction innovative products, so the real-time data processing system is already used in many projects in our region. This is a requirement of the current time and our Company has developed «Omac Pro» reporting software as part of our development program, which meets to all international requirements and production ramp-up plan. The formation of its own data center for the collection and processing of information provides a tremendous advantage in the planning and construction of wells. At the moment we have fully implemented and successfully continue to use this product in our projects and most importantly, customers see the enormous help of this product. Accountability and manageability mostly depends on the efficiency and reliability of received data during construction of wells.

Mirrico: Fluid parameters are in direct relation with the drilling parameters and the mud engineer should make adjustments in a timely manner.

Today’s main LWD systems do not differ much from those applied 30-50 years ago: Weight, pressure, torque indicators, capacity, and flow rate.

Advanced technologies may significantly minimize well construction problems. For example, if we know the current reservoir pressure while drilling, we can change the fluid density and equivalent circulating density: This will allow us to minimize kicks, differential sticking and reduce lost circulation.

Specialized LWD software is of high priority (and demand), for extended reach drilling wells prone to slides and cavings. The density of the applied fluid to get into the narrow mud window should withstand unstable rock to avoid hydraulic fracturing. Hydraulic calculations while drilling are also important.

PSK Burteсhnologii: The work of drill fluid engineer, as well as of process support team, comprises not only preparation of mud according to works program and measurement of parameters. They should also perform a continuous analysis of all incoming available process information on well cleaning and drilling technique, as well as monitor the first indications of any problem development, efficient wellbore cleaning, sticking of the drilling tool, etc. They should ensure a prompt response to this information and perform drilling fluid conditioning. They may also change some parameters, which are different from those specified in cleaning program, as agreed with Client.

7. As the drilling of new wells becomes more sophisticated – one of the major well construction risks is lost circulation, especially in the high lost circulation zones found in Kazakhstan and Russian (such as in Volga-Urals area: areas along Volga River, Orenburg area, Bashkortostan).

What solutions do you offer to ensure minimal loses of costly fluids within these zones?

Kaz M-I SWACO: Lost circulations have always been and remain the most unpredictable challenge in the industry. Despite all efforts made in attempts to simulate, predict, prevent and eliminate the lost circulations – we still have no technologies to reach even 80% efficiency. In addition, it is not infrequent that a successful experience of one field cannot be successfully applied in the neighbouring field or region. The basic solution to this problem is to dilligently study several options, assessment of their efficiency and development of the particular procedures for each particular field and interval. There are no ready-made efficient solutions at the moment. Alongside with that, just as prevention is better than cure, there are some technologies and measures (including geomechanical surveys), which allow a significant reduction of lost circulation risk both at the stage of planning and while drilling.

Halliburton: Most high lost circulation zones in Kazakhstan are related to subsalt hydrocarbon reservoirs, which are prevalent in fractured limestone formations. Acid soluble lost circulation materials (LCMs) effectively remediate losses in these formation types where damage to natural fractures may be of significant concern. In event of seepage and partial fluid losses occurring in fracture widths up to 3,000 microns, Halliburton offers engineered, composite solution BaraBlend®-657 LCM, which is designed specifically for reservoir formations where return permeability is highly crucial to facilitate optimum hydrocarbon production. BaraBlend-657 LCM is a multi-modal engineered, composite solution composed of all acid soluble particulates. For severe and total fluid losses occurring in thief zones with fracture widths larger than 3,000 microns, BaraBlend-657 LCM can be supplemented with Halliburton’s BARAFLAKE® C LCM. A combination of BaraBlend-657 LCM and BARAFLAKE C LCM has been successfully proven to seal fracture widths greater than 3,000 microns. In vugular zones where particulate LCM fails to restore circulation, Halliburton’s newly improved chemical sealant ThermaTek® RSP is a fast setting acid soluble chemical sealant designed to seal vugular and cavernous formations. It rapidly develops a compressive strength up to 2,500 psi while eliminating the risk of premature setting in or around bottom hole assembly.

Omac Integrated: It is necessary to consider several different options; lost circulation control by the same method is not the way to solve this problem. At this stage, various lost circulation materials are available on the market, many chemical reagent producers are developing and introducing new technologies to eliminate this problem. Our company, in recent years has moved very far in solving this issue, by conducting laboratory studies to determine the particle size composition and concentration of components to control loss circulation. Our technical group carries out these researches and developments in the central laboratory (Aktobe) and regional laboratories (Uralsk, Samara, Nizhnevartovsk), and together with our international partners, who have access to all the latest technologies in the world.

Mirrico: Mirrico is the leader in the RF to offer lost circulation control measures. Today, the Company offers a wide list of technologies to address the issue. Most of them have been successfully proven. Our portfolio includes the following products:

1. QUICK-STONE. Quick setting, successful lost circulation control.

2. ARMO-BLOCK. Controlled setting time, applied for low reservoir temperatures 10-40 °C.

3. CAVE-BLOCK. Applied for disastrous lost circulation.

4. CAVE-BLOCK M. Applied for disastrous lost circulation, hardens over time.

5. OSNO-PLUG. Polymer cross-linked composition.

PSK Burteсhnologii: First of all, to select the proper remedial measures for lost circulation, complete and actual information on lost circulation nature and zones is required. This information may be obtained through drilling monitoring, hydraulic, mechanical and geotechnical survey, as well as analysis of the previous experience. In some cases, computer modeling methods cannot provide a good result, which is why only actual experience allows development of efficient insulation methods. Along with widely used methods of pumping of different insulation compounds with colmatants, quick-set mixtures and cement slurries, we can offer technology reducing the material and time expenditures for prevention of lost circulation through operating layout, including displacement motor and MWD. The basic technology of works using BHA is a High Viscosity Pill (HVP) with adjusted gelling period. The main feature of this compound is its capability to create an elastic rubberlike body inside of the rock defects. This method allows prompt reducing the lost circulation during drilling with minimum time lost.

8. As Kazakhstan starts to plan and drill more complex wells in the near future, including horizontal wells – what should the region learn from operations in neighbouring countries, in terms of knowledge, system selection etc.?

Kaz M-I SWACO: As I said before, early and efficient cooperation between the engineers of operating companies and engineers of service companies at the stage of planning of these wells (and, of course, during construction) is critically important. This is absolutely imperative that they work in an environment of openness, trust, collaboration and free exchange of views, experience and information. We need to reverse the existing trend in relations and interaction pattern between customers and contractors, which is now reminiscent of circular firing squads and bringing the O&G industry to the brink of collapse.

Halliburton: As we prepare to drill ultradeep and ERD wells in the region, we anticipate implementing drilling fluid solutions that deliver HTHP performance as well as unique density and rheology properties. Delivering HTHP wells is always a challenge when drilling with water-based muds and can require the implementation of high-performance water-based fluids such as the recently introduced Halliburton BaraXtreme™ water-based fluid system that provides stable characteristics up to 204°C.

When evaluating OBM systems for more complex HPHT and horizontal wells, Halliburton Baroid’s INNOVERT® fluid system can provide low ECDs with great suspension properties for densities over 16 ppg and temperatures up to 250°C.

Omac Integrated: First of all, it should be taken into consideration the fact that horizontal and super deep wells need to be drilled by separate services because of the fact that technologies do not stand still and various service companies are always ready to offer new ways of solution in the construction of such wells. As for our service directly, today we provide services in the Russian Federation and we have depth of experience in the drilling of horizontal wells (more than 200 wells drilled). We use various systems and products in the territory of the Russian Federation, and we are ready to use them in Kazakhstan taking into account the gained experience.

Mirrico: We believe that our experience is the strength that will allow us to overcome these challenges. Both your own experience and the experience of others should be taken into account. Our Company will gladly participate in Kazakhstani projects. We offer effective fluids to maintain well stability in unstable argillites, such as Algypo and Well-Slide. Our lost circulation control techniques have been proven in Orenburg region, Tatarstan, Bashkortostan. QUICK-STONE has also demonstrated good results in Kazakhstan. Each project is unique, yet, despite of our extensive experience of work with similar formations and other parameters, we understand that our solutions cannot be a universal remedy for any region. Therefore, it is important to be ready and able to bring adjustments as guaranteed by us.

PSK Burteсhnologii: First of all, the geological and technical conditions and well construction technologies (including drilling fluids and remedial measures for lost circulation) should be compared. And after that, we can offer the particular technologies, which will allow reducing the time and material expenditures and providing the process safety.

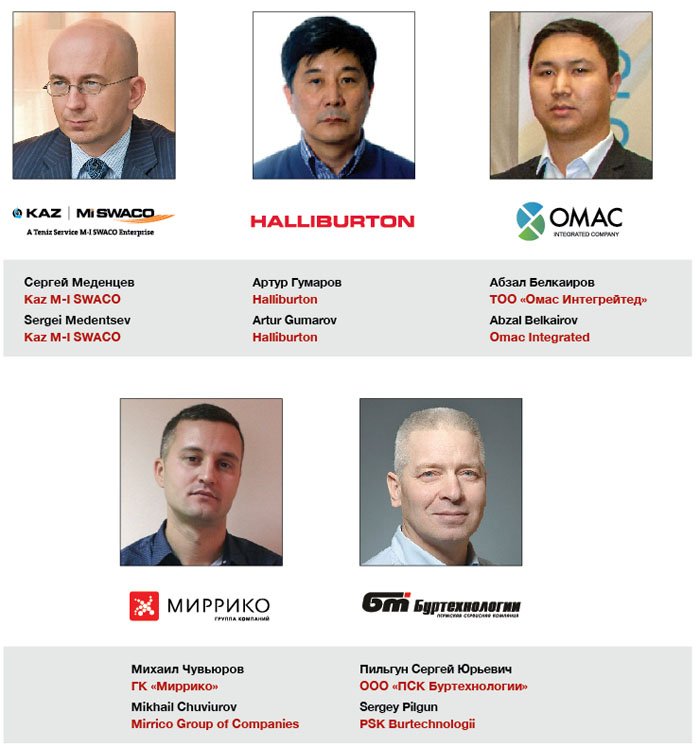

Sergei Medentsev

Kaz M-I SWACO

Sergei Medentsev is the Production Deputy Director General for Kaz M-I. He Graduated from Gubkin Russian State University of Oil and Gas in Oil&Gas Drilling. From 1993 working with M-I SWACO. Main competence – drill fluids, well completion and killing fluids, drilling mud treatment equipment.

Mikhail Chuviurov

Mirrico Group of Companies

In 2004 Mikhail enrolled in the Mining & Oil College specialising in Drilling Technologies. In 2011 he continued his education for Drilling Engineering at the Ukhta Technical University. He is the Deputy Manager of Drilling Fluid Process Department, Drilling Fluids and Technologies Division (Mirrico Group of Companies). Experience: 13 years in drilling and 6 years in drilling fluids.

Artur Gumarov

Halliburton

Artur Gumarov is the East Caspian Baroid Technical Manager for Halliburton based in Kazakhstan. His overall experience in the oil&gas drilling industry is almost 32 years, with over 20 years in drilling fluids. He started working from 1985 as a Driller Assistant, becoming a Tool Pusher then as a Drilling Engineer in “EmbaMunay” Kazakh Petroleum Company. He graduated from the Almaty Polytechnic Institute, RoK in 1991 by correspondence. From 1995 he commenced profession activity as Drilling Fluids Engineer and grew up to Head of Drilling Department in the KazNIGRI Company. In 2000 he joined the Halliburton Baroid team in Kazakhstan and served from Drilling Fluids Engineer to Field Coordinator. Since 2007, Artur held position of Fluids Technical Coordinator on the major OKIOC/AGIP KCO North Caspian project which develops one of largest oil fields in the world – East Kashagan. From 2010 on he has been Technical Manager for the East Caspian leading and supporting all operations in Kazakhstan and Turkmenistan.

Abzal Belkairov

Omac Integrated

Abzal graduated from the Kazakh-British Technical University in 2008. After university, he worked as a process engineer at Munai Service. After this he worked at Kaz MI SWACO as a drilling fluid engineer for the Tengiz project. Then he moved to Omac Integrated. Starting as a field fluid engineering he was promoted through the ranks to Project Manager. After 5 years of working for Omac Integrated he was promoted to Operations Director where he had the overall responsibilities of launching new products, interacting with customers, tender participation and monitoring overall operations of the company.

Sergey Pilgun

PSK Burtechnologii

Sergey studied at Perm State Technical University, specialising “Drilling oil and gas wells” in 1992. He has 25 years experience in the oil industry. He has supervised the production and technical departments of PSK Burtechnologii since 2003 to the present day. Sergey is Technical Director of PSK Burteсhnologii.